Semi-continuous automatic feed liquid evaporation device and feed liquid evaporation recovery method

An evaporation device and semi-continuous technology, applied in chemical instruments and methods, evaporation, separation methods, etc., can solve the problems of small concentration, corrosion of devices, and incompatibility of materials, so as to reduce delivery pump components and exhaust emissions Small, smooth feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

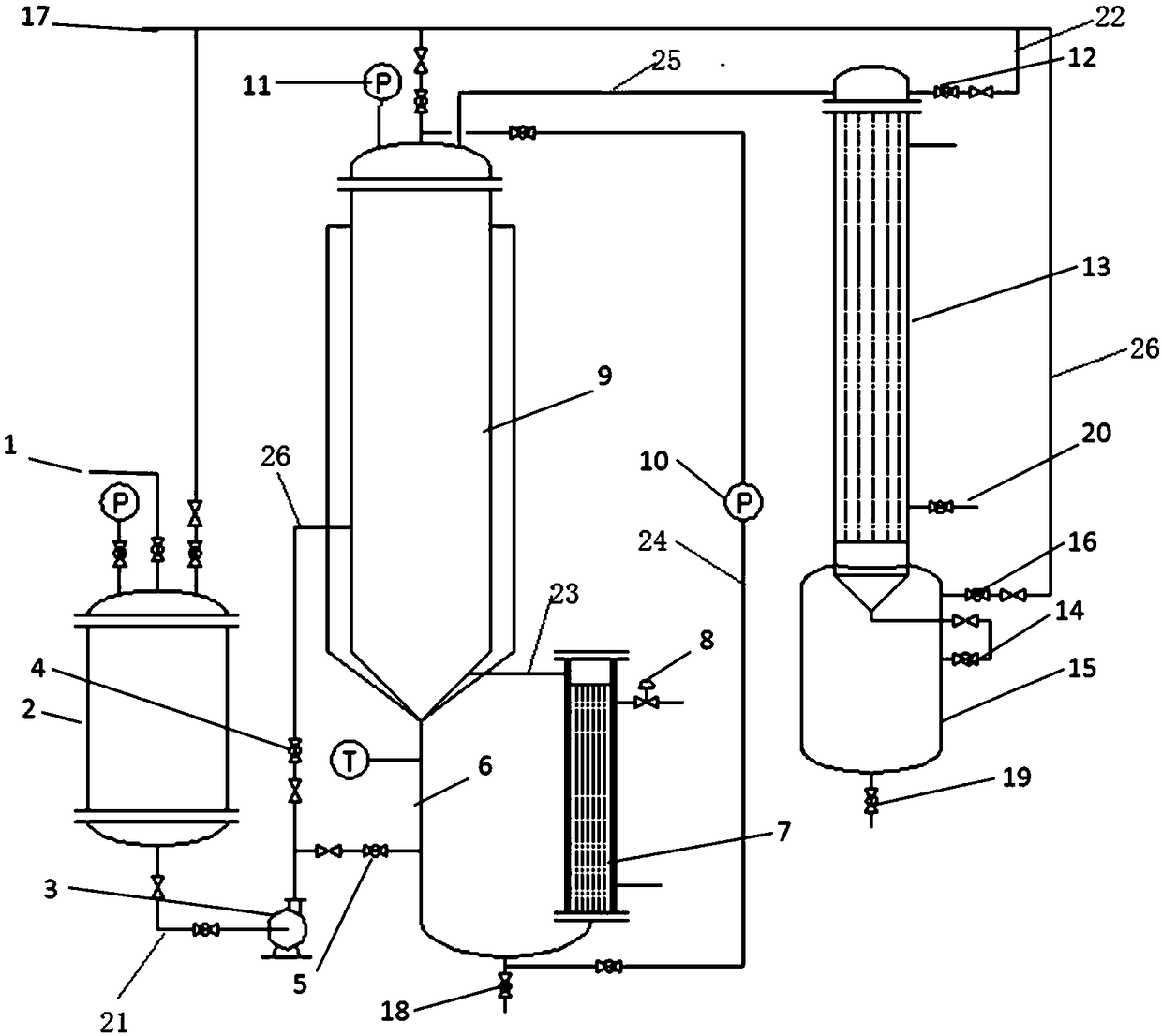

[0037] A semi-continuous automatic material-liquid evaporator of this embodiment includes a raw material tank 2, a separation chamber 9, a steam heating chamber 7, a condenser 13 and a condensate recovery tank 15;

[0038] The bottommost end of the separation chamber 9 communicates with the bottommost end of the steam heating chamber 7 through the lower circulation pipe 6, and the middle and lower part of the separation chamber 9 communicates with the upper part of the steam heating chamber 7 through the upper circulation pipe 23. The lowest end of the circulation pipe 6 is provided with a finishing liquid discharge valve 18, and the pressure introduction pipe 24 connecting the lowest end of the lower circulation pipe 6 with the topmost end of the separation chamber 9 is provided with a separation chamber liquid level sensor 10, The top steam inlet of the steam heating chamber 7 is provided with a steam regulating valve 8, and the liquid level sensor 10 of the separation chambe...

Embodiment 2

[0056] Add a volume of 80L magnesium nitrate solution into the raw material tank, set the pressure of the separation chamber to -80kPa, the liquid level of the separation chamber to 780mm, the feed rate to 8L / h, the concentration factor to 16, the discharge level of the condensate to 680mm, the compressed air to 0.3MPa, and the heating steam Pressure 0.2MPa. Turn on the cooling water, steam generator, and run the evaporation device. The metering pump continuously adds the magnesium nitrate solution into the heating chamber. When the liquid level in the separation chamber reaches 780mm, the evaporation starts automatically, and the evaporation continues for 9.4 hours. After the feeding is completed, the completed liquid is automatically discharged into the recovery container, and the cleaning port is fed with water to clean the heating chamber. , lower circulation pipe 1 time, respectively measure the amount of magnesium nitrate retained in the finished liquid, condensate, and ...

Embodiment 3

[0058] Add copper nitrate solution with a volume of 150L into the raw material tank, set the pressure of the separation chamber to -80kPa, the liquid level of the separation chamber to 780mm, the feed rate to 5L / h, the concentration factor to 30, the discharge level of the condensate to 680mm, the compressed air to 0.3MPa, and the heating steam Pressure 0.2MPa. Turn on the cooling water, steam generator, and run the evaporation device. The metering pump continuously adds the copper nitrate solution into the heating chamber. When the liquid level in the separation chamber reaches 780mm, the evaporation starts automatically and lasts for 29 hours. Lower the circulation pipe once, measure the amount of copper nitrate retained in the finished liquid, condensate, and device respectively, and the calculated recovery rate is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com