Wet flue gas desulfurization device and method for enhancing gas-liquid mass transfer reaction

A wet flue gas desulfurization and mass reaction technology, applied in chemical instruments and methods, measuring devices, separation methods, etc., can solve the problems of large floor space, high operating cost of desulfurization equipment, and low desulfurization efficiency. Save energy, reduce usage, highly disperse and mix fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

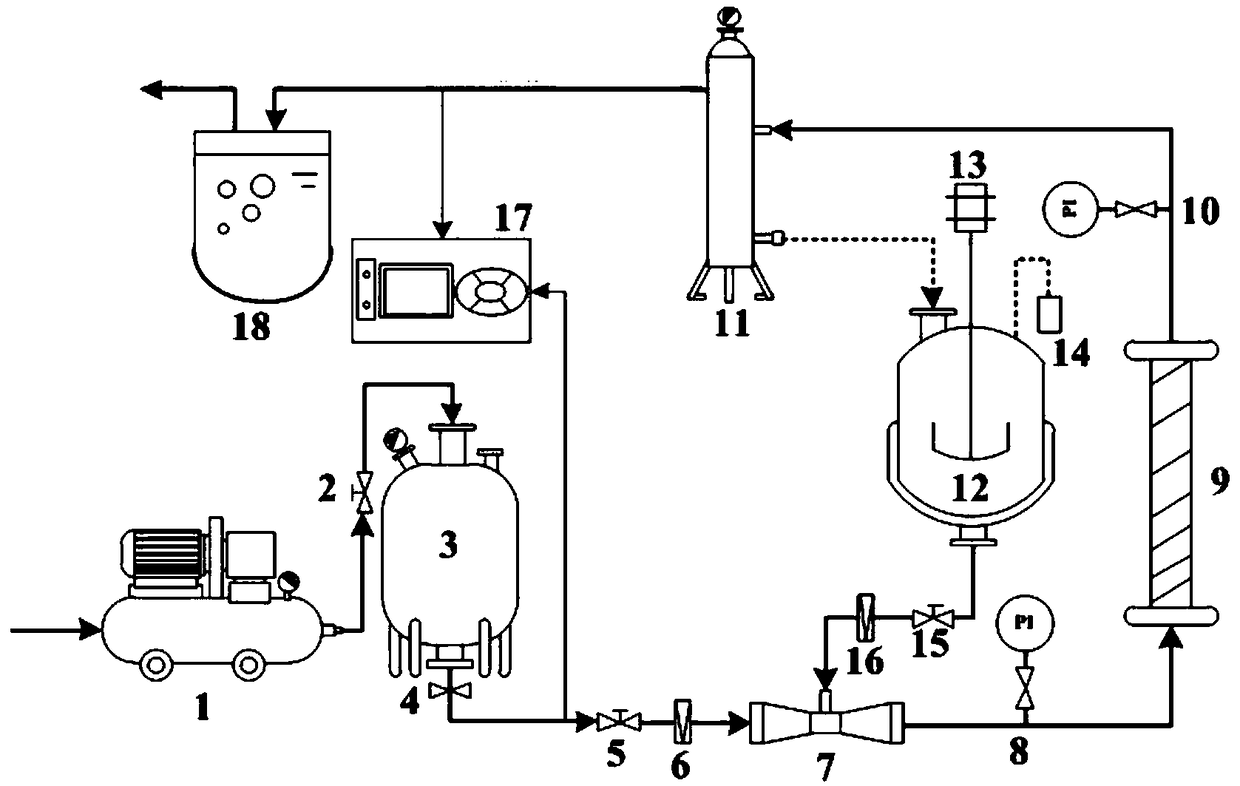

Method used

Image

Examples

Embodiment 1

[0056] Using air compressor and SO 2 Gas cylinders (pure SO2, purity 99.99%) pass the flow ratio of the two to obtain different SO 2 Concentration of simulated flue gas;

