Patents

Literature

71results about How to "Guaranteed construction speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

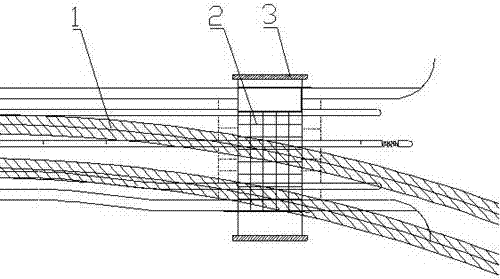

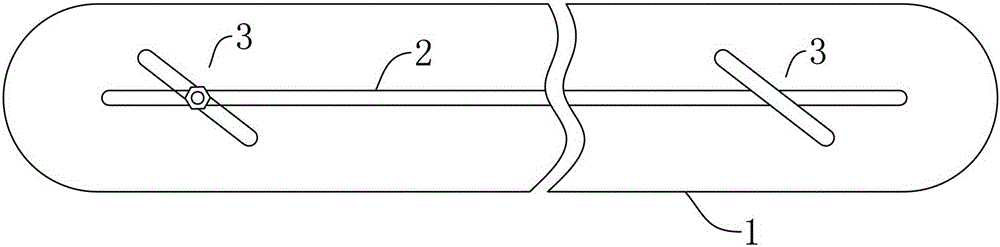

Concrete pavement casting vibration device and construction method thereof

InactiveCN104911980AGuaranteed construction speedAccurate speedRoads maintainenceArchitectural engineeringRoad surface

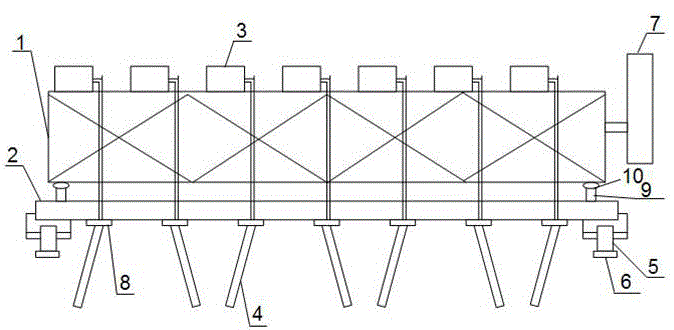

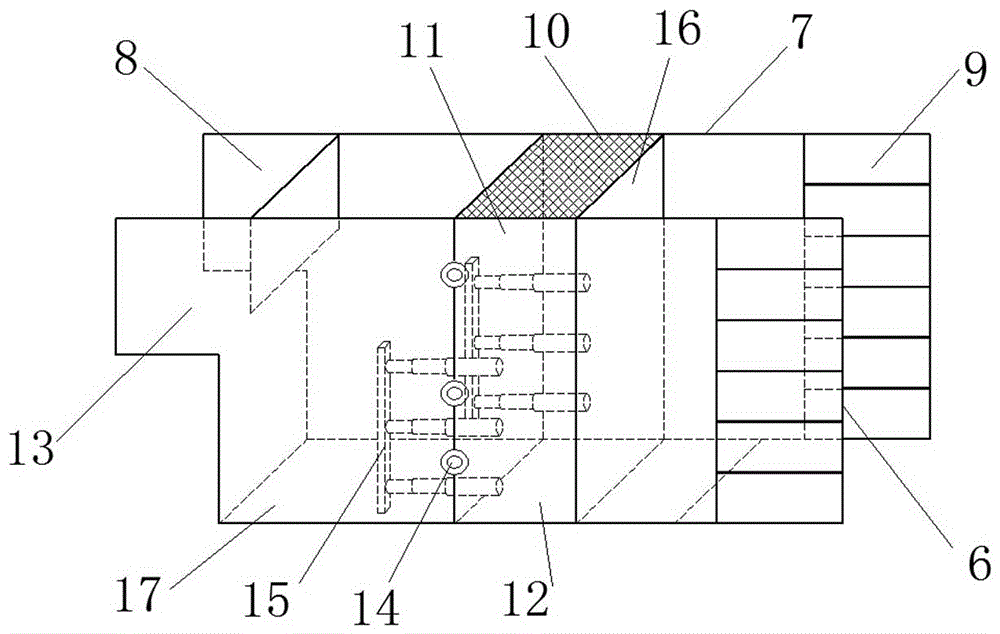

The invention discloses a concrete pavement casting vibration device and a construction method thereof. The vibration device comprises a truss, vibration rods and a control box, wherein shafts are respectively mounted at the two sides of the truss; a cross bar is movably hinged to the shafts on the truss through two connecting rods; 5-10 vibration rods are provided, and are uniformly distributed on the cross bar; each vibration rod is controlled by a motor to vibrate; the motors are connected and controlled through the control box; the tail ends of the vibration rods are connected with the cross bar through fixing devices distributed on one horizontal line; the front ends of adjacent two vibration rods are staggered at the two sides of the truss in tandem, and are provided with walking flattening rollers having chain wheels; and rails are paved below the walking flattening rollers. As the vibration rods are staggered, concrete in each place is vibrated; and the walking speed and the vibration time are accurately controlled, so that the sufficient vibration is realized, and the construction progress can be guaranteed.

Owner:JINAN URBAN CONSTR GRP

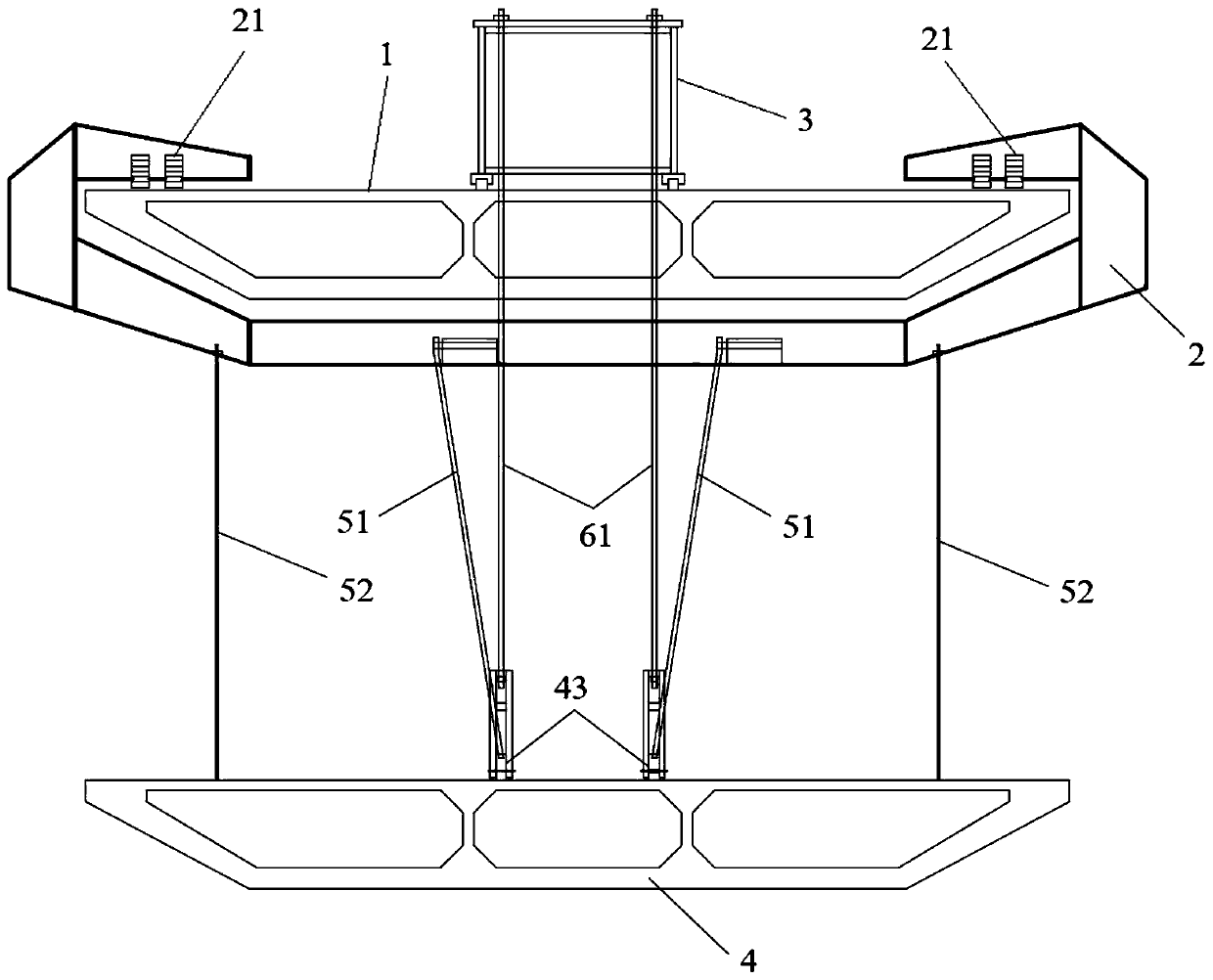

Supporting and retaining device for open excavation construction of comprehensive pipe gallery and construction method thereof

ActiveCN106049532AReduce usageHigh degree of mechanizationArtificial islandsUnderwater structuresEngineeringSheet pile

The invention belongs to the technical field of underground project construction, particularly relates to a supporting and retaining device for open excavation construction of a comprehensive pipe gallery and a construction method thereof, and discloses the movable supporting and retaining device for open excavation construction of the comprehensive pipe gallery and the construction method thereof. The supporting and retaining device for open excavation construction of the comprehensive pipe gallery has the advantages of economization and high efficiency of the open excavation method and does not have to utilize building envelopes such as pile rows and steel sheet piles. The movable supporting and retaining device for construction mainly comprises a front supporting and retaining part, a middle supporting and retaining part and a tail supporting and retaining part, the front supporting and retaining part is composed of expansion blocks on the two sides of the front supporting and retaining part, the middle supporting and retaining part mainly comprises a top plate, side plates and a bottom plate and is connected to the tail supporting and retaining part through hinging oil cylinders, and propelling devices are arranged between the tail supporting and retaining part and the middle supporting and retaining part. According to the supporting and retaining device, the main problems that the construction occupation range is wide and the environmental influence is serious in the construction process of the underground comprehensive pipe gallery and pipelines through the open excavation method are effectively solved. The construction method has the advantages that the mechanization degree is high and the construction speed is high.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

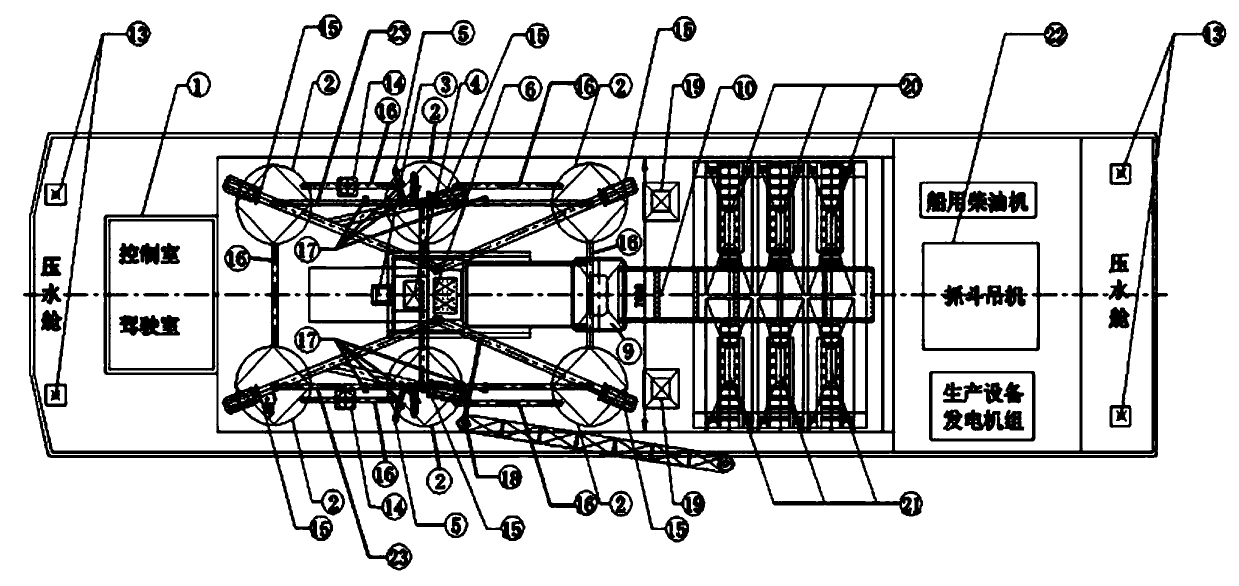

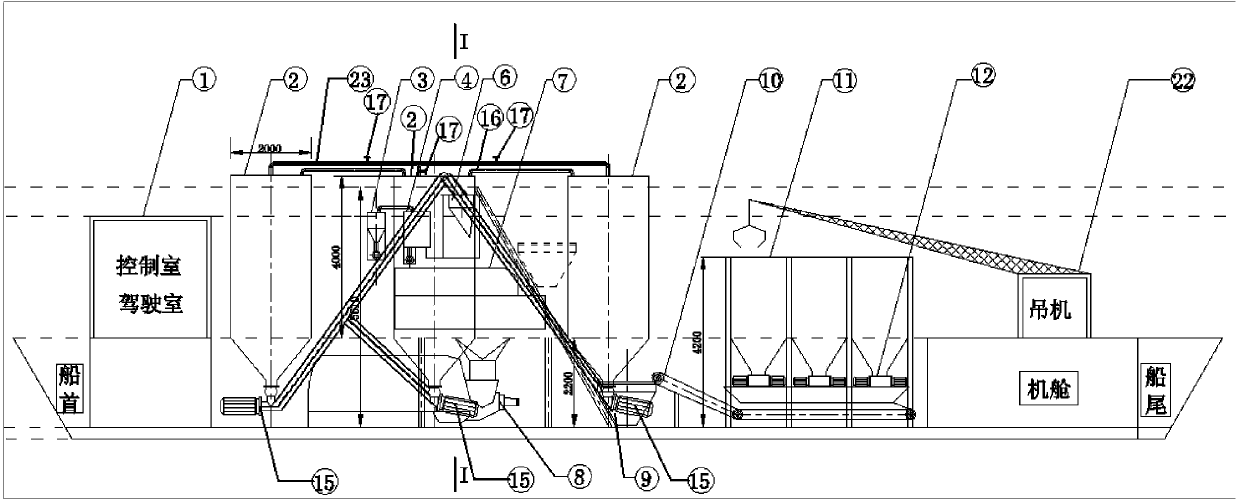

Waterborne mobile concrete stirring boat in inland waterway

ActiveCN104260209AEconomic savingsCompact structureWaterborne vesselsSpecial purpose vesselsControl roomEngineering

The invention discloses a waterborne mobile concrete stirring boat in an inland waterway. The waterborne mobile concrete stirring boat comprises a cab and control room, wherein four pressurized water warehouses are symmetrically arranged at the front end of a stem and the tail end of a stern; a grab bucket crane is arranged on a deck of the stern; boat positioning piles are symmetrically arranged at the middle part of a boat body; sand aggregate storehouses and stone aggregate storehouses are positioned on two sides of a cabin behind the boat positioning piles; a material mixing machine and weighing belt machines are arranged at the bottom of the cabin; an aggregate conveying machine is arranged under the weighing belt machines; a lifting hopper is arranged at the other end of the aggregate conveying machine; a stirring host machine is arranged below the top of a rail of the lifting hopper; cement bins are arranged at the front parts of the boat positioning piles; a helical conveying machine is correspondingly arranged at the bottom of each cement bin; a powder weighing device is positioned over the stirring host machine; the stirring host machine is also provided with a water weighing device and an additive mixing adjustment device; a concrete discharging hopper is arranged under the stirring host machine, and the lower part of the concrete discharging hopper is connected with a concrete pump; the concrete pump pumps concrete to a material distribution rod at the upper edge of the deck for concrete pouring construction.

Owner:江苏路航建设工程有限公司

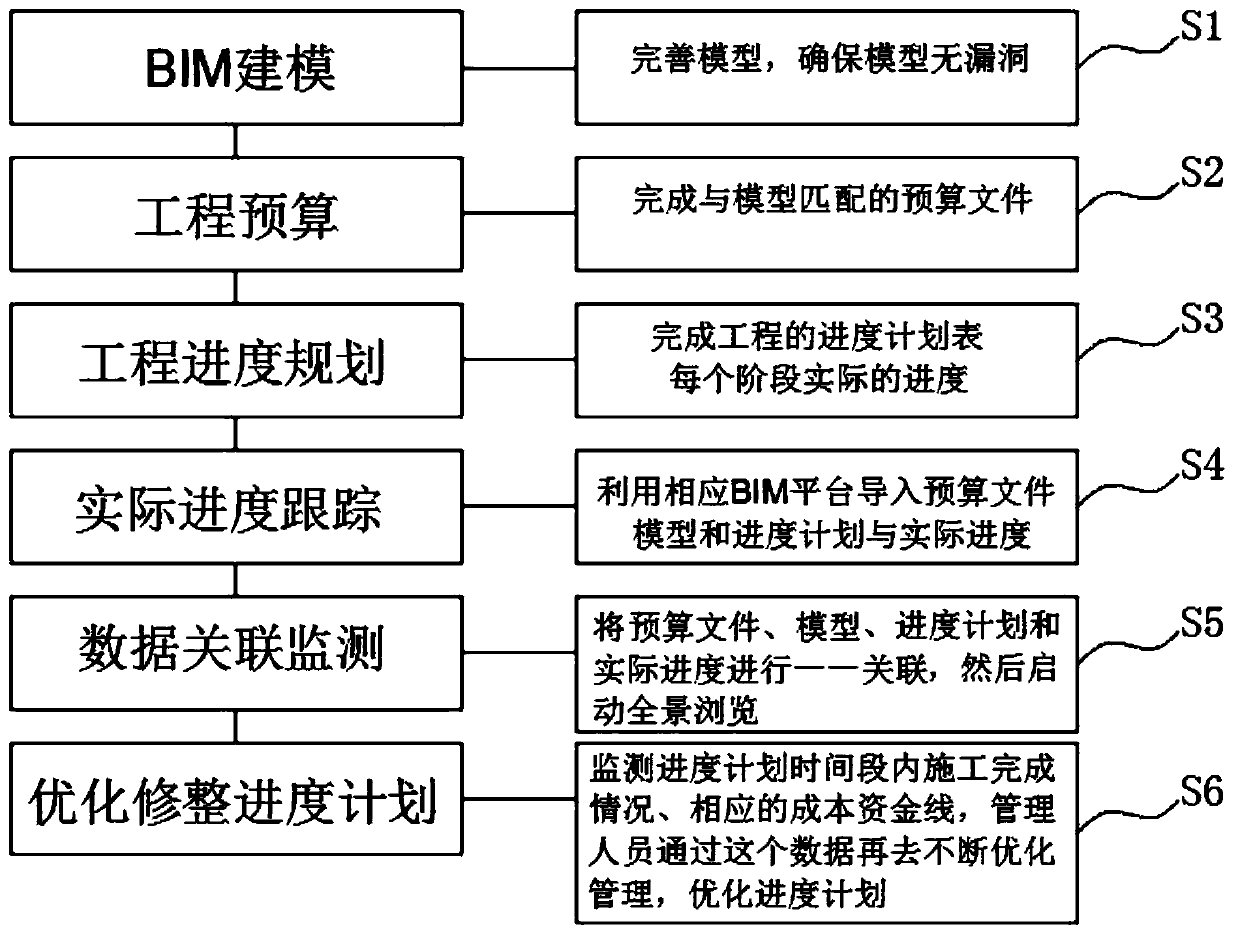

Investment cost control method based on BIM

PendingCN110599072ASchedule syncImprove the ability of cost analysisFinanceResourcesProcess dynamicsCost analysis

The invention discloses an investment cost control method based on BIM, and particularly relates to the technical field of investment control, which comprises BIM modeling, engineering budget, engineering progress planning, actual progress tracking, data association monitoring and finishing progress plan optimization. According to the invention, the budget, the progress and the model are associated, so that cost personnel and project management personnel can carry out dynamic management; the cost control of the whole project process is mastered; an advanced and visual cost management mode is provided; distinguished from conventional management modes, the budget and the progress plan are associated; performing whole process dynamic management, the cost and progress and model connection, long-term planning and short-term regulation and control phase structure can be visually seen at the same time, so that the actual progress and the worksheet arrangement progress are basically synchronous, it is guaranteed that construction can be completed in expectation, the material price level and the fluctuation amplitude of the material price level are considered, the cost control capacity of the design stage is improved, and the engineering cost analysis capacity is improved.

