Static spiral mixer in tube

A mixer and internal spiral technology, applied in fluid mixers, mixers, mixing methods, etc., can solve the problems of miniaturization and swirling flow that static mixers cannot solve, achieve reliable use value, improve heat exchange efficiency, Achieving a continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Referring to Fig. 4, Fig. 5, Fig. 6, Fig. 10 and Fig. 11, a static in-pipe spiral mixer includes a pipeline 4 for forming a fluid flow space, a helical monomer 1, and the helical monomer 1 shaft Arranged in the pipeline 4, the said helical monomer 1 is fixedly connected with the pipeline 4, the said mixer comprises two or more than two helical monomers 1, and each helical monomer is equal in size; The adjacent helical monomers are tangent or approximately tangent to each other and between the helical monomers and the pipe wall; the helical angle of the helical monomers is 360°.

[0042]The pipeline 4 is a circular pipeline, and the number of the spiral monomers is 1+6, including 1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-6 , the axis of a helical monomer 1-1 is the same as that of the circular pipe, the 6 helical monomers in the outer layer are tangent or approximately tangent to the adjacent inner helical monomers, and the adjacent helical monomers in the same layer The monomers...

Embodiment 2

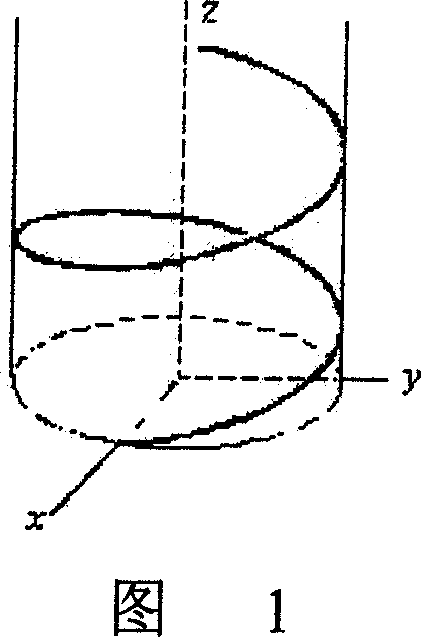

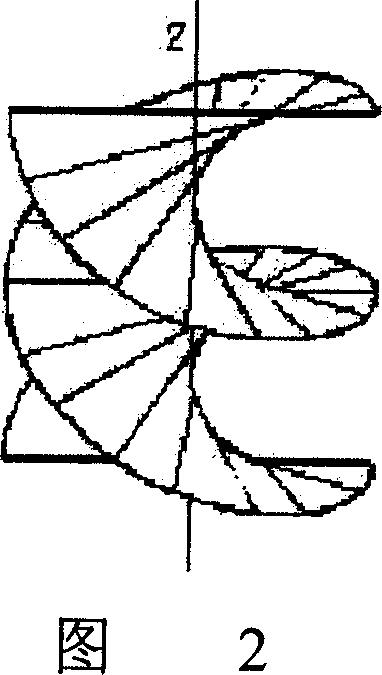

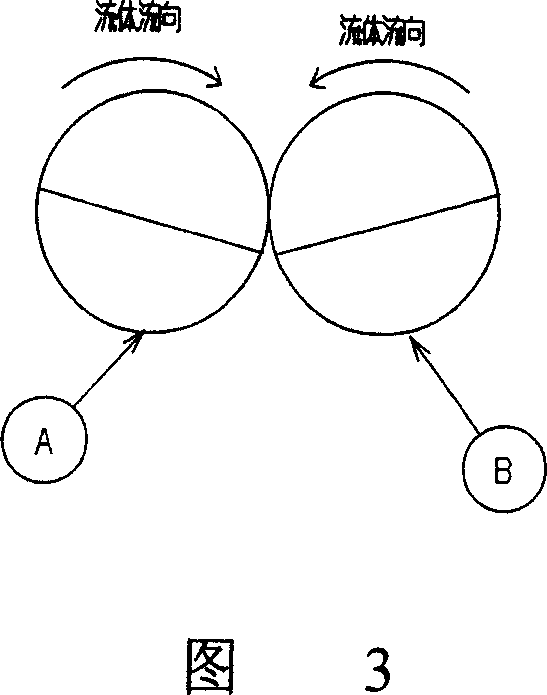

[0049] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 10, and Fig. 11, the helical monomer 1 of this embodiment is a normal helical monomer, and the rest of the structure is the same as that of Embodiment 1.

[0050] The constant helix (helix is a kind of space curve formed by the generatrix of a right cylinder rotating at a certain angle. The diameter d of the bottom surface of the right cylinder has the following constant helix equation in the orthogonal three-axis coordinates at a certain angle α. x= acost, y=εasint, z=attanα (ε=±1). Wherein z is the coordinate axis of a straight cylinder, because the curvature and the swing rate on each point on the constant spiral are constant, so the motion track of its main normal A constant helix can be formed, and a constant helix can be formed when the tangent of each point on the space curve moves in a certain direction and angle.

[0051] The course of work of the present embodiment is: the generatrix of the ri...

Embodiment 3

[0054] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 7, Fig. 10, and Fig. 11, the pipeline in this embodiment is a circular pipeline, and the number of spiral monomers is 1+6+12, one The axis of the helical monomer is the same as that of the circular pipe, the 6 helical monomers in the middle layer are tangent or approximately tangent to the adjacent inner helical monomers, and the 12 helical monomers in the outer layer are adjacent to the middle layer The helical monomers in the same layer are tangent or approximately tangent, and the adjacent helical monomers in the same layer are tangent or approximately tangent. The connection of the centers of the six helical monomers in the middle layer can form a regular hexagon, and the outer layer has 12 helices. The connection of the centers of the monomers can form a regular dodecagon. All the other structures are identical with embodiment 2.

[0055] Referring to Fig. 9, the method for calculating the diameter of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com