A kind of environment-friendly shield tail sealing grease and preparation method thereof

A shield tail sealing and environment-friendly technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of easy hardening and poor pumpability, and achieve the effects of strong adhesion, corrosion prevention and good pumping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

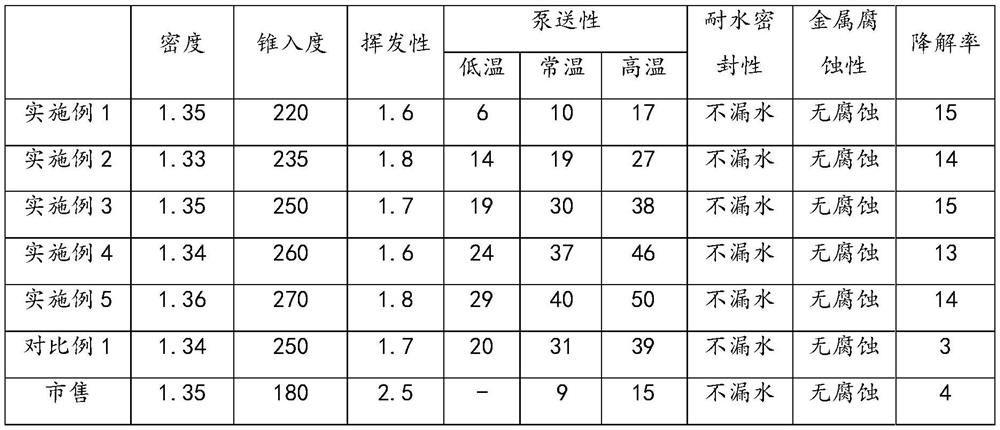

Examples

Embodiment 1

[0037] Environmentally friendly shield tail sealing grease is composed of the following components of mass percentage: poly-α olefin base oil 5%, talc powder 40%, bamboo powder 14%, composite aluminum-based grease 10%, petroleum resin 20%, diethylamine-based methyltriethoxysilane 3%, degradable wood fiber 5%, microcapsule 3%, microcapsule wall material is polylactic acid - hydroxyacetic acid copolymer and polyvinyl alcohol crosslinker, the core material is Bacillus subtilis, Bacillus licheniformis, Saccharomyces cerevisiae mixture. After testing, the environmentally friendly shield tail sealing grease is a yellow-white uniform fiber paste.

Embodiment 2

[0039]Environmentally friendly shield tail sealing grease, consisting of the following mass percentage components: polyol ester synthetic oil 10%, calcium carbonate 40%, sunflower shell powder 10%, composite aluminum-based grease 10%, degradable polyester resin 20%, diethylamine-based methyltriethoxysilane 3%, degradable cotton fiber 4%, microcapsules 3%, microcapsules wall material is polylactic acid - hydroxyacetic acid copolymer and polyvinyl alcohol crosslinker, the core material is Bacillus subtilis, gram-negative bacteria, Pseudomonas aeruginosa, Candida pseudomonas aeruginosa mixture. After testing, the environmentally friendly shield tail sealing grease is a yellow-white uniform fiber paste.

Embodiment 3

[0041] Environmentally friendly shield tail sealing grease consists of the following components of mass percentage: biodiesel 13%, talc 45%, compound aluminum-based grease 15%, ethylene propylene copolymer 16%, diethylaminomethyltriethoxysilane 4%, degradable cotton fiber 4%, microcapsules 3%, microcapsule wall material is polylactic acid - hydroxyacetic acid copolymer and polyvinyl alcohol crosslinker, the core material is Bacillus licheniformis, gram-negative bacteria, Pseudomonas aeruginosa, Candida pseudomonas, Saccharomyces saccharomyces a mixture. After testing, the environmentally friendly shield tail sealing grease is a yellow-white uniform fiber paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com