Garbage pyrolysis and gasification incineration system and process

A technology of pyrolysis gasification and garbage, which is applied in the direction of incinerator, combustion type, combustion method, etc., can solve the problems of lowering the calorific value of garbage raw materials, no independent drying link, and large fluctuations in reaction temperature, so as to avoid incomplete reaction Full or even flameout, uniform and stable reaction, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

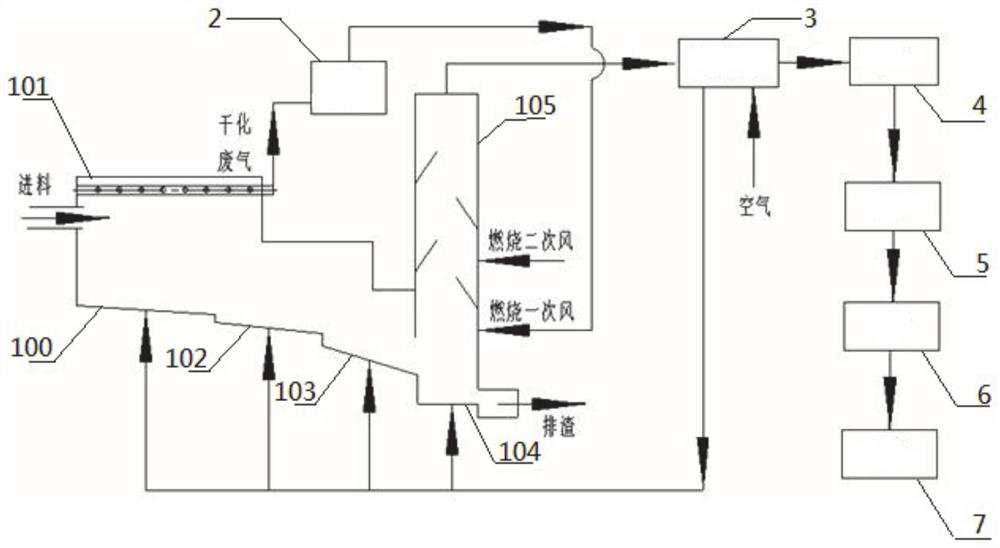

[0050] as attached figure 1 As shown, in this embodiment, a garbage pyrolysis gasification incineration system is provided. and the exhaust device are connected in sequence;

[0051] The pyrolysis gasification furnace has an integrally formed drying zone 100, pyrolysis zone 102, gasification zone 103, ash burnout zone 104 and gas combustion zone 105, wherein the drying zone 100, pyrolysis zone 102, gas The combustion zone 103 forms a stepped downward-sloping passage leading to the ash burnout zone 104, and the gas combustion zone 105 is located above the ash burnout zone 104;

[0052] A gas recovery pipeline 101 is arranged above the drying zone 100, and the gas recovery pipeline 101 leads to the gas combustion zone 105 after passing through the dehydration device; the top of the gas combustion zone 105 has a pipeline leading to a high-temperature heat exchanger, and the ash and slag There is a slag outlet at the bottom of the burnout zone for transferring the incinerated ga...

Embodiment 2

[0056] In this embodiment, a process for pyrolysis and incineration of waste based on the waste pyrolysis gasification incineration system described in Embodiment 1 is provided. The waste is fed through the feed port of the drying zone 100, and the The high temperature, the air distribution at the bottom of the furnace body, and the gas recovery pipeline 101 at the top of the drying area work together to extract the moist air from the garbage, reduce the moisture content of the garbage, and make it easier to ignite in the furnace without adding additional fuel . The dry exhaust gas containing water vapor is drawn out of the pyrolysis gasification combustion furnace through the negative pressure pipeline 101 with small holes provided on the upper part of the drying area 100, and is condensed and dehydrated by the dehydration device 2, and then sent back to the pyrolysis gasification combustion as the primary combustion air Furnace burning.

[0057] In the pyrolysis incinerator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com