Owner:贵州百胜数源工程技术管理有限公司

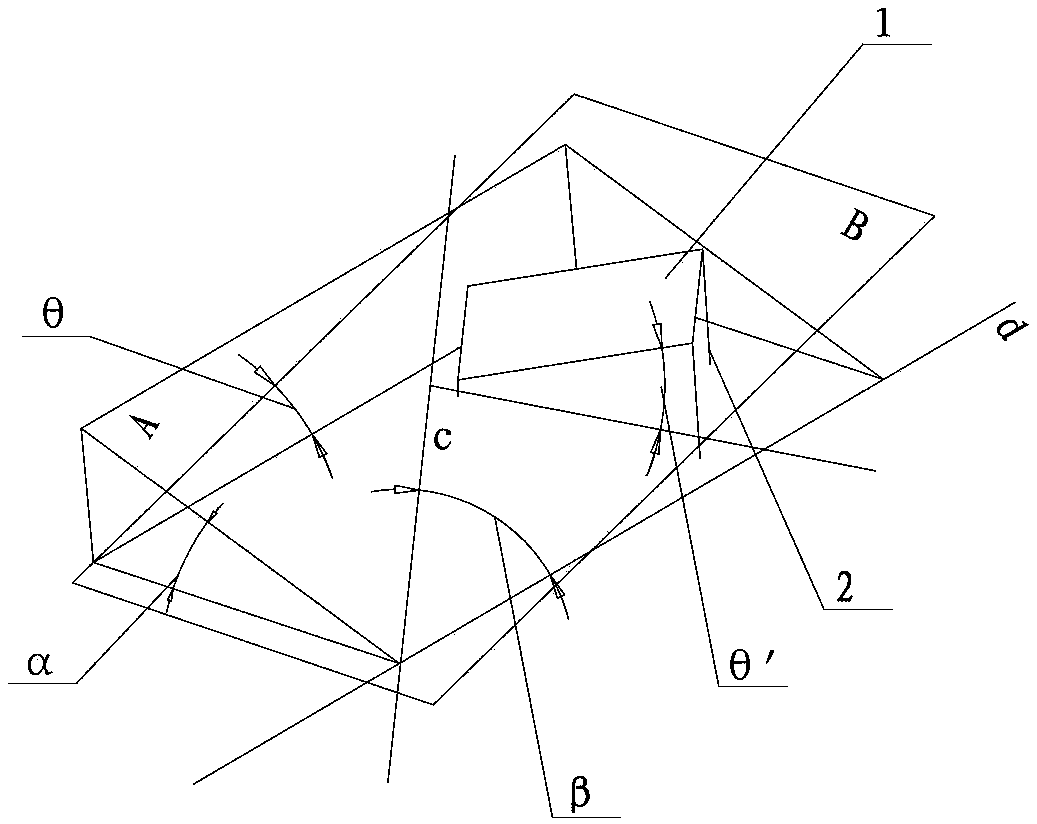

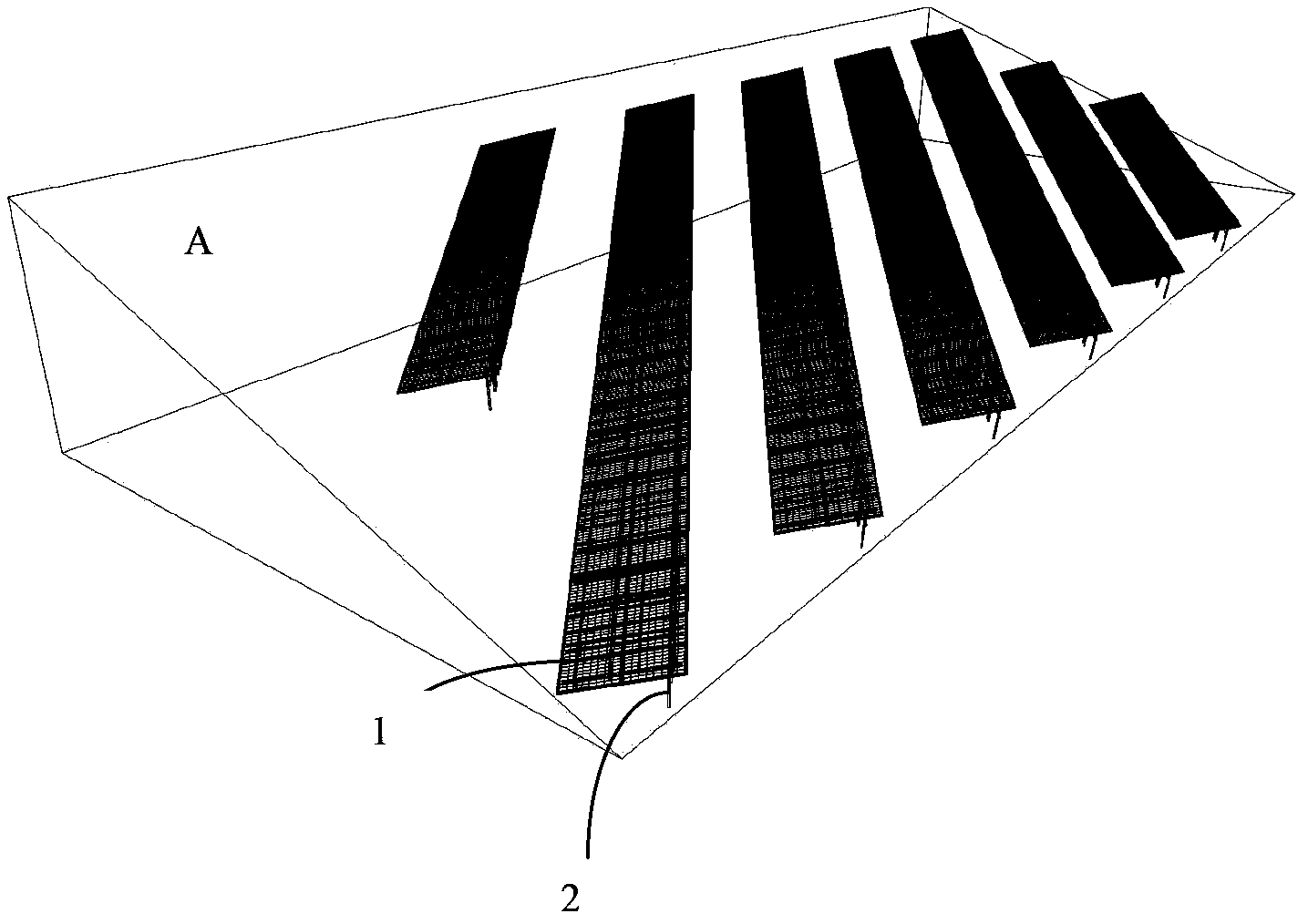

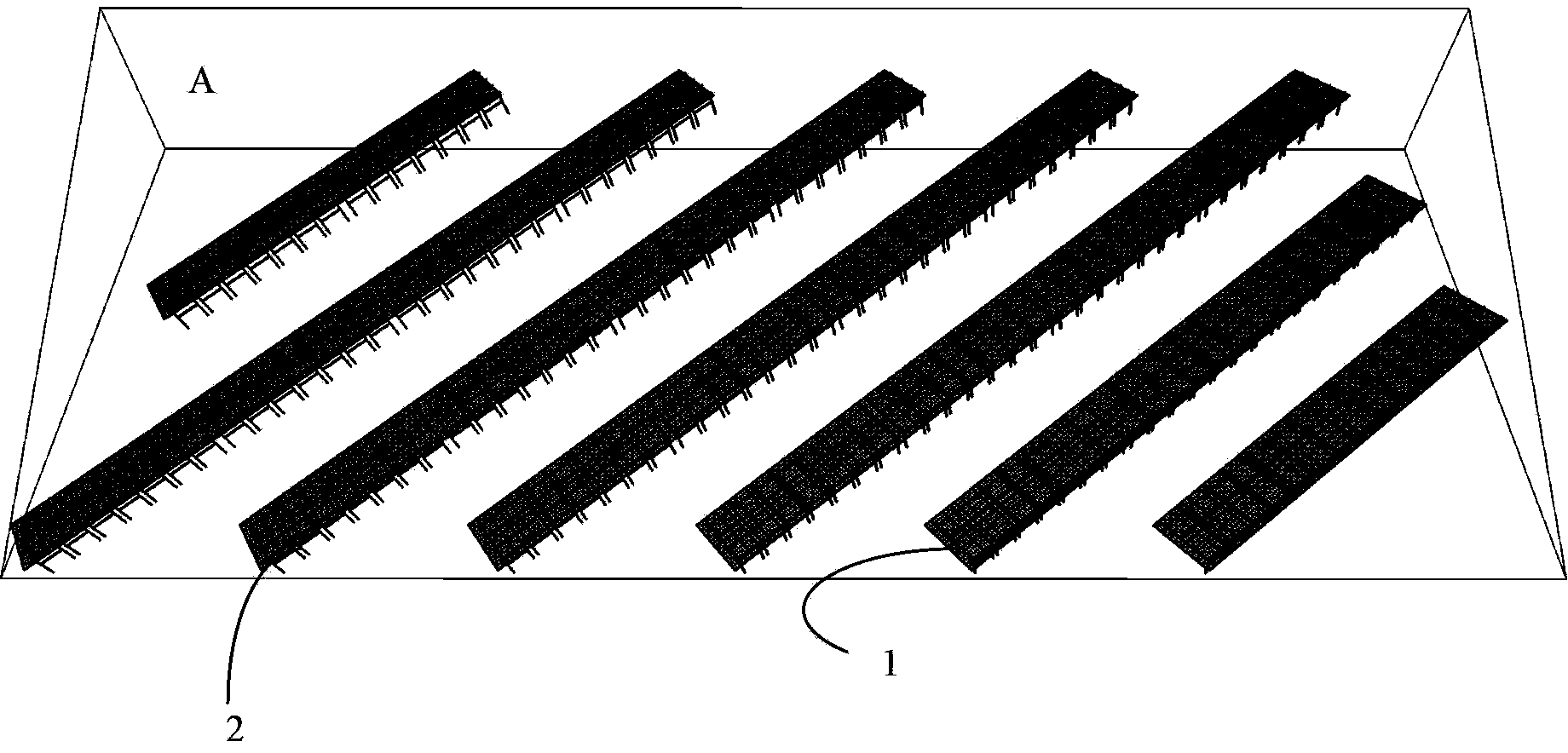

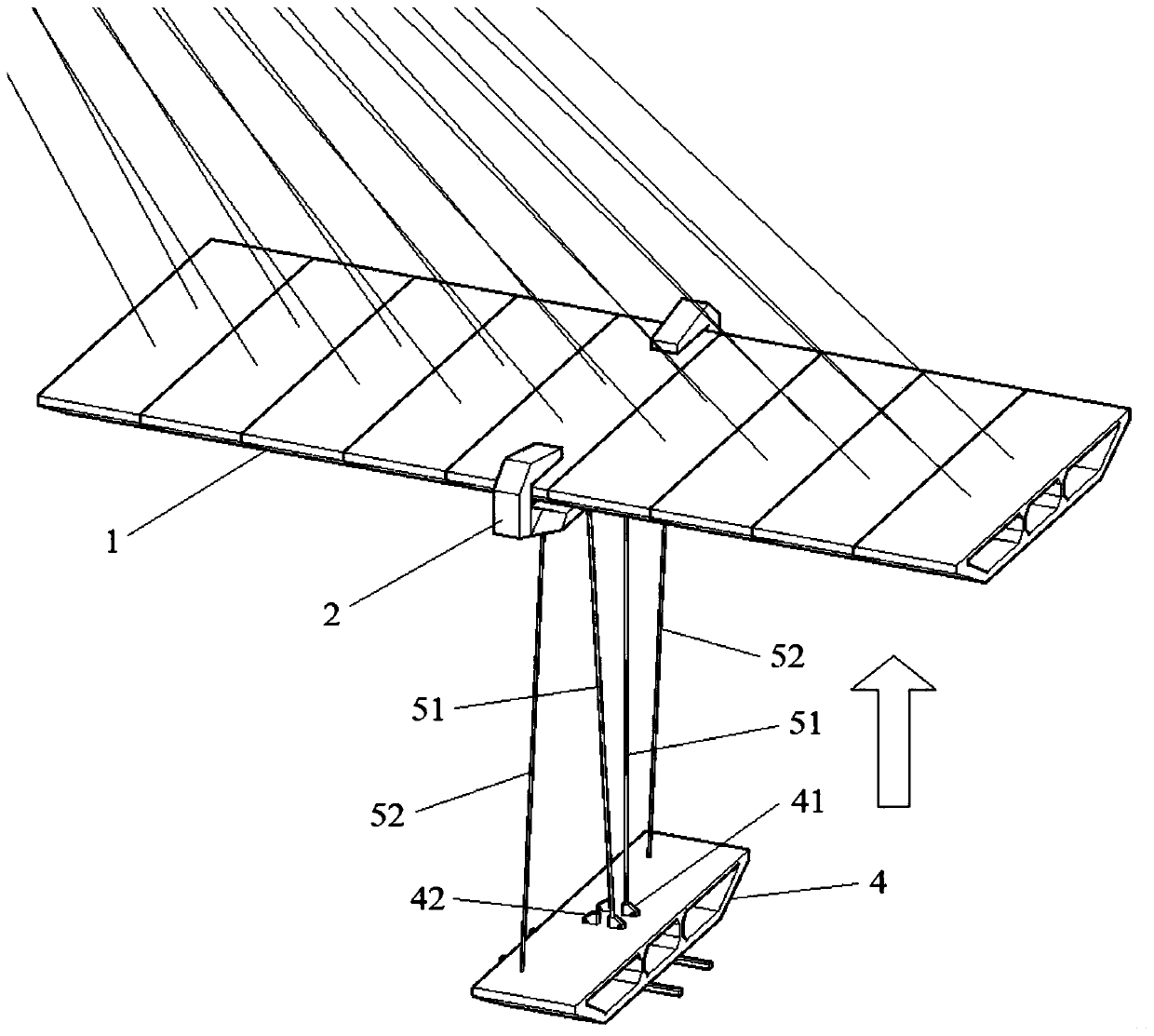

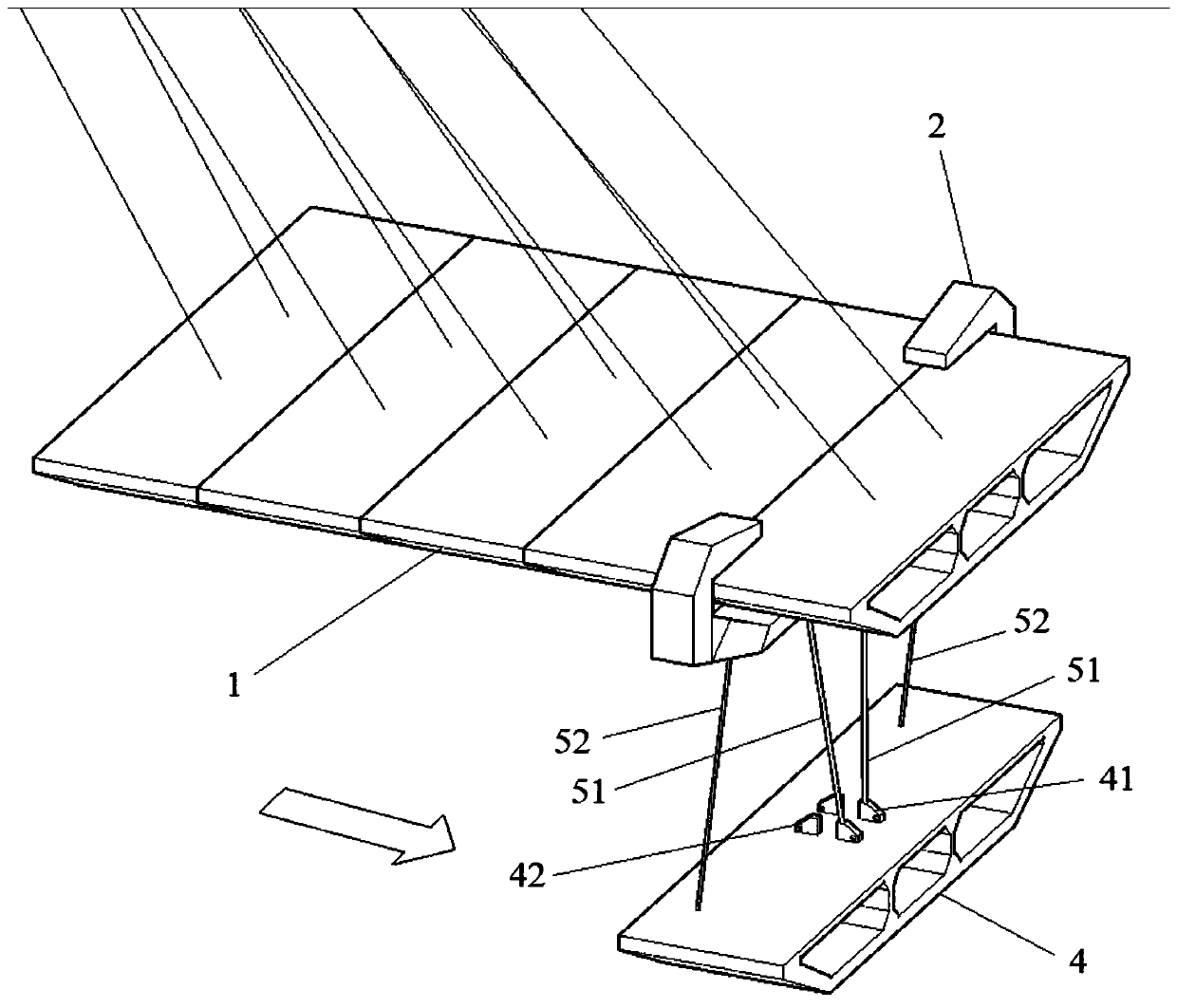

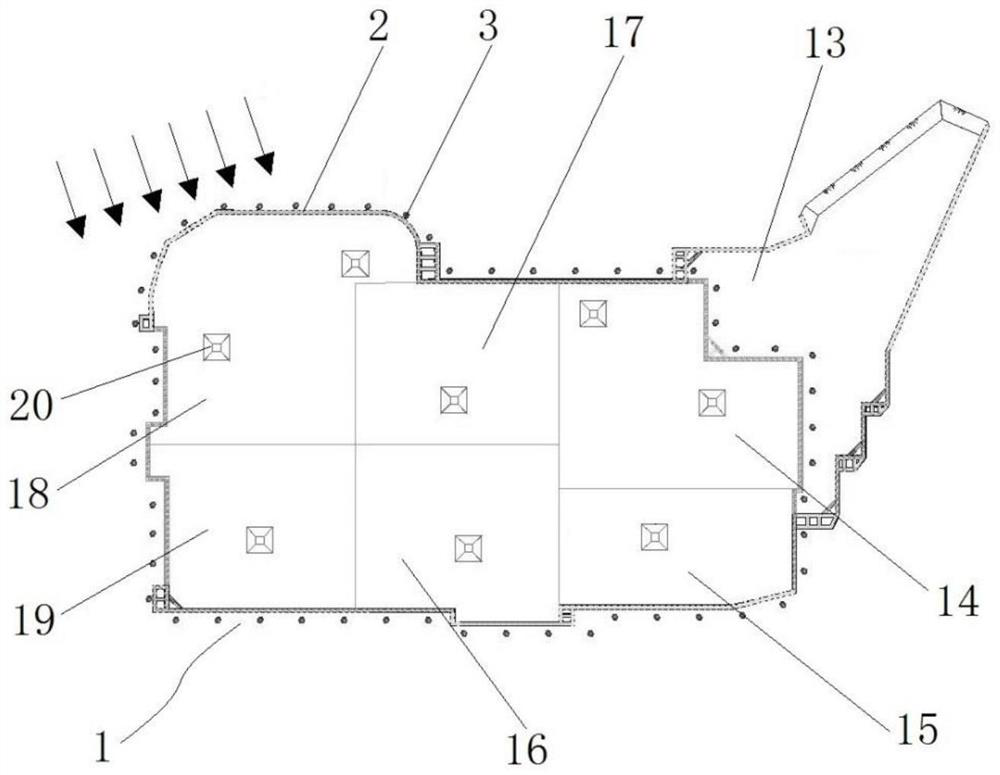

Method and device used for installing photovoltaic array on east-and-west-facing slopes

InactiveCN103441185AIncrease profitEasy to installLight-sensitive devicesFinal product manufactureSupporting systemPower station

The invention belongs to the technical field of photovoltaic application, and particularly discloses a method used for installing a photovoltaic array on an east-facing slope or on a west-facing slope. The method comprises the steps of (1) setting the oblique plane of the slope as A and determining the slope angle Alpha; (2) determining the optimal installation tilt angle Theta of the photovoltaic array in the area, determining the installation azimuth angle Zeta of the photovoltaic array, setting the oblique plane of the photovoltaic array as B and enabling the oblique plane B of the photovoltaic array to intersect with the oblique plane A of the slope on a straight line c; (3) arranging the photovoltaic array in the direction parallel to the straight line c, enabling the included angle between the straight line c where the oblique plane A of the slope intersects with the oblique plane B of the photovoltaic array and the bottom edge straight line d of the slope to be Beta, and enabling the included angle between the oblique plane B of the photovoltaic array and the oblique plane A of the slope to be Theta'. According to the method, the photovoltaic array can be installed on the east-facing slope or on the west-facing slope in the north-south direction by means of a front support and a rear support which are uniform in length specification, a support system can be manufactured conveniently, materials can be saved, installation of the photovoltaic array can be achieved more easily, construction accuracy, efficiency and quality are improved, influence caused by shading of shadows between a front row and a back row of the photovoltaic array is reduced, and then the land utilization rate and electric energy production in a power station are improved.

Owner:SUN YAT SEN UNIV +1

Beam section transportation method for bridge girder cantilever assembly

InactiveCN111172882ANot affected by layoutReduce extra workBridge erection/assemblyArchitectural engineeringCofferdam

The invention discloses a beam section transportation method for bridge girder cantilever assembly. A beam transporting vehicle is connected to the lower portion of an installed beam section, a to-be-mounted beam section can be lifted at a fixed lifting point close to a pier and the like, a construction shortcut or a cofferdam platform of a pier can be directly utilized to reduce additional work amounts, reduce construction measure expenses and avoid the influence of bridge floor arrangement; when the to-be-mounted beam section is transported to a preset position, the lifting part II of the beam erecting machine is anchored on the to-be-mounted beam section and is moved to a design position, then the lifting part I is loosened, the lifting part I is lifted to a preset position for furtherinstallation, the beam section transportation method is convenient for construction operation, high in the mechanization level, safe and reliable and high in construction efficiency, a large amount ofadditional engineering cost is effectively avoided, the beam section transportation method is widely suitable for hoisting and transporting cable-stayed bridges or continuous rigid frame bridges limited by terrain features, and the construction speed and the construction quality are guaranteed.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

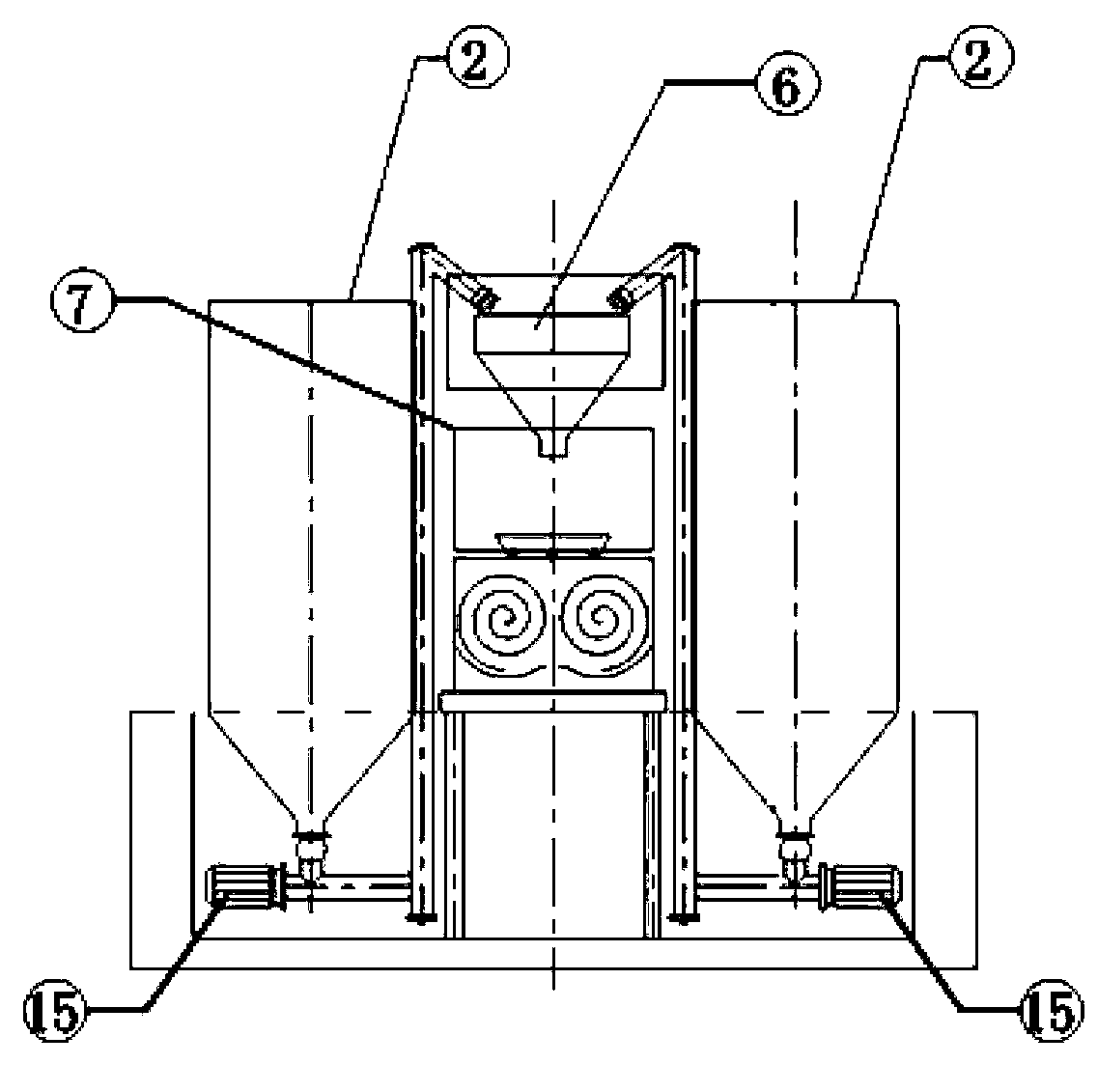

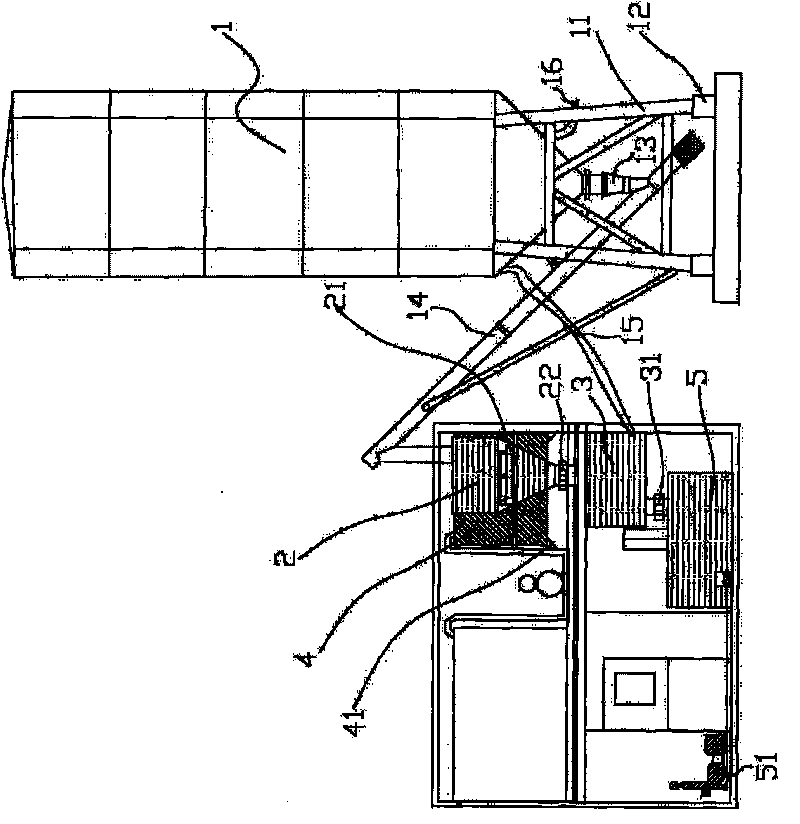

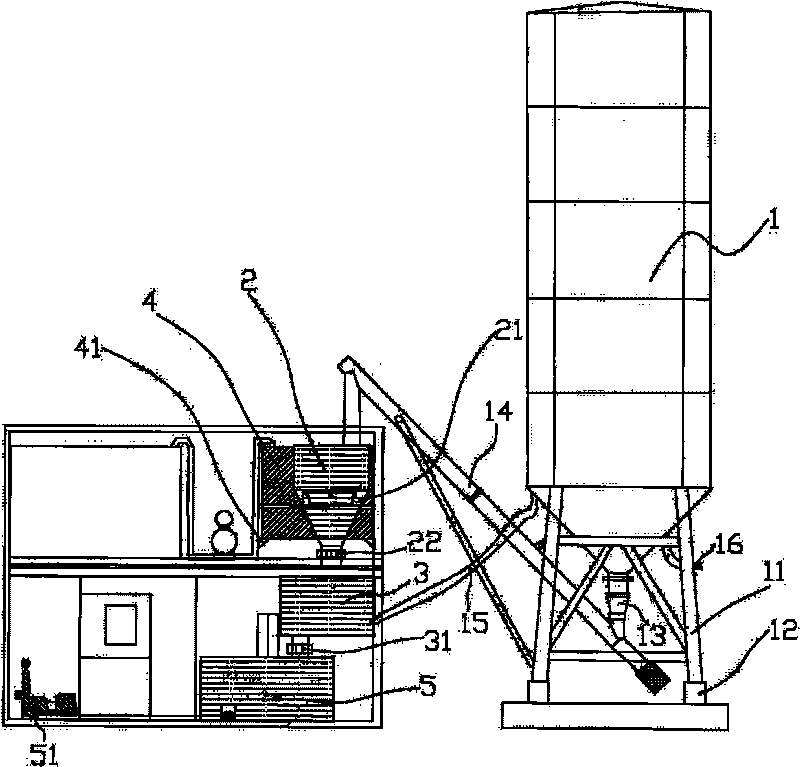

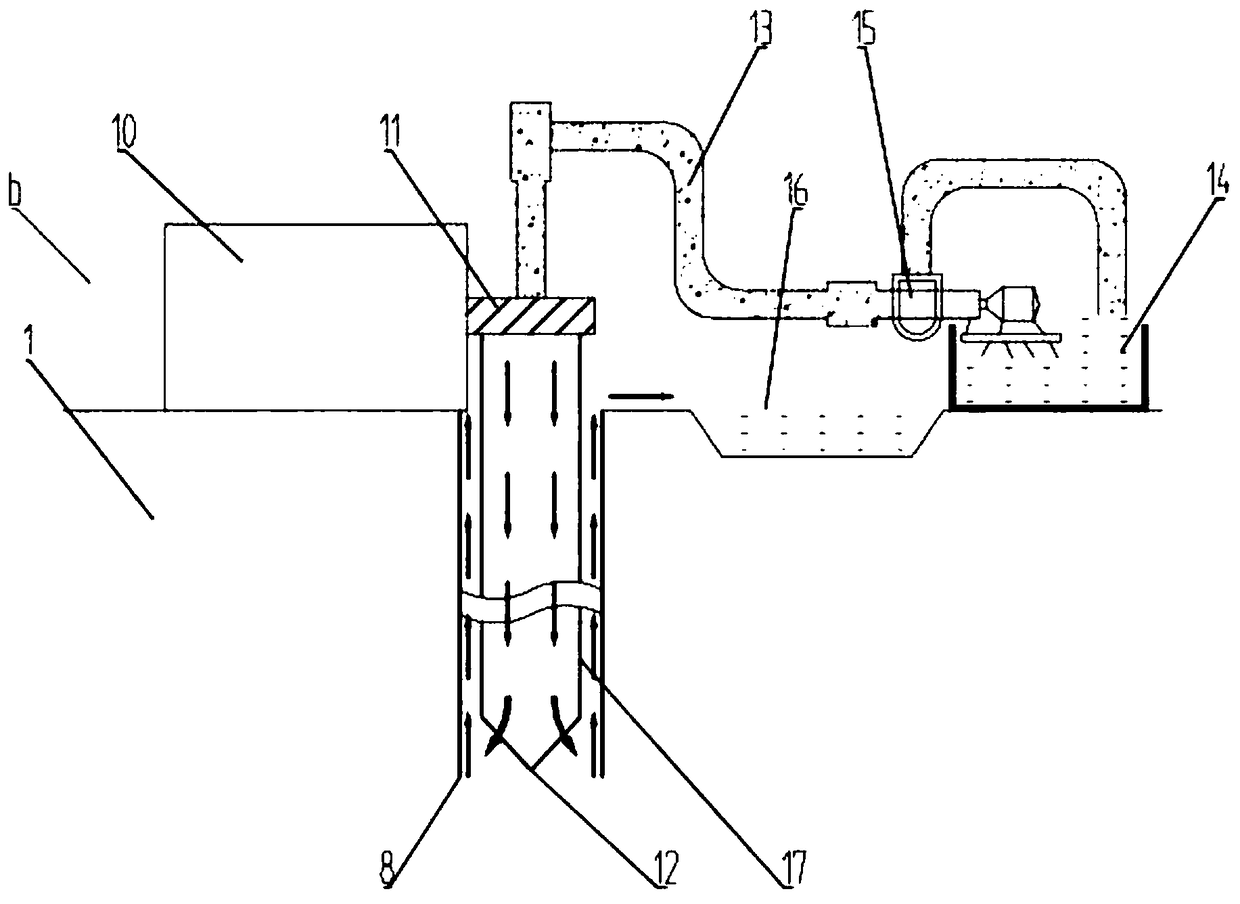

Cement mixing-filling system

ActiveCN101704270ANo pollution in the processGuaranteed construction speedCement mixing apparatusSold ingredients supply apparatusMaterials scienceGrout

The invention provides a cement mixing-filling system. The system comprises a vertical type cement storage bucket, of which the lower part is provided with a funnel, the funnel is connected with a worm used for conveying the cement, the other end of the worm is connected with a cement weighing bucket, the lower part of the cement weighing bucket is connected with a cement mixing bucket, of which the upper part is connected with a weighing water tank and the lower part is connected with a grout storage bucket, and the grout storage bucket is connected with a grout pump used for pumping the grout to the outside. In the cement mixing-filling system, bulk cement is used and directly conveyed in the cement storage bucket by a pipe, and in the process of conveying the cement, dust pollution is avoided and the conveying process is of environmental protection and hygiene; and the mixing station of the invention can continuously supply the grout, so that the construction speed and efficiency of a project are ensured, and all mechanisms are provided with a weighing device respectively, and the grout can be prepared as required, so that the cement mixing-filling system is high in automaticity and reliable in operation.

