Chain type false nail tree feeding and dismounting device

A fake nail and chain technology, applied in the field of feeding and removing devices, can solve the problem of low efficiency and achieve the effect of simple structure and reliable material removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

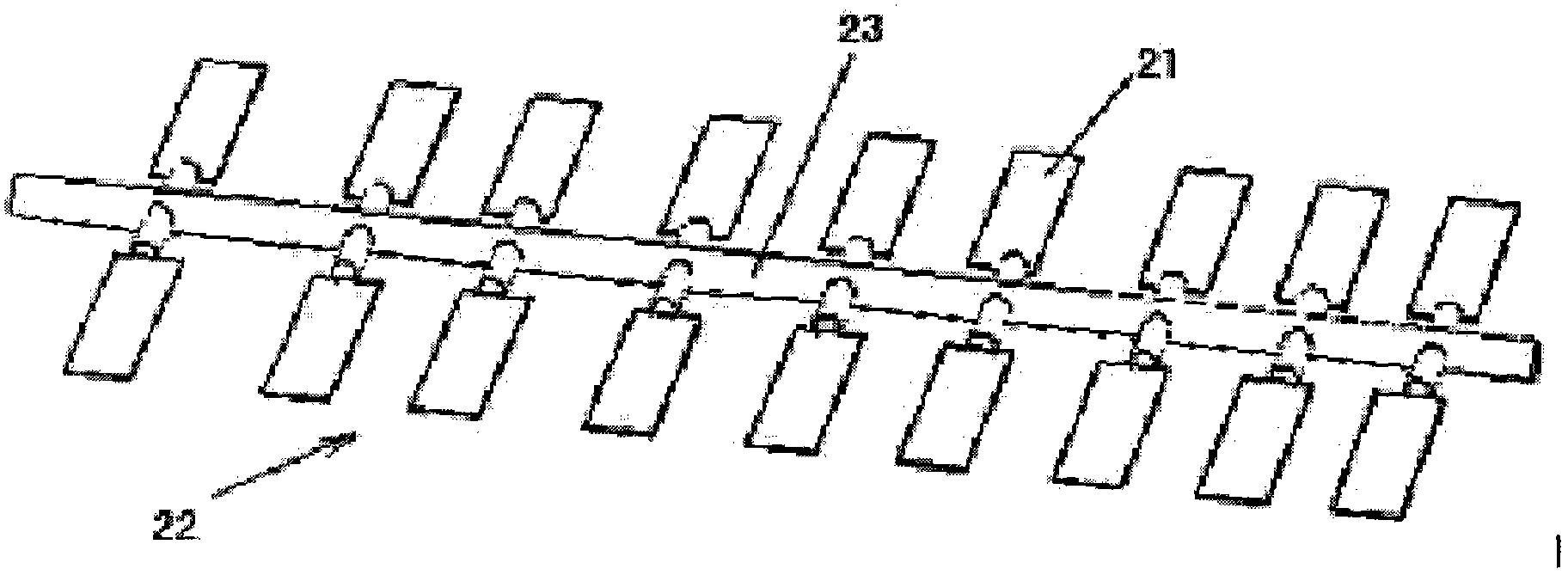

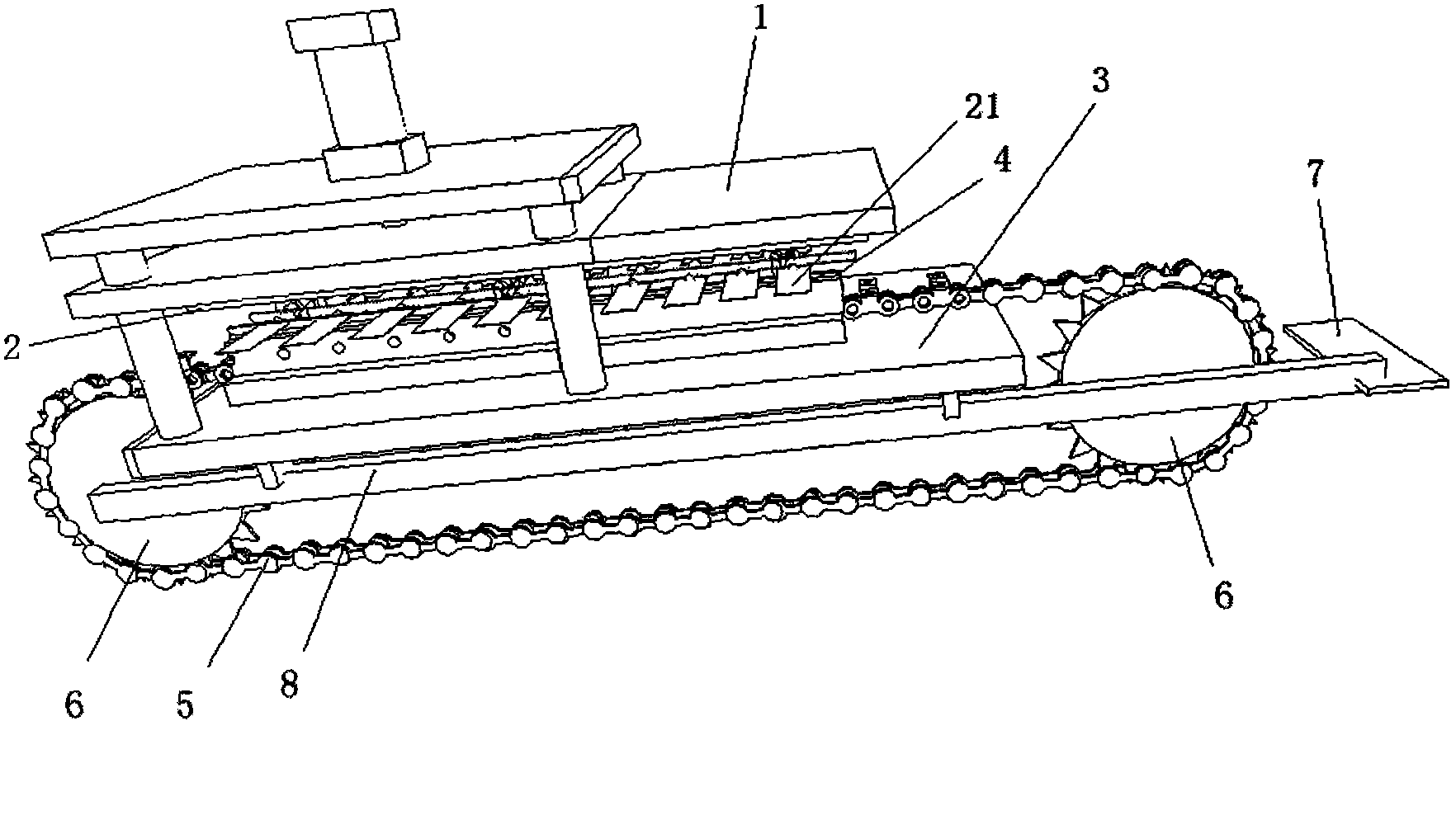

[0010] Such as Figures 1 to 2 As shown, a chain type false nail tree feeding and removing device of the present invention comprises an upper blade 2 for cutting the false nail tree 22 arranged at the lower end of the upper sliding frame plate 1 of the punch press, and is arranged on the lower fixed frame of the punch press The upper end of the board 3 is used to cut the lower blade 4 of the false nail tree 22. The lower blades 4 are two symmetrical front and rear, and a chain 5 for transmitting the false nail tree 22 is arranged between the two lower blades 4. The chain 5 is provided with a draw-in slot for clamping the false nail tree 22, the chain 5 is driven by a gear 6, and a discharge plate 7 is provided at the end of the discharge end of the chain 5, and the discharge plate 7 is a rectangular flat plate , it is affixed with described lower holder plate 3 by cross bracket 8, leaves gap between rectangular plate and end chain 5, and this gap size can be as little as possi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com