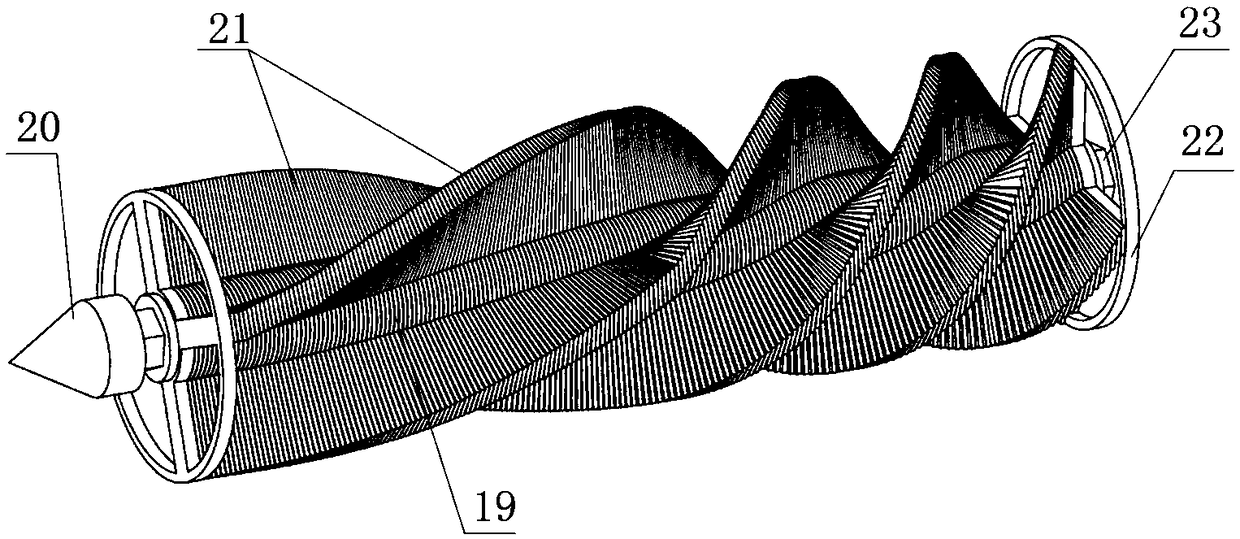

[0057] Structural parameters: the diameter of the cutting blade mounting rod of the static spiral cutter 9 is 25 mm, and the compression index is 0.5;

