Defoaming and adding method and defoaming and adding device for wet-process phosphoric acid extraction reaction

A technology of wet-process phosphoric acid and feeding method, which is applied in the direction of chemical instruments and methods, liquid solution solvent extraction, phosphorus compounds, etc. It can solve the problems of affecting the heat dissipation of slurry, difficult to eliminate foam, and splashing of sulfuric acid, so as to speed up cooling and reduce Corrosion, effect that favors dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of defoaming feeding method of wet process phosphoric acid extraction reaction, this defoaming feeding method comprises the following steps:

[0030] (1) Phosphate slurry is added in the extraction tank;

[0031] (2) Add sulfuric acid into the phosphate rock slurry from the lower part of the extraction tank. Sulfuric acid is added from the lower part of the extraction tank, avoiding the traditional method of adding liquid surface, so that the phosphate rock slurry and sulfuric acid react violently on the liquid surface to produce a large amount of foam accumulation. The present invention uses this adding method to make the phosphate rock slurry and sulfuric acid Reaction below the liquid surface, when the foam generated during the reaction overflows from the slurry, the slurry will squeeze it to destroy the formation of the foam, and finally form a gas on the surface of the slurry and discharge it, which fundamentally solves the problem of the extraction tank. b...

Embodiment 2

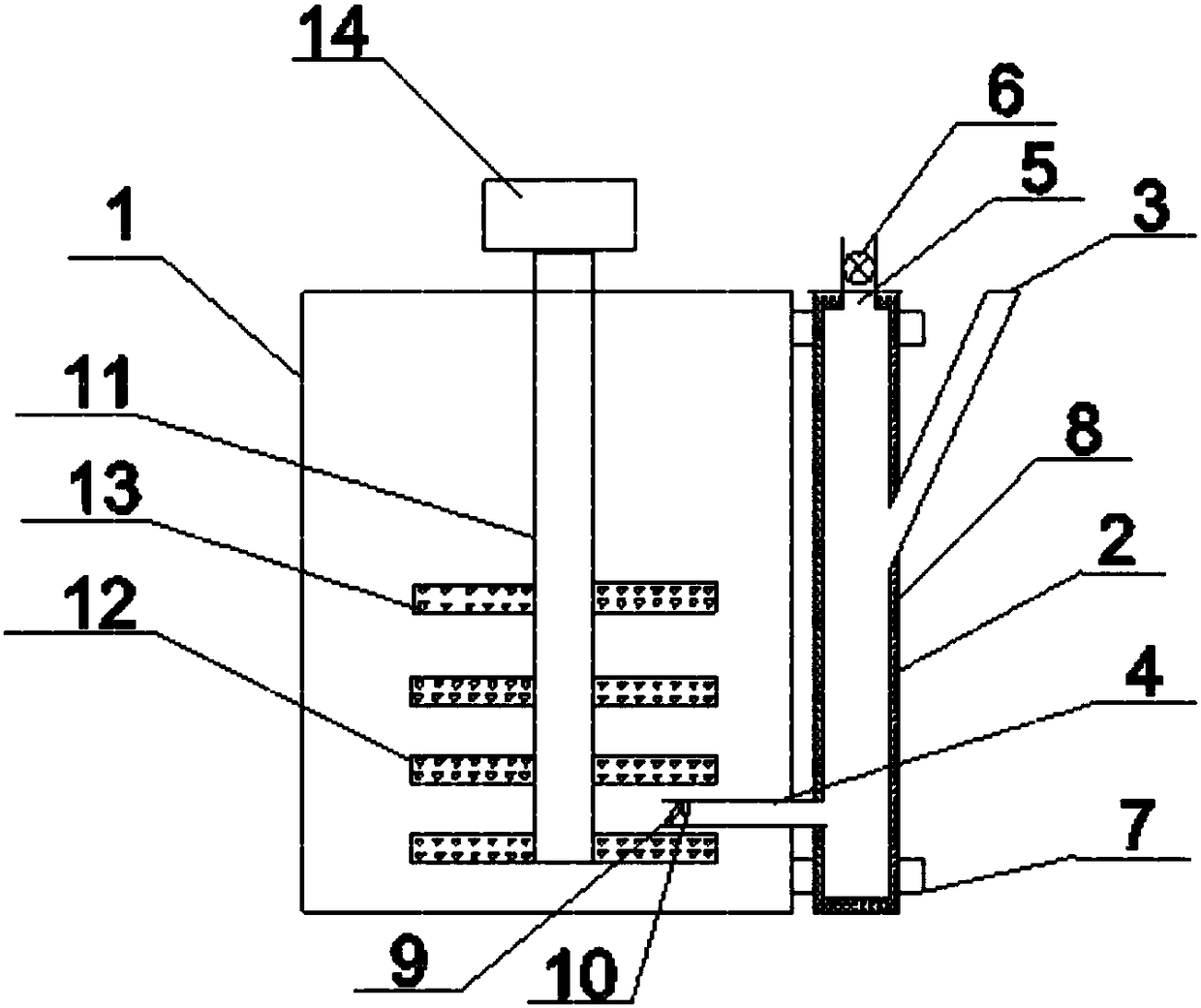

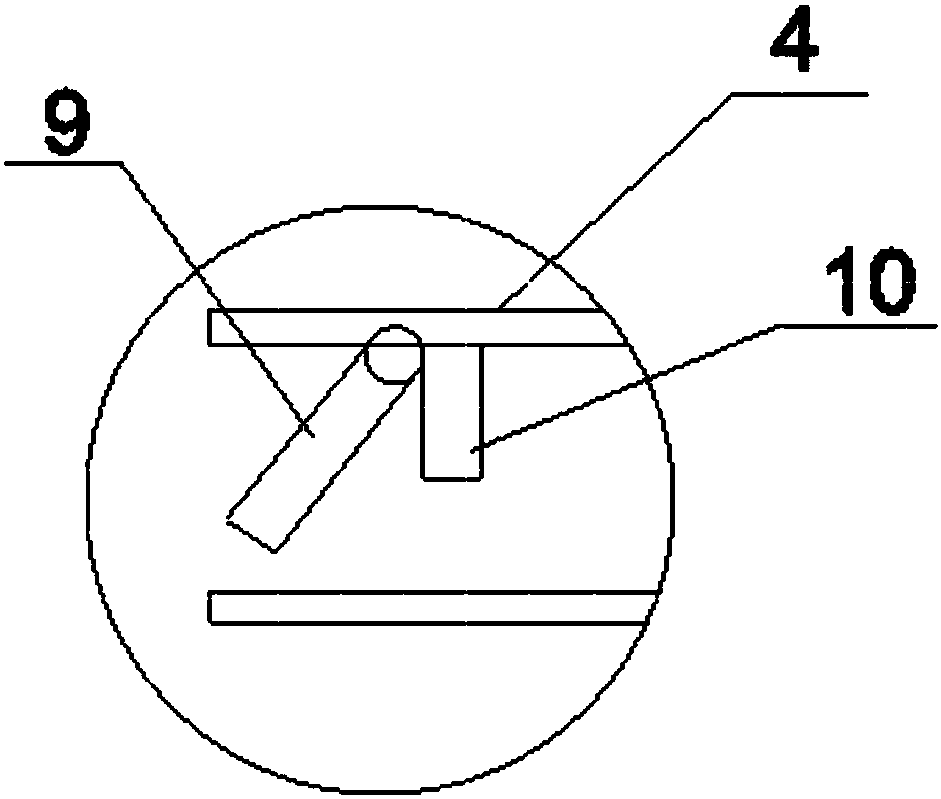