Owner:SHANGHAI STRONG FOUND ENG

Method for manufacturing steel pattern plate of taper-end concrete pier

ActiveCN101733643AEasy to installExcellent adhesionOther manufacturing equipments/toolsFlame cuttingCost savings

The invention relates to a method for manufacturing a steel pattern plate of a taper-end concrete pier. The method comprises the following steps: calculating circular arc points based on design parameters and marking on a plate, using a flame cutting machine to adjust the curvature radius of the track at the marked cutting points and fixing the track, then cutting the taper-end preliminarily-cut plate into fan-shaped pattern plates, welding the fan-shaped pattern plates two by two to obtain two semi-taper pattern plates, and welding and shaping the straight rectangular plate and the semi-taper pattern plates to obtain a sectional pattern plate. By using the method for making a steel pattern plate of a taper-end concrete pier and a simple tool, a large taper-end steel pattern plate, which can only be finished under specified conditions, can be manufactured and finished under primitive conditions on the construction site; and the pattern plate can be conveniently installed, tightly affixed and quickly erected, thereby ensuring construction quality and speed and completely meeting the construction requirements of piers of such big special shapes. Besides, the pattern plate has the advantages of low manufacturing cost, simple process and significant construction cost saving.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

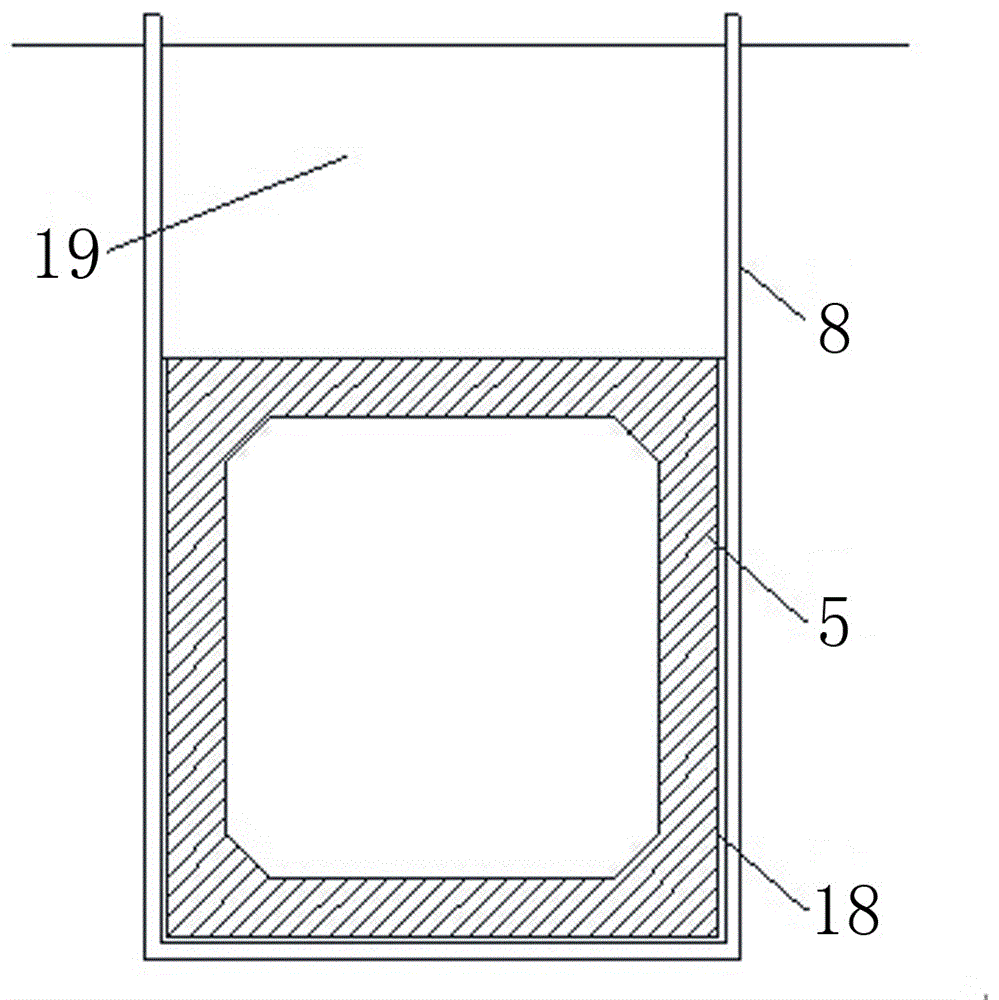

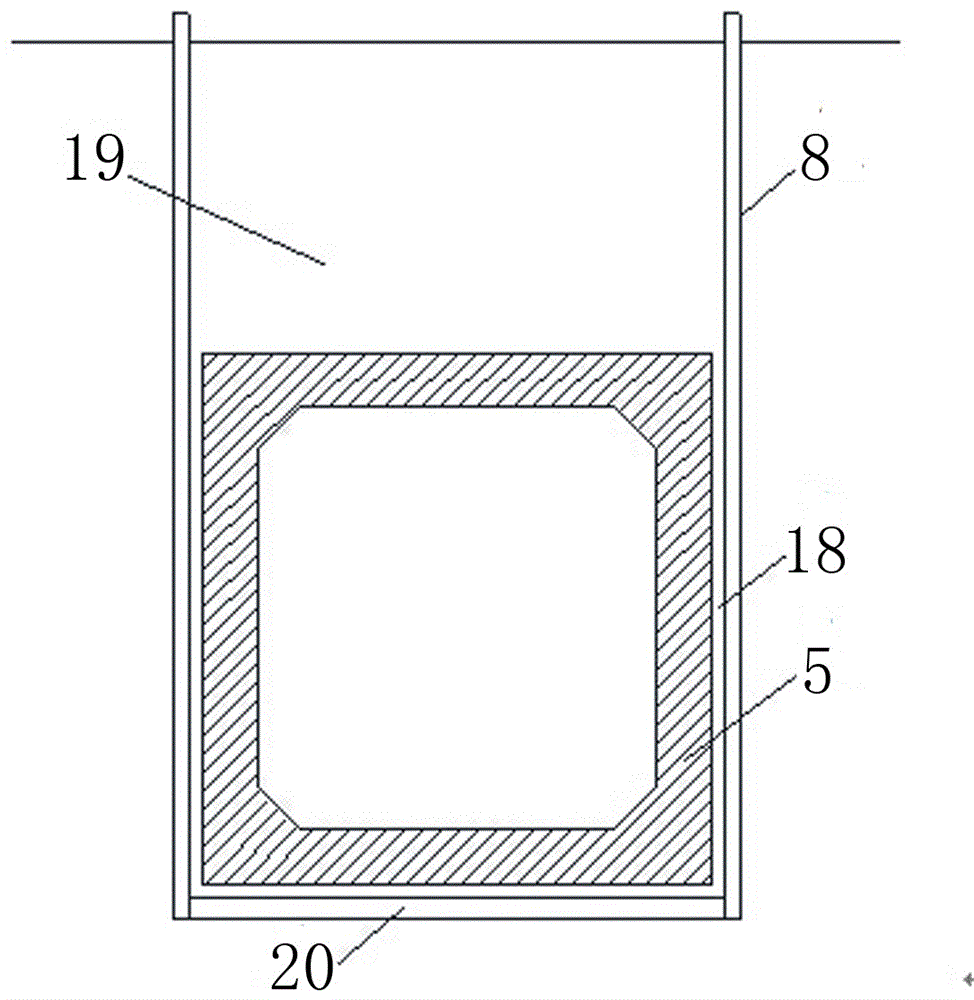

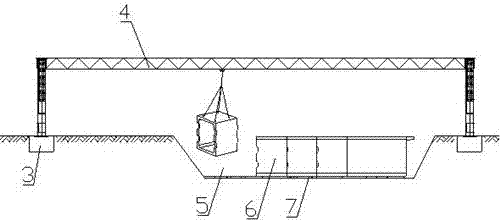

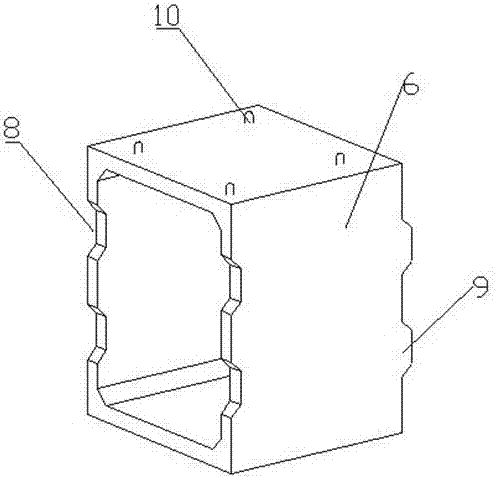

Construction method for prefabricated box culvert above running subway shield interval structure

ActiveCN107142965APrevent floatingAvoid deformationArtificial islandsUnderwater structuresCulvertPrefabrication

The invention discloses a construction method for a prefabricated box culvert above a running subway shield interval structure. The method mainly comprises the steps of box culvert prefabrication, site prefabrication, foundation pit excavation, cushion ply pouring, box culvert splicing, continuous construction, track monitoring and the like. According to the construction method for the prefabricated box culvert above the running subway shield interval structure, the method is conducted in two stages of in-field prefabrication and field assembling, the field assembling stage executes the tau-effect principle of partitioning, layering, blocking and time limiting, excavation is conducted in partitioned and blocked modes, cushion plies are constructed along with excavation, box culverts are hoisted as quick as possible, loading is conducted in time, the influences of the whole operation process on a track structure below are small, and track floating and deformation can be effectively prevented.

Owner:SUZHOU ZHONGHENGTONG ROAD & BRIDGE GRP CO LTD

Shield tunneling machine station and starting construction method

InactiveCN108316307AAvoid damageShorten the construction periodArtificial islandsExcavationsArchitectural engineeringShield tunneling

The invention provides a shield tunneling machine station and starting construction method, and aim at simultaneously carrying out construction of a station and starting of a shield tunneling machinein an excavated foundation pit. The method comprises the following steps of (1) construction of a base layer plate, and building of supporting frames and a scaffold; (2) assembly of the shield tunneling machine and entering of components into the foundation pit; and (3) construction of upper layer plates. According to the shield tunneling machine station and starting construction method, construction of the upper layer plates can be carried out while the assembly components of the shield tunneling machine enter the foundation pit one by one for assembly, so that the structure of the station isconstructed layer by layer, construction of the station is carried out, the assembly and starting of the shield tunneling machine and construction of the station can be carried out at the same time,mutual waiting is not needed, the progress of tunnel construction is guaranteed, meanwhile, the construction period of the station is greatly shortened, the influence on the ground road is reduced, and walking convenience is improved; the shield tunneling machine is assembled in the supporting frames, and the supporting frame can protect the shield tunneling machine, so that the situation that theshield tunneling machined is damaged due to the fact that a falling object falls onto the shield tunneling machine when the station that construction is carried out at the same time is avoided; and meanwhile, the supporting frames can play a temporary supporting role of the scaffold, the upper layer plate are constructed, construction of the station is facilitated, and the construction speed of the station is ensured.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

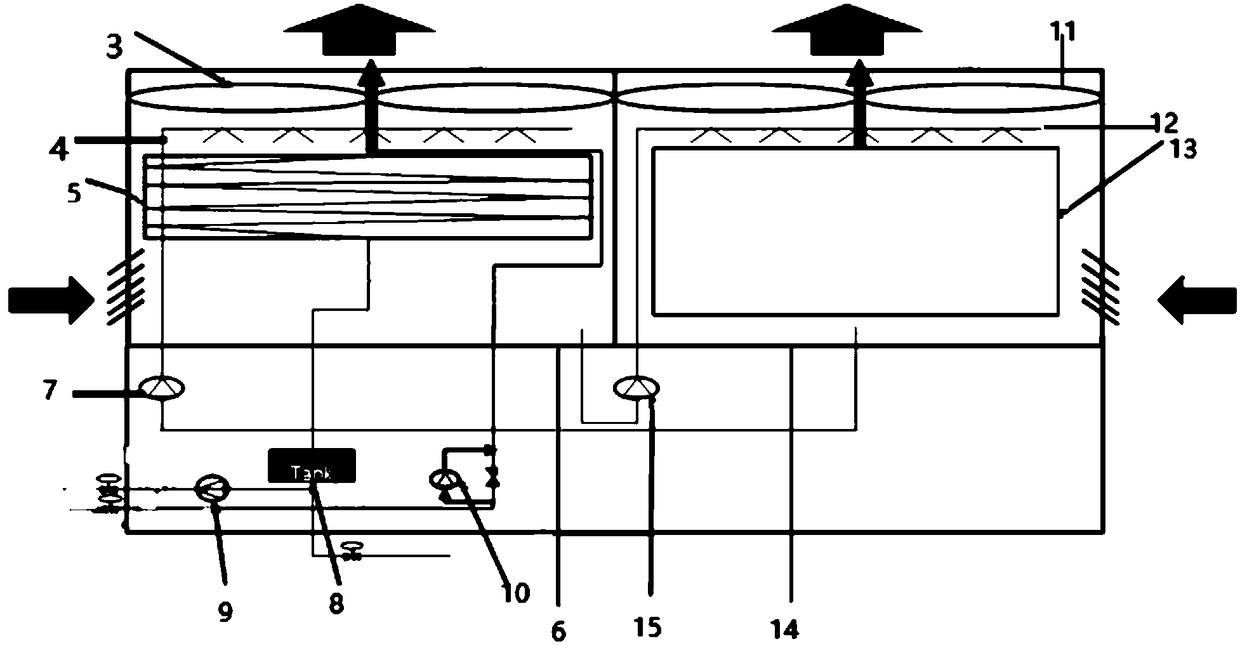

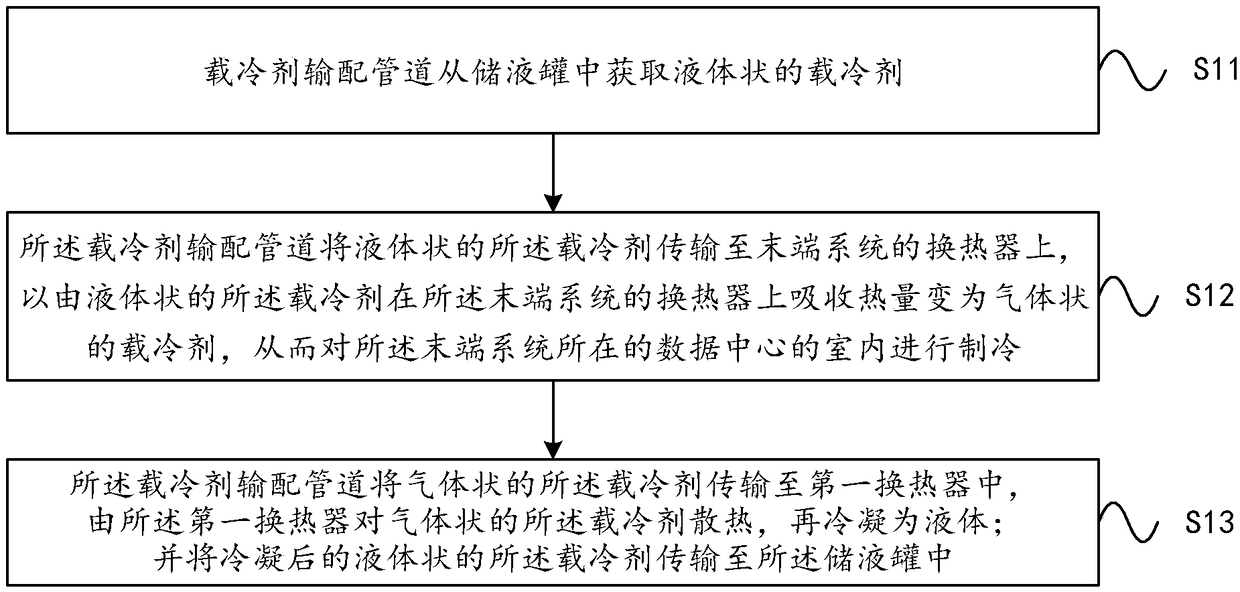

Phase-change cooling tower and refrigeration method

The embodiment of the invention provides a phase-change cooling tower and a refrigeration method. The phase-change cooling tower comprises a phase-change refrigeration unit and a cold water unit; thephase-change refrigeration unit comprises a first fan, a first spray thrower, a first heat exchanger, a first water storage disc, a first water pump, a liquid storage tank and a liquid pump; the coldwater unit comprises a second fan, a second spray thrower, a second heat exchanger, a second water storage disc and a second water pump; water in the second water storage disc is sprayed to the uppersurface of the first heat exchanger, partial water evaporates so that heat can be taken away, and partial water which does not evaporate falls on the first water storage disc; water in the first waterstorage disc is sprayed to the second heat exchanger, partial water evaporates so that heat can be taken away, and partial water which does not evaporate falls on the second water storage disc. The phase-change cooling tower has the advantages that compared with an existing cooling tower, colder water provided by the cold water unit can be used for cooling a gas-shaped secondary refrigerant in the first heat exchanger, and the tolerance level to the outdoor air temperature is higher.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

