Magnetic steel replacer

A changer and magnet technology, applied in the direction of laying tracks, roads, tracks, etc., can solve the problems of only replacement, difficult joint management, coordination and coordination, etc., to save material costs, save magnetic materials, and shorten construction. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

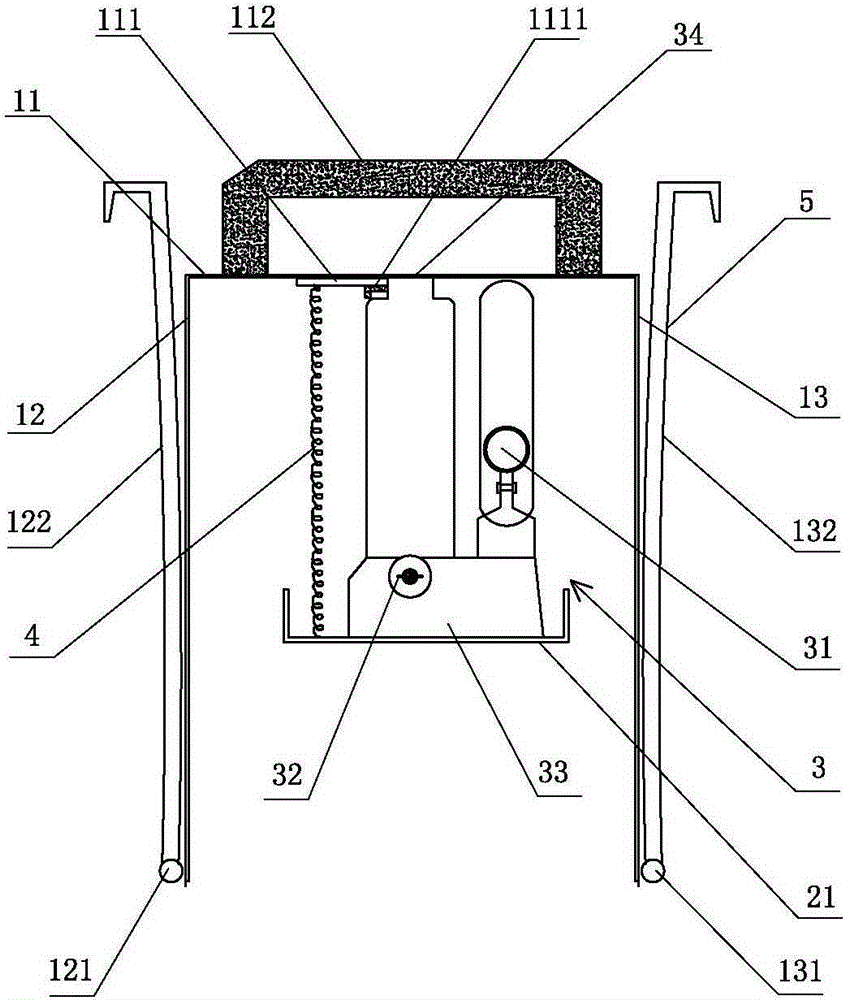

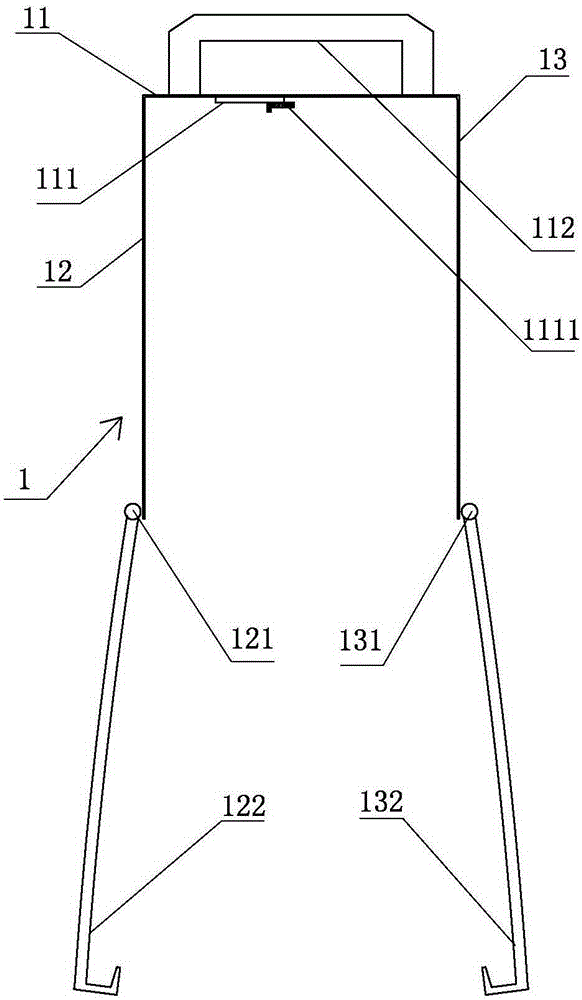

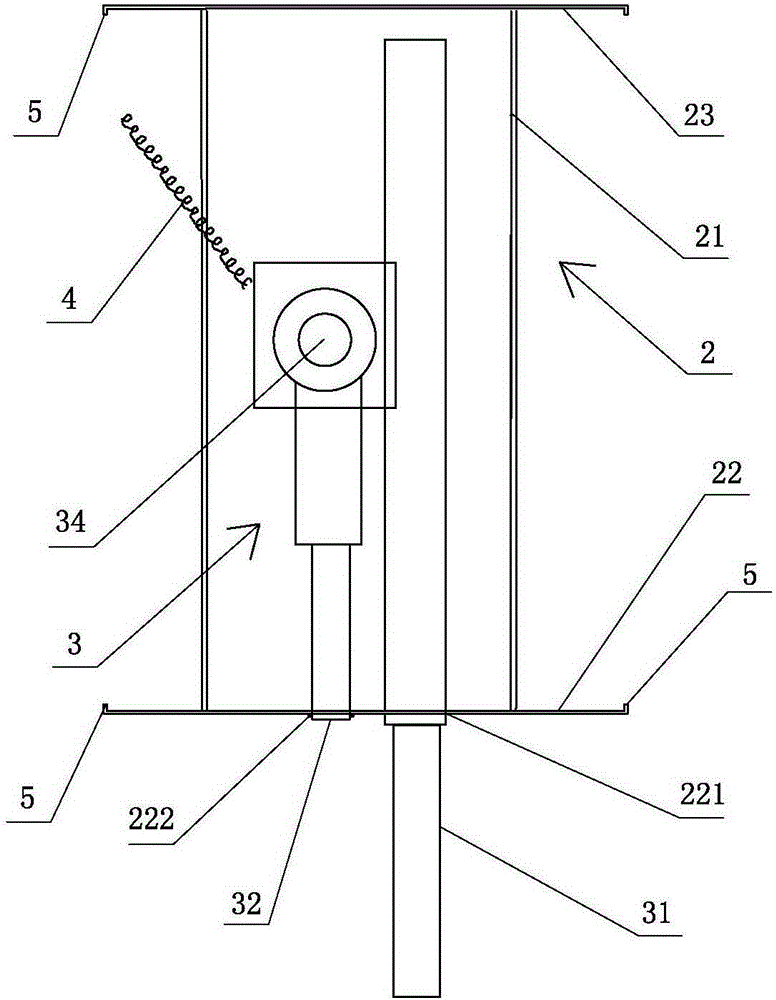

[0027] Such as figure 1 , 2 , 3, a magnetic steel changer, including a "Π"-shaped frame 1 and an "H"-shaped bracket 2 sleeved in it, the "Π"-shaped frame 1 is composed of a top plate 11 and the left and right sides connected to it. Side plate 12, right side plate 13 are made up of, and the outer surface of left side plate 12, right side plate 13 bottoms, respectively horizontally, vertically arrange left rotating shaft 121, right rotating shaft 131, left pull hook is respectively installed on left rotating shaft 121, right rotating shaft 131 122. The right pull hook 132, the left pull hook 122, and the right pull hook 132 can rotate up and down around the left rotating shaft 121 and the right rotating shaft 131;

[0028] The "H"-shaped support 2 is composed of a central horizontal plate 21 and its front and rear side plates 22 and rear side plates 23; Movement; the jack 3 includes an operating handle 31, an oil return valve knob 32, a base 33, and a top cover 34, and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com