Kitchen waste filtrate treatment equipment and method

A technology for processing equipment and kitchen waste, applied in separation methods, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as lack of good engineering examples, aquatic biological hazards in water areas, and destruction of human water resources. Achieve good removal effect, improve biodegradability, reduce load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

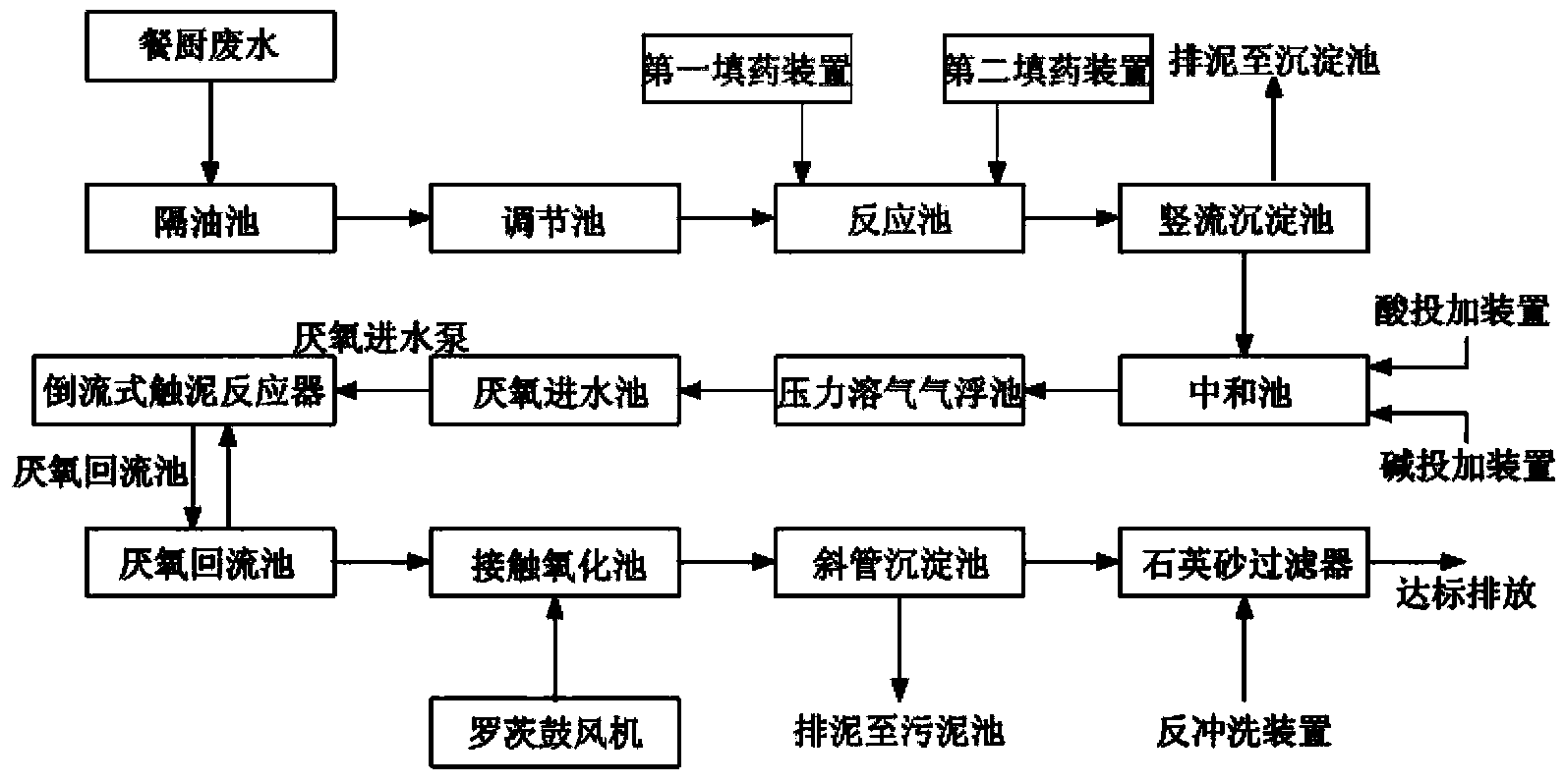

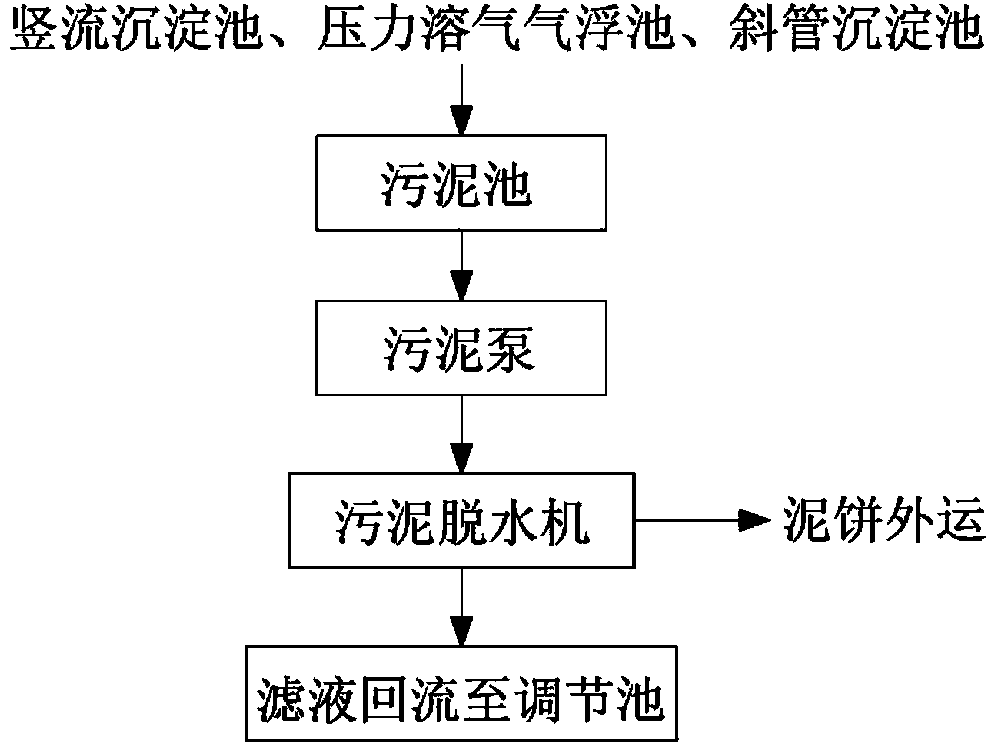

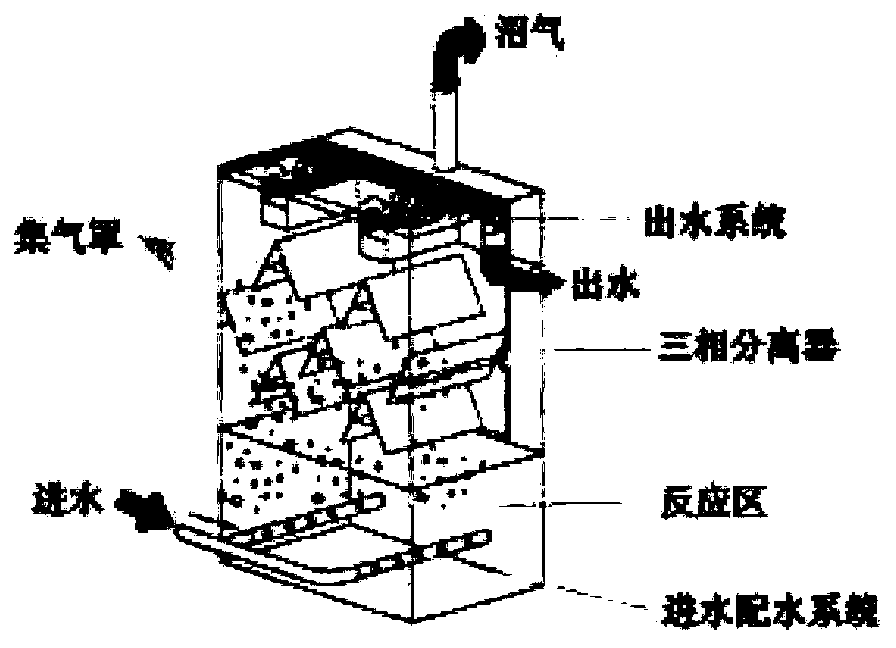

[0051] The invention provides a treatment equipment for kitchen garbage filtrate, which includes a grease trap, a regulating tank, a reaction tank, a vertical flow sedimentation tank, a neutralization tank, a pressure dissolved air flotation tank, an anaerobic water inlet tank, and a backflow type tank connected in sequence. Sludge reactor, anaerobic reflux tank, contact oxidation tank, inclined tube sedimentation tank, quartz sand filter. The reaction tank is connected with the first dosing device and the second dosing device; the neutralization tank is connected with the acid and alkali dosing device; a jet pressurized air dissolving device is installed in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com