Novel dressing machine

A mineral concentrator, a new type of technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as high production costs, waste of water resources, environmental pollution, etc., and achieve high recovery rate , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

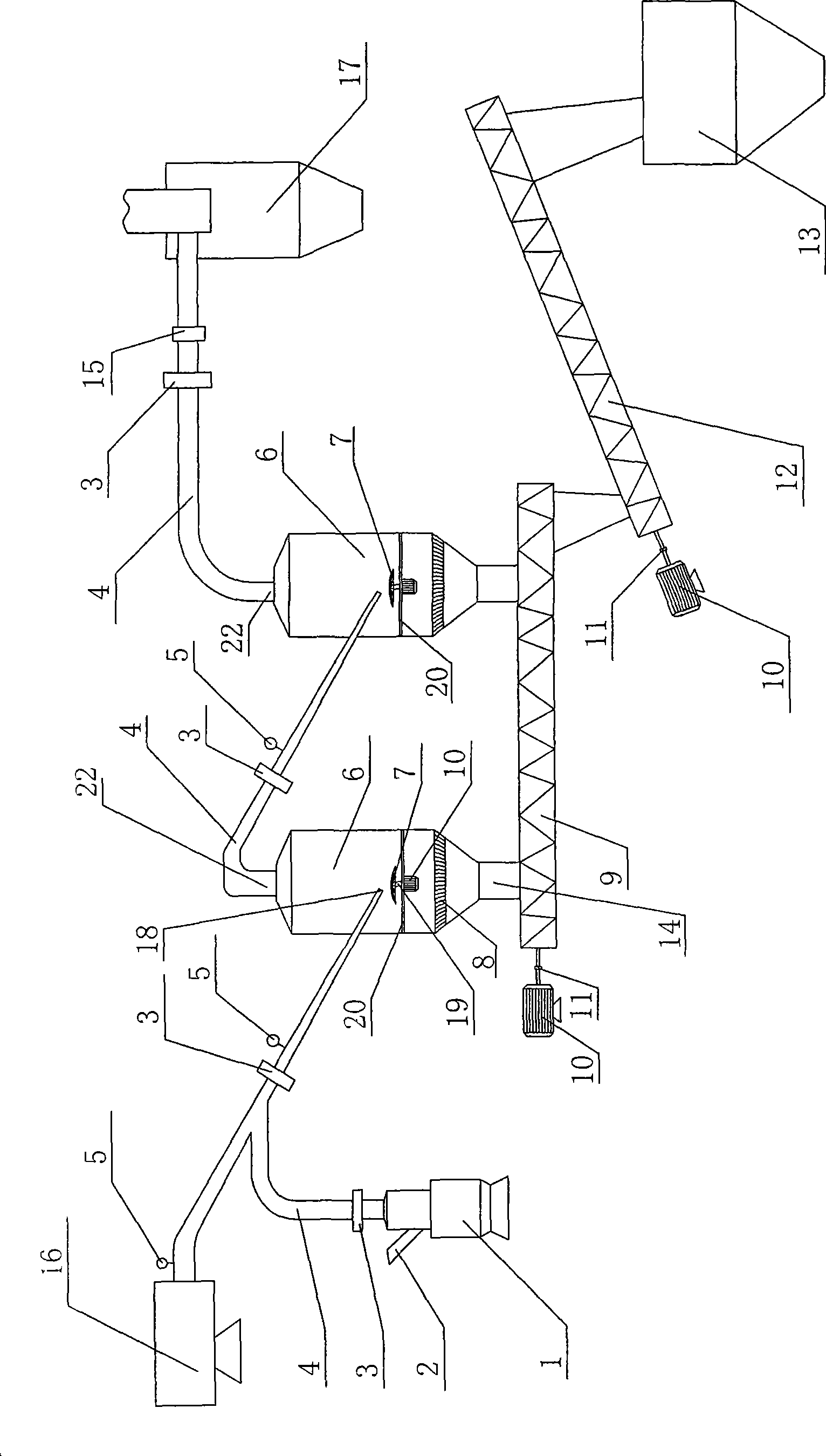

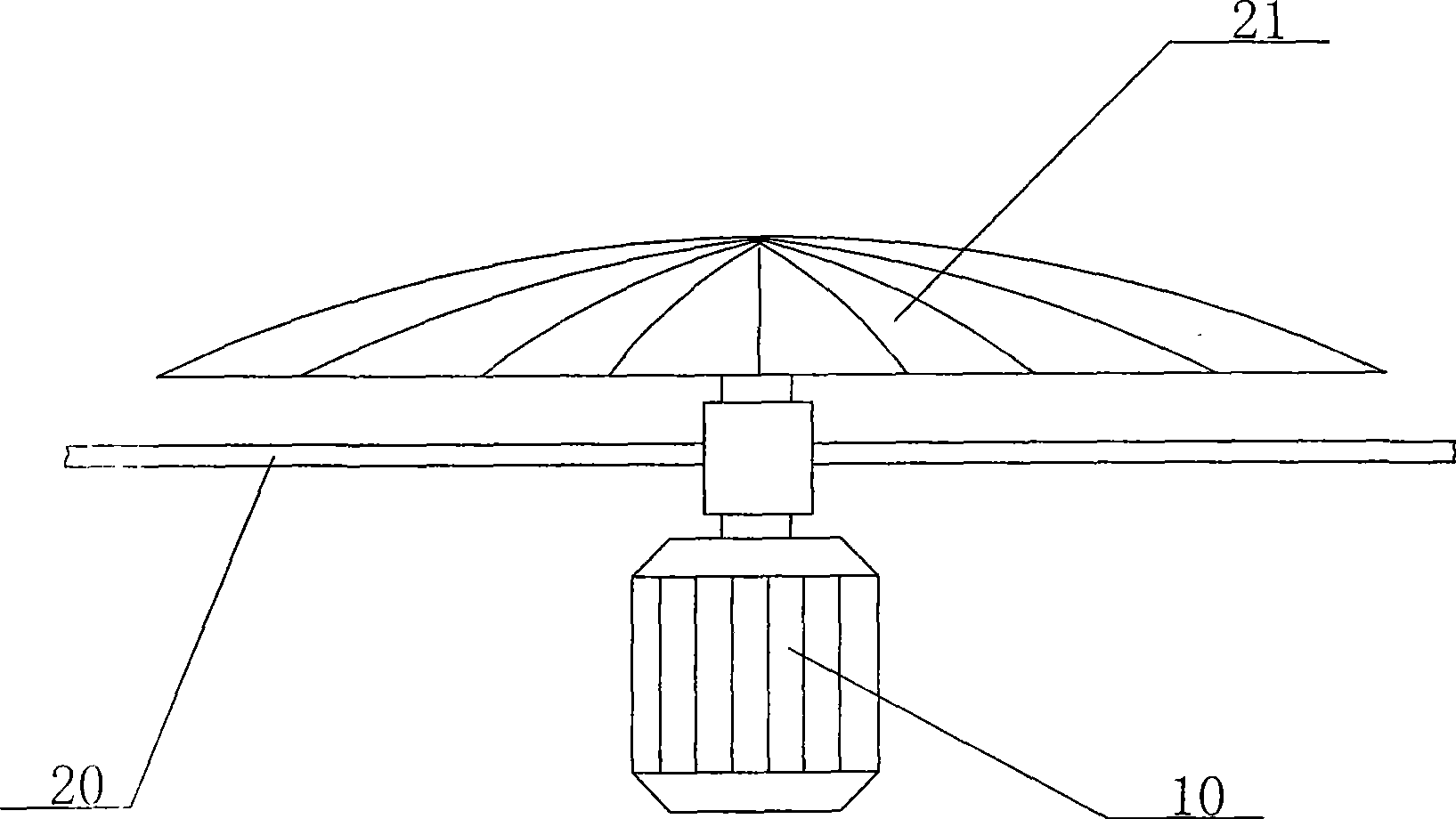

[0015] Such as Figure 1 to Figure 2 As shown, there is a feeding nozzle 2 on the pulverizer 1, and the pulverizer 1 is connected with the first beneficiation bin 6 through a feeding pipe 4, and the feeding pipe 4 is provided with an induced draft fan 3, a blower 16 and a pressure gauge 5; The beneficiation bin 6 is a hollow container with a feeding port 22 and a feeding pipe 4 at the top, and a cone-shaped lower part with a funnel-shaped discharge port 14 and an air inlet 8, and a distributor is arranged above the air inlet 8 , the feeder includes a distribution tray 7, a rotating shaft 19 and a motor 10, the distribution tray 7 is an umbrella or a cone, and its upper surface has a distribution tank 21, the motor 10 is connected to the rotation shaft 19, and the rotation shaft 19 is connected to the material distribution The disc 7 is connected, and the motor 10 drives the distribution disc 7 to rotate. The motor 10 is fixed in the middle of the mineral processing bin 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com