High-specific-energy sodium-ion battery manganese-based layered positive electrode material and preparation method thereof

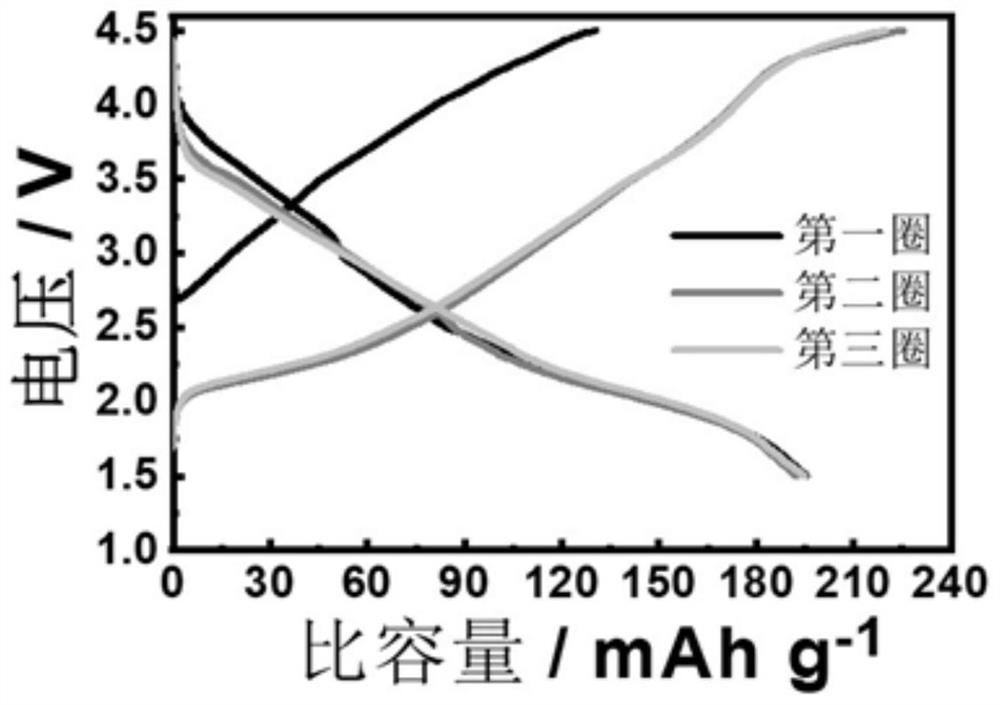

A sodium-ion battery and cathode material technology, applied in the field of electrochemistry, can solve the problems of high-voltage platform attenuation or disappearance structure, rapid capacity potential attenuation, first cycle irreversibility, etc., to improve electrochemical stability and improve cycle stability , Excellent structural stability and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) According to the molar ratio of 0.6:0.2:0.6:0.2, accurately weigh the corresponding mass of Na 2 CO 3 (5% excess), LiOH•H 2 O, MnO 2 and RuO 2 , added to the ball mill jar, and then added ball mill balls, at 300 r min -1 Under the conditions of ball milling for 15 h, the above precursors were mixed evenly, and the mixed precursors were dried in an oven at 100 °C for 12 h.

[0052] (2) Press the ball-milled mixture into a disc with a diameter of 16 mm under a pressure of 10 MPa.

