Online thermal-drying equipment for automobile wire harness pressure-welding point

A technology for wire harnesses and crimping points, which is applied to vehicle connectors, circuits, connections, etc., can solve problems such as long operation time, high labor intensity, and risk of thermal shrinkage quality, and achieve simple and convenient operation, low labor intensity, and heat The effect of controllable drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

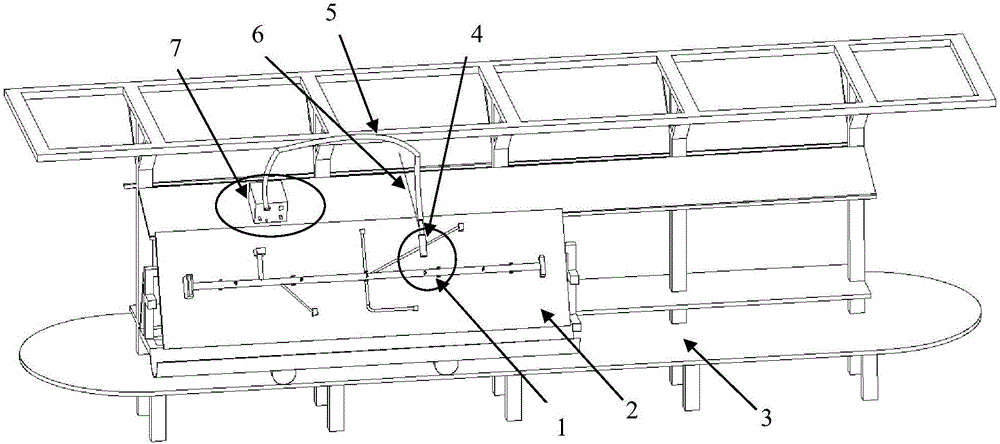

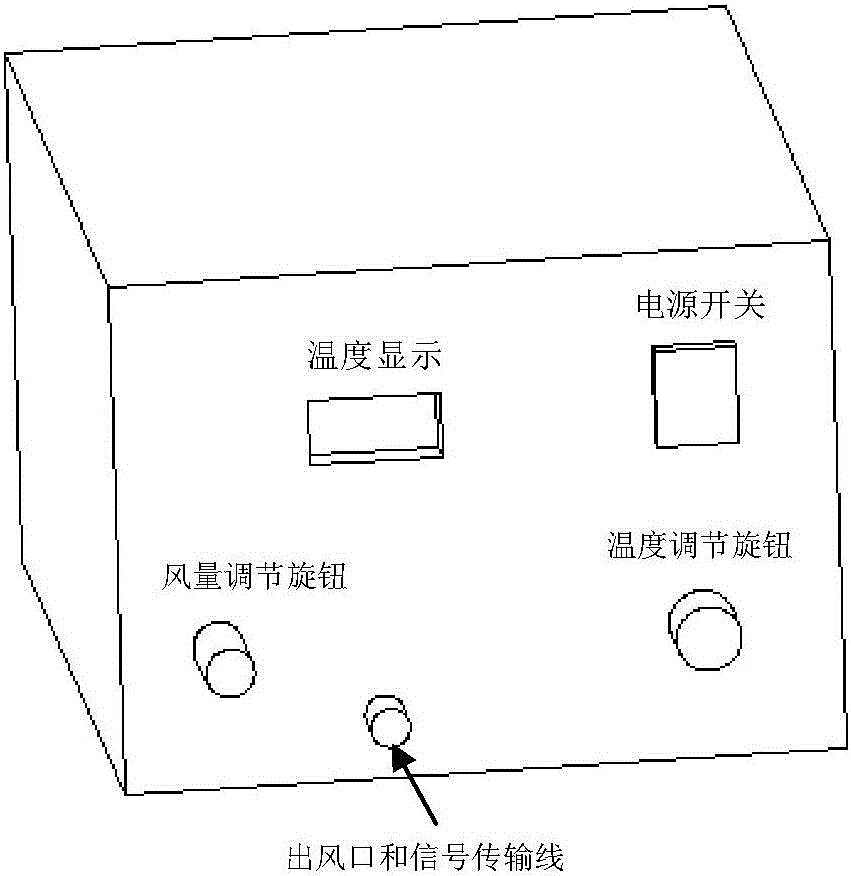

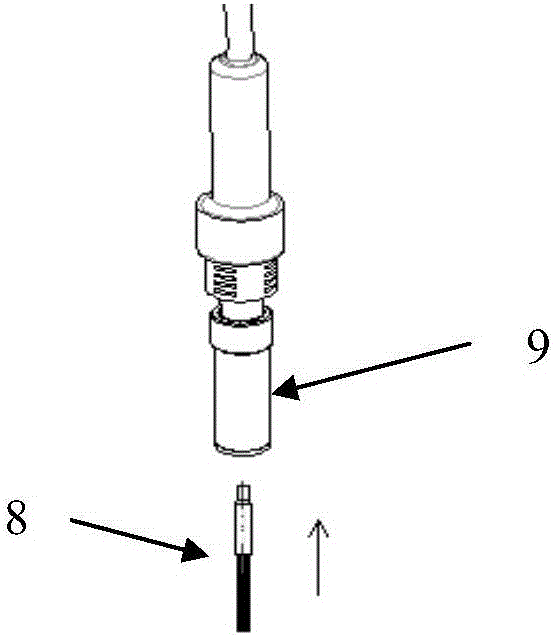

[0012] Such as Figure 1-3 As shown, the on-line heat drying equipment for crimping points of automobile wire harness includes body wiring harness 1, tooling plate 2, assembly line 3, heat drying gun 4, hose 5, wire rope hoist 6, controller 7, and wires assembled with heat shrinkable tubes 8. Quick change mold9.

[0013] The employees first set the relevant parameters of the heating equipment controller 7 according to the requirements of the work instructions. The body wiring harness 1 is set on the tooling board 2, and the tooling board 2 is fixed on the assembly line 3 for rotation. The employees will crimp them together and assemble them. The wire 8 of the heat-shrinkable tube is ready, and then take the heat-drying gun 4 suspended on the support of the assembly line 3 through the wire rope hoist 6, and put the wire 8 of the heat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com