Contact pipeline well used on inclined ore and construction method of contact pipeline well

A construction method and ore body technology, applied to mining equipment, earthwork drilling, tunnels, etc., can solve problems such as poor safety conditions, endangering the personal safety of operators, and low level of mechanization, so as to reduce construction operation time and simplify construction technology , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

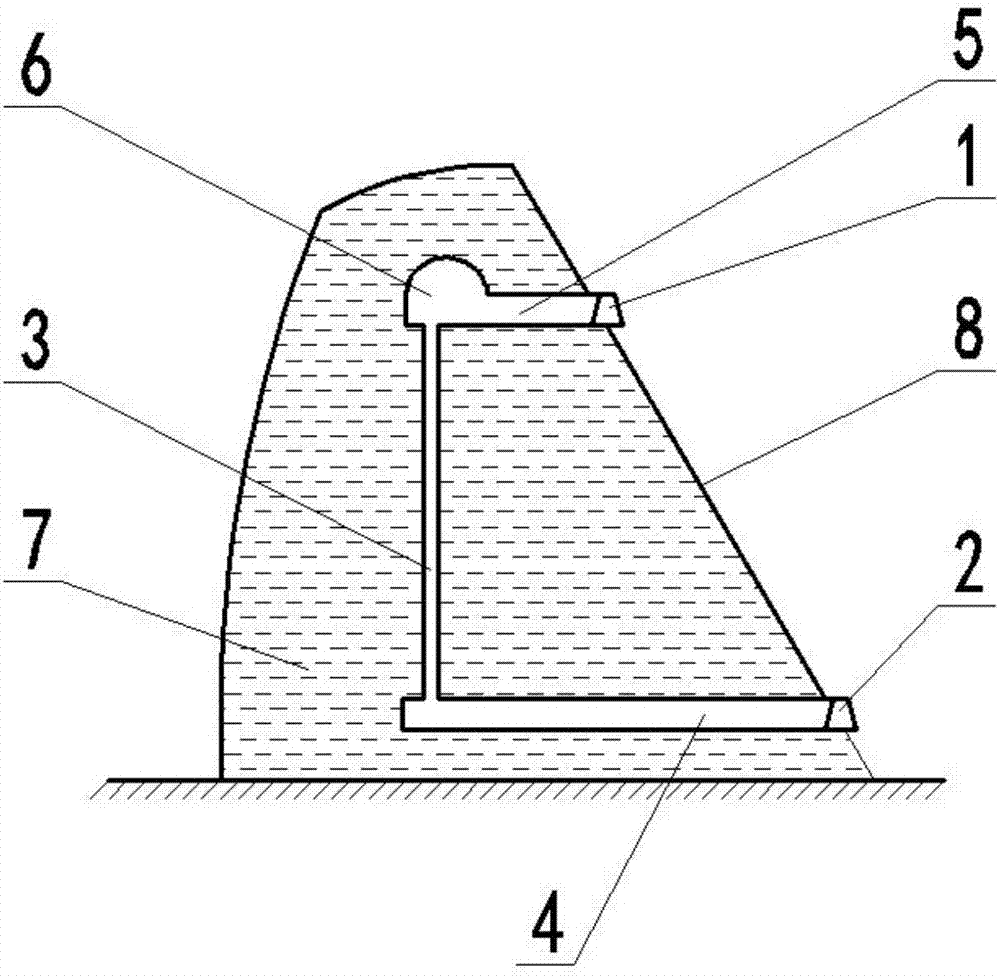

[0026] The invention provides a connecting pipeline shaft and a construction method for inclined ore bodies, such as figure 1 As shown, it includes upper tunnel 1, lower tunnel 2, vertical tunnel 3 and lower tunnel 4, one end of vertical tunnel 3 communicates with upper tunnel 1, and the other end of vertical tunnel 3 communicates with one end of lower tunnel 4 , the other end of the lower tunnel 4 communicates with the lower tunnel 2 . By using the trackless drilling jumbo and the raise drilling rig to excavate the pipeline shaft, the pipeline shaft is no longer parallel to the side of the ore body slope, but consists of vertical channels and several horizontal channels. Drilling and reaming of straight tunnels and other technological operations, while the trackless rock dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com