Built-in type positioning and unloading device for auto power diverter

A technology of power steering gear and unloading device, which is applied in mechanical steering gear, fluid steering mechanism, etc., can solve the problems of difficult installation, poor sealing performance, increased pressure of hydraulic system, etc., and achieves simple positioning and unloading structure, automatic Good sealing performance and timely unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

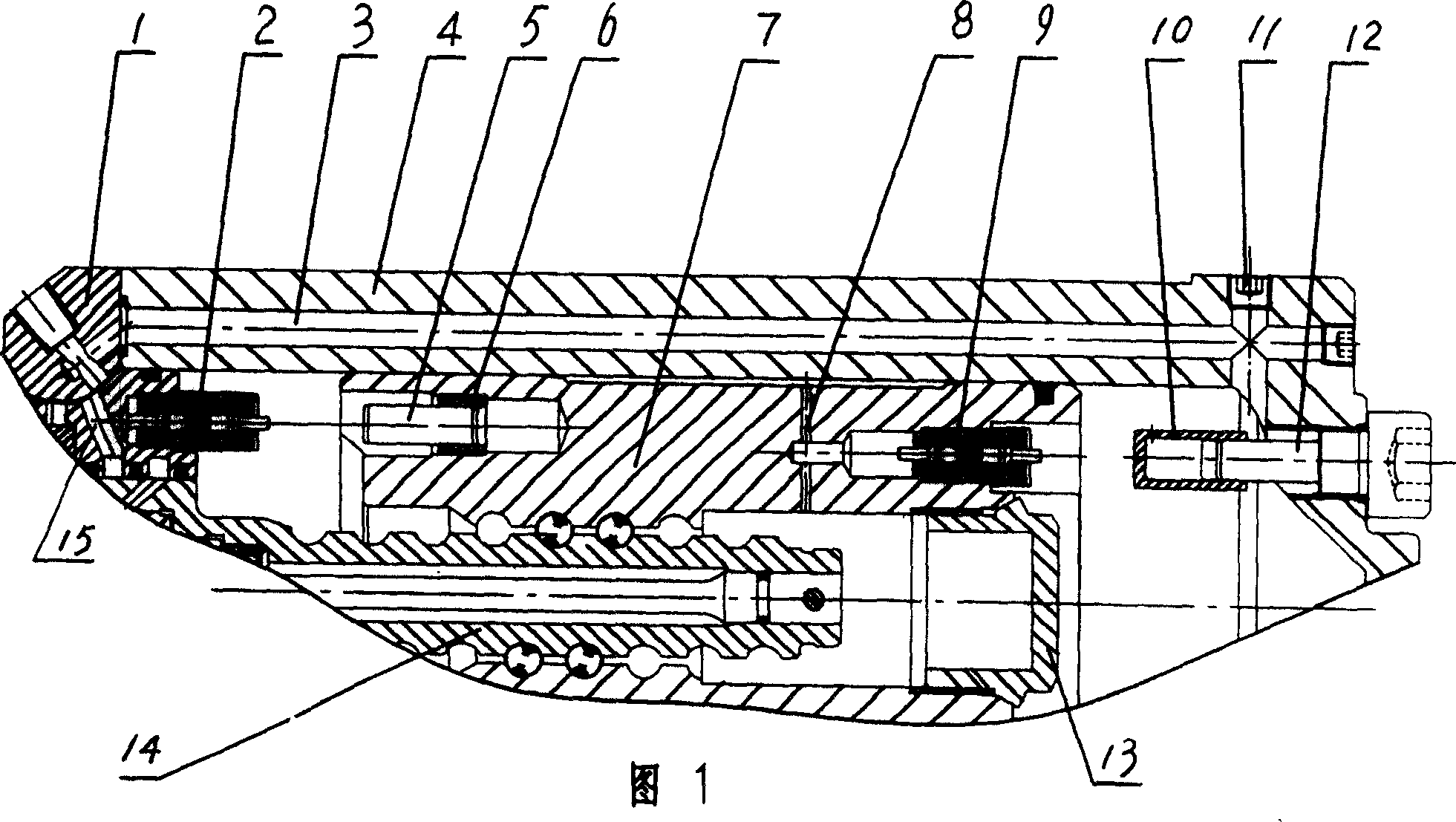

[0012] The automotive power steering gear has a built-in positioning and unloading device, which consists of valve seat 1, left unloading valve 2, oil delivery channel 3, housing 4, positioning rod 5, left positioning sleeve 6, rack piston 7, radial oil channel 8 , right unloading valve 9, right positioning sleeve 10, process plug 11, threaded column 12, middle oil plug 13, screw assembly 14 and inner oil passage 15 are jointly formed. The screw assembly 14 is screwed with the rack piston 7, and the rack piston can move left and right in the housing 4. The right side of the valve seat 1 is axially threaded to the left unloading valve 2, and the inner oil passage 15 communicates with the left end of the left unloading valve 2. On one side of the left end face of the rack piston 7 and the corresponding position of the left unloading valve 2 installed on the right end face of the valve seat 1, there is an axial blind hole for installing the left positioning sleeve 6, and the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com