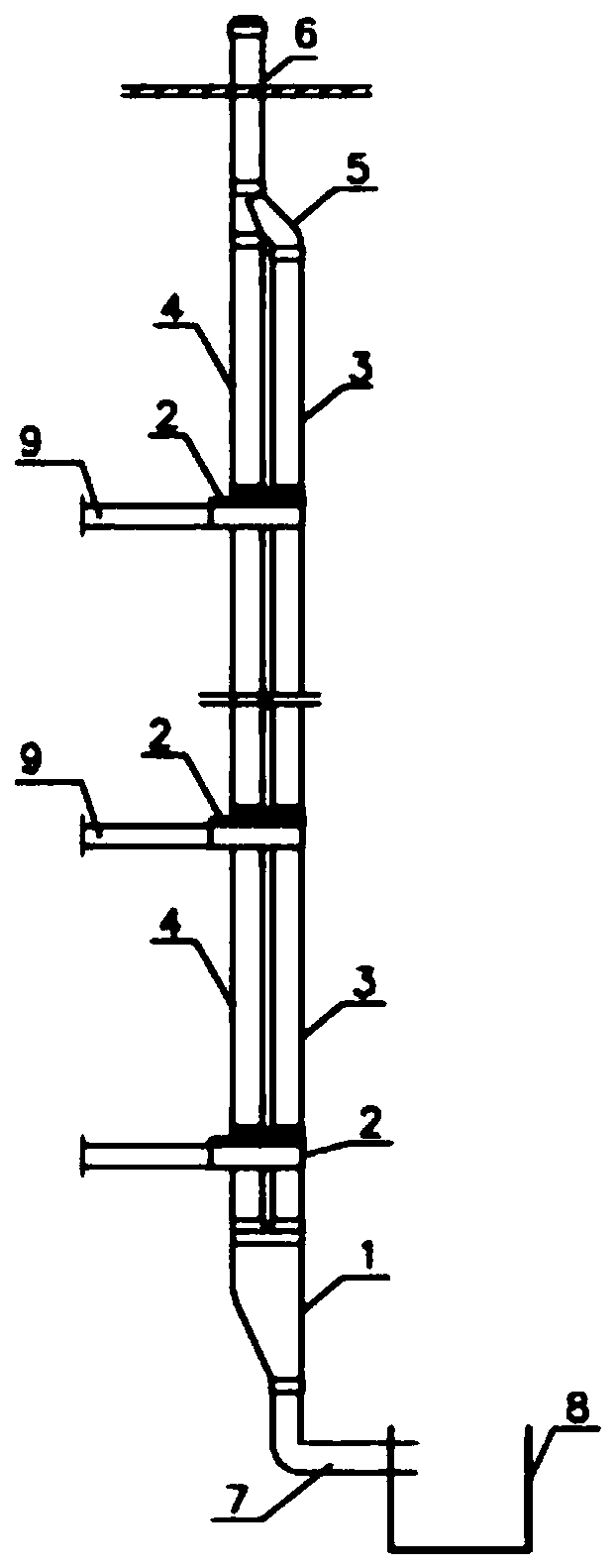

Water-gas full separation drainage system

A drainage system and water-air separation technology, applied in water supply installations, indoor sanitary piping installations, buildings, etc., can solve the problems of poor water-air separation, affecting the effect of ventilation, unstable air pressure, etc., achieving a simple structure, avoiding the The effect of reflux and stable air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