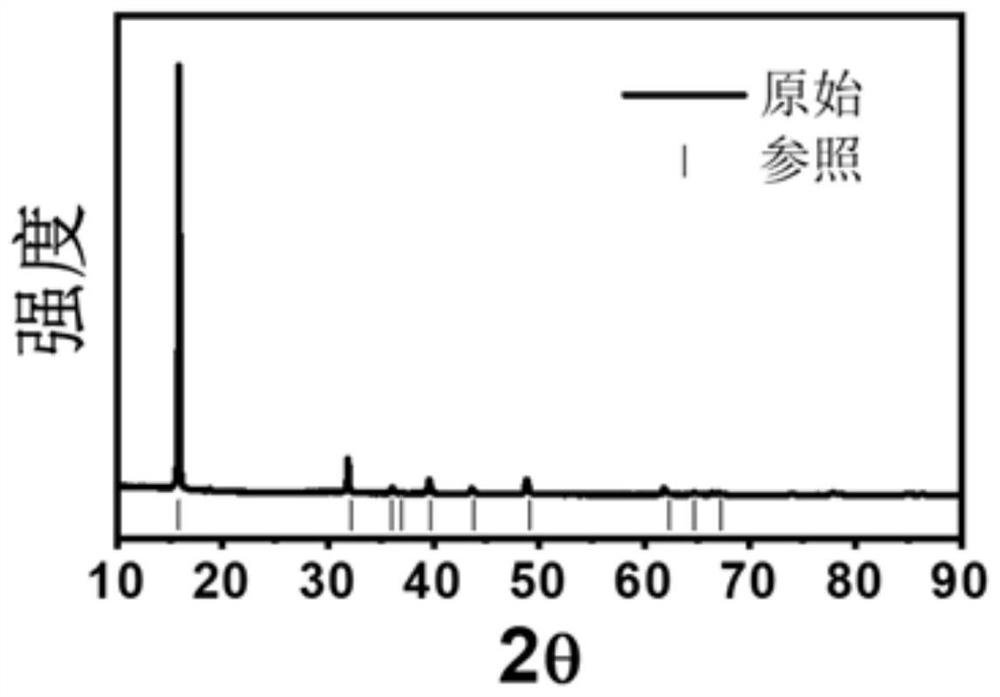

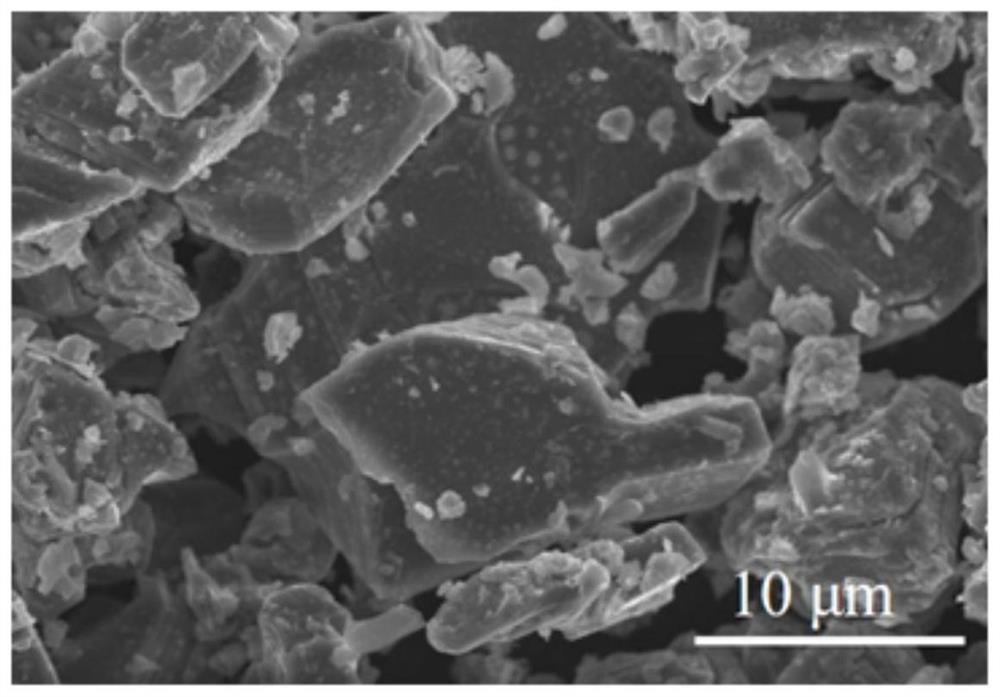

[0053] (3) The flake samples obtained in step (2) were calcined step by step in a tube furnace, at 5°C min in an air atmosphere -1 Heat up to 500°C, calcine for 5 h; cool down to room temperature with the furnace, grind it and press it again, heat up to 700°C, and calcine for 7 h; repeat the above operation and heat up to 1100°C, after calcination for 11 h, cool down in the furnace and take out the sample for grinding The original powder is obtained, whose molecular formula is Na 0.6...

Embodiment 2

[0064] Change the molar ratio of each substance, according to the molar ratio of 0.6:0.05:0.9:0.05, accurately weigh the corresponding mass of Na 2 CO 3 , MnO 2 and RuO 2 According to the method of steps (1)-(3) in Example 1, a high specific energy manganese-based layered cathode material for a sodium ion battery was prepared, and its molecular formula was Na 0.6 Li 0.05 mn 0.9 Ru 0.05 o 2 .

Embodiment 3

[0066] Change the molar ratio of each substance, according to the molar ratio is 0.6:0.1:0.8:0.1, accurately weigh the Na of corresponding quality 2 CO 3 , MnO 2 and RuO 2 According to the method of steps (1)-(3) in Example 1, a high specific energy manganese-based layered cathode material for a sodium ion battery was prepared, and its molecular formula was Na 0.6 Li 0.1 mn 0.8 Ru 0.1 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com