Powder storage and transportation tank truck

A technology for tank trucks and powder materials, applied in the field of powder material storage and transportation tank trucks, can solve the problems of unsatisfactory discharge process efficiency, low operating efficiency, and large transportation time ratio, so as to improve transportation efficiency and operating efficiency, and highlight substantial Features, the effect of speeding up the transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

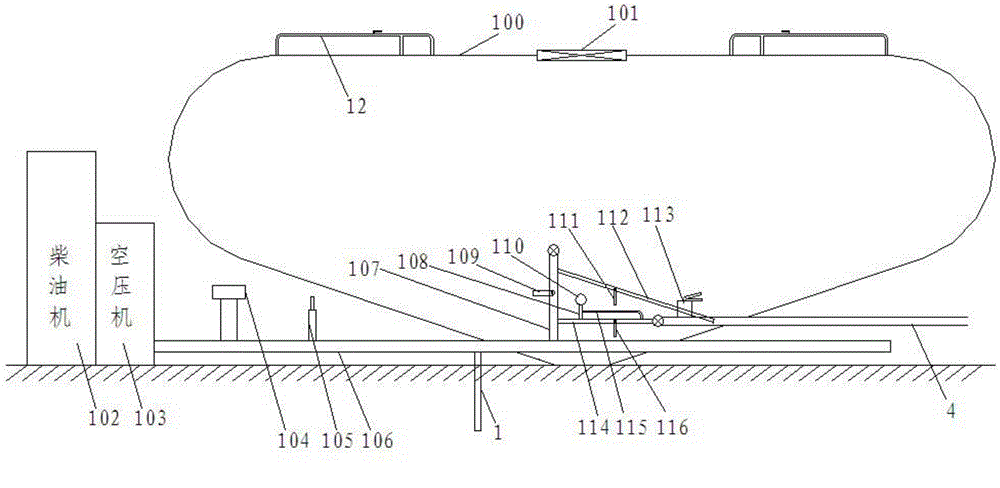

[0035] The present invention is described by taking a cement powder storage and transportation tank car as an embodiment.