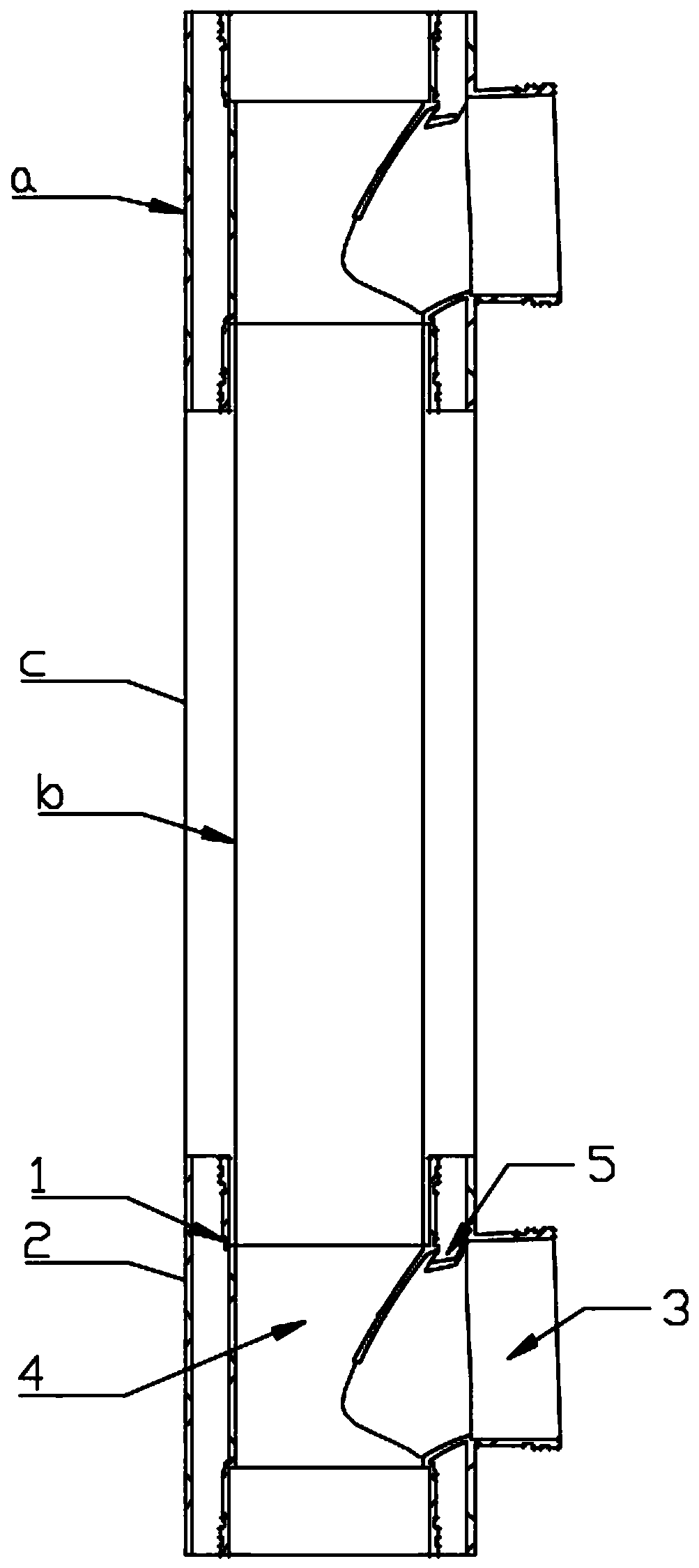

Method used

Image

Examples

no. 1 example

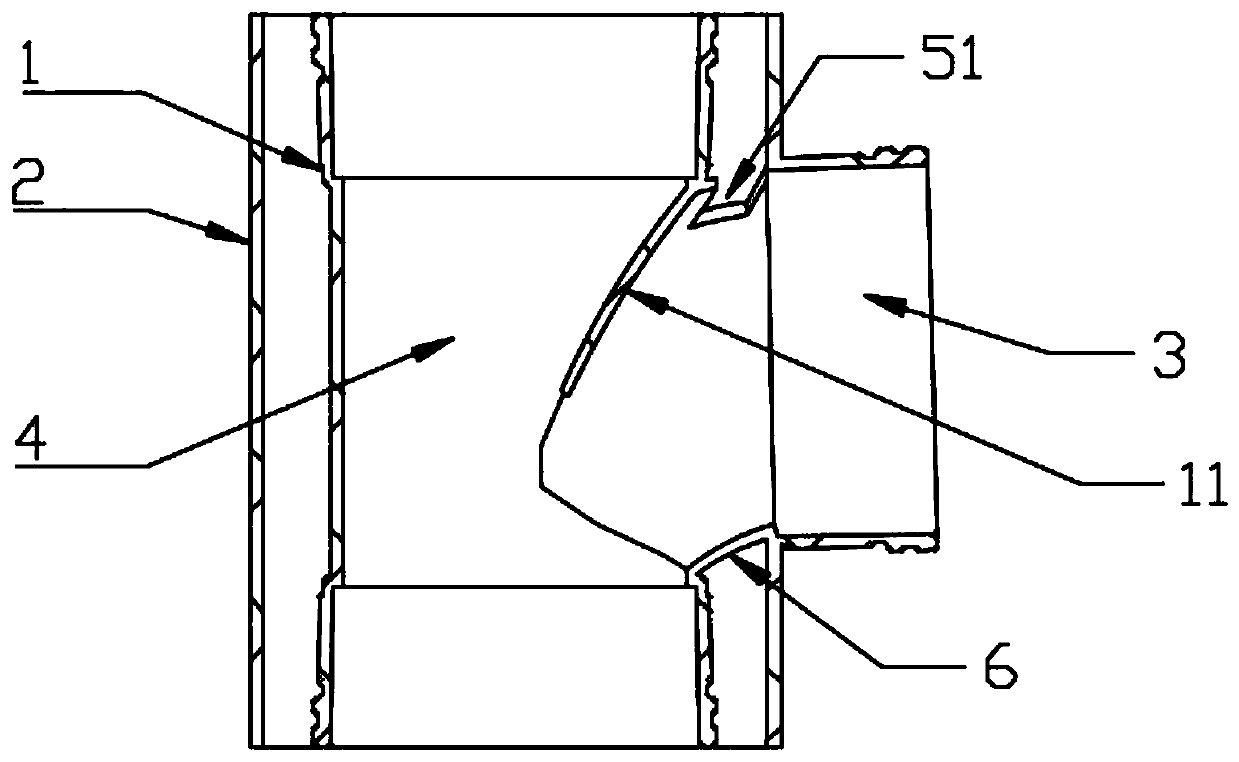

[0032] See Figure 4 , In the second embodiment of the present invention, there is an inwardly inclined blocking piece 12 between the transverse branch pipe interface 3 and the air hole 51 . The blocking sheet 12 is shorter than the drainage sheet 11 . When the water flow entering from the transverse branch pipe interface 3 is too large, the water flow hits the drainage sheet 11 to cause splashing, while the blocking sheet 12 reduces the splashing range of the water flow, preventing part of the water flow from entering the ventilation pipe c through the ventilation hole 51. Compared with the first embodiment, this embodiment uses the blocking sheet 12 to block the splashing of the water flow, preventing the water flow from passing through the air hole 51 and entering the air pipe c.

[0033] See Figure 5 , Figure 6 , In the third embodiment of the present invention, the drain pipe 1 is provided with a connecting sleeve 7 extending downward and having a diameter smaller th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com