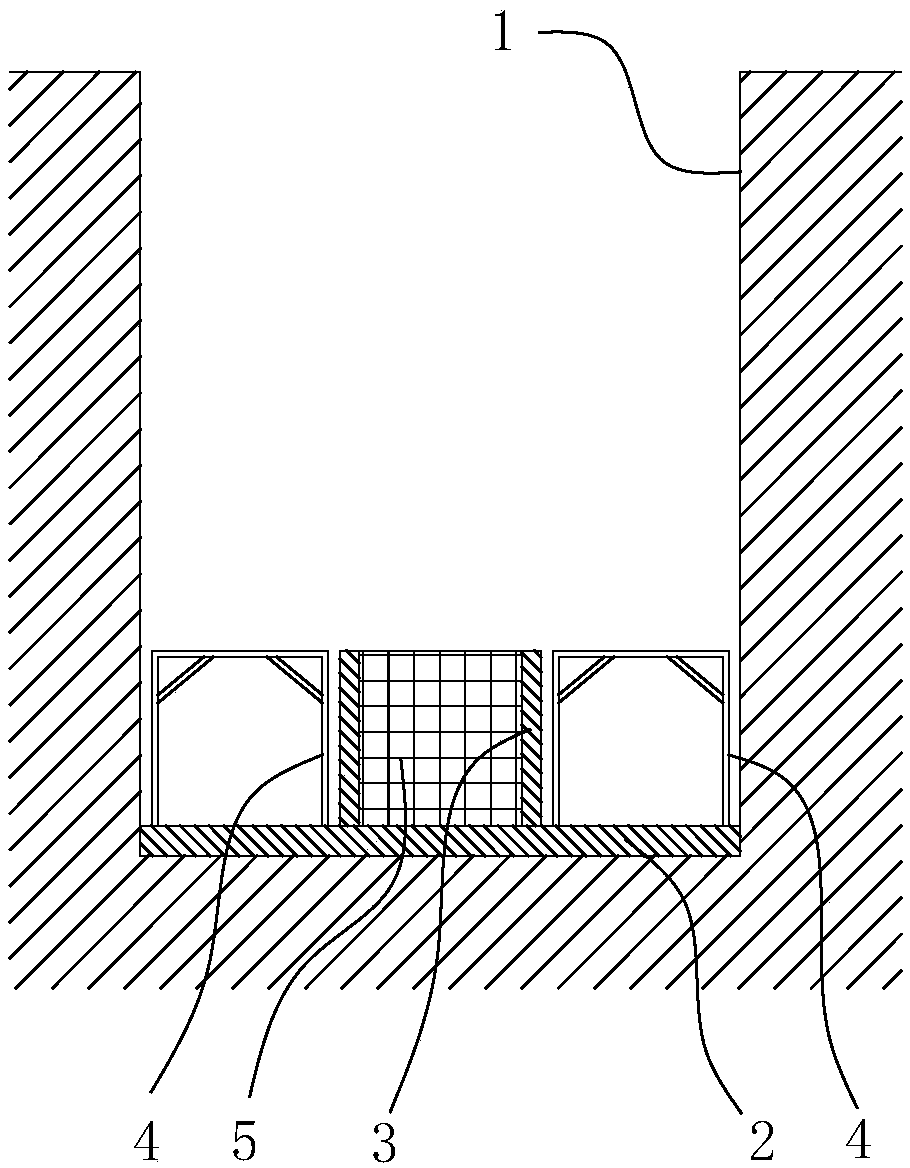

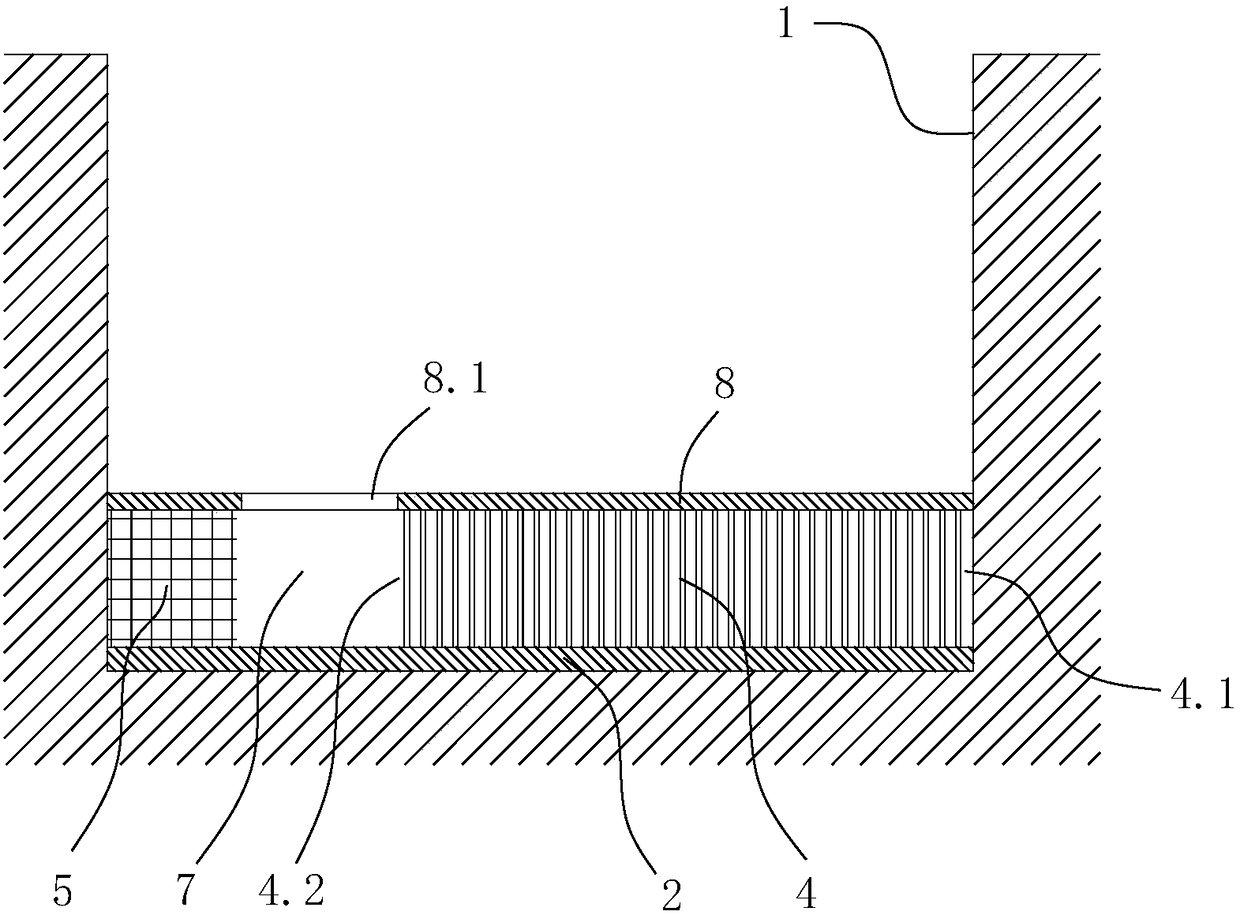

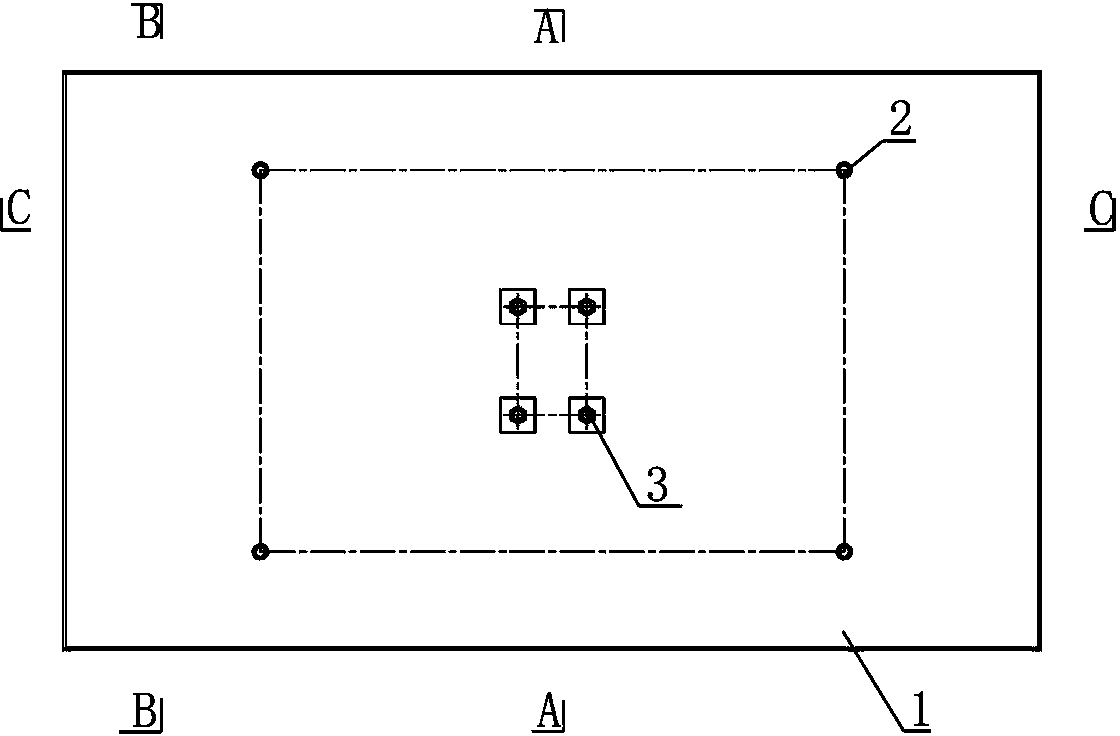

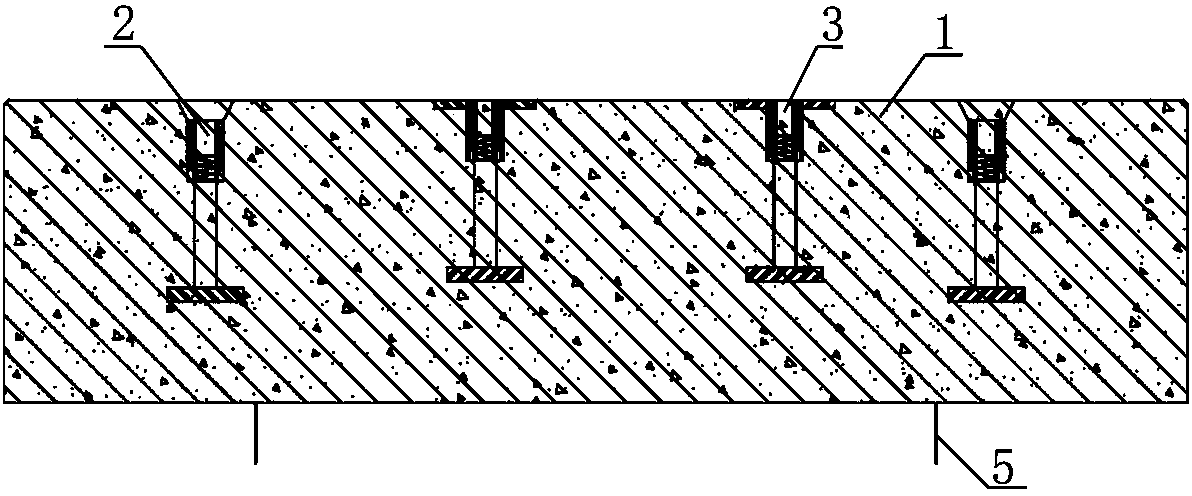

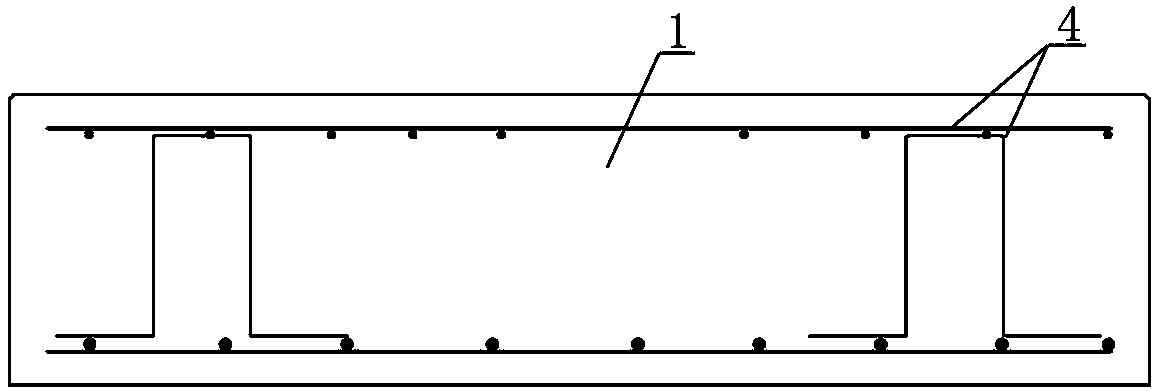

Container prefabricated house assembling type steel reinforced concrete single-double-column foundation and construction method thereof

InactiveCN103352471ALight structureEasy to transportFoundation engineeringReinforced concreteSteel columns

Disclosed are a container prefabricated house assembling type steel reinforced concrete single-double-column foundation and a construction method thereof. The container prefabricated house assembling type steel reinforced concrete single-double-column foundation comprises a prefabricated foundation slab and an H-shaped steel column. Four asymmetrical H-shaped embedded parts which are in rectangular distribution are embedded in the central position of the upper surface of the prefabricated foundation slab. Four T-shaped embedded parts which are in rectangular distribution are embedded in the border position, close to the upper surface of the prefabricated foundation slab. The H-shaped steel column is placed in the central position of the upper surface of the prefabricated foundation slab and is inserted into the asymmetrical H-shaped embedded parts and the prefabricated foundation slab through bolts for achieving fixed connection. Connecting keyholes are formed in the flange of the upper portion of the H-shaped steel column. Compared with a traditional cast-in-situ type foundation, the container prefabricated house assembling type steel reinforced concrete single-double-column foundation has the advantages of being high in structural strength, convenient to transport, capable of being recycled, efficient in construction and the like, is mainly used for rapid constructing of the foundation of a container prefabricated house, guarantees the construction speed of construction temporary facilities, and provides a guarantee for completing a construction project on time.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

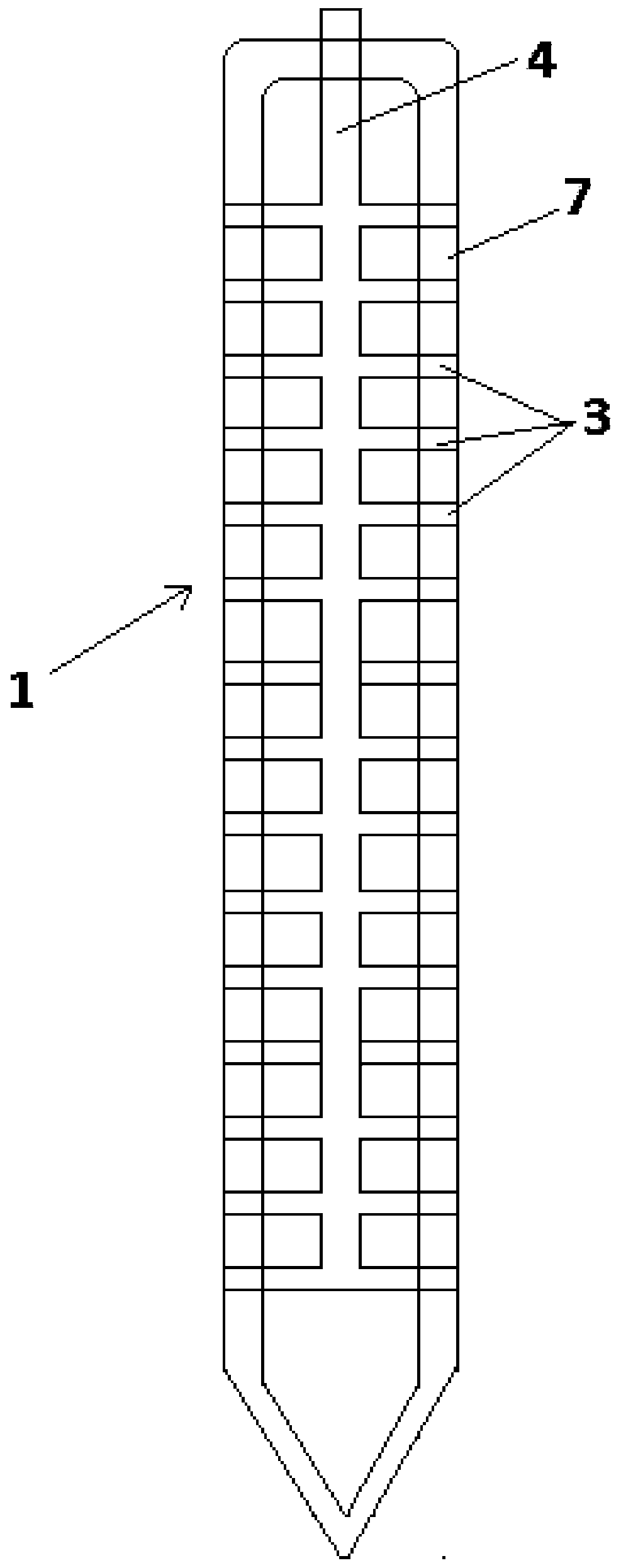

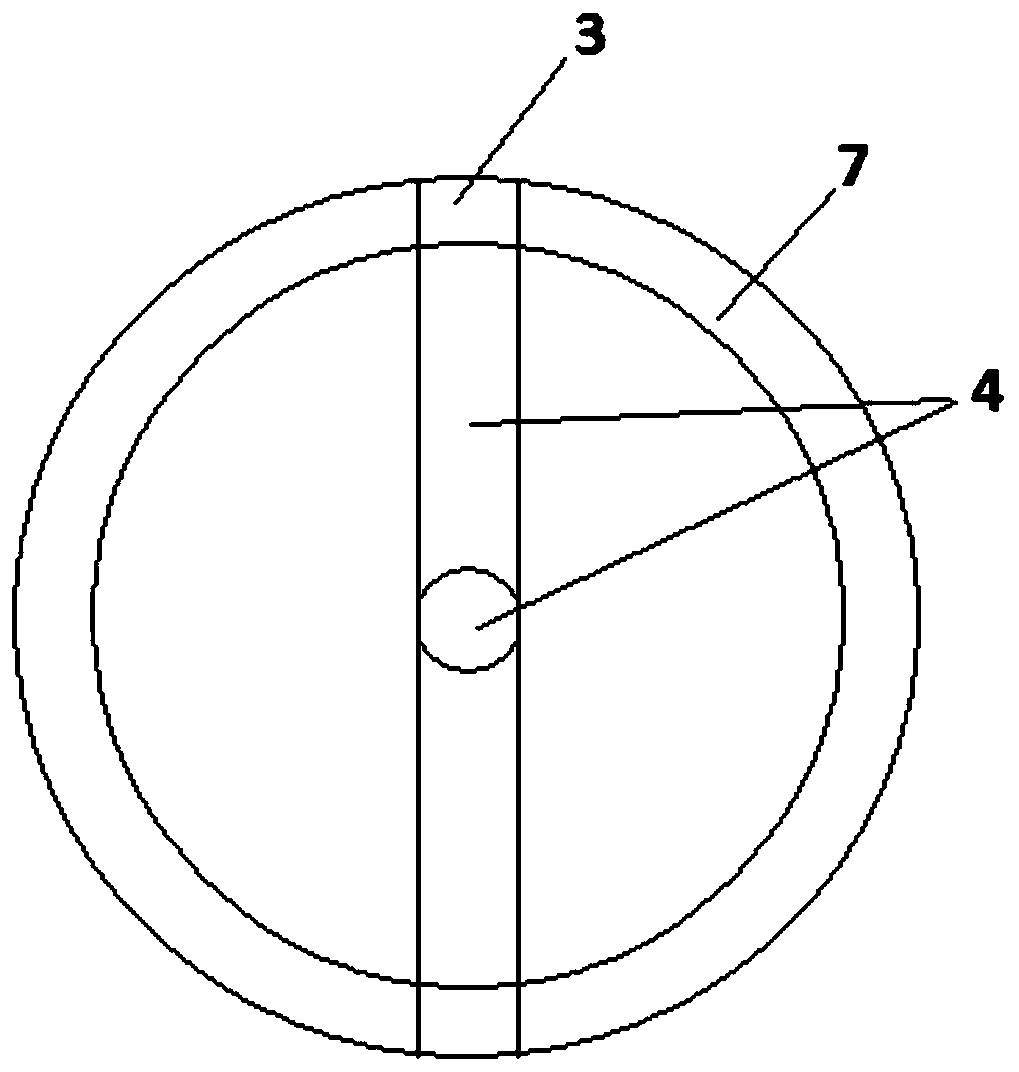

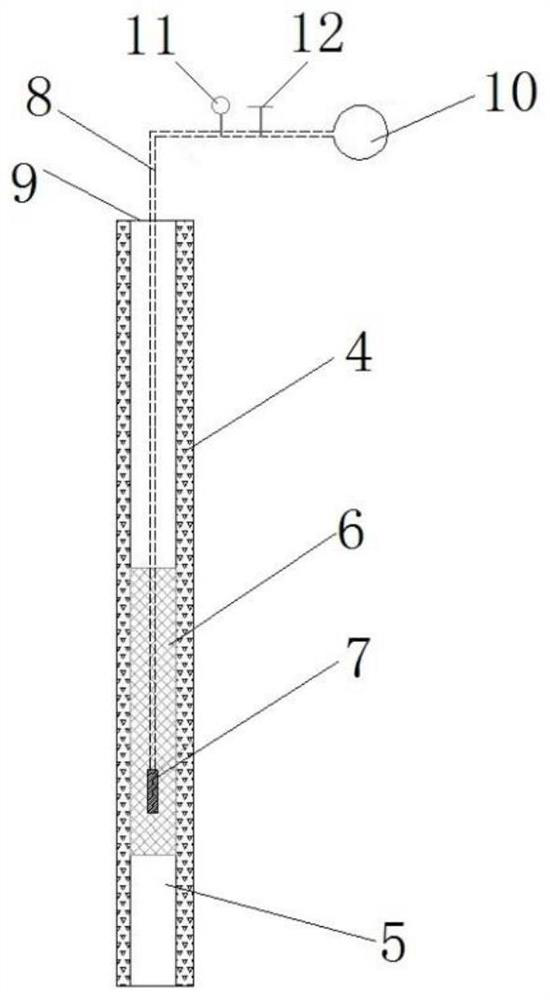

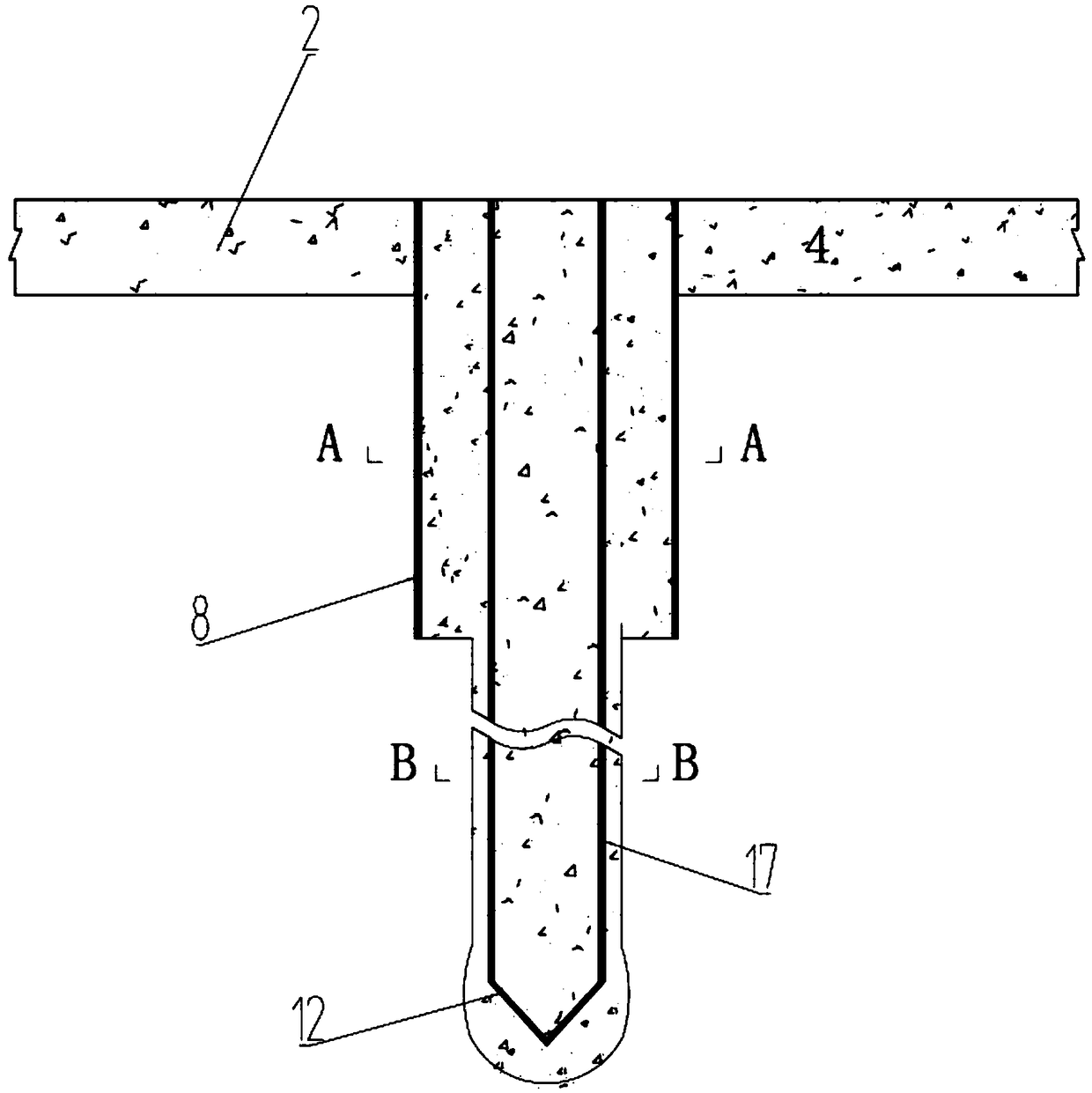

Post-grouting precast hollow pipe root pile structure and construction method

ActiveCN108265710AGuaranteed verticalityPlay a supporting roleAfforestationBulkheads/pilesButt jointCement slurry

The invention discloses a post-grouting precast hollow pipe root pile structure and a construction method, and belongs to the field of buildings. The precast hollow pipe is internally provided with acement slurry cast pipe and an electric wire. A connecting part is arranged on the butt-joint part of the precast hollow pipe and is a cylinder. A plurality of radial sliding parts are evenly arrangedon the parts, on the periphery of the cement slurry cast pipe, in the cylinder. A hollow radial sliding shaft is slidably arranged on the sides, close to the cement slurry cast pipe, of the radial sliding parts. A guide pipe and the electric wire are arranged in the radial sliding shaft, and a micro welding gun is arranged at the wire end and connected to a plurality of parts of the radial sliding parts. The radial sliding shaft communicates with the cement slurry cast pipe. The upper end, in the precast hollow pipe, of the electric wire is connected with an electric welding machine. Throughthe post-grouting precast hollow pipe root pile structure provided by the structure, the bearing capacity of the precast hollow pipe pile can be improved, settlement of a pile foundation is reduced, the strength of soil layers around the pile foundation is improved, and the defects that the post-grouting technology is long in construction period, complex in process and the like are overcome.

Owner:刘寅平

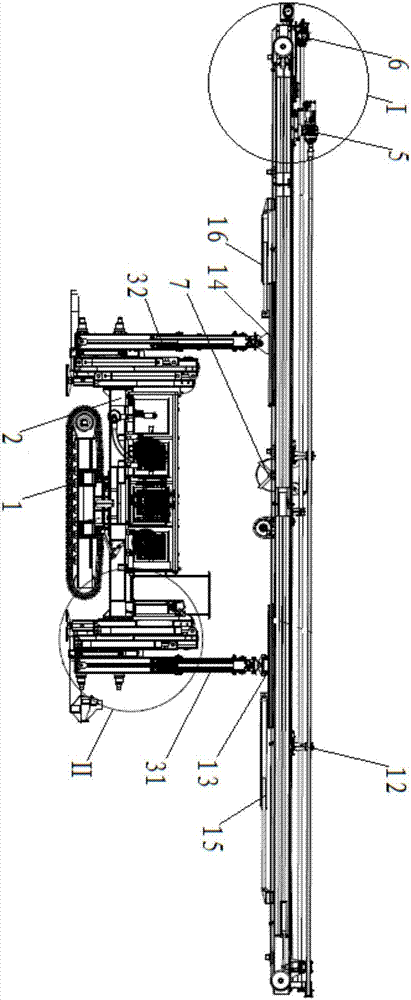

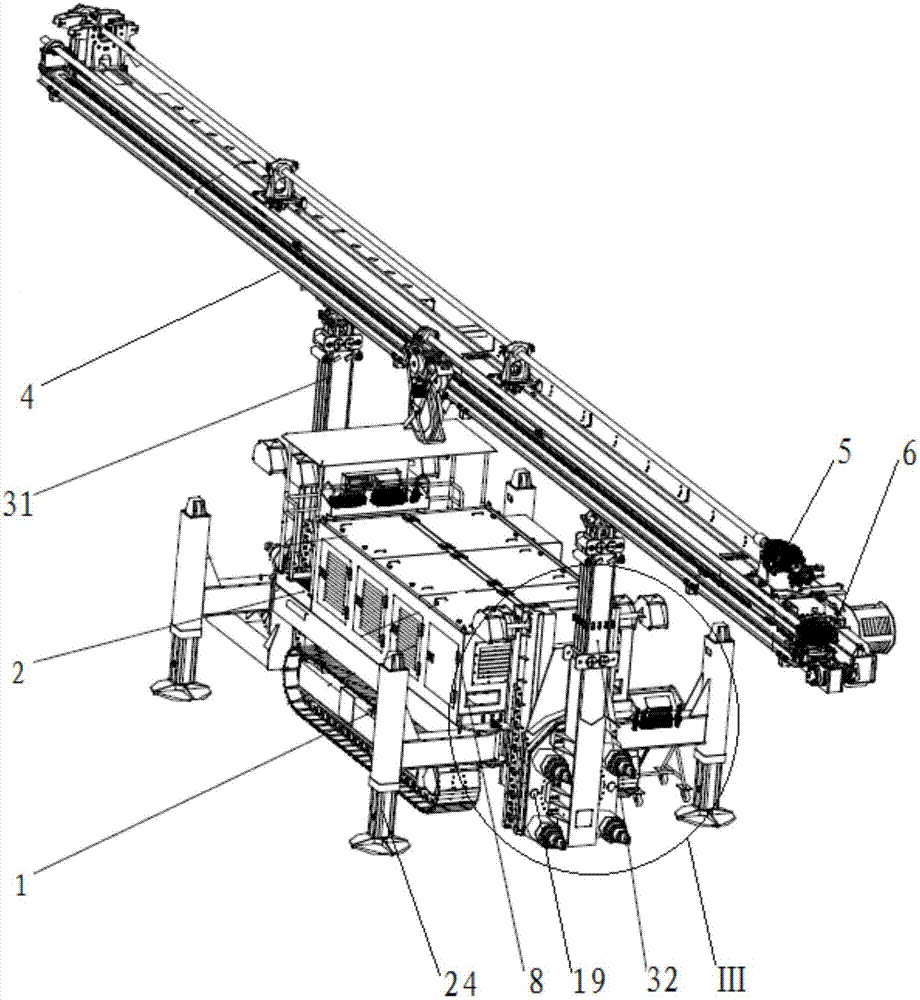

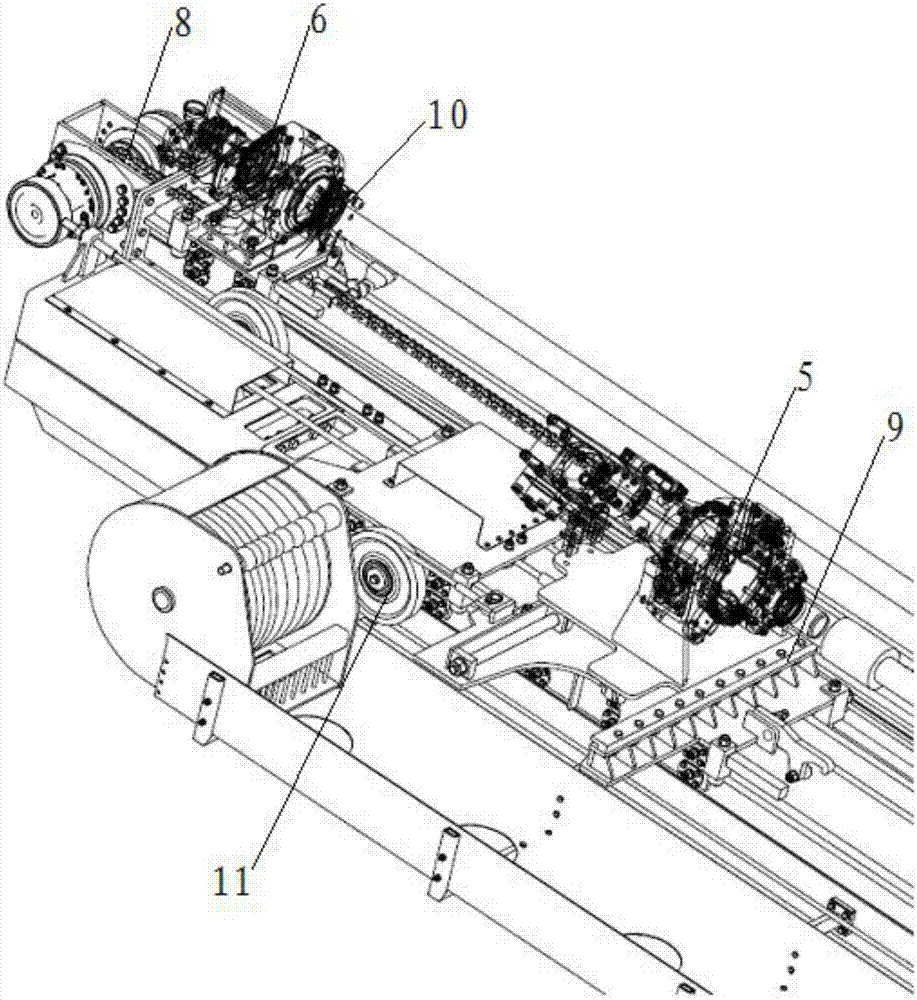

Horizontal jet grouting drilling machine

PendingCN107178314ASwing action implementationMeet construction requirementsDerricks/mastsDrilling machines and methodsGear wheelMachine

The invention discloses a horizontal jet grouting drilling machine which comprises a drilling machine platform and a lifting arm, wherein rotary working devices are arranged at the front end and rear end of the drilling machine platform; each of the rotary working devices comprises a fixing base, a rotating base, a gear motor and a rotary support with teeth on external circle and without tooth on internal circle; the fixing base is fixedly connected with the drilling machine platform; the rotating base is fixedly arranged at the bottom end of the lifting arm; the gear motor is arranged on the rotating base; the internal circle of the rotary support is fixedly connected with the rotating base; the external circle of the rotary support is fixedly connected with the fixing base; the external circle of the rotary support is meshed with the teeth of the gear motor; the gear motor is used for driving the rotating base and the lifting arm to swing so as to drive a cantilever crane to swing; front and rear dual rotary working devices are adopted for synchronously driving the cantilever crane to swing, so that sufficient power can be supplied to the machine for swinging under various working conditions, the rotating angle of the cantilever crane can be guaranteed, the machine can meet the construction requirement, the machine stability can be guaranteed, the machine loss is less, the construction quality is guaranteed and the construction safety is promoted.