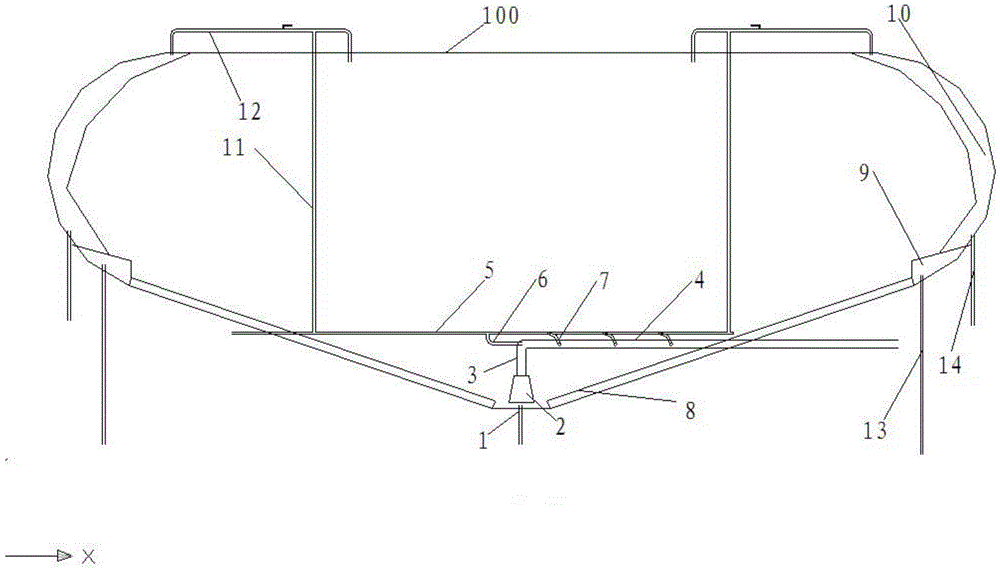

[0036] Such as figure 1 As shown, the powder storage and transportation tank truck includes a tank body 100, the two ends of the tank body 100 have a head cavity 10, the bottom of the tank body 100 is in the shape of a funnel, and the bottom end of the funnel shape near the inside of the tank body 100 is provided with an inlet to the bottom of the tank body 100. The lower discharge vertical pipe 3, the upper end of the discharge vertical pipe 3 is connected with the discharge horizontal pipe 4 extending out of the tank body 100; The open end of is provided with trumpet tube 2, and the inlet of horn tube 2 is opposite to the outlet of vertical blowing pipe 1.

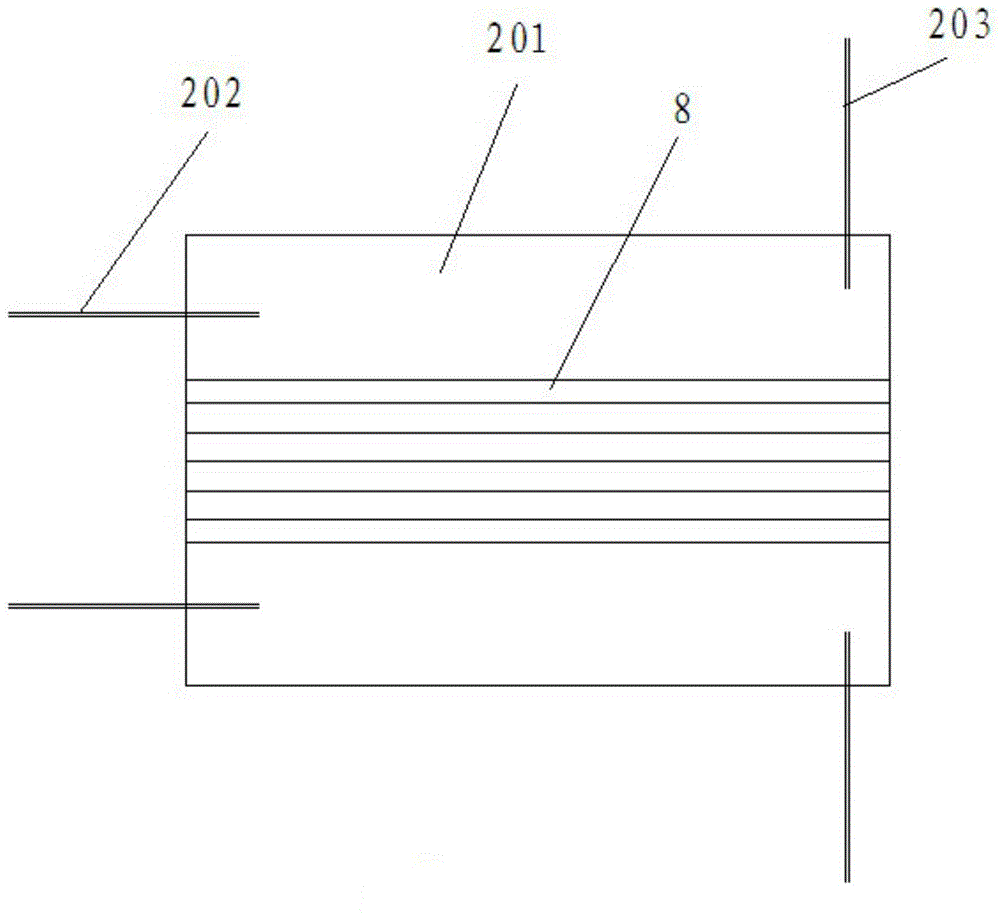

[0037] Wherein, the discharge horizontal pipe 4 is provided with a parallel air supply pipe 5 in parallel, and the joint of the discharge vertical pipe 3 and the discharge horizontal pipe 4 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com