Preparation method of hercynite

A technology of iron-aluminum spinel and iron salt, which is applied in the field of preparation of iron-aluminum spinel, can solve the problems of non-compact structure, high sintering temperature of iron-aluminum spinel, low content of iron-aluminum spinel, etc., and achieve internal Compact structure, shortened reaction time, fully and evenly reacted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

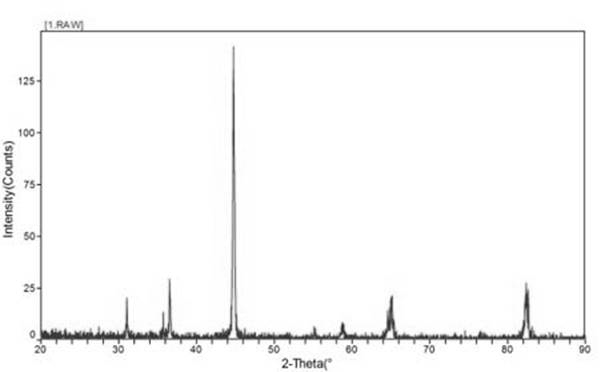

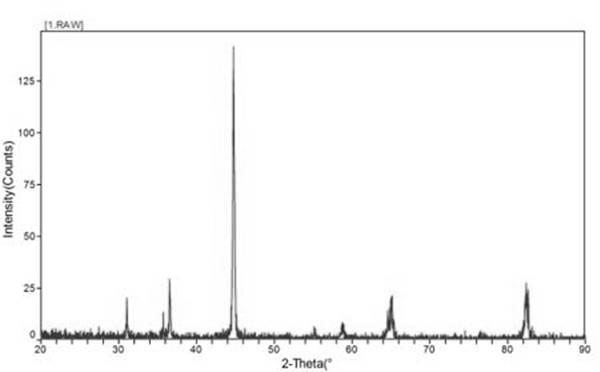

Image

Examples

Embodiment 1

[0029] A method for preparing iron-aluminum spinel, the steps are as follows:

[0030] 1) Mix aluminum nitrate and ferric nitrate at a molar ratio of 2:1 and dissolve them in ethanol to make a mixed solution with a concentration of 1mol / L for later use;

[0031] 2) Add ammonia water dropwise to the mixed solution prepared in step 1 for neutralization while stirring until the pH value of the mixed solution is 7, and a precipitate is formed during the neutralization process;

[0032] 3) Filter out the precipitate in step 2, wash with distilled water, add ethylene glycol to disperse, then dry and set aside;

[0033] 4) Calcinate the precipitate dried in step 3 at 300°C-800°C for 1-3h, then add 5% carboxypropyl cellulose and 1.6% graphite powder of the total weight of the precipitate, and mix well , pressed into compacts by cold isostatic pressing, and set aside;

[0034] 5) The compact obtained in step 4 was sintered under a vacuum condition of 1400° C. for 4 hours, and cooled ...

Embodiment 2

[0036] A method for preparing iron-aluminum spinel, the steps are as follows:

[0037] 1) Mix aluminum chloride and ferric chloride at a molar ratio of 2:1 and dissolve them in distilled water to make a mixed solution with a concentration of 1mol / L for later use;

[0038] 2) Add sodium hydroxide solution dropwise to the mixed solution prepared in step 1 for neutralization while stirring until the pH value of the mixed solution is 7, and a precipitate is formed during the neutralization process;

[0039] 3) Filter out the precipitate in step 2, wash with distilled water, add absolute ethanol to disperse, then dry and set aside;

[0040] 4) Calcinate the dried precipitate in step 3 at 300°C-800°C for 1-3h, then add 3% polyvinyl butyral and 1% graphite powder of the total weight of the precipitate, and mix well Finally, press it into a compact with cold isostatic pressing, and set it aside;

[0041] 5) The briquette obtained in step 4 was sintered at 1550° C. under the protecti...

Embodiment 3

[0043] A method for preparing iron-aluminum spinel, the steps are as follows:

[0044] 1) Mix aluminum sulfate and ferrous sulfate according to the molar ratio of aluminum ions and iron ions of 2:1 and dissolve them in distilled water to make a mixed solution with a concentration of 1mol / L;

[0045] 2) Add potassium hydroxide solution dropwise to the mixed solution prepared in step 1 for neutralization while stirring, until the pH value of the mixed solution is 7, and a precipitate is formed during the neutralization process;

[0046] 3) Filter out the precipitate in step 2, wash with distilled water, add ethylene glycol to disperse, then dry and set aside;

[0047] 4) Calcinate the precipitate dried in step 3 at 300°C-800°C for 1-3h, then add 1% polyethylene glycol and 2.5% graphite powder of the total weight of the precipitate, and mix well, Press into compacts by cold isostatic pressing and set aside;

[0048] 5) The briquette obtained in step 4 was sintered at 1700° C. for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com