Owner:CHINA RAILWAY CONSTR HEAVY IND

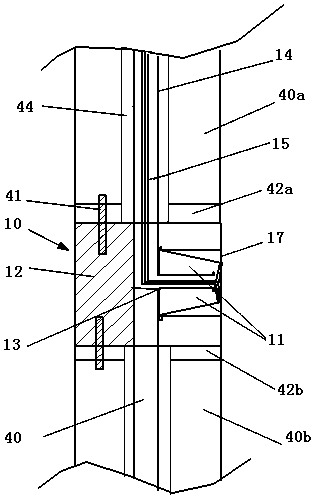

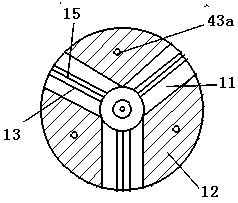

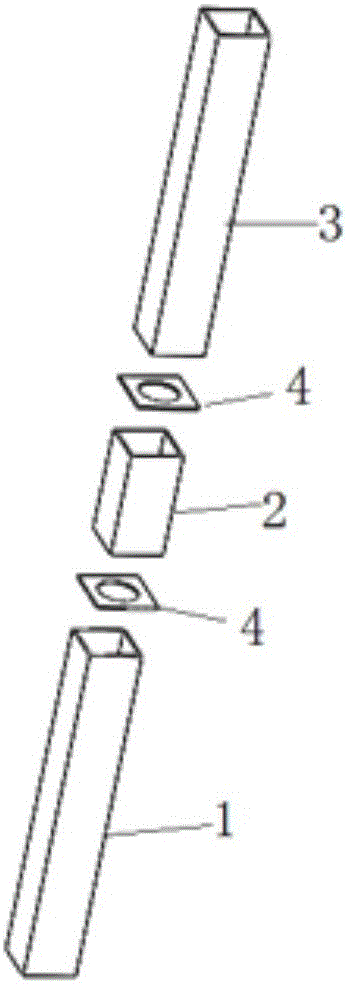

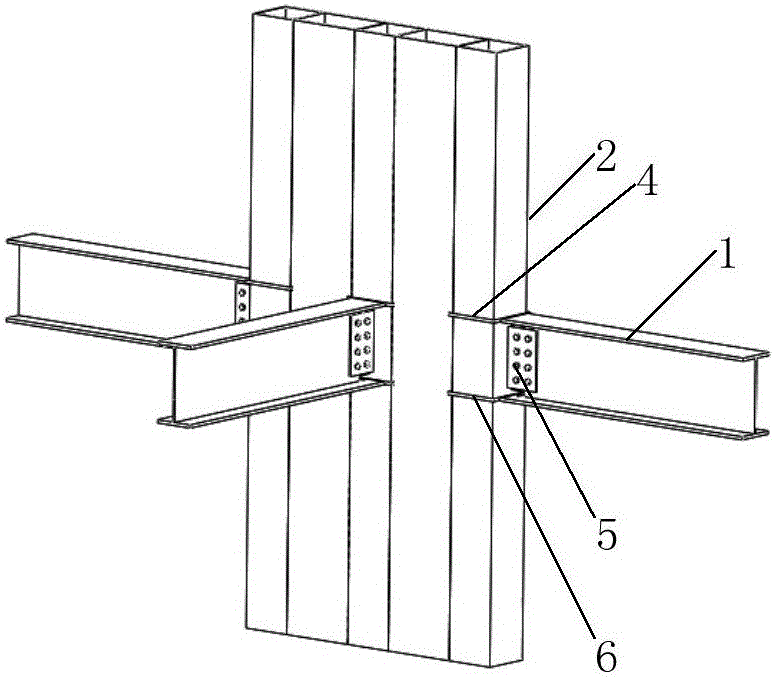

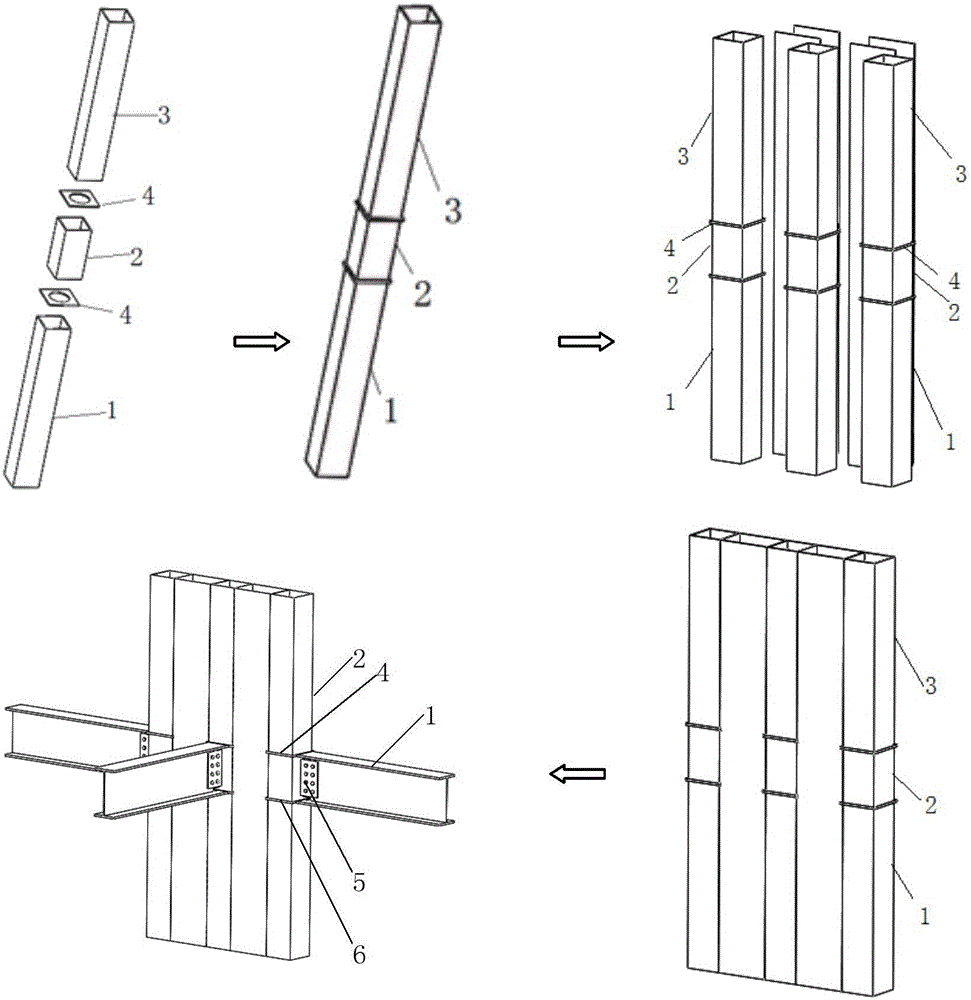

T-shaped through clapboard-type multi-chamber concrete filled steel tube combination column and steel beam joint and assembly method thereof

ActiveCN105863082AReduce decreaseGuaranteed vertical force transmissionBuilding constructionsSteel tubeMaterials science

The invention relates to a T-shaped through clapboard-type multi-chamber concrete filled steel tube combination column and steel beam joint and an assembly method thereof. The T-shaped through clapboard-type multi-chamber concrete filled steel tube combination column and steel beam joint comprises a multi-chamber concrete filled steel tube combination column and an I-steel beam, wherein the multi-chamber concrete filled steel tube combination column comprises three embedded columns which are arranged at intervals, and parallel web plates are arranged between two adjacent embedded columns; a first through clapboard and a second through clapboard are arranged on each embedded column and are horizontally arranged and extend out of the embedded column, and the first through clapboard is connected with the top flange of the I-steel beam; the second through clapboard is connected with the bottom flange of the I-steel beam. The through clapboards fully penetrate through the embedded columns, the lateral dimension of the clapboard is wider than the beam, and the beam web plates are connected with the multi-chamber concrete filled steel tube combination column through double connecting plates to achieve a design guideline of strong column and weak beam, strong joint and weak rod piece. Because the through clapboards only penetrate through the embedded columns, a column cross-section is less weakened, and the vertical transmitting force of the multi-chamber concrete filled steel tube combination column is effectively ensured.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

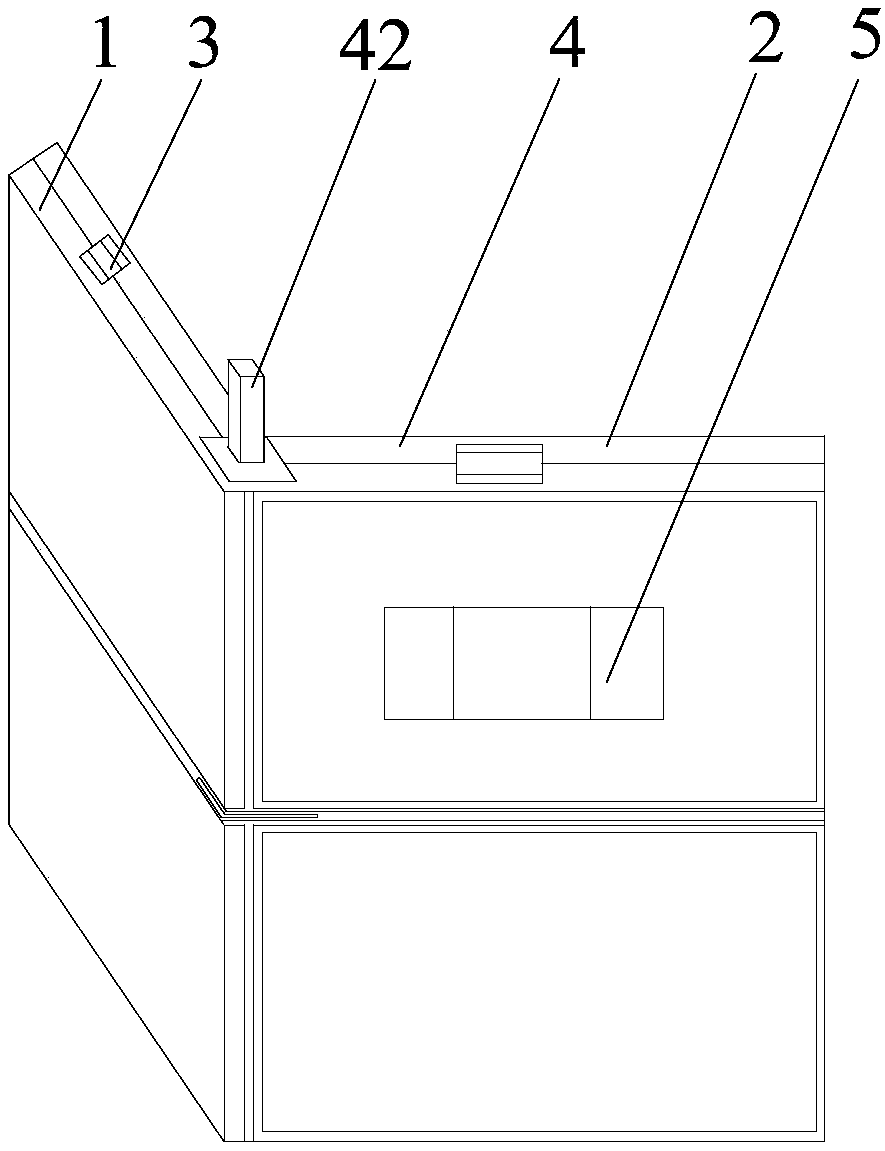

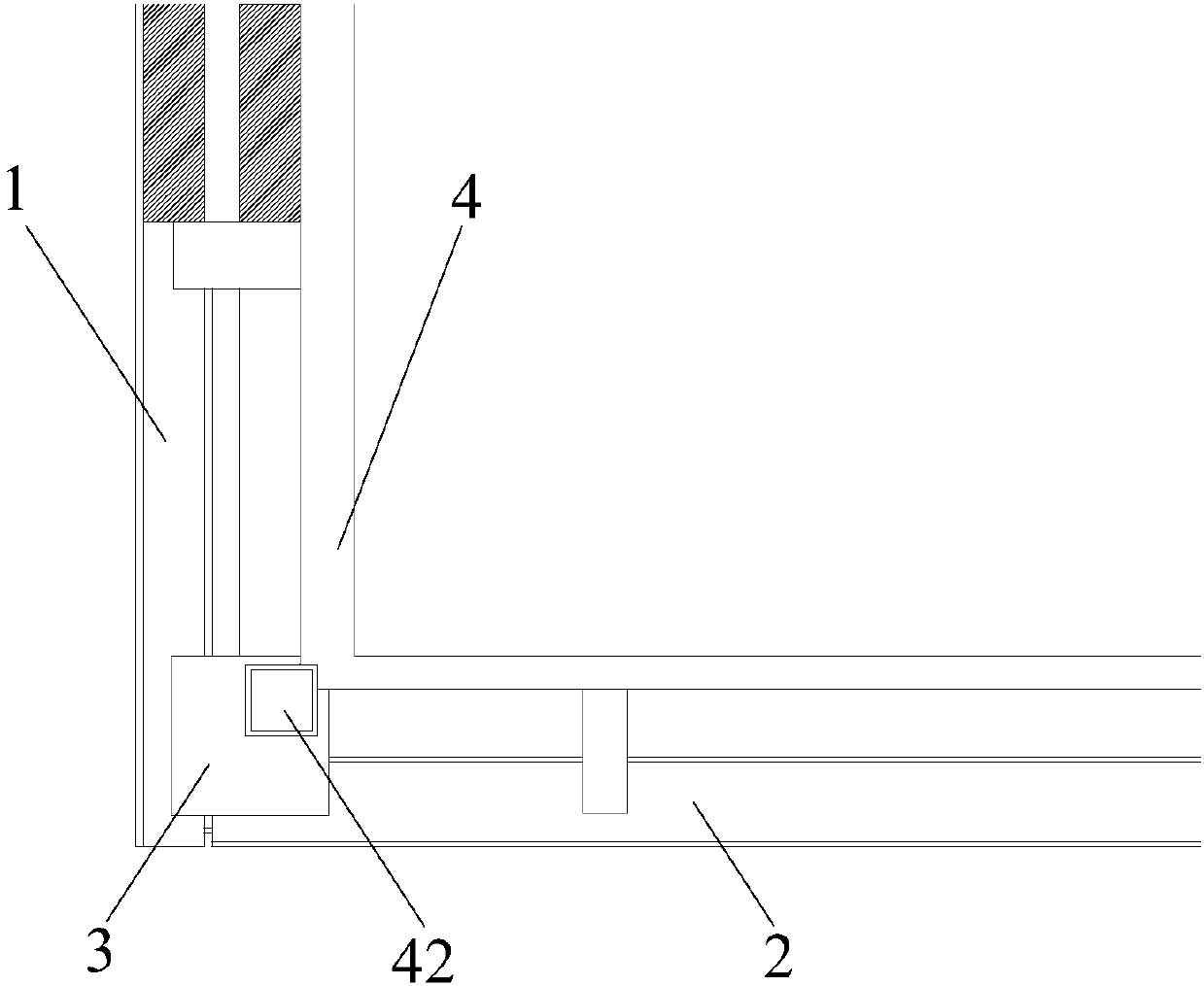

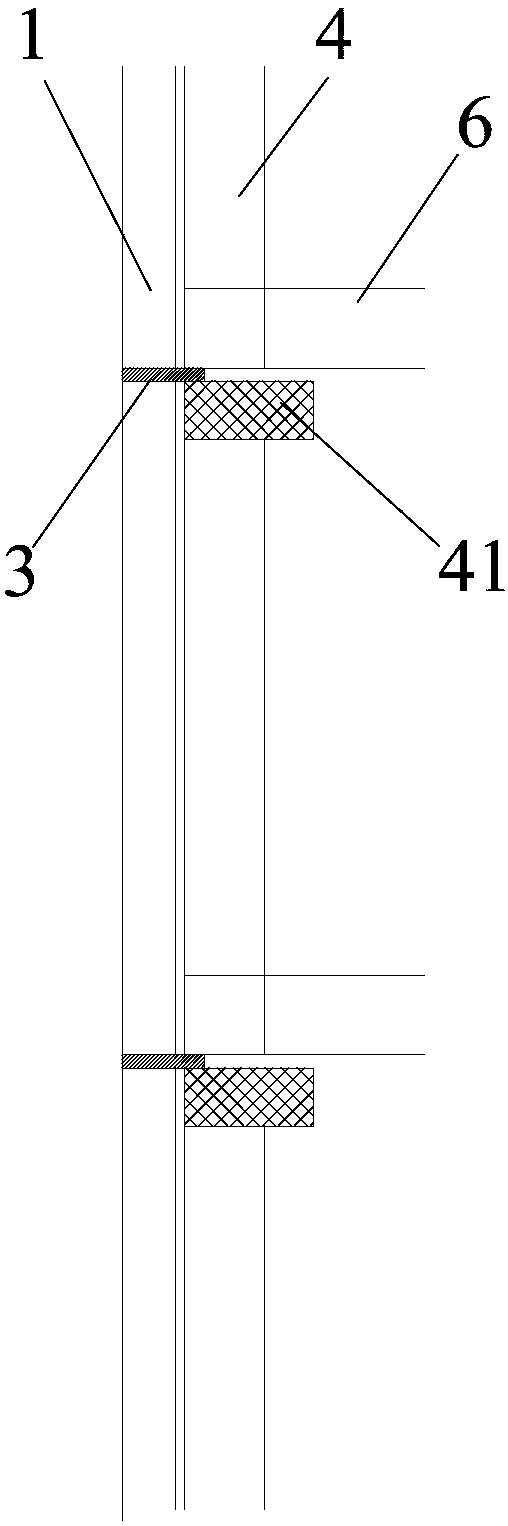

Fabricated building

ActiveCN107620402ALow costGuaranteed construction speedWallsClimate change adaptationWall plateBuilding construction

The invention relates to the technical field of buildings, in particular to a fabricated building. The fabricated building comprises a steel structure frame and prefabricated external wall plates. Themultiple layers of external wall plates are arranged from top to bottom, and each layer of external wall plate is fixed to the outer side of the steel structure frame through a connection part. By fixing the prefabricated external wall plates to the steel structure frame to form the building, the problems that an in-situ concrete pouring method is large in transporting amount and high in construction cost, the construction quality cannot be ensured, environmental pollution is serious, the cost is high, energy waste is prone to being generated can be solved. The external wall plates are transported to a construction site after being prefabricated in a factory, and mounted by adopting hoisting in the construction site to assemble an overall building, thus achievement of housing industrialization is facilitated, and the defects of in-situ formwork building, reinforcement assembling and concrete pouring of a traditional construction method are overcome. Mounting of windows and doors and construction of heat preservation layers and decoration layers are not needed after the main structure of the building is completed, and thus the construction procedures are simplified.

Owner:柏秋

Large-altitude-difference non-planar modeling suspended ceiling structure and construction method thereof

InactiveCN104234289ASimple structureGuaranteed construction speedCeilingsStructural engineeringMechanical engineering

The invention relates to a large-altitude-difference non-planar modeling suspended ceiling structure. A switching layer main skeleton is provided with a first-level switching layer assistant skeleton through a first-level connecting rod and a second-level switching layer assistant skeleton through a second-level connecting rod, wherein the first-level switching layer assistant skeleton is lower than the second-level switching layer assistant skeleton; the lengths of the first-level connecting rod and the second-level connecting rod are both not greater than 6000mm; the first-level switching layer assistant skeleton is provided with a first-level light steel keel through a first-level upper hanging rib and a first-level lower hanging rib; the second-level switching layer assistant skeleton is provided with a second-level light steel keel through a second-level upper hanging rib and a second-level lower hanging rib; the first-level light steel keel is lower than the second-level light steel keel; the lengths of the first-level upper hanging rib and the second-level upper hanging rib are both not more than 1000mm; the lengths of the first-level lower hanging rib and the second-level lower hanging rib are both not more than 500mm; the lower ends of the first-level lower hanging rib and the second-level lower hanging rib are connected with the surface layer of the suspended ceiling. According to the invention, the structure is simple, a multi-layer gradual retreating type bearing skeleton structure is adopted, the non-planar display of the surface layer of the suspended ceiling is realized through close joint connection and the construction speed and integral precision are ensured.

Owner:THE CONSTR DECORATION OF CHINA CONSTR NO 7 ENG BUREAU

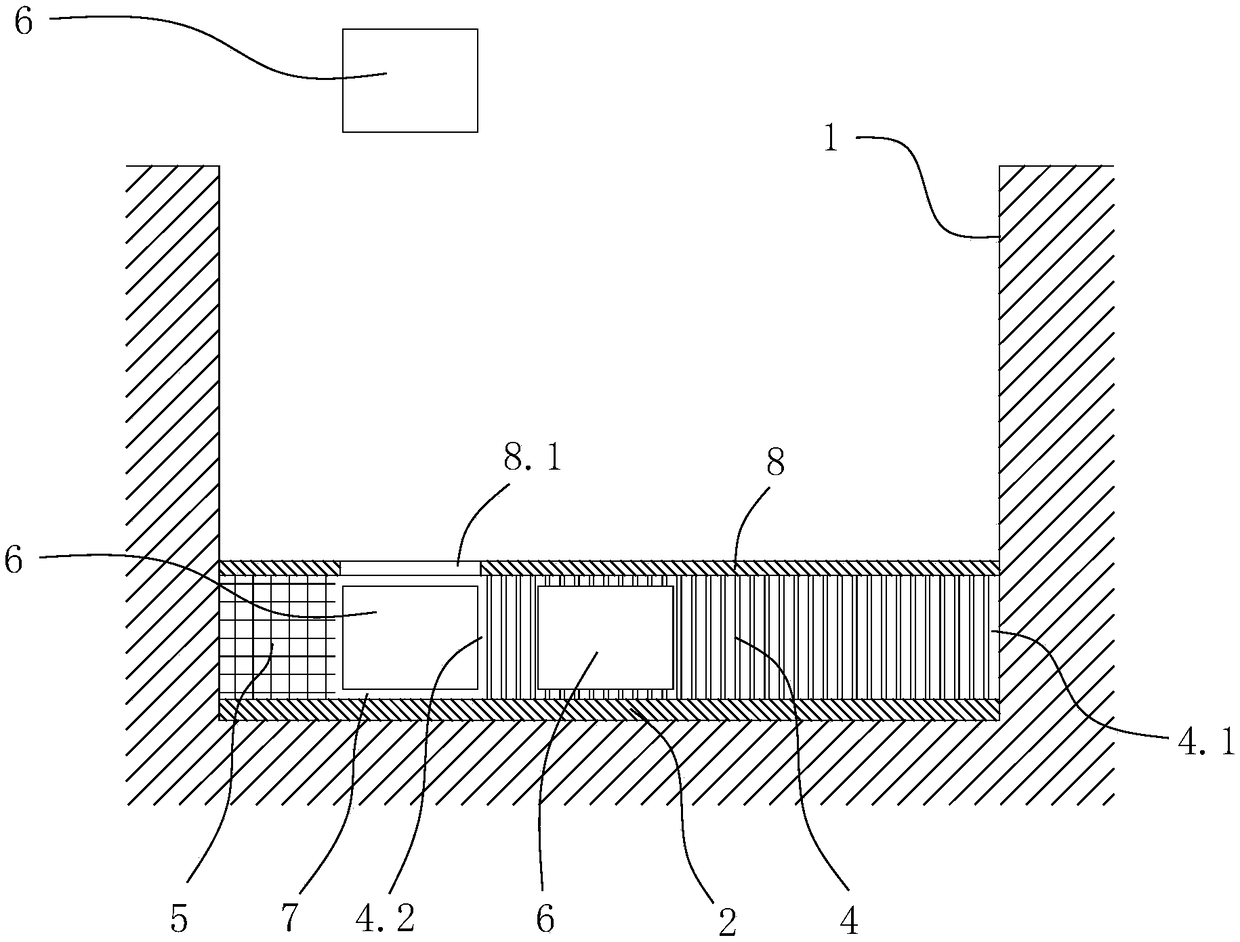

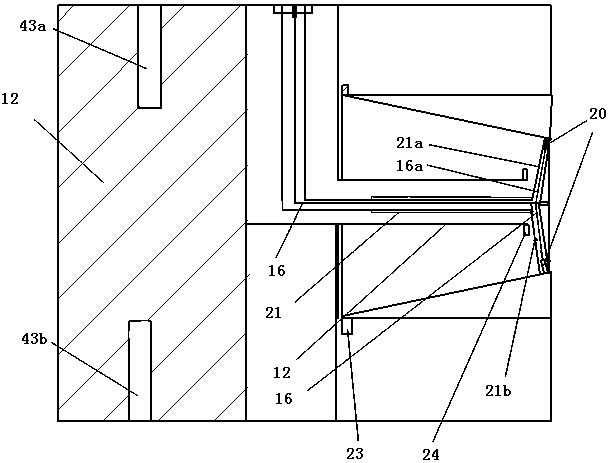

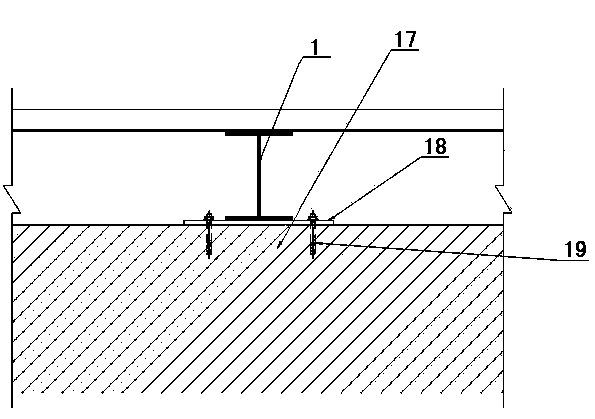

Falling plate connection structure and construction method thereof

PendingCN110042962AGuarantee welding qualityGuarantee the construction qualityFloorsArchitectural engineeringWelding

The invention provides a falling plate connection structure and a construction method thereof, and relates to the technical field of constructional engineering. The falling plate connection structurecomprises a supporting plate and a steel beam. The supporting plate and the steel beam can be prefabricated in a workshop, the accuracy of positioning can be ensured, the quality of welding can also be ensured, after the steel beam is directly installed on a site, the falling plate connection structure can be formed by pouring a first floor bearing plate on an upper wing plate and pouring a secondfloor bearing plate on the supporting plate, site redundant welding is not required, the construction quality and the construction speed can be ensured, the positioning accuracy and welding quality of components can be ensured, a great deal of welding work on the site can also be avoided, and the quality risk affected by site operation can be reduced.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

Foundation pit supporting composite retaining wall and construction method thereof

InactiveCN109914429ASimple construction operationShort construction periodArtificial islandsExcavationsEngineeringRetaining wall

The invention provides a foundation pit supporting composite retaining wall. The foundation pit supporting composite retaining wall comprises a plurality of pipe piles arranged in the circumferentialdirection, and a cement soil retaining wall part positioned between two adjacent pipe piles and connected with the pipe piles to form a circumferentially closed retaining wall, wherein a grouting structure corresponding to the cement soil retaining wall part is arranged on the pipe wall of the pipe pile. The foundation pit composite cement soil retaining wall is simple in structure, simple in overall construction operation, short in construction period and low in cost. The invention further provides a construction method for the foundation pit supporting composite retaining wall.

