Anti-cracking drilling fluid rock debris curing agent and use method thereof

A curing agent and drilling fluid technology, applied in the field of environmental protection engineering materials and cuttings curing agent, can solve the problems of difficult removal of organics and heavy metals, high cost, cuttings curing agent cost, etc. The effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Anti-cracking drilling fluid cuttings curing agent of the present invention

[0032] The cuttings solidifying agent of the invention contains slag powder, desulfurized gypsum, β-type hemihydrate gypsum, fly ash, construction waste powder, potassium salt or ammonium salt and an activator. The slag powder used is the molten slag with calcium aluminosilicate as the main component obtained when the ironworks smelt pig iron in the blast furnace.

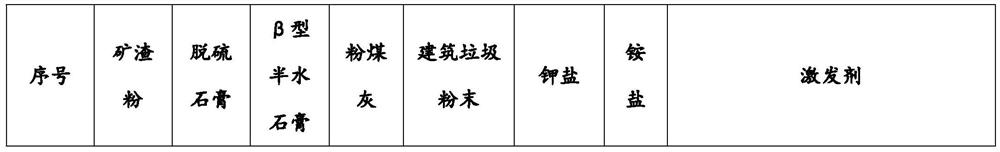

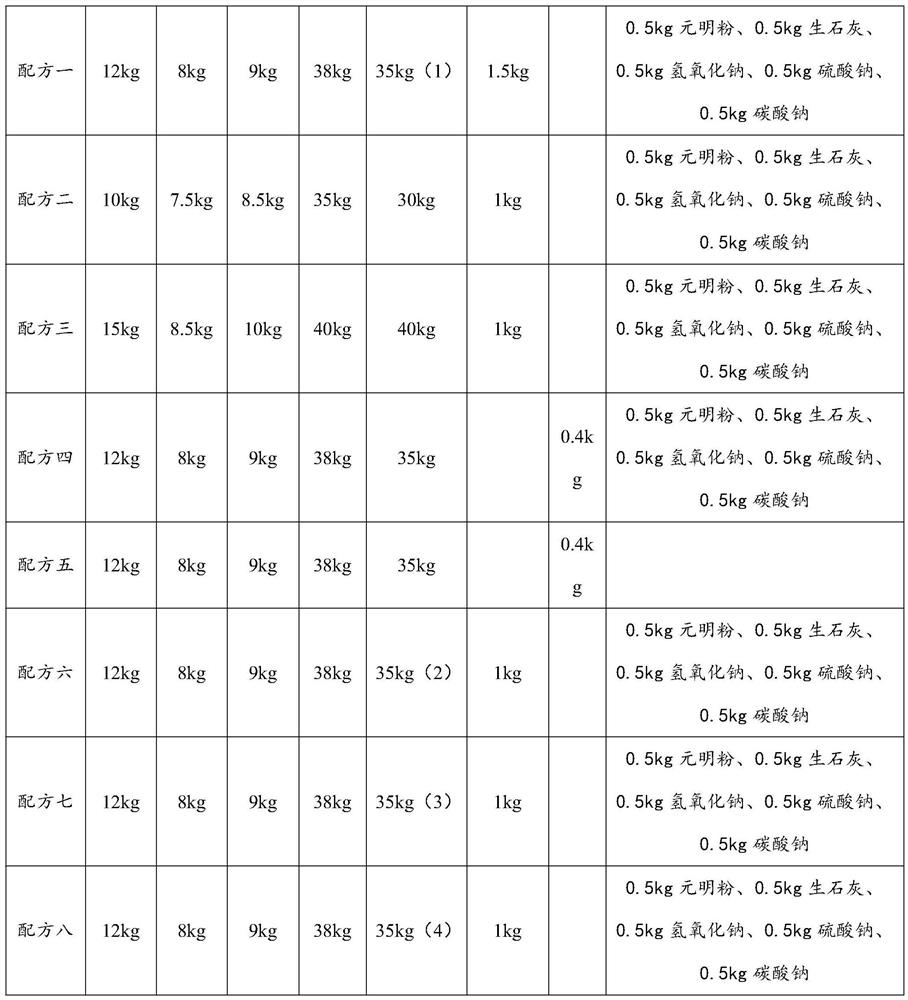

[0033] Specifically, the formula used in this embodiment is as follows:

[0034]

[0035]

[0036]In the above formulations, all formulations also added 2 kg of dithiocarbamate with a concentration of 0.1%. The construction waste powder used is different in formulas 1, 6, 7 and 8. The construction waste powder (1) in formula 1 is 18kg cement fine powder and 17kg red brick fine powder. The construction waste powder (2) in formula six is 15kg cement fine powder and 15kg red brick fine powder. The construction...

Embodiment 2

[0037] Embodiment 2: The use method of the anti-cracking drilling fluid cuttings curing agent of the present invention

[0038] The invention provides a method for using an anti-cracking drilling fluid cuttings curing agent, comprising the following steps:

[0039] (1) Mix the raw materials according to the ratio and grind them thoroughly to form a curing agent product with a fineness of about 300 mesh.

[0040] (2) Measure the water content of the target cuttings to be used, and determine the optimal water addition amount according to the water content of the cuttings, so that the cuttings are easy to mix and not too thin to solidify or too dry to mix evenly.

[0041] (3) Add water to the curing agent product in step (1) and mix it with cuttings, then use an excavator to repeatedly knead the mixture so that the curing agent and cuttings are in full contact.

[0042] In the present invention, in the step (3), 80-100KG curing agent is added per cubic meter and fully stirred. ...

Embodiment 3

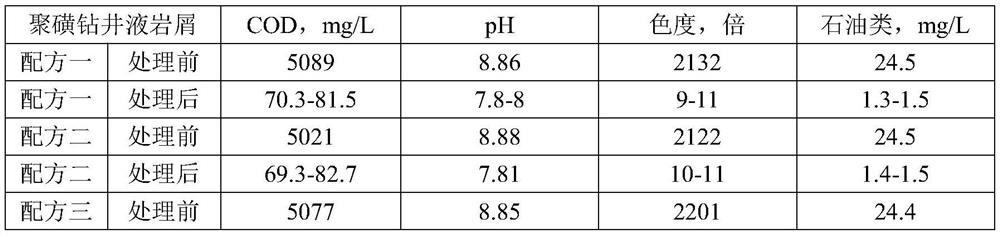

[0043] Example 3: Performance test of anti-cracking drilling fluid cuttings curing agent

[0044] When detecting the anti-cracking drilling fluid cuttings solidifying agent performance of the present invention, adopt following detection method:

[0045] (1) Chemical Oxygen Demand (COD); determined according to GB / T11914 "Determination of Chemical Oxygen Demand by Potassium Dichromate Method".

[0046] (2) pH value; determined according to the national standard GB / T6920 "Glass Electrode Method for Determination of pH Value of Water Quality".

[0047] (3) Chromaticity: Measured according to the national standard GB / T11903 "Determination of Water Quality Chromaticity by Dilution Multiple Method".

[0048] (4) Petroleum: determined according to the national standard GB / T16488 "Determination of Water Quality Petroleum and Animals and Plants by Infrared Photometry".

[0049] (5) Curing strength; refer to the technical index of cement JX-GH.

[0050] The test results are as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com