Waterborne mobile concrete stirring boat in inland waterway

A technology for concrete and mixing ships, which is applied in mixing plants, motor vehicles, mixing operation control, etc., can solve the problems of changing the construction technology of concrete in inland waterways, and achieve the goal of suitable for large-scale promotion and application, reasonable design and large demand. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

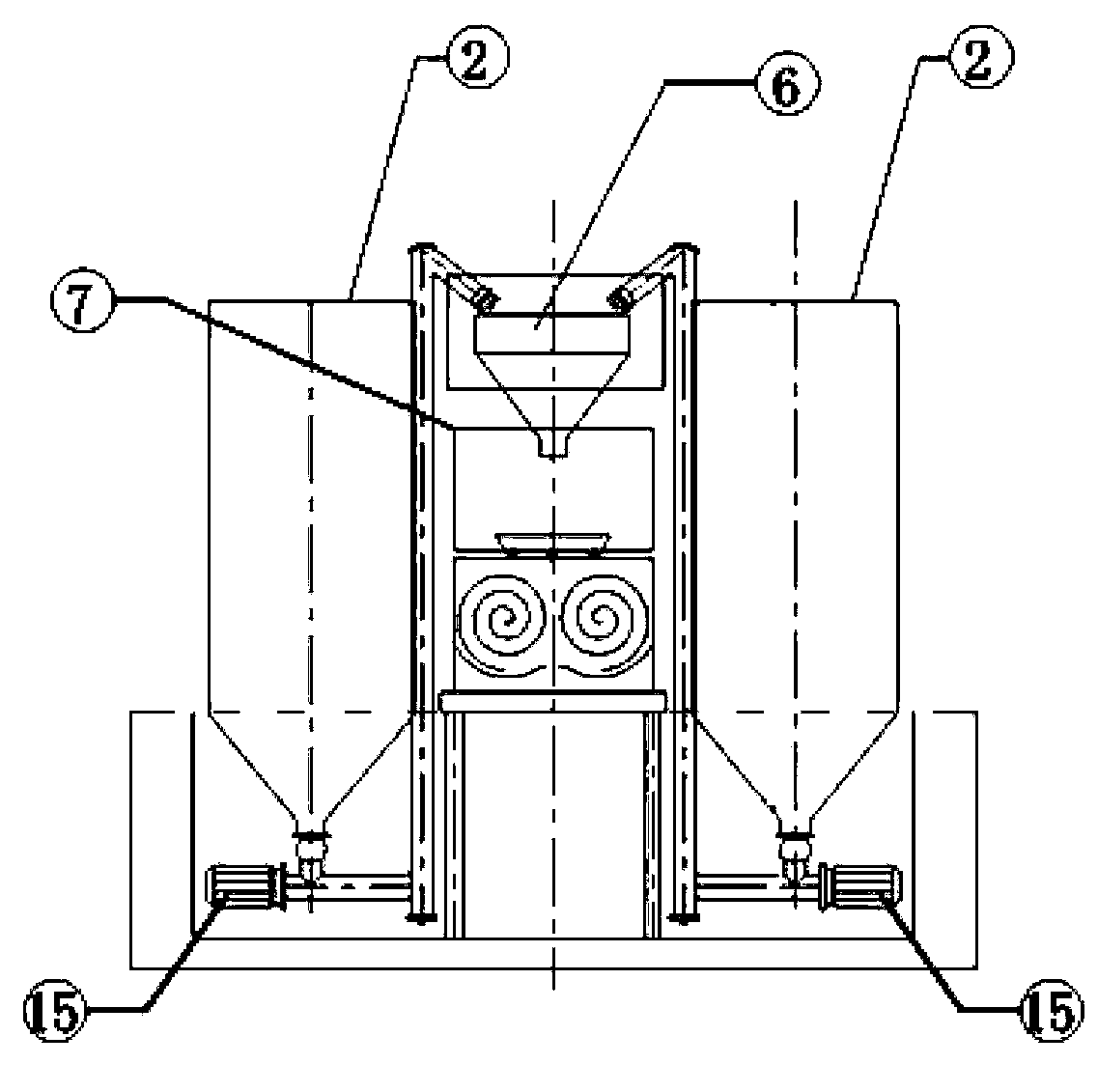

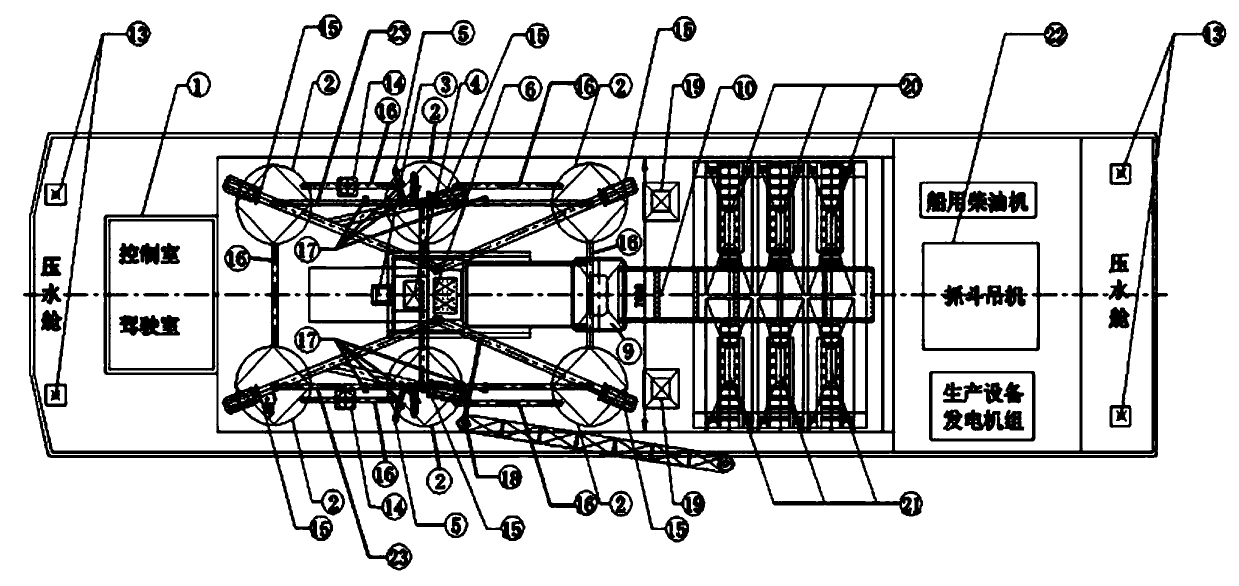