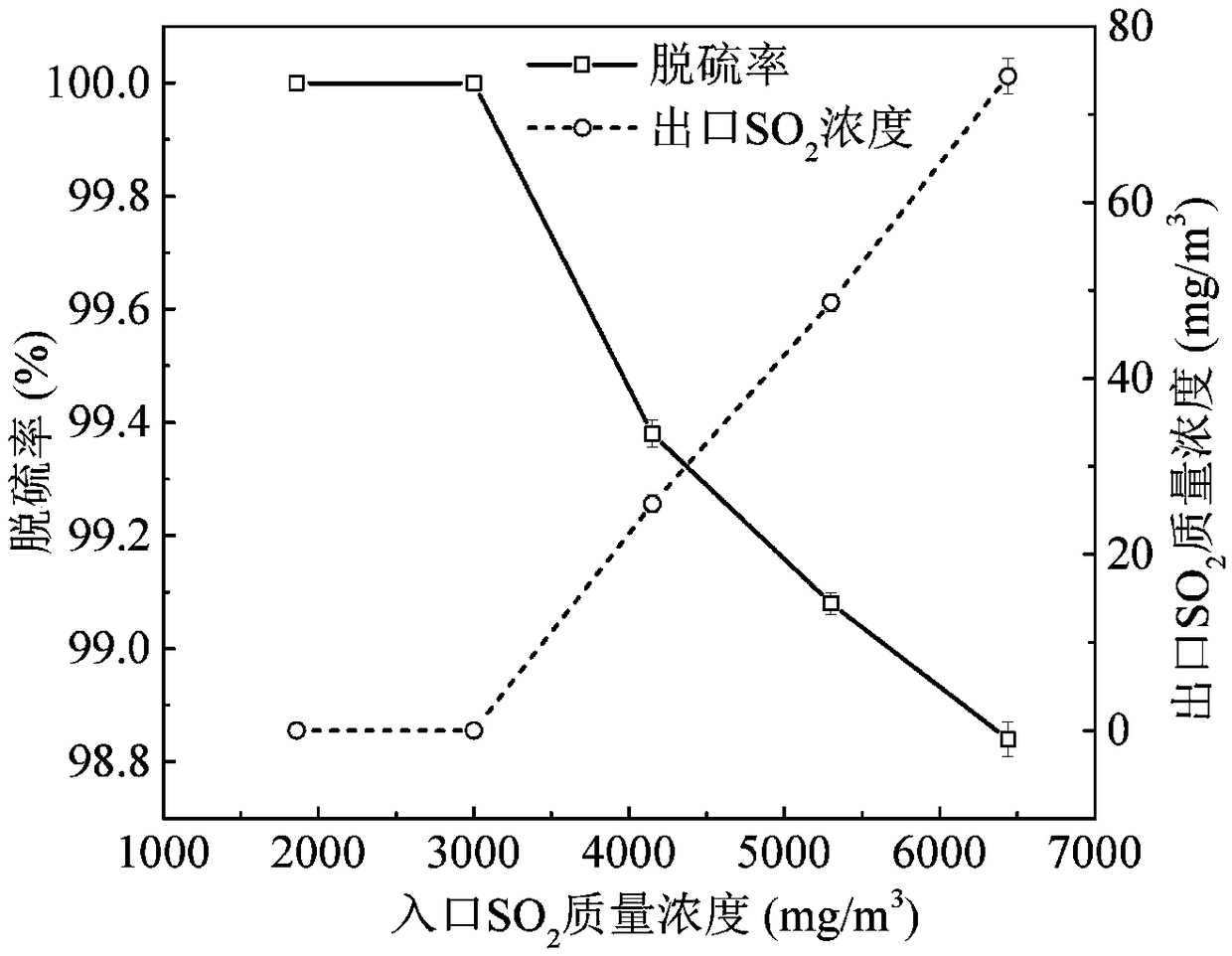

[0058] Process parameters: desulfurizer mass fraction 20wt%, flue gas flow rate 18Nm 3 / h, under the condition that the desulfurizer circulation flow rate is 300mL / min 2 The mass concentration is 1860-6440mg / m 3 The flue gas is treated, and the SO of the flue gas after the reaction 2 The concentration is detected online by the flue gas analyzer and the analysis results are given on the display screen. The desulfurization results are as follows: image 3 shown.

[0059] Depend on image 3 It can be seen that when the inlet flue gas SO 2 The mass concentration is lower than 3000mg / m 3 The whole system exhibits excellent desulfurization performance. Th...

Embodiment 2

[0061] Equipped with SO in flue gas 2 The concentration is 2960mg / L;

[0062] Structural parameters: the diameter of the cutting blade mounting rod of the static spiral cutter 9 is 80 mm, and 10 static spiral cutters 9 with a compression ratio of 0.5 are connected in parallel;

[0063] Process parameters: desulfurizer mass fraction 20wt%, flue gas outflow pressure 0.3MPa, flow rate 2100 Nm3 / h, desulfurizer circulation flow rate 30L / min. SO in the flue gas after the reaction of the first-stage spiral cutter 2 With a concentration of 38-50mg / L, the SO in the flue gas after the reaction of the secondary helical cutter (two helical cutters connected in series) 2 The concentration is 18-30mg / L, meeting the standard of ultra-low emission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com