Twin-roll cast-rolling device for aluminum alloy clean production and deep processing

A clean production, aluminum alloy technology, applied in the field of twin-roll casting and rolling equipment, to achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

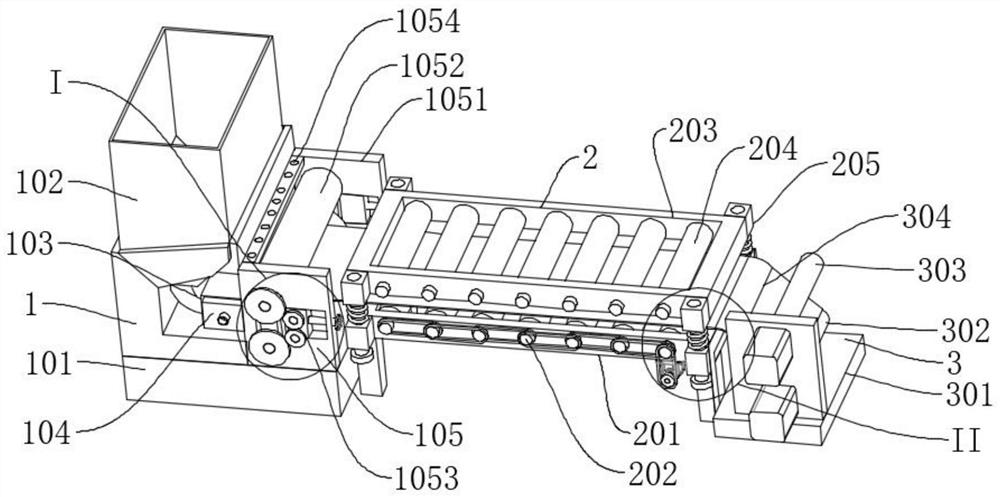

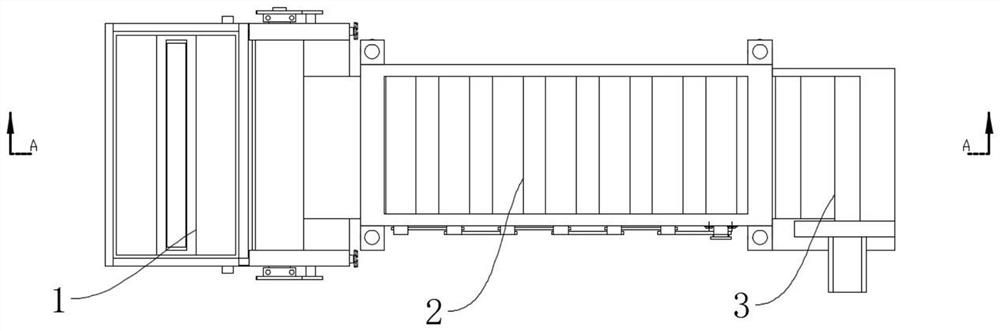

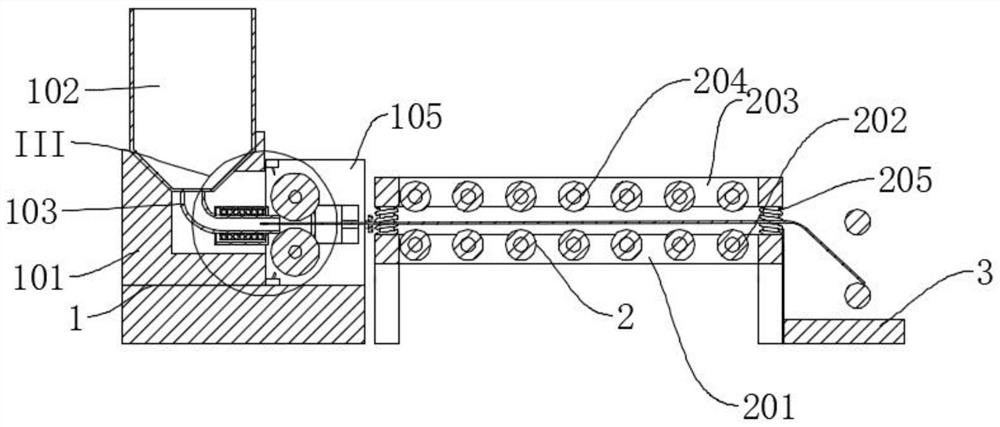

[0033] Such as Figure 1-Figure 7 As shown, a twin-roll casting and rolling device for clean production and deep processing of aluminum alloys includes an oil absorbing mechanism 2, a traction and winding mechanism 3, and a casting and rolling mechanism 1. An oil absorbing mechanism 2 is arranged on one side of the casting and rolling mechanism 1, and the oil absorbing mechanism 2. A traction and winding mechanism 3 is provided on the side away from the casting and rolling mechanism 1. The casting and rolling mechanism 1 includes a supporting platform 101, a tundish 102, a blanking mold 103, a cooling assembly 104, and a forming assembly 105. The top of the supporting platform 101 is connected by bolts. There is a tundish 102, the bottom of the tundish 102 is connected with a blanking mold 103 by bolts, the outer side of the blanking mold 103 is provided with a cooling assembly 104, and the outlet of the blanking mold 103 is provided with a molding assembly 105, so that the ins...

Embodiment 2

[0035] Such as Figure 8 As shown, the difference between embodiment 2 and embodiment 1 is that: the end of the pulling plate 304 away from the pulling roller 302 is welded with a hanging plate 3042, which can effectively pull the solidified aluminum alloy plate.

[0036] In the above structure, when in use, the ejector rod 2053 is first lifted, and the ejector rod 2053 drives the upper fixing block 2052 to rise, thereby causing the fixing frame 203 to rise, so that the distance between the pressure roller 204 and the idler roller 202 becomes larger, and then the traction plate is pulled 304, so that one end of the traction plate 304 passes between the forming rollers 1052 and stretches into the inside of the blanking mold 103, and then releases the ejector pin 2053, so that the pressure roller 204 is pressed down on the traction plate 304, and then the liquid in the tundish 102 is It flows into the blanking mold 103, and the cooling assembly 104 is connected to the water sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com