High temperature resistant glue and its preparation method and application

A high-temperature-resistant adhesive and polymer resin technology, applied in adhesives, non-polymer adhesive additives, device parts, etc., can solve the problem of uncontrollable volatilization speed of inorganic adhesive, uncontrollable flatness of adhesive layer, low mechanical strength, etc. problems, achieve good thixotropy and stability, controllable drying time, and simplify the production process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

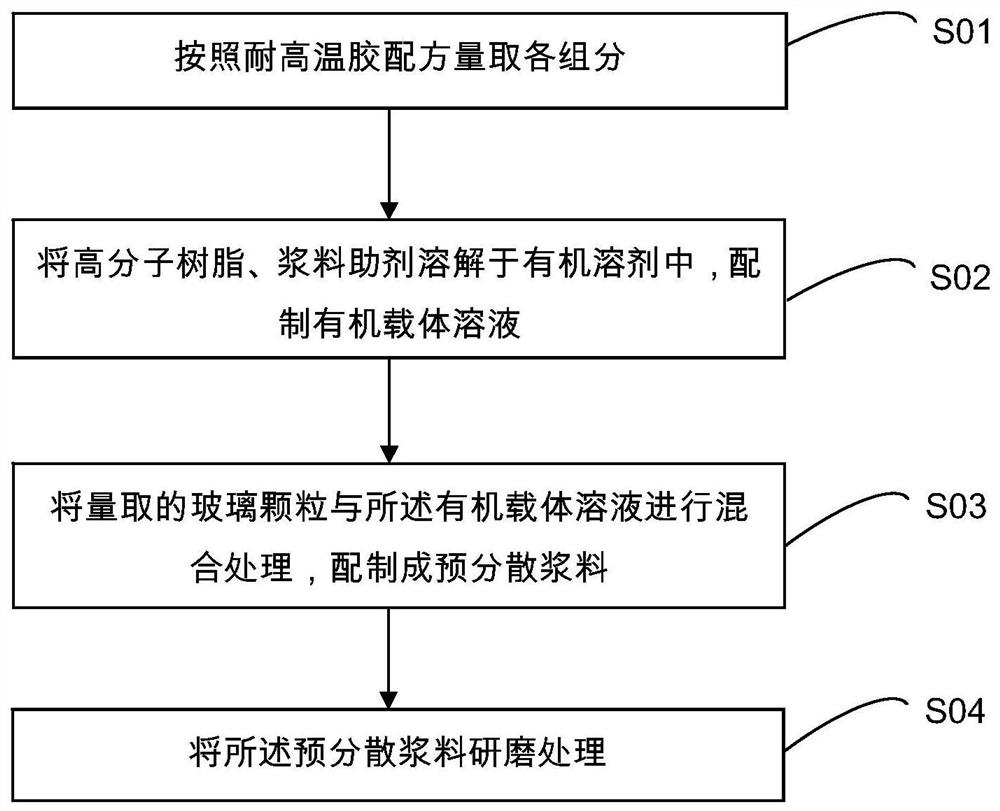

[0047] Correspondingly, based on the above-mentioned high temperature resistant adhesive, the embodiment of the present invention also provides a preparation method of high temperature resistant adhesive. The technological process of the preparation method of described high temperature resistant glue is as follows figure 1 shown, it includes the following steps:

[0048] S01: Measure each component according to the formula of the high temperature resistant adhesive;

[0049] S02: Dissolve the polymer resin and slurry auxiliary in an organic solvent to prepare an organic carrier solution;

[0050] S03: mixing the measured glass particles and the organic carrier solution to prepare a pre-dispersed slurry;

[0051] S04: grinding the pre-dispersed slurry.

[0052] In this way, the preparation method of the high temperature resistant adhesive mixes and grinds the organic carrier and the glass particles according to the components contained in the high temperature resistant adhes...

Embodiment 1

[0063] This embodiment provides a high temperature resistant adhesive and a preparation method thereof. The high temperature resistant adhesive comprises an organic carrier and glass particles dispersed in the organic carrier, and the content of the glass particles in the high temperature resistant adhesive is 60wt%;

[0064] Wherein, taking the total weight of the organic carrier as 100%, it includes the following components:

[0065] Terpineol 63%, Butyl Carbitol Acetate 17%, Alcohol Ester Twelve 10%, Polyvinyl Butyral 6.5%, Ethyl Cellulose 2%, Polymer Defoamer 0.2%, Dispersant Byk110 It is 0.5%, and the organic bentonite thixotropic agent is 0.8%.

[0066] The preparation method of the high temperature resistant adhesive comprises the following steps:

[0067] S11. Preparation of organic carrier: add each component into a three-necked flask according to the components and contents of the organic carrier contained in the high temperature resistant adhesive described in thi...

Embodiment 2

[0071] This embodiment provides a high temperature resistant adhesive and a preparation method thereof. The high temperature resistant adhesive comprises an organic carrier and glass particles dispersed in the organic carrier, and the content of the glass particles in the high temperature resistant adhesive is 64wt%;

[0072] Wherein, taking the total weight of the organic carrier as 100%, it includes the following components:

[0073] Butyl carbitol 62%, butyl carbitol acetate 22.2%, dioctyl phthalate 5%, polyvinyl butyral 7%, ethyl cellulose 2%, polymer defoamer 0.2 %, the dispersant Byk110 is 0.4%, and the organic bentonite thixotropic agent is 1.2%.

[0074] The preparation method of the high temperature resistant adhesive comprises the following steps:

[0075] S11. Preparation of organic carrier: according to the components and contents of the organic carrier contained in the high temperature resistant adhesive described in this example, each component was added to a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com