Integral type organic waste gas treatment device

A technology for organic waste gas and treatment devices, applied in gas treatment, combined devices, membrane technology, etc., can solve the problems of limited organic waste gas interception capacity, unguaranteed gas residence time, and reduced effective treatment channel length, so as to maintain high adsorption performance , treatment efficiency and thoroughness, and the effect of solving the problem of ozone pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, invention is described in further detail.

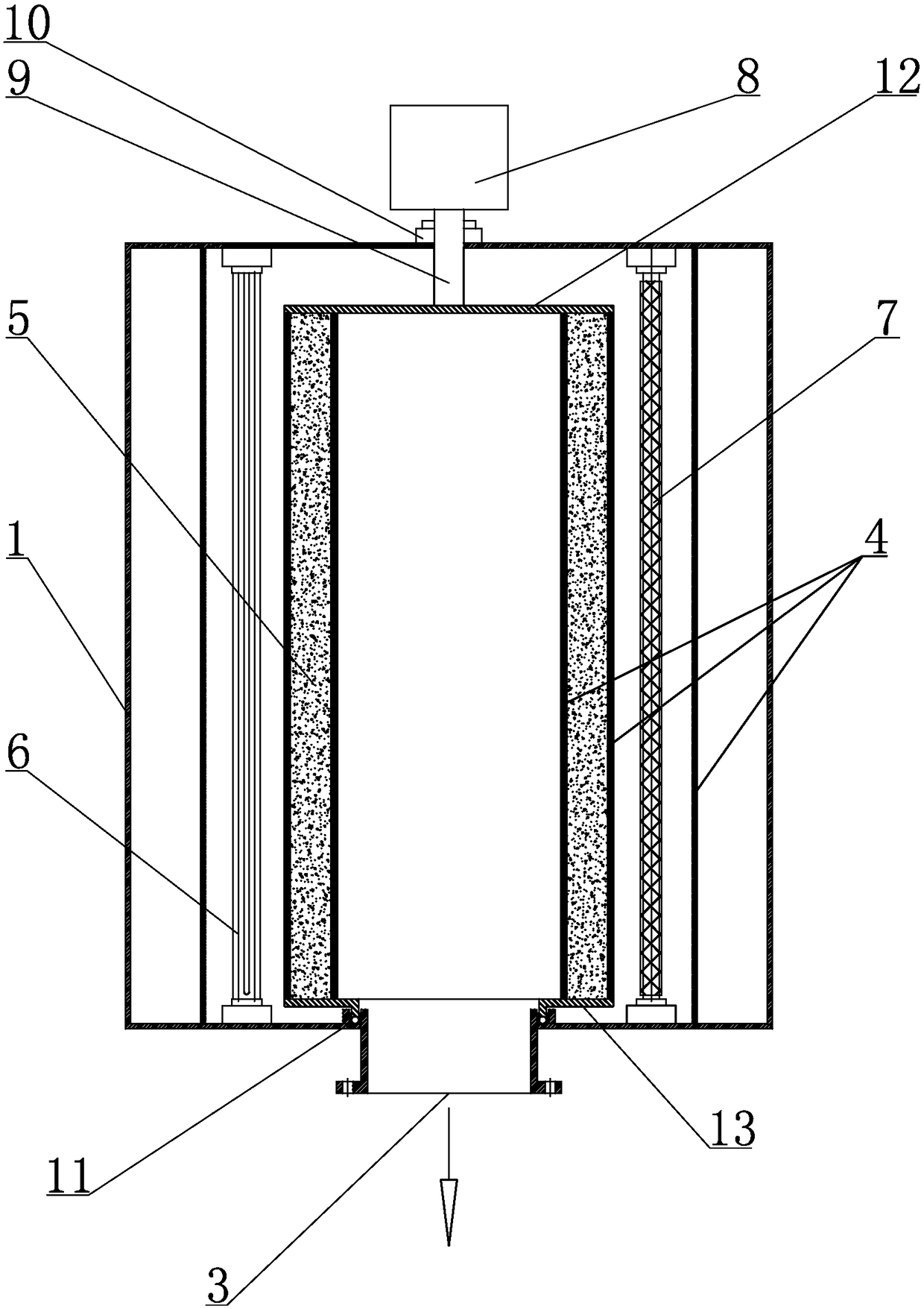

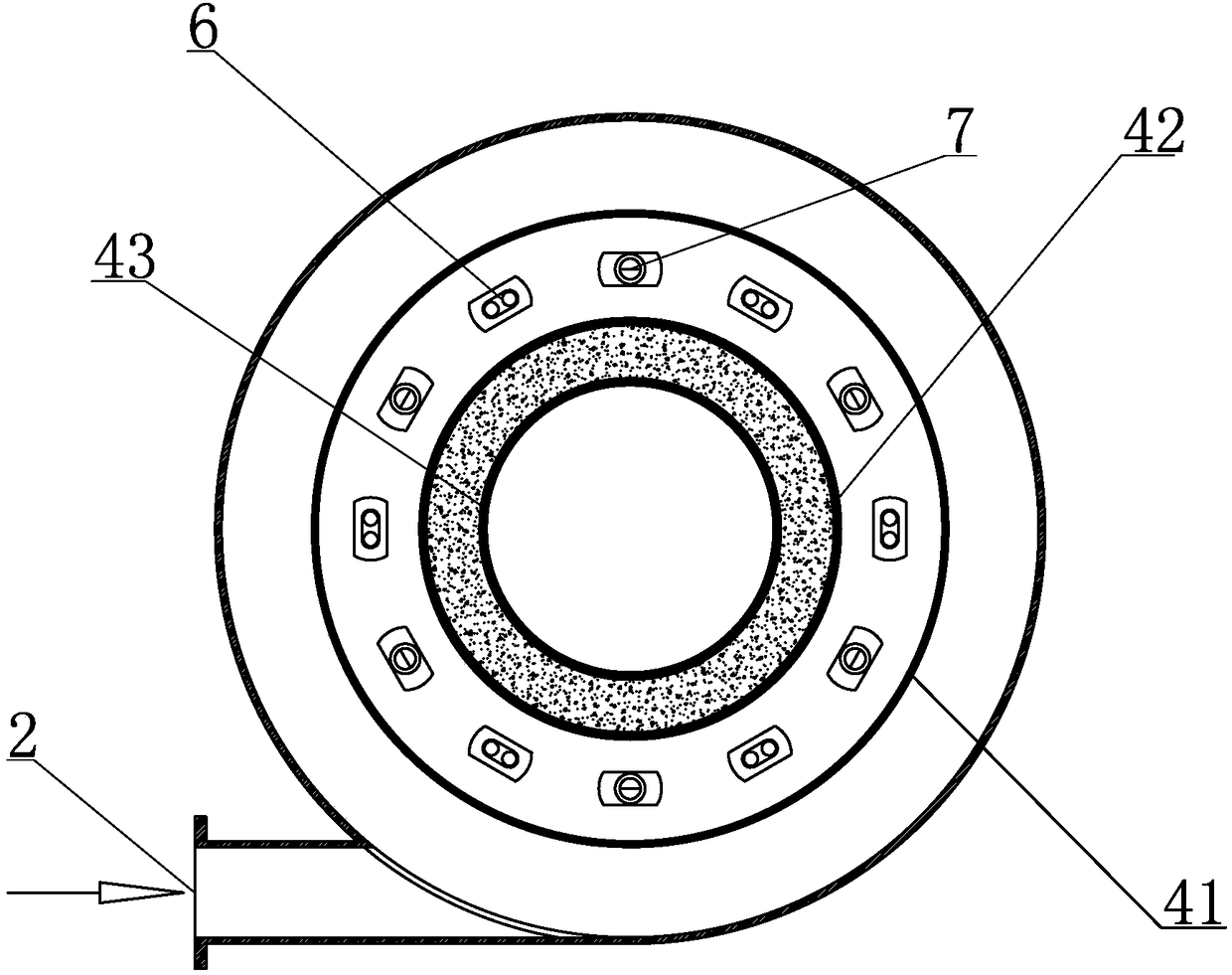

[0021] Such as Figure 1-2 As shown, an integrated organic waste gas treatment device includes a housing 1, an air inlet 2 provided on the side of the housing 1, an air outlet 3 provided on the upper or lower end surface of the housing 1, and an air outlet 3 provided on the side of the housing 1. The inside of the body 1 is provided with a rotating main shaft 9 extending from the inside to the outside, a geared motor 8 is provided on the end of the rotating main shaft 9 outside the housing 1, and a first filter cartridge 41 is provided layer by layer in the housing 1 , the second filter cartridge 42 and the third filter cartridge 43, between the first filter cartridge 41 and the second filter cartridge 42, a plurality of plasmas 7 and ultraviolet lamps 6 distributed in annular intervals are provided, and in the second filter cartridge The activated carbon layer 5 is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com