Owner:刘小檀 +1

Paint thinner

The invention discloses a paint thinner. The paint thinner comprises the following components by mass percent: 70 to 95% of dichloropropane, 2 to 10% of butyl acetate, 0 to 15% of diethylene glycol butyl ether, 0 to 10% of #1500 solvent, and 0 to 20% of butanone. By adopting the paint thinner, the air drying speed of the paint is adapted to the environmental temperature and the environmental humidity; the paint thinner is high in dissolubility, so that coatings can be fully absorbed; and the paint thinner is stable in performance and convenient to use.

Owner:CHANGZHOU GANYING CHEM TECH CO LTD

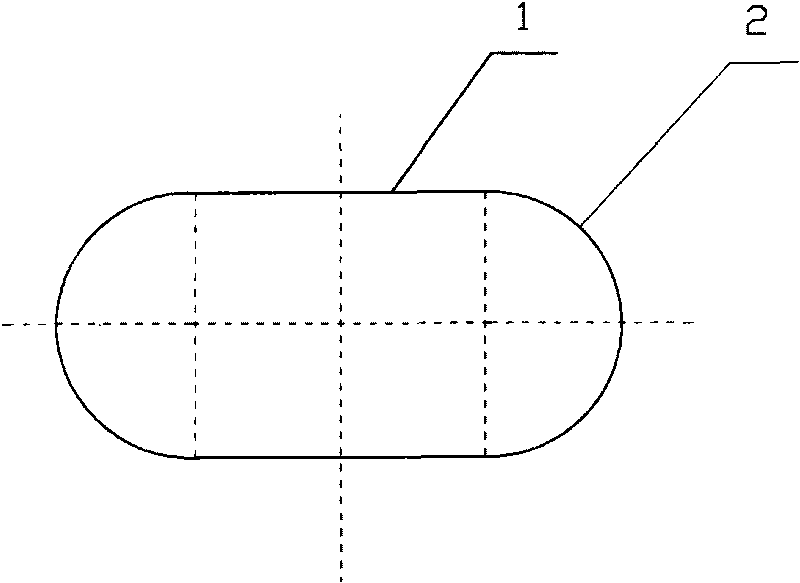

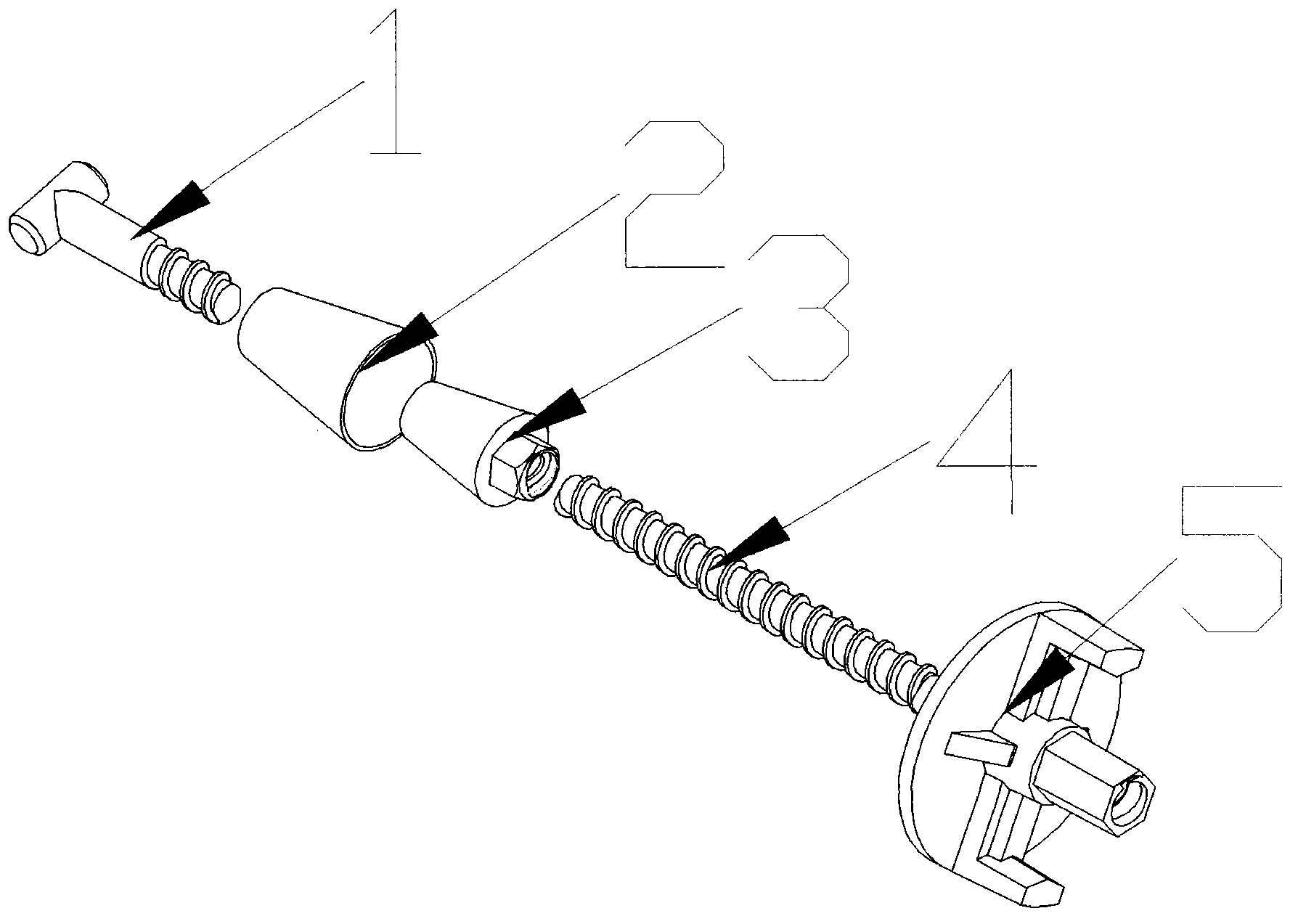

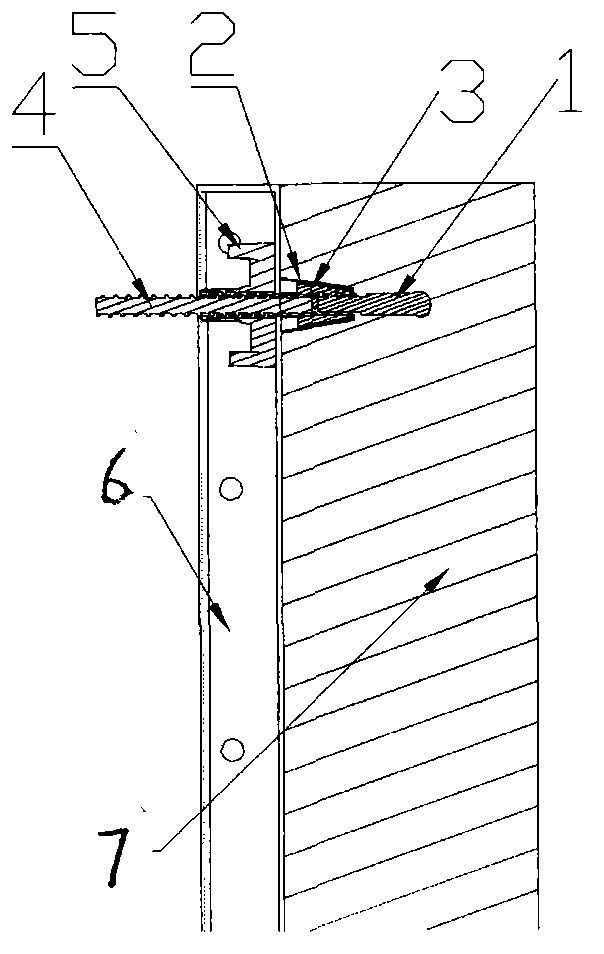

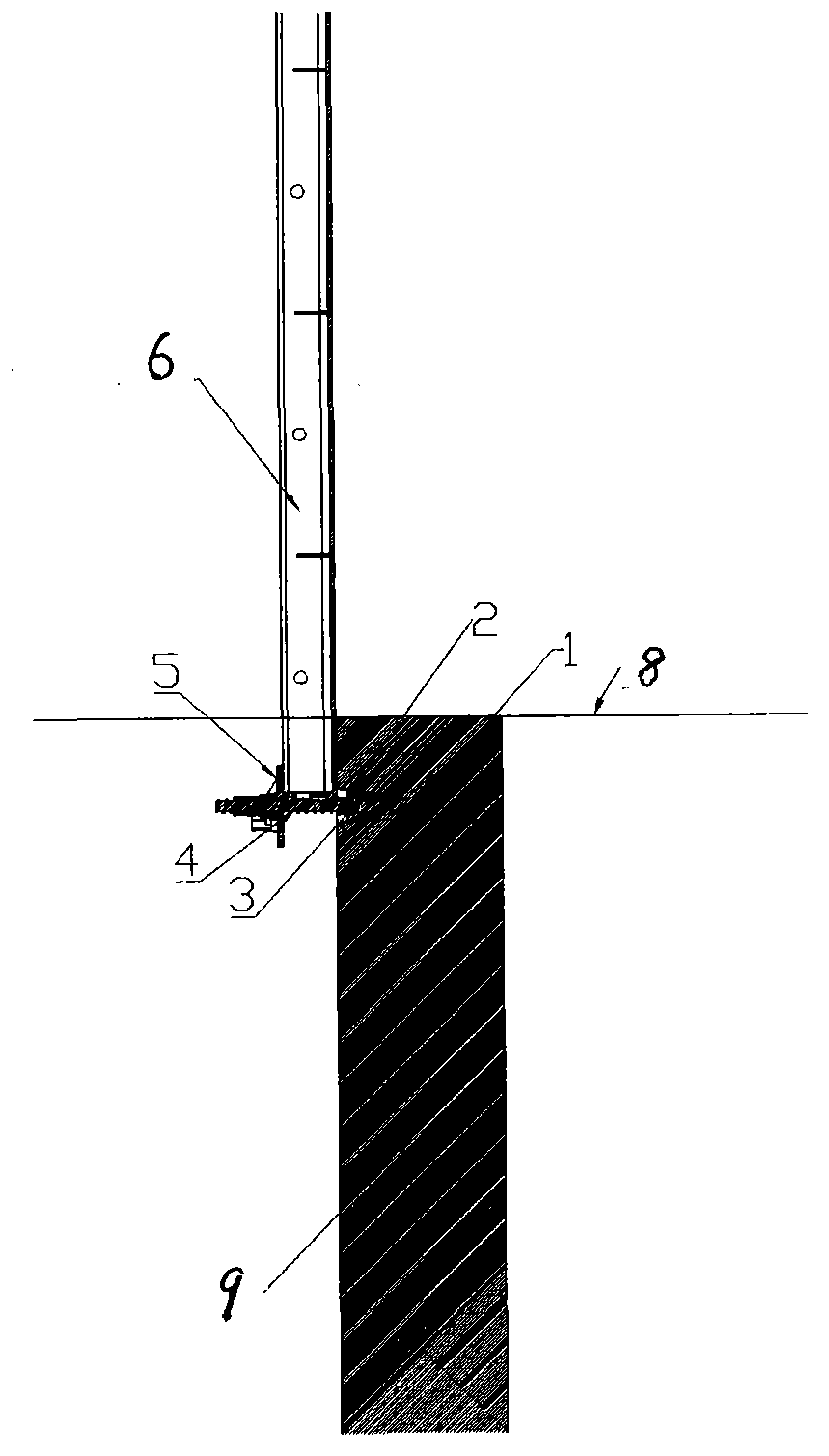

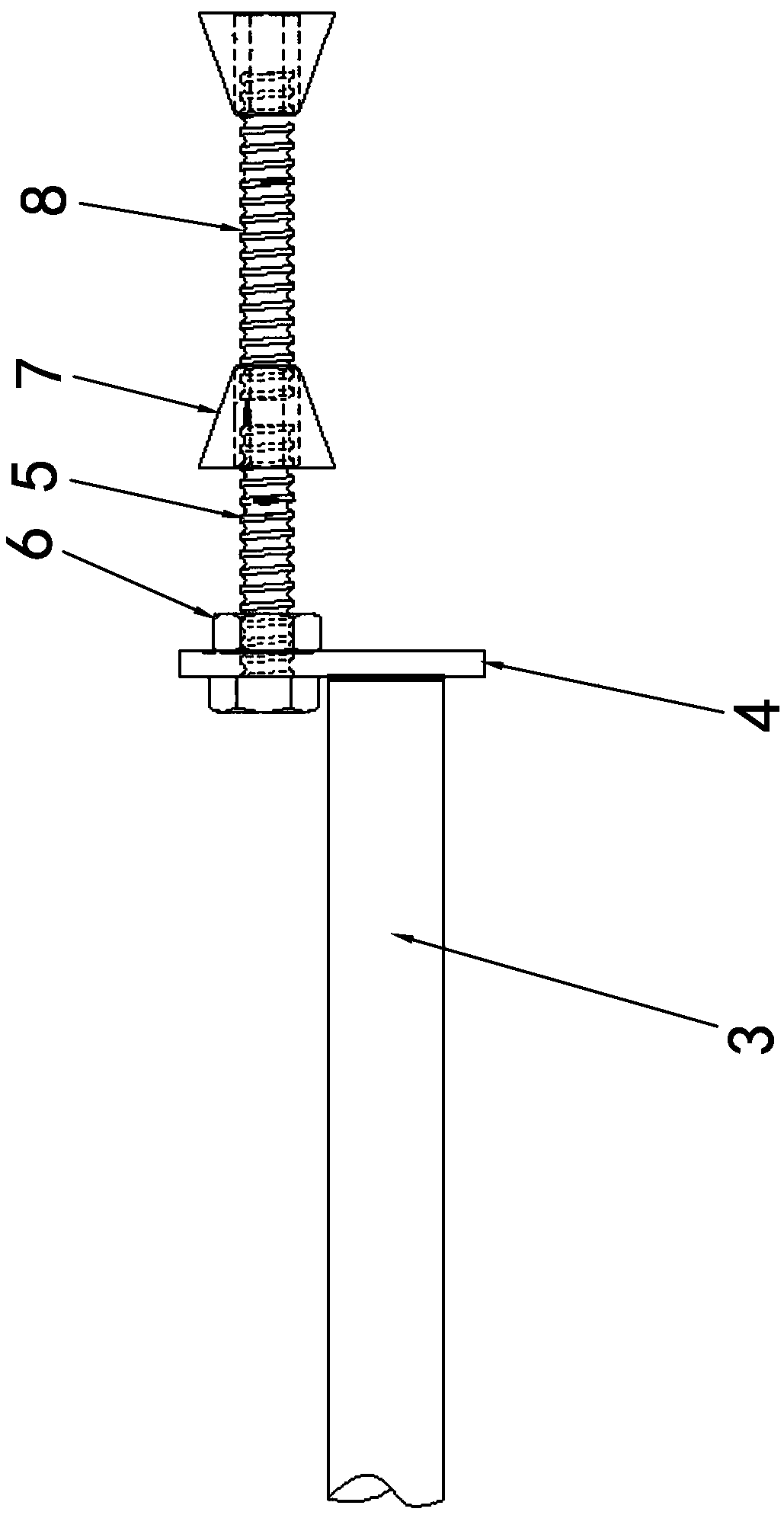

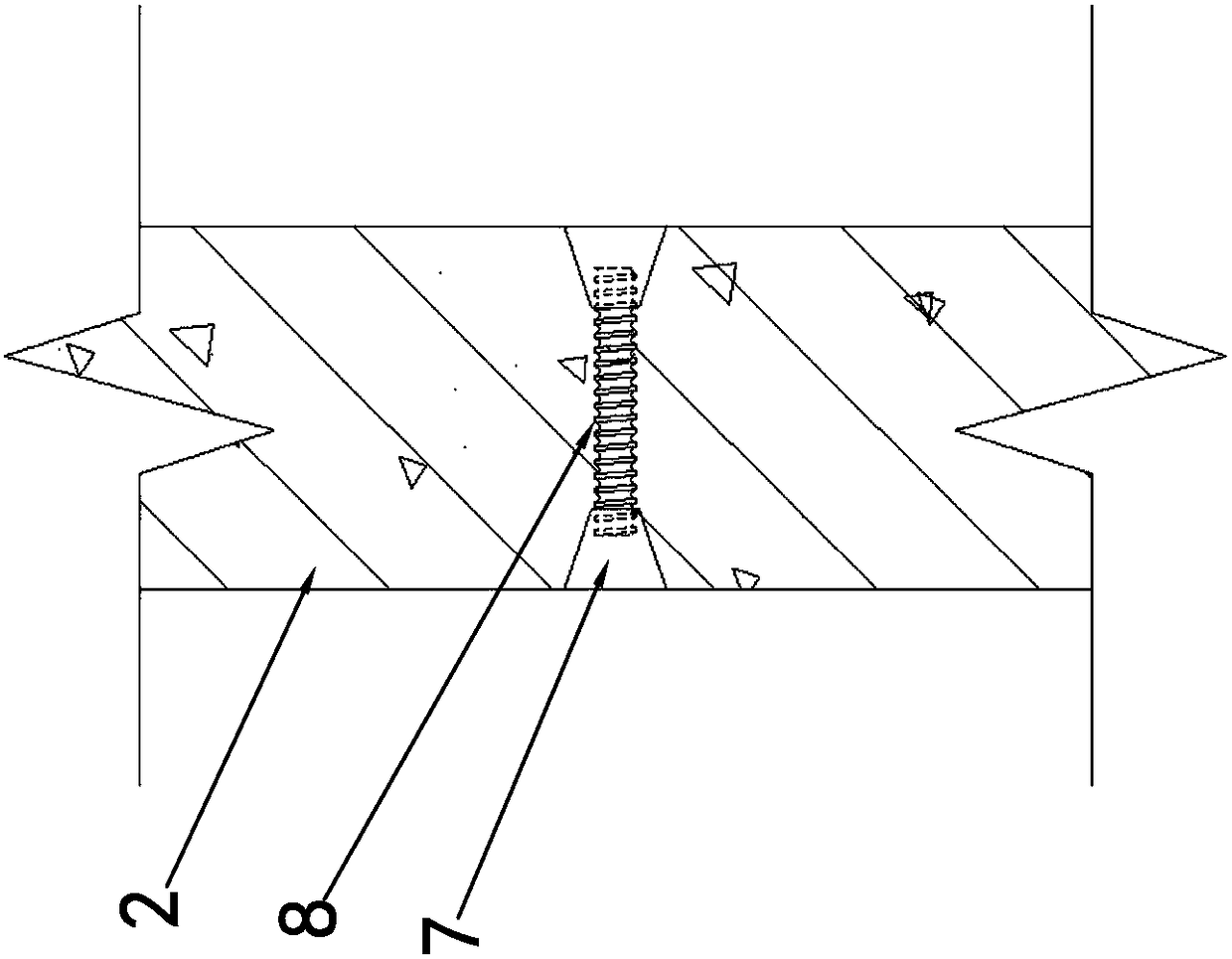

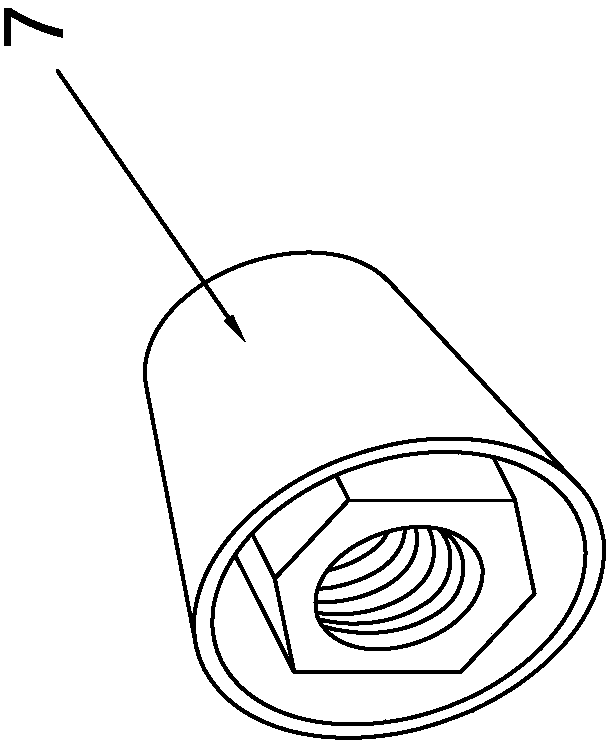

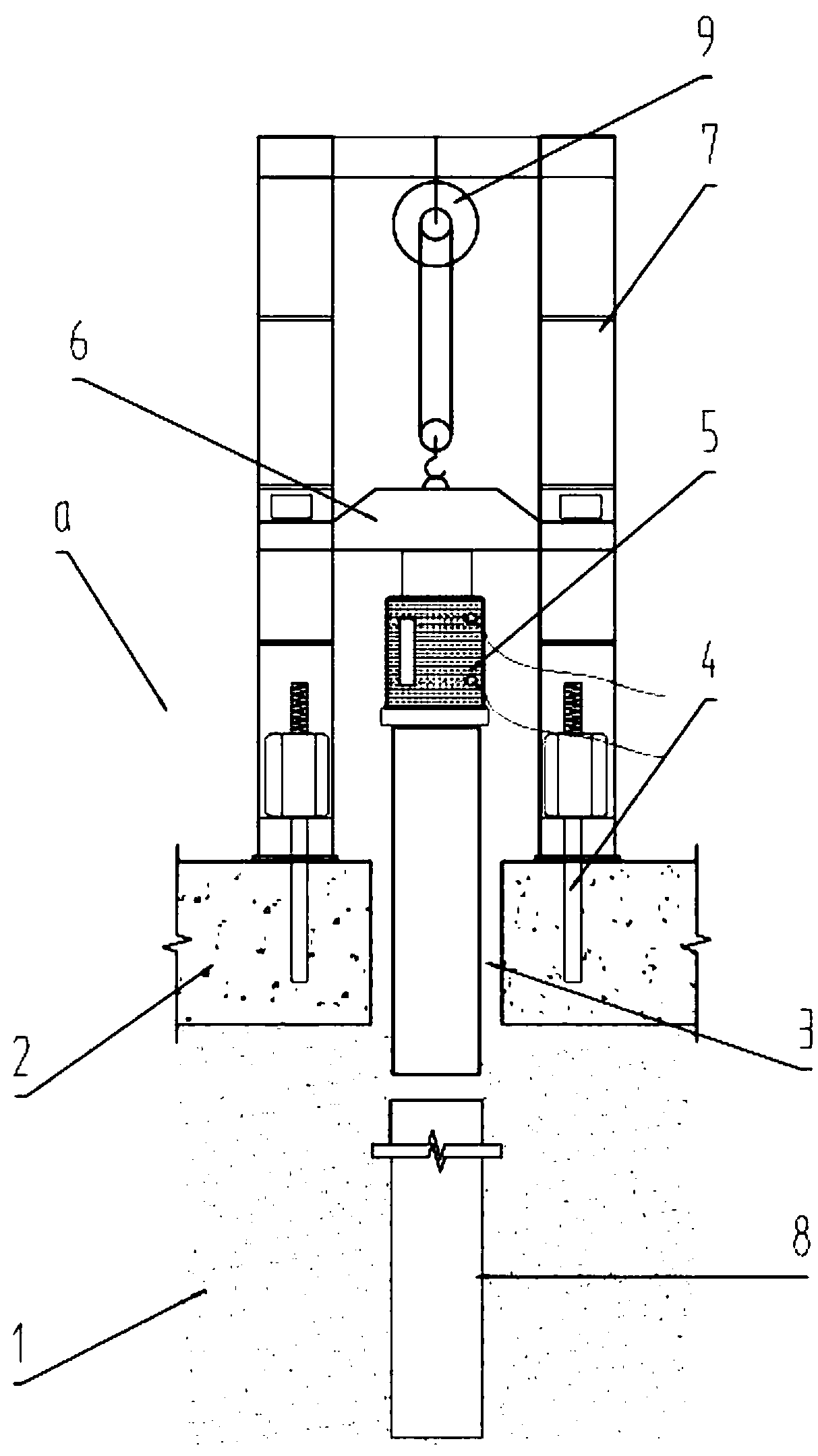

Novel outer wall joint straightness ensuring device and use method thereof

InactiveCN103912118AGuaranteed to be straightGuaranteed construction speedForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksBiomedical engineeringEnvironmentally friendly

The invention provides a novel outer wall joint straightness ensuring device which is convenient to use and environmentally friendly, saves energy, can be reused, and is high in strength and high in efficiency. The technical scheme is that the device is composed of a location screw (1), a plastic sleeve (2), a location cone body (3), a split screw (4) and an E-shaped nut (5), wherein the location cone body (3) enables the location screw (1) and the split screw (4) to be connected, the plastic sleeve (2) sleeves the cone body (3) tightly, and the E-shaped nut (5) is connected with the split screw (4) to form a linear whole. A use method of the device is further disclosed.

