Super-deep well wireless transmission well testing system

A wireless transmission, ultra-deep well technology, applied in the direction of wellbore/well components, measurement, earthwork drilling and production, etc., can solve the problems of easy waste of time, long recovery time, long pressure recovery time, etc., to achieve simple operation and maintenance, The effect of improving accuracy and completeness and shortening construction work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

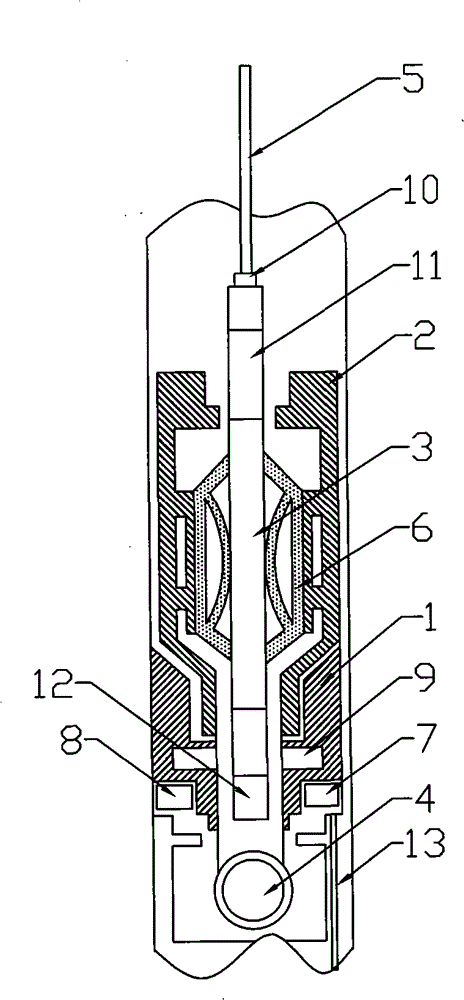

[0026] Such as figure 1 As shown, the test system of this scheme is composed of three parts: downhole equipment, cable 5 and ground equipment. Analyze various data to draw conclusions about the underground situation.

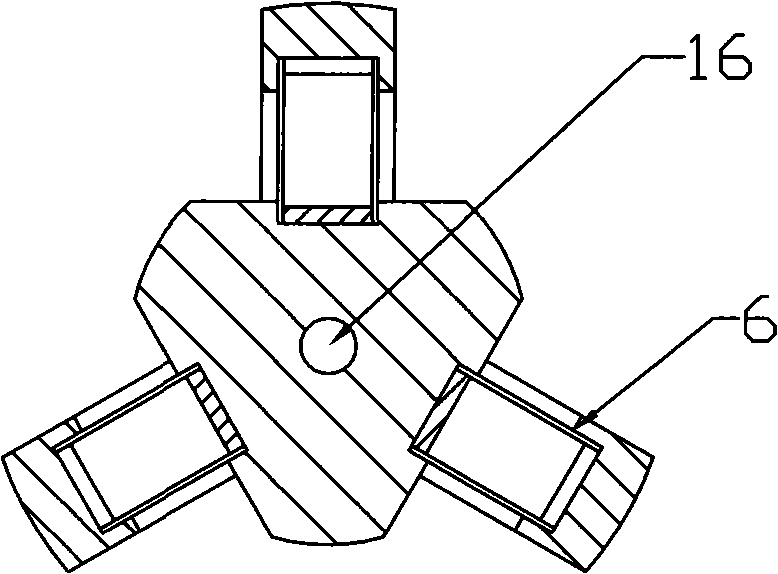

[0027] The downhole equipment includes: support tube 1, positioning joint 2, direct reading pressure gauge 7, receiver 12, battery 6, storage electronic pressure gauge 9, etc. Multiple grooves 15 are opened on the outer wall of the support tube depending on the situation. There are four grooves 15 on the outer wall of the cylinder 1, in which the direct-reading pressure gauge 7, the battery 8, and optionally one or two storage pressure gauges 9 are installed, and a pressure transmission channel is opened in the tube wall of the cylinder 1 13 Transmit the pressure under the test valve test valve 4 to the direct-reading pressure gauge 7 or / and storage pressure gauge 9, inside the direct-reading pressure gauge 7 are installed sensors, A / D modules, microcontrollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com