[0034] An extraction tank with a submerged feeding device, comprising an extraction tank 1, and a submerged feeding device arranged on the outer wall of the extraction tank 1, the submerged feeding device includes a feeding body 2, and the feeding body (2 ) is provided with a feeding port 3 and an air outlet 5, and the bottom of the feeding body 2 is provided with a feeding pipe 4 communicating with the bottom of the extraction tank 1; a stirring shaft 11 is arranged in the extraction tank 1, and There are several stirring blades 12, and several spikes 13 are arranged on the stirring blades 12, and one end of the feeding pipe 4 extends between two adjacent stirring blades 12 in the extraction tank 1, and the top of the extraction tank 1 is provided with The driving device that drives the stirring shaft 11 to stir, and the driving device is a motor 14 .

[0035] Working principle: When phosphate rock and sulfuric acid in wet-process phosphoric acid react in extraction tank 1, t...

Embodiment 3

[0039] Further optimization on the basis of Example 1, in this embodiment, the feed inlet 3 is arranged on the side of the feeding body 2, the air outlet 6 is arranged on the top of the feeding body 2, and an exhaust fan is arranged at the air outlet 5 6. Because if the exhaust fan 6 is arranged on the side, and the feed port 3 is arranged on the top, that is to say, the position of the draft port 5 is lower than the feed port 3, so that the added material may flow out from the draft port 5, therefore, like this The unique design ensures that the added material does not flow out from the air outlet 5, ensuring smooth feeding and ventilation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com