Owner:青岛两仪环保工程有限公司

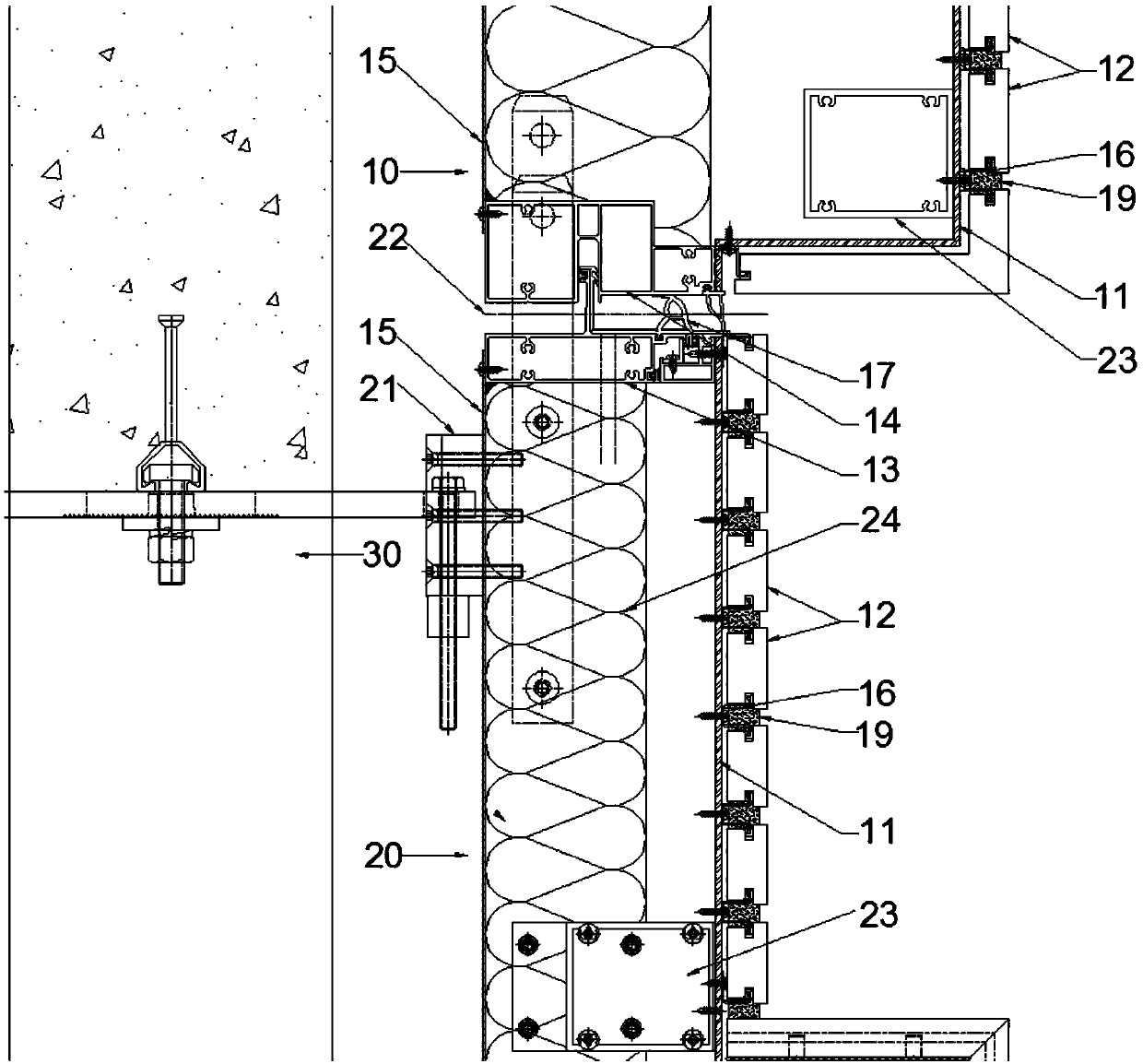

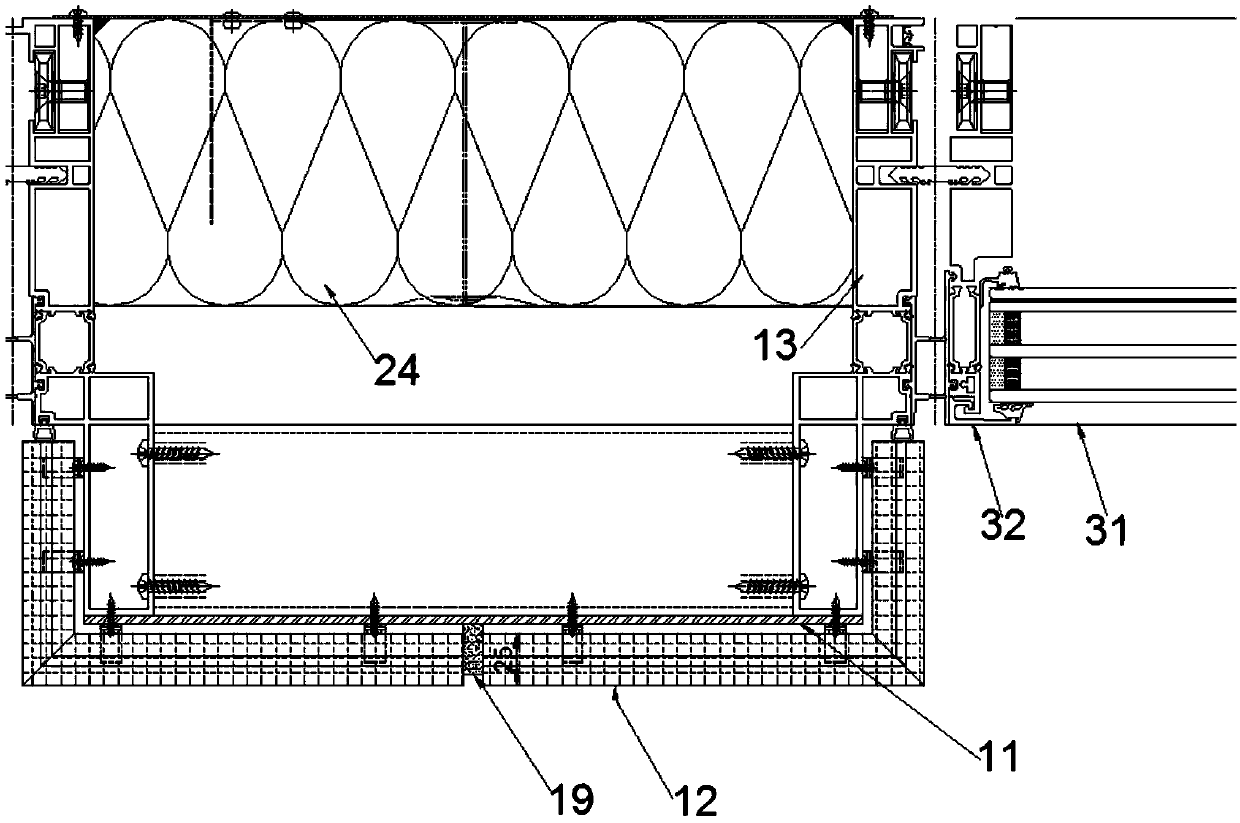

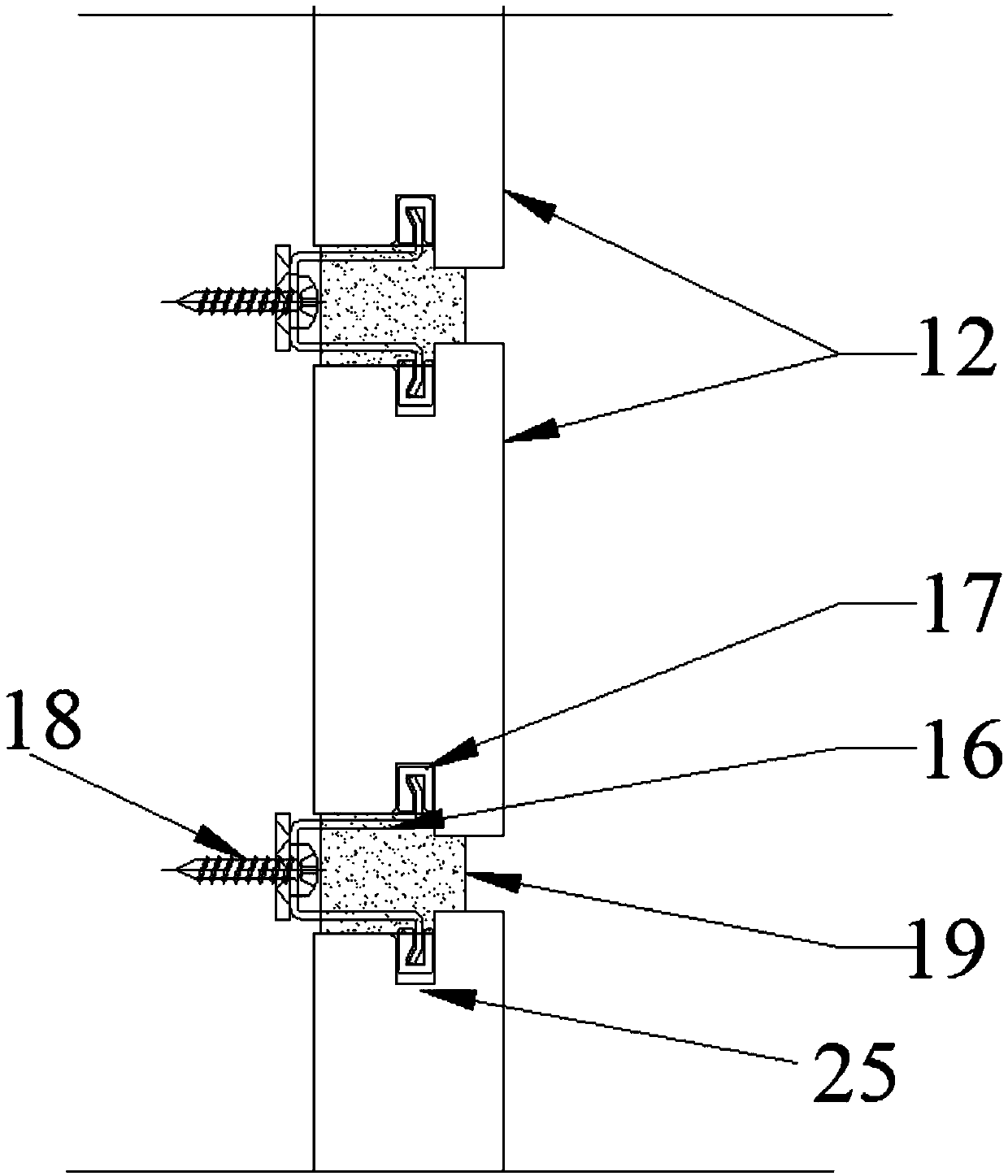

Unit type face brick system

ActiveCN109594731ALow costImprove on-site construction periodCovering/liningsStress concentrationBrick

The embodiment of the invention discloses a unit type face brick system. The unit type face brick system comprises a plurality of upper unit systems and lower unit systems which are connected in sequence vertically, wherein unit expansion joints are arranged between the upper unit systems; the unit upper transverse frame aluminum profiles of the lower unit systems are inserted into the unit lowertransverse frame aluminum profiles of the upper unit systems through the unit expansion joints so as to connect the upper unit systems and the lower unit systems; and EPDM adhesive tapes fill betweenthe unit upper transverse frame aluminum profiles and the unit lower transverse frame aluminum profiles inside the unit expansion joints. The unit type face brick system disclosed by the invention isnaturally transited with traditional unit systems and combined into one body, a uniform watertight and airtight system is formed, the installation construction is convenient and quick, the installation period is easy to control, the site operation cost and the construction cost are reduced, stainless steel hooks are used for being combined with the EPDM adhesive tapes, the damage of slotting caused by stress concentration of the hooks is avoided, the heat stress of face bricks also can be absorbed, the changeability of a single face brick is facilitated, and the maintenance cost of a board isreduced.

Owner:武汉凌云建筑装饰工程有限公司

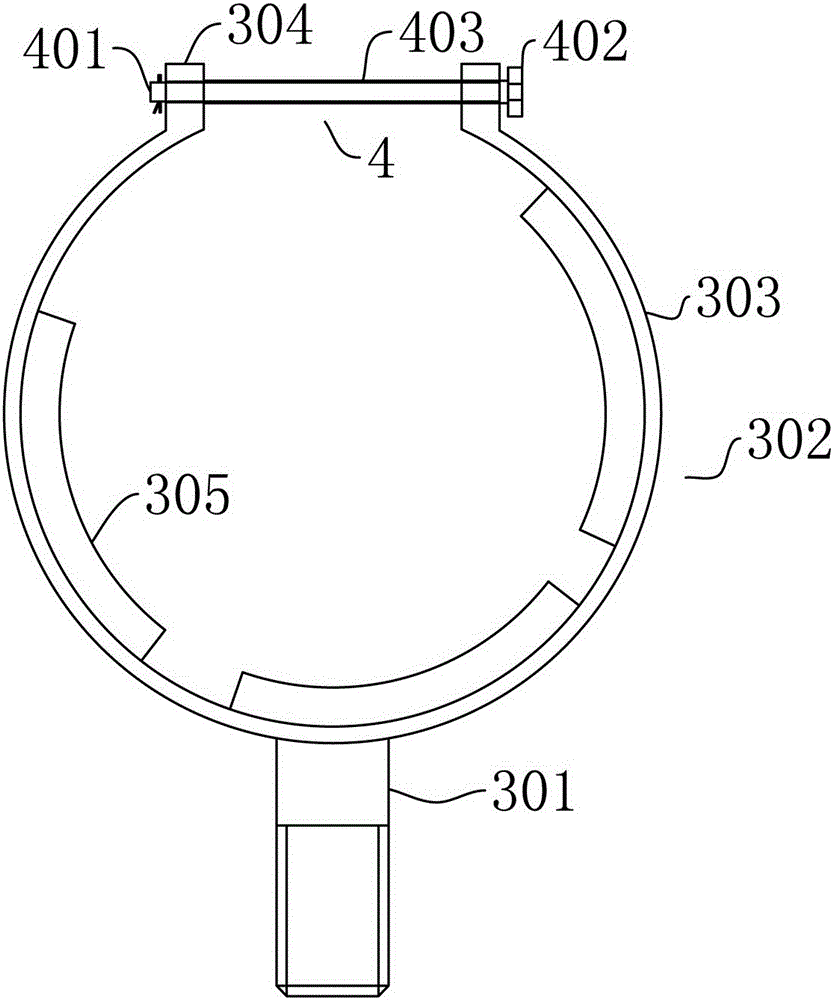

Cross-direction supporting pipe fixing device

InactiveCN106522383AReduce difficultyGuaranteed construction speedBuilding constructionsEngineeringBlock match

The invention provides a cross-direction supporting pipe fixing device. The problem that since the radian of the end portion of a supporting pipe is difficult to ensure, the building period is long, and work efficiency is affected is solved. The cross-direction supporting pipe fixing device comprises a rigid fixed part, and a sliding groove is formed in the middle of the fixed part in the length direction of the fixed part. The sliding groove is in sliding connection with a plurality of fixed bases in a rotating mode. Each fixed base comprises a sliding block matched with the sliding groove, and the sliding block is provided with an annular hoop. Each hoop comprises an outer ring which is located on the outer circle and made of an elastic material, wherein the upper end of the outer ring is provided with an opening, convex lugs extend outwards from the two ends of the opening, an adjusting bolt is arranged between the two convex lugs, one end of the adjusting bolt is fixedly connected with one of the convex lugs in a rotating mode, and a plurality of arc inner circle portions are fixedly connected to the inner circle of the outer ring at intervals. The cross-direction supporting pipe fixing device ensures the building speed and greatly improves work efficiency.

Owner:河南申发企业管理有限公司

Construction method for preformed end bearing pile in lava region

InactiveCN103306275AQuality assuranceSolve the problem of usingBulkheads/pilesReinforced concreteEngineering

A construction method for a preformed end bearing pile in a lava region belongs to the technical field of construction of a pile foundation of a large-tonnage road, bridge, or house in the building industry. The invention provides the construction method for the preformed end bearing pile in the lava region. The construction method for the preformed end bearing pile in the lava region is implemented according to the following sequences: (1) forming a pore; (2) pouring a filler; and (3) pressing the pile. A static pressure large-tonnage pile machine is used to press a reinforced concrete preformed end bearing pile in a CFG (cement flyash gravel) pile in the pore till a bearing stratum set in the design, and two or more reinforced concrete preformed end bearing piles are pressed according to the design requirements to complete the construction. The method provided by the invention is simple in operation, easy in implementation, and wide in scope of geological environments, both the quality of the pile and the construction speed are guaranteed, the cost is also lowered, and the difficult problem of application of the end bearing pile of the static pressure large-tonnage preformed pile in the lava region is solved.

Owner:潘建杰

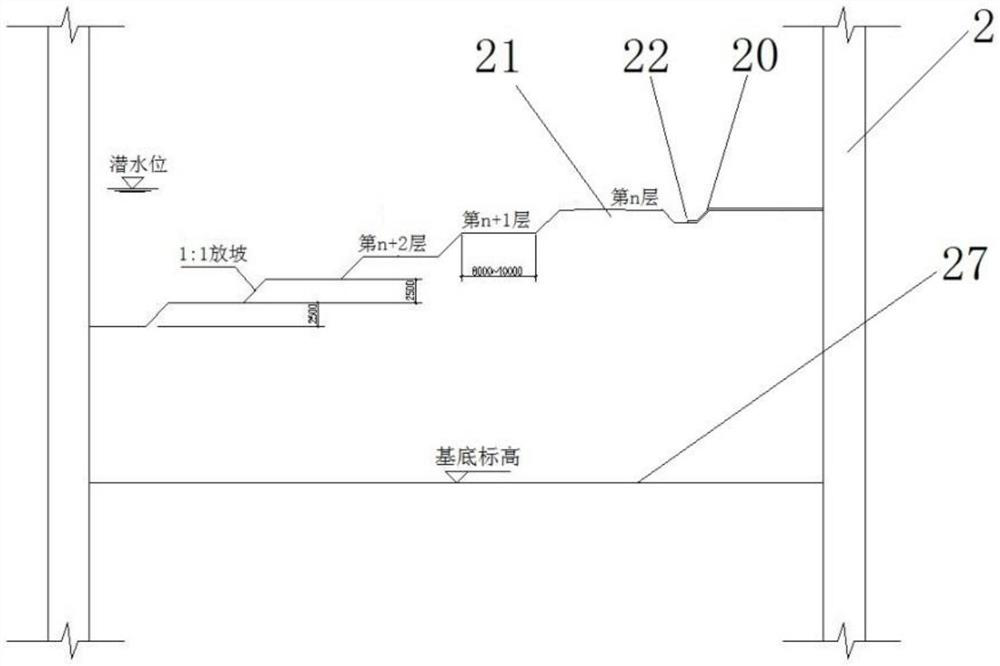

Foundation pit dewatering construction method in stratum containing laminar flow supply source

ActiveCN114250798AShort working hoursReduce usageFoundation engineeringSewer pipelinesWater collectionAquifer

The invention belongs to the field of foundation pit dewatering excavation construction, and particularly relates to a foundation pit dewatering construction method in a stratum containing a laminar flow supply source. According to the method, a foundation pit is excavated in a layered mode, and when an aquifer is excavated, the aquifer is divided into two or more excavation sections for dewatering and excavation; according to the stratum water replenishing speed of each excavation section, the following modes are adopted for dewatering the corresponding excavation section: (1) firstly, tube well pre-dewatering is adopted, and then water collection pit open drainage continues to drain water for dewatering; in the second mode, tube well pre-precipitation is adopted firstly, before tube well pre-precipitation is finished, water collecting pit open drainage is adopted for collaborative precipitation, and after collaborative setting time is finished, water collecting pit open drainage is adopted for precipitation; (3) tube well pre-precipitation is adopted firstly, before tube well pre-precipitation is finished, water collection pit open drainage collaborative precipitation is adopted, and tube well precipitation at least lasts until excavation of the excavation section is completed; and the stratum water replenishing speeds of the excavation sections corresponding to the mode 1, the mode 2 and the mode 3 are sequentially increased, and low-cost and environment-friendly rainfall in the construction period is achieved.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Connecting structure for wall scaffold

PendingCN108316636AEasy to pre-processShorten the construction periodScaffold accessoriesFalseworkEconomic benefits

The invention discloses a connecting structure for a wall scaffold. The connecting structure for the wall scaffold comprises embedded parts and auxiliary parts, the embedded parts and the auxiliary parts are embedded in a wall, the embedded parts do not protrude from the wall, and the auxiliary parts are provided with connecting rods which can be connected to the scaffold in an overlapping mode. The embedded parts are provided with screw holes, the auxiliary parts are provided with bolts, and the bolts are connected with the screw holes, so that the auxiliary parts are detachably fixed on theembedded parts. The connecting structure has the advantages of high safety performance, fast construction period and good economic benefits. The connecting structure for the wall scaffold is used in the construction field of concrete walls, fair-faced concrete walls and fair-faced fence slabs, and so on.

Owner:GUANGDONG JINHUIHUA GROUP

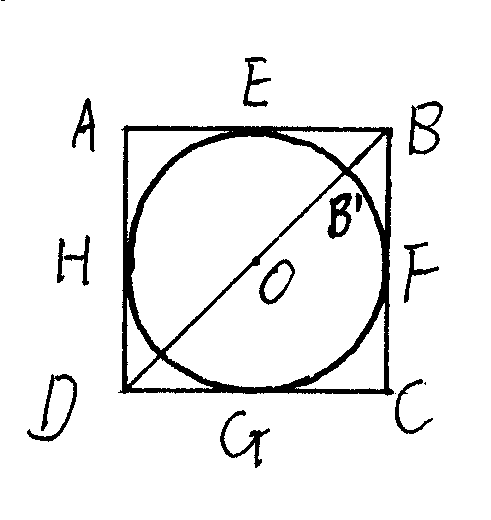

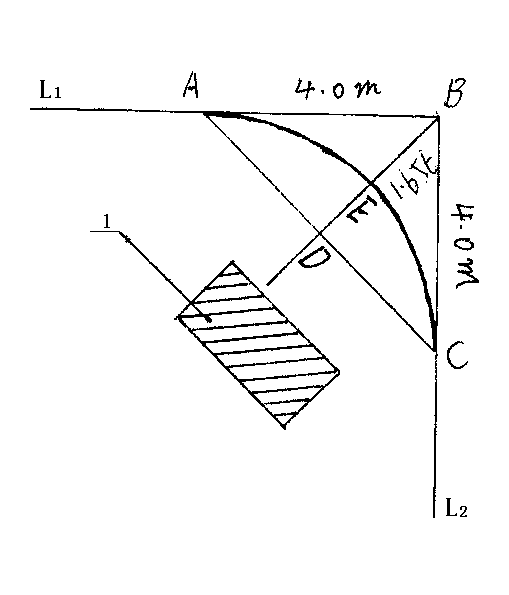

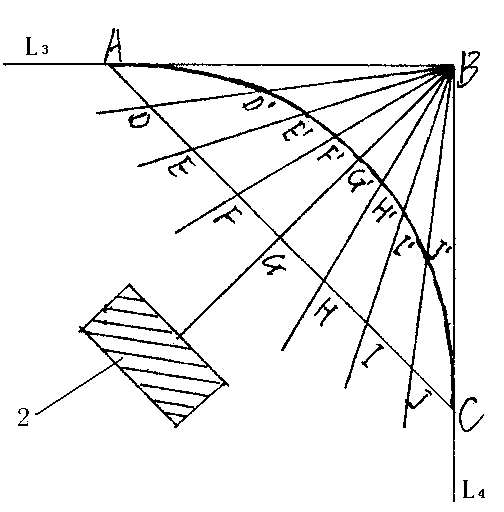

Method for determining tracks of arcs in road construction

InactiveCN103255691AEffective drawingGuarantee the construction qualityRoadwaysStructural engineeringRoad construction

The invention discloses a method for determining tracks of arcs in road construction. The method comprises the following steps of: determining a reference value of a distance from a corner point of a road to a midpoint of an arc line for the design of a radius of turning circle, applying the reference to the determination of the track points of construction arc lines with the designed radii of turning circle within 10m, and applying the reference value to the determination of the track points of construction arc lines with the designed radii of turning circle greater than 10m. According to the method, the problem that the construction arc lines cannot be drawn by using center points due to obstacles when the arc lines with radii of turning circle prescribed by construction drawings are drawn on the sites in road construction can be solved.

