Vertical magnet separator with rotary magnetic system

A magnetic separator and magnetic system technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of thick material layer, inability to fully disperse, reduce the grade of magnetic materials and the recovery rate of non-magnetic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

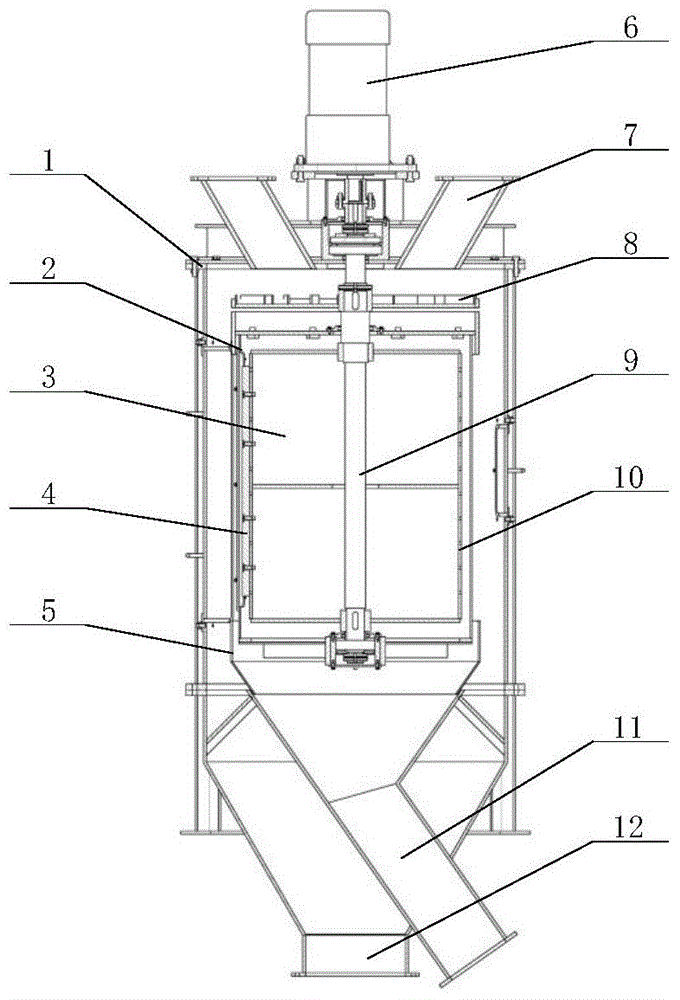

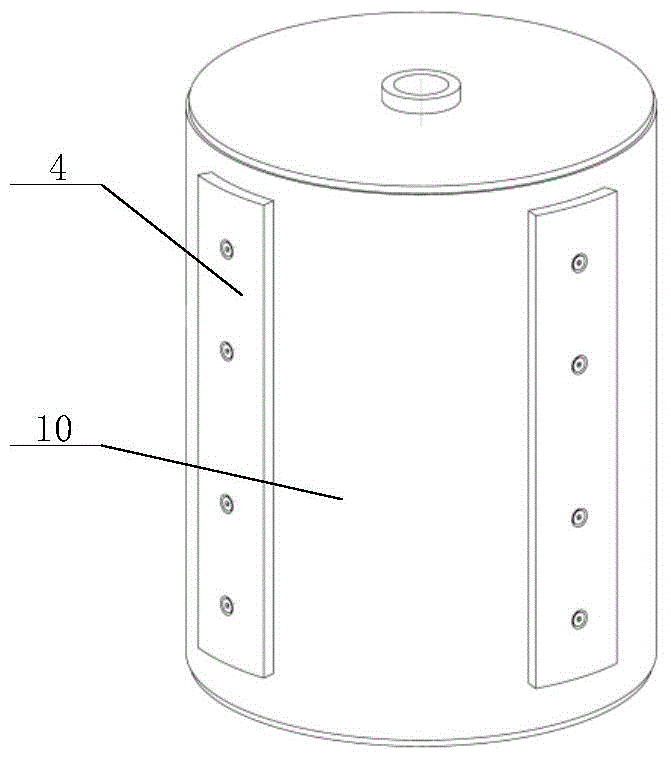

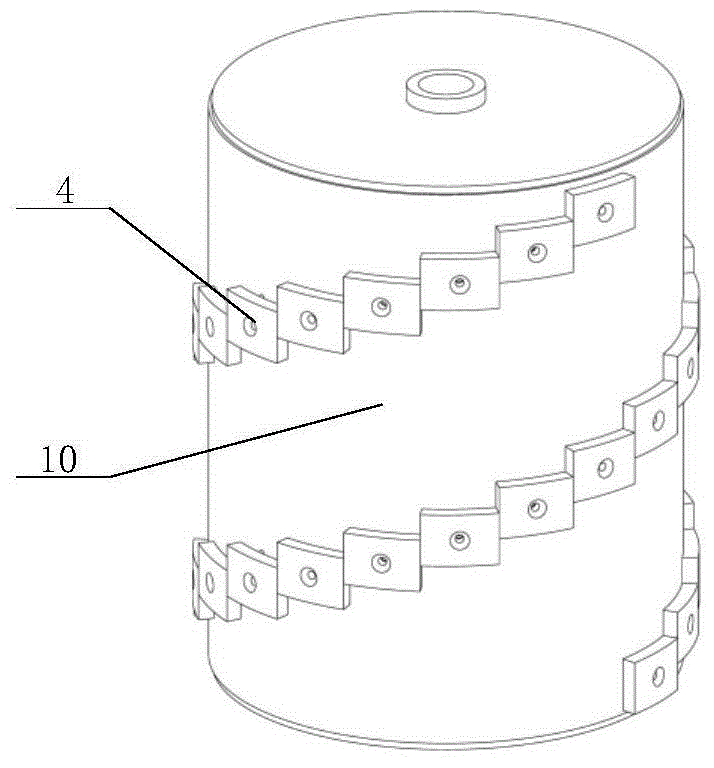

[0019] figure 1 It is a schematic cross-sectional structure diagram of an embodiment of a vertical magnetic separator with a rotating magnetic system in the present invention, including an outer cylinder 1 , an inner cylinder 2 , a magnetic system 3 , a spreading disc 8 , and a separation cylinder 5 . The outer cylinder 1 and the inner cylinder 2 are fixed on the frame, and there is a certain gap between the two cylinders. The upper end cover of the outer cylinder is equipped with a plurality of feeding ports 7 evenly distributed along the circumference and a vertical shaft 9, and the vertical axis passes through the end cover of the outer cylinder, the spreading disc 8, the inner cylinder 2 and the magnetic system cylinder 10 respectively. The upper end of the vertical shaft 9 is equipped with a driving device 6, which is composed of a motor and a reducer, and drives the spreading disc 8 and the magnetic system 3 to rotate through the vertical shaft 9, wherein the speed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com