Construction method for pile-anchor press-in caisson sinking

A construction method and press-in technology, which is applied to caissons, sheet pile walls, foundation structure engineering, etc., can solve problems that are difficult to apply to large-scale caissons for rapid and stable construction, frequent changes in caisson construction methods, and adverse effects of surrounding environmental buildings and other problems, to achieve the effect of simple and continuous construction process, small adverse effects, and small construction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

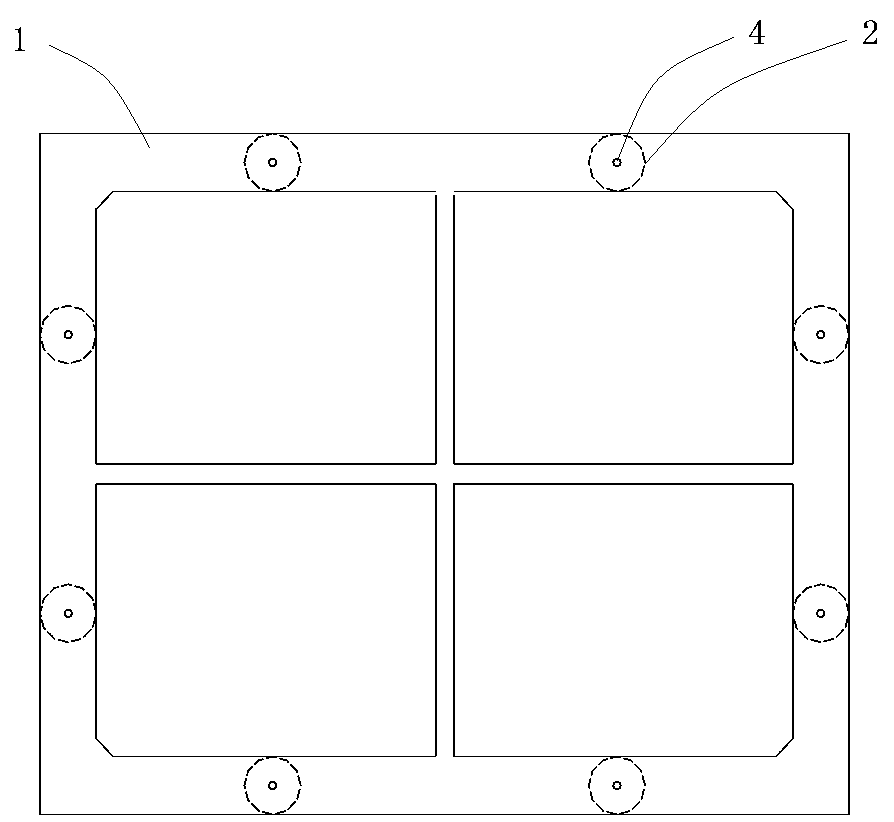

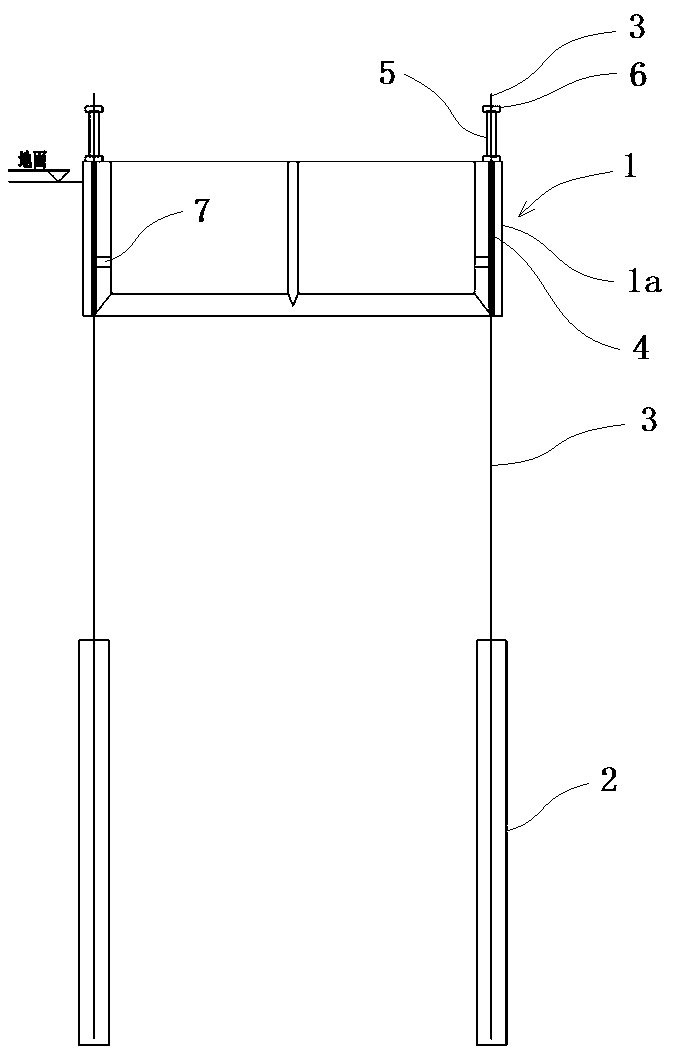

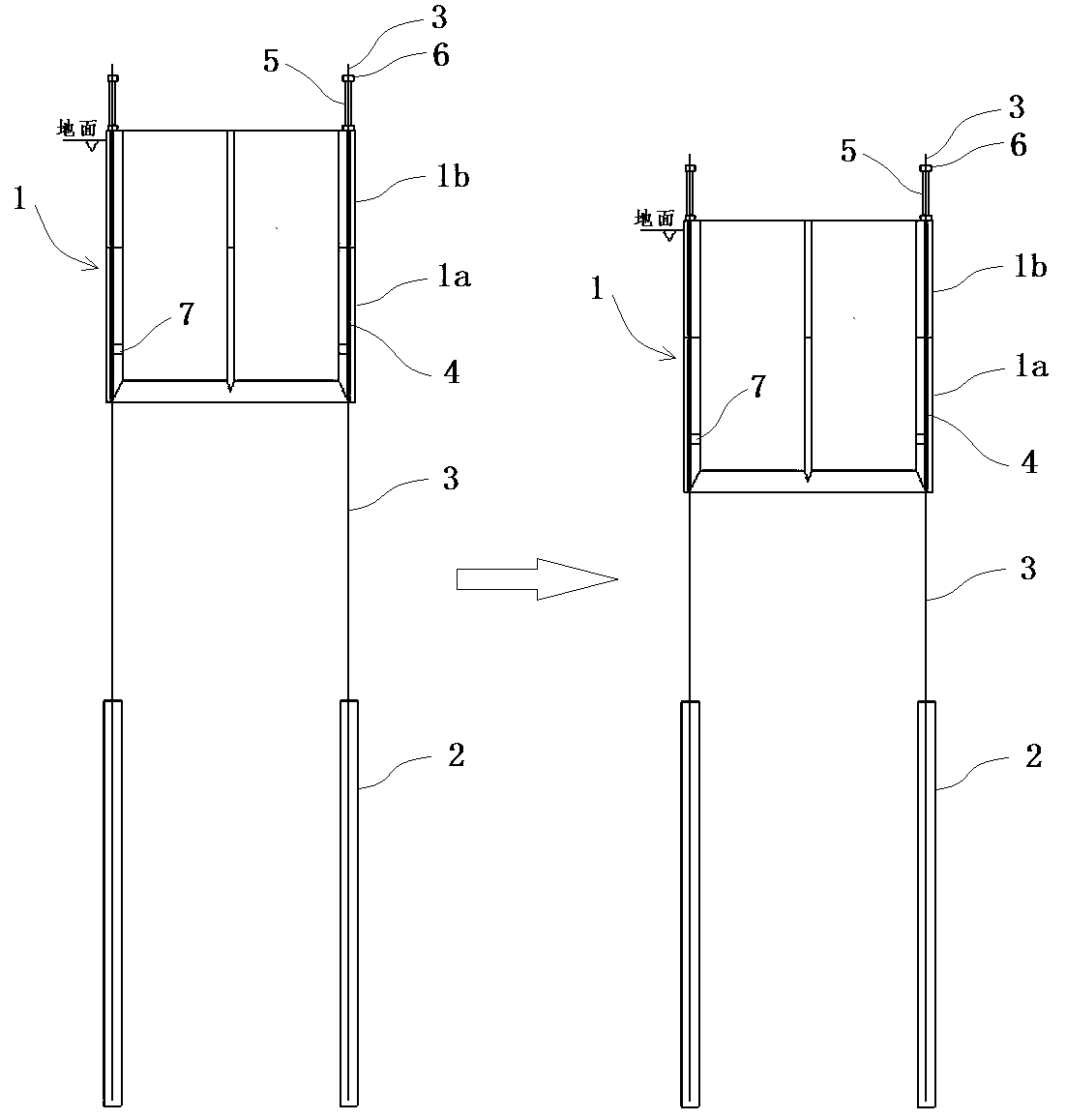

[0025] Example: such as Figure 1-8 As shown, this embodiment specifically relates to a pile-anchor press-in caisson sinking construction method. The caisson sinking construction method pre-embeds anchor piles 2 in the soil, and sets up a vertical through-hole on the well wall of the caisson 1. The through hole 4 of the wall is used to fix one end of the anchor cable 3 to the anchor pile 2, and the other end passes through the through hole 4 and passes through the through-hole jack 5 and is fixed on the upper end of the through-hole jack 5 with the anchor nut 6, and the through-hole jack 5 connects the oil cylinder The pressure generated by the upward ejection acts on the well wall of the caisson 1 to make it sink, so that the sinking process of the caisson is stable, controllable and repeatable, and the impact on the buildings around the construction site is reduced.

[0026] like Figure 1-5 As shown, the caisson 1 in this embodiment is a caisson with multiple rows of holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com