Owner:许顺周

Efficient construction structure and method for micro steel pipe pile

PendingCN109056747AGuaranteed construction speedIncrease pile lengthExcavationsDrill bitFrictional resistance

The invention discloses an efficient construction structure for a micro steel pipe pile. The efficient construction structure comprises an anchor rod static pressure pile construction mechanism and asteel pipe pile construction mechanism; the anchor rod static pressure pile construction mechanism comprises a foundation arranged on pile periphery soil, a pile pressing hole is formed in the foundation, and a reaction frame is mounted on the position, corresponding to the pile pressing hole, of the foundation through a plurality of anchor rods; a baffle is mounted on the reaction frame, and a jack is mounted on the baffle; and the steel pipe pile construction mechanism comprises a drilling rig, a rotating device, a geological pipe and a drilling bit. The efficient construction structure hasthe beneficial effects that firstly, anchor rod static pressure piles are constructed on to-be-supported positions of the ground foundation, a foundation pit and a slope, then the steel pipe pile is constructed, due to the wall protecting effect of the anchor rod static pressure piles, drilling of the steel pipe pile is not subjected to frictional resistance of a soil mass within the pile length range of the anchor rod static pressure piles, in this way, the construction speed of the steel pipe pile is ensured, the pile length can be increased, it is ensured that the steel pipe pile reaches abearing layer, and the efficient construction structure is especially suitable for a loess area or a large-thickness filling area.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

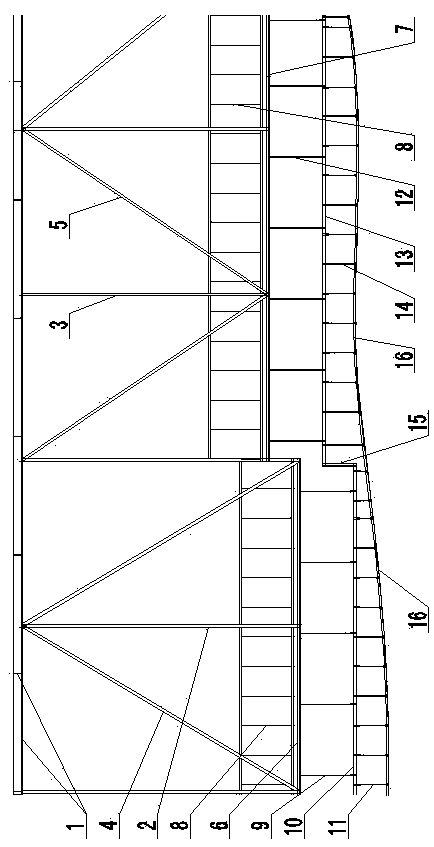

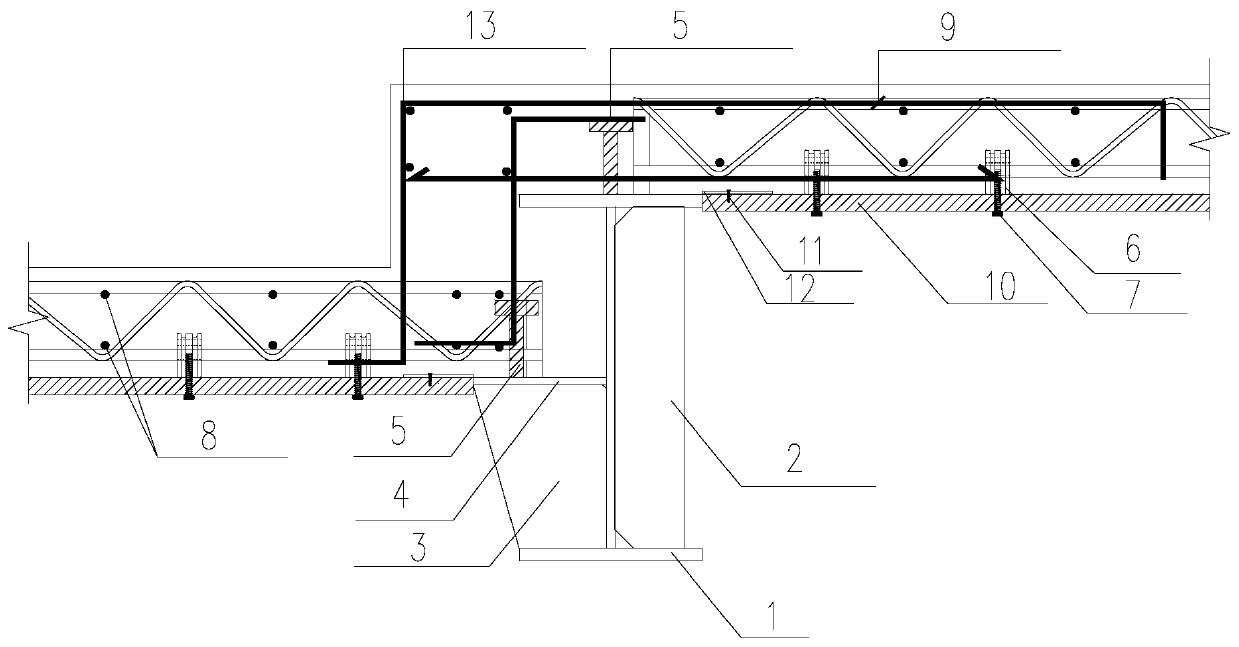

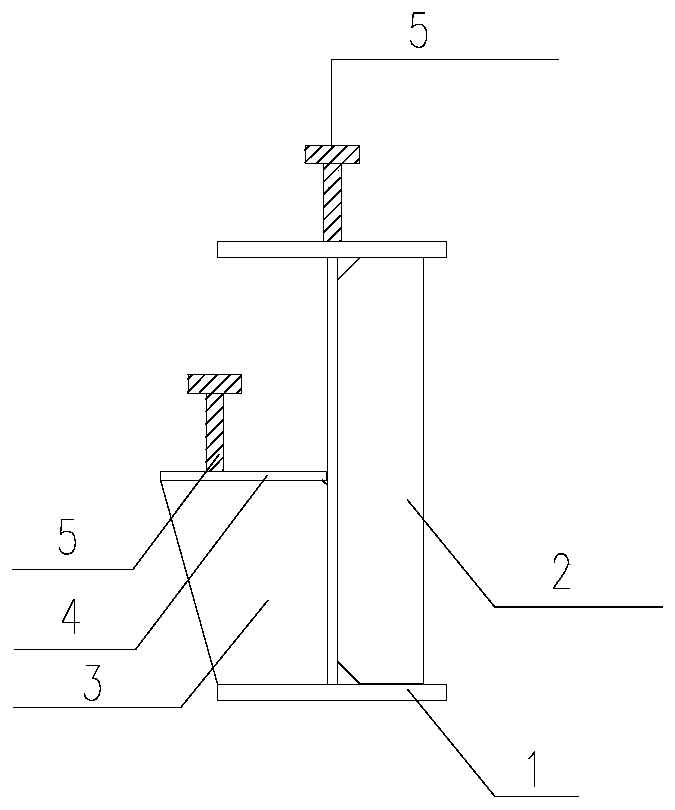

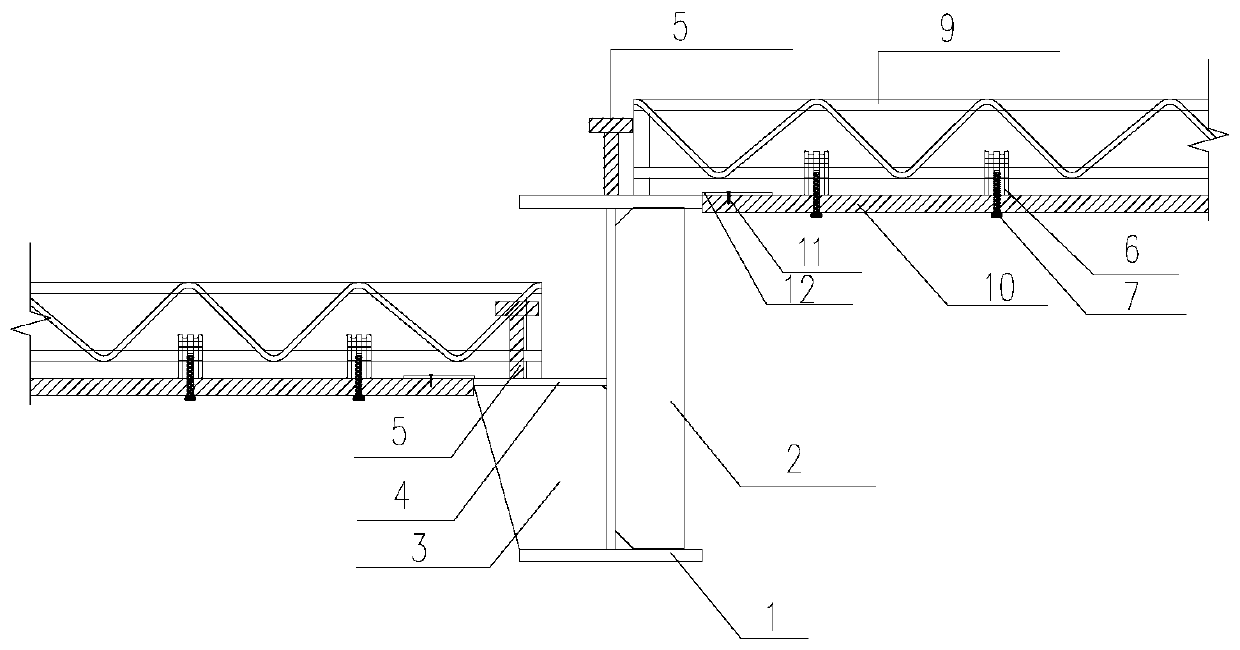

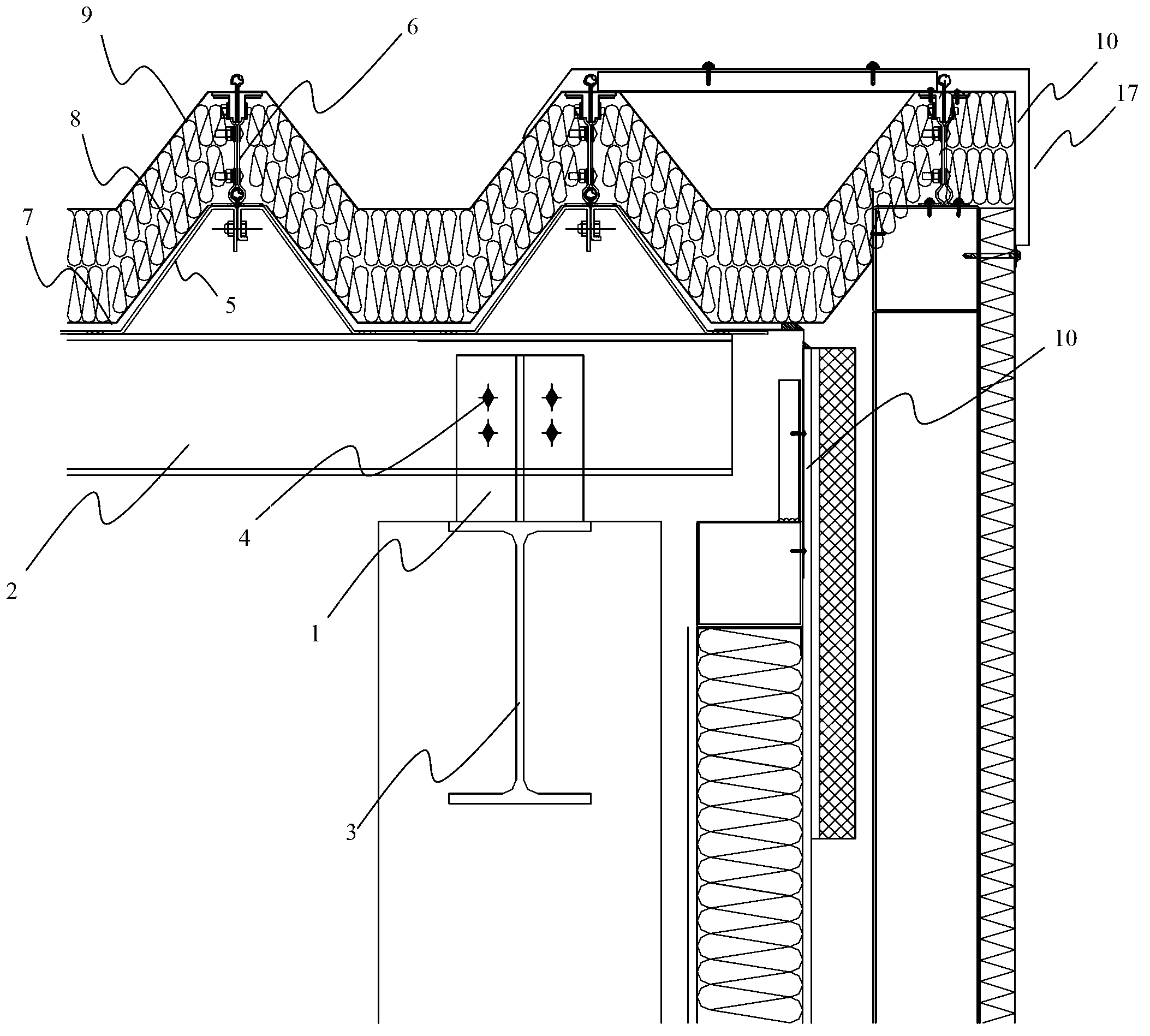

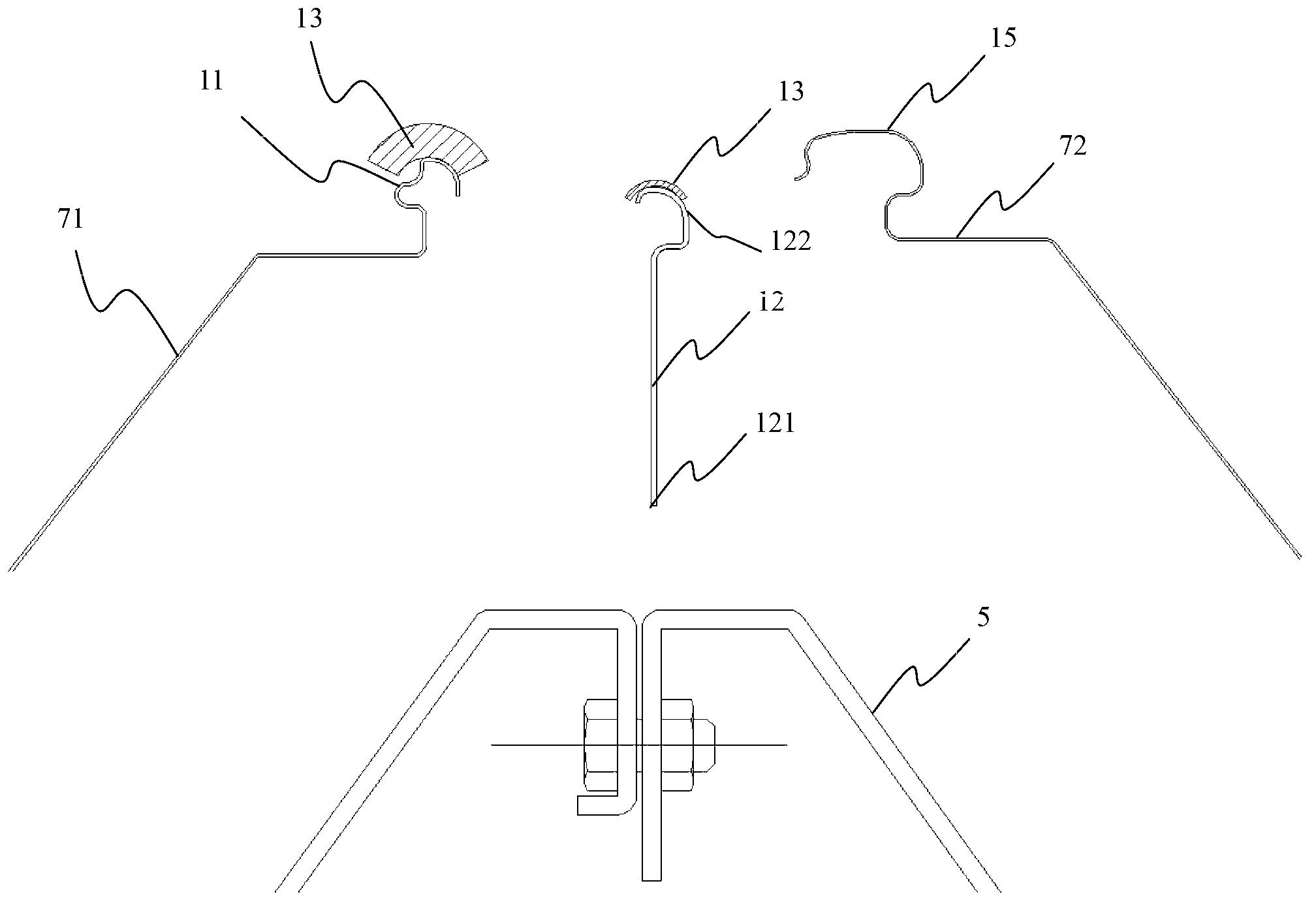

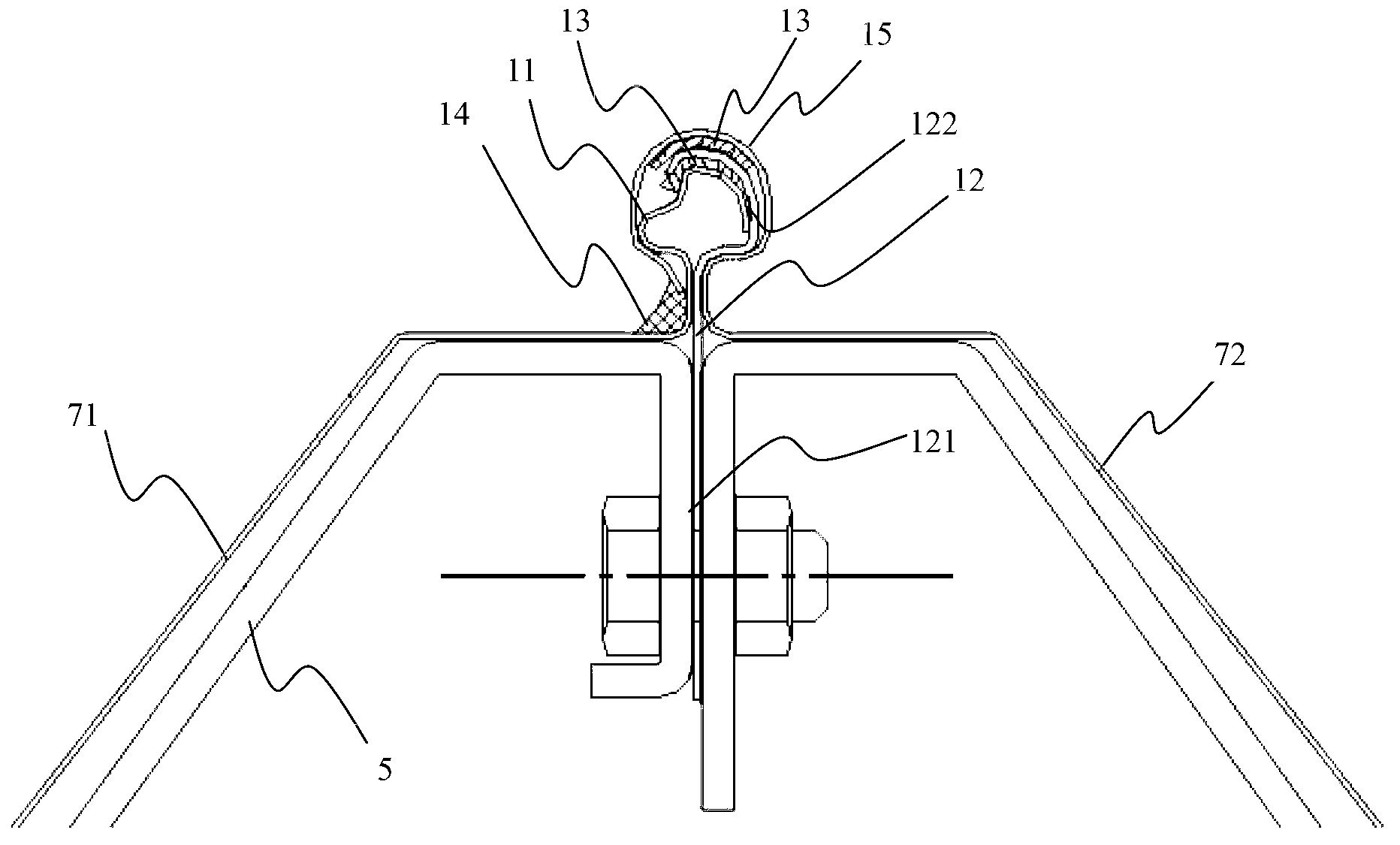

Air-tight heat insulation metal roof and construction method thereof

ActiveCN102409811BHigh airtight and heat insulationGuaranteed construction speedRoof covering using slabs/sheetsRoof toolsArchitectural engineeringGlass wool

The invention discloses an air-tight heat insulation metal roof and a construction method thereof. The air-tight heat insulation metal roof comprises a roof truss, a plurality of purline supports, a plurality of purlines, a plurality of metal bottom plates, a plurality of metal top plates and glass wool, wherein the purline supports are welded on the truss at fixed intervals; the plurality of purlines are fixed on the purline supports through bolts; the adjacent metal bottom plates are mutually buckled and fixed on the purlines through a plurality of fixed bases; the adjacent metal top plates are mutually buckled and fixed on the metal bottom plates through a heat insulation metal fixed seat; and the glass wool is spread between the metal bottom plates and the metal top plates. By adopting the air-tight heat insulation metal roof and the construction method thereof, air-tight heat insulation construction of plant roofs of high-technology industries such as electronics, biological pharmacy and the like is realized; and the air-tight heat insulation metal roof and the construction method have the advantages of high construction efficiency, low construction cost and a small number of construction processes.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

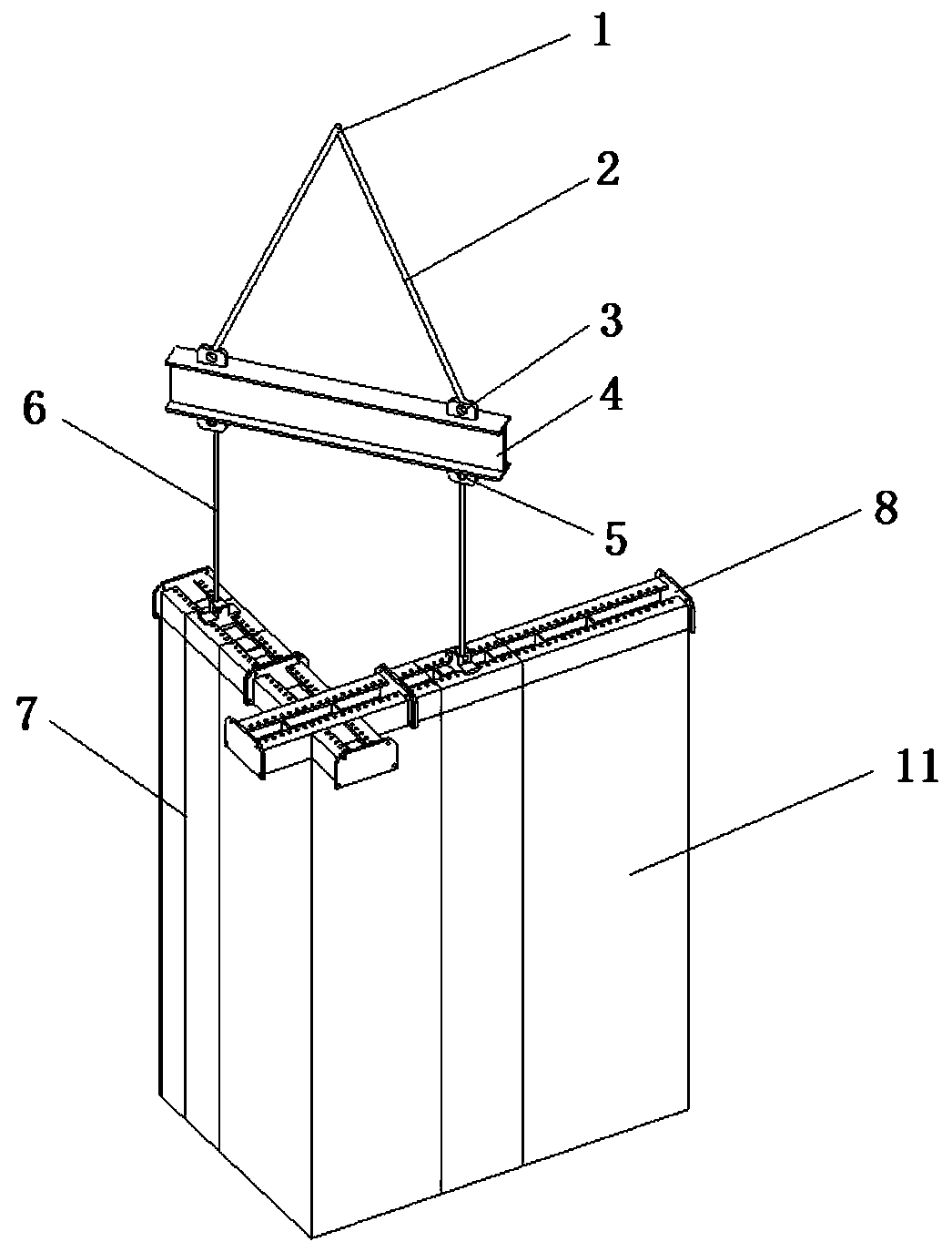

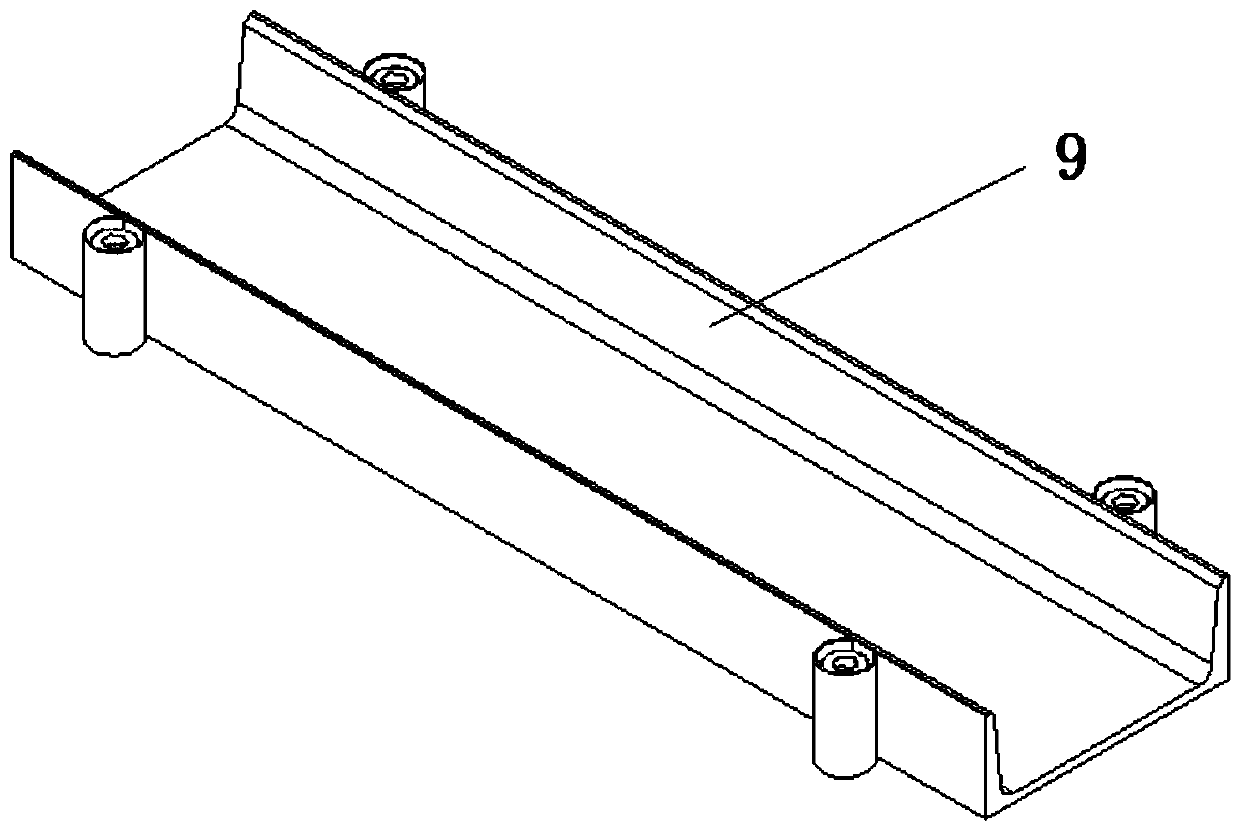

Concrete block masonry component fabricated construction method and construction device

PendingCN111186763ARealize hoistingFast assembly constructionBuilding material handlingLoad-engaging elementsArchitectural engineeringGravity center

The invention provides a concrete block masonry component prefabricated construction method and prefabricated construction device. According to the method, a binding beam, a block wall piece and a base are bound together in the vertical direction through binding ropes; the horizontal position of a lifting hook is determined; the positions of the two lifting points A1 and A2 are selected in a planview, so that the gravity center of the block wall piece is located on the connecting line of the two lifting points A1 and A2, and it is guaranteed that the distances between the two lifting points A1 and A2 and the gravity center are equal; the position of a sliding block on the binding beam is fixed through a bolt pin, and the length between the two lifting points A1 and A2 is measured and recorded; and the lifting hook is connected with a balance beam through a lifting rope and then connected with the binding beam through a lower lifting rope for lifting. The method solves the problem thatthe operation of respectively adjusting the sliding blocks on the balance beam and the binding beam every time in an existing two-point hoisting method is tedious, hoisting can be implemented only byadjusting the sliding blocks on the binding beam and setting the positions of hoisting points on the sliding blocks, and the method is a feasible, simple, convenient, safe and efficient constructionmethod.

Owner:HARBIN DACHENG GREEN BUILDING TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com