Construction method for preventing erection of crossing frame by using overhead ground wire to perform pulley block hanging operation

A technology of overhead ground wire and construction method, which is applied in the direction of overhead line/cable equipment, etc., to achieve the effect of saving manpower and material resources, simple operation, and saving construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The steps of the present invention are as follows:

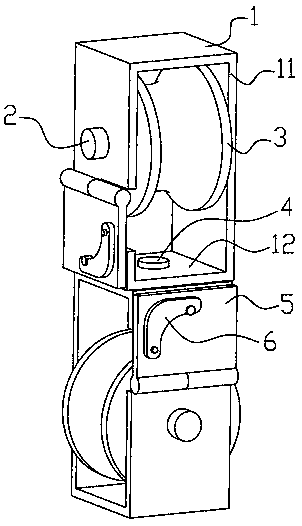

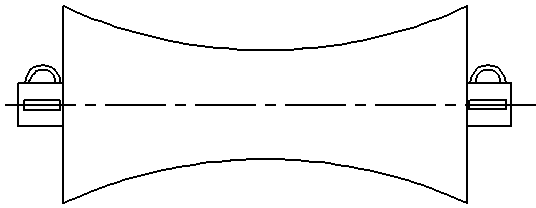

[0020] 1. First arrange the workers to cross the nearby pole tower, and hang the three-axis pulley block on the overhead ground on the pole tower. The three-axis pulley block consists of an upper pulley frame, an upper pulley set on the upper pulley frame, and a lower pulley frame. It is composed of two lower pulleys arranged side by side on the lower pulley frame, and the upper and lower pulley frames can rotate mutually, such as figure 1 with figure 2 As shown, the three-axis pulley block includes a rectangular ring-shaped bracket 1, a rotating shaft 2, a pulley 3, a pin shaft 4, a baffle plate 5, and a lock block 6. The ring-shaped bracket 1 has a side plate 11 and a bottom plate 12. The specific structure and patent number It is the same as "a three-axis pulley block" of "ZL201320399382.0"; the overhead ground wire is passed through the upper pulley of the three-axis pulley block; the two lower pulleys parallele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com