Local electroplating apparatus of mold

A local electroplating and mold technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high labor intensity, complicated process, reduction of electroplating effect and electroplating efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

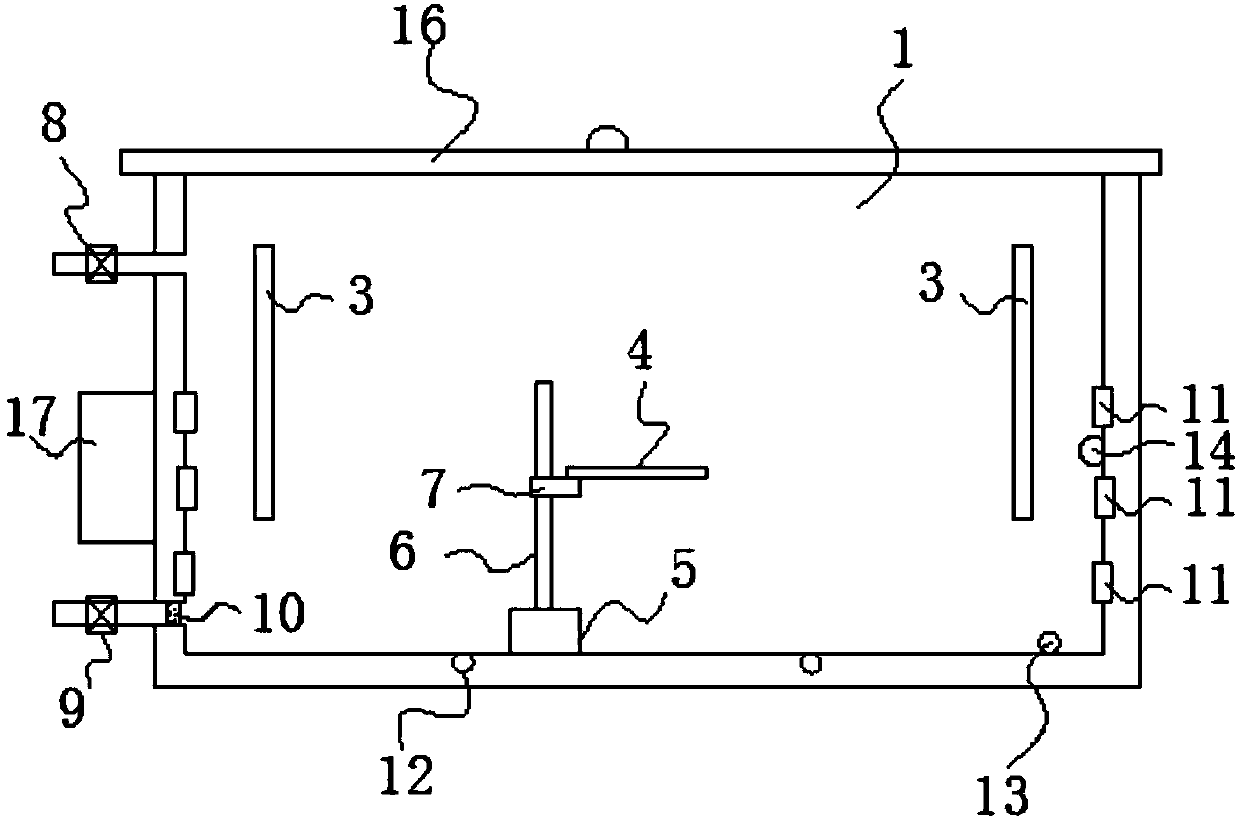

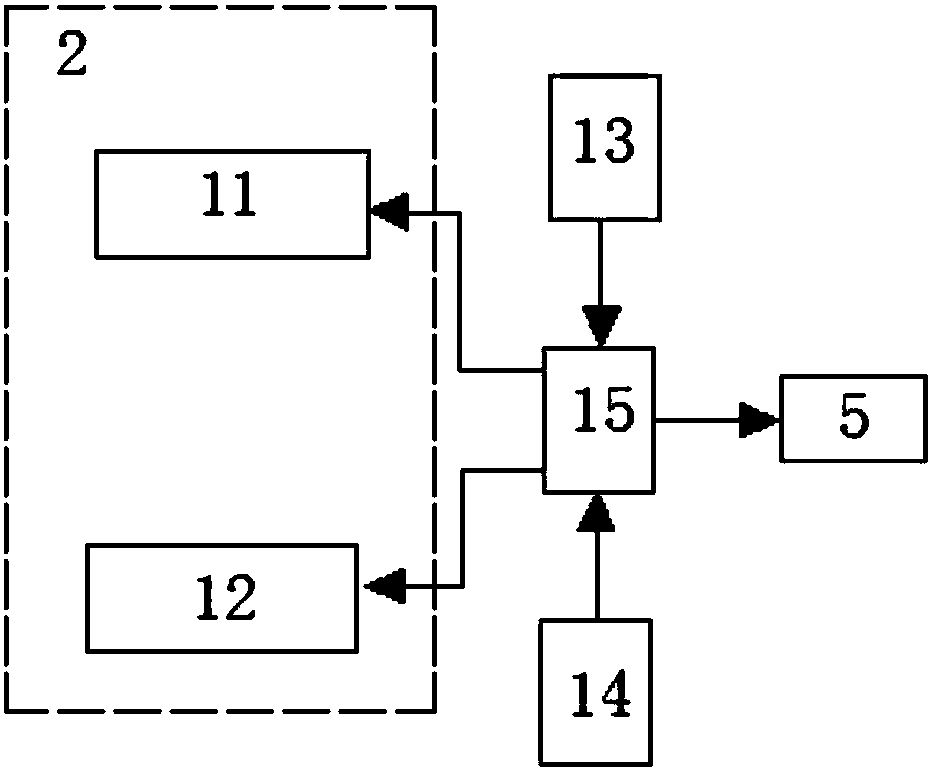

[0026] Example: A partial electroplating device for a mold, such as figure 1 with figure 2 As shown, it includes an electroplating tank 1, a heater 2, an anode conductive rod 3, and a cathode conductive seat 4. The heater, the anode conductive rod and the cathode conductive seat are all located in the electroplating tank, and the electroplating tank There is a driving unit at the bottom and inside of the cathode conductive base to drive the cathode conductive base up and down;

[0027] The drive unit includes a motor 5, a lead screw 6 and a slider 7. The output shaft of the motor is connected to the lead screw, and the slider is sleeved on the lead screw and is driven by the motor. The lead screw moves up and down, the cathode conductive seat is installed on the slider, and the cathode conductive seat is installed with a clamp for placing a mold, and the clamp is a hollow clamp;

[0028] A liquid injection valve 8 is installed at the upper end of one side of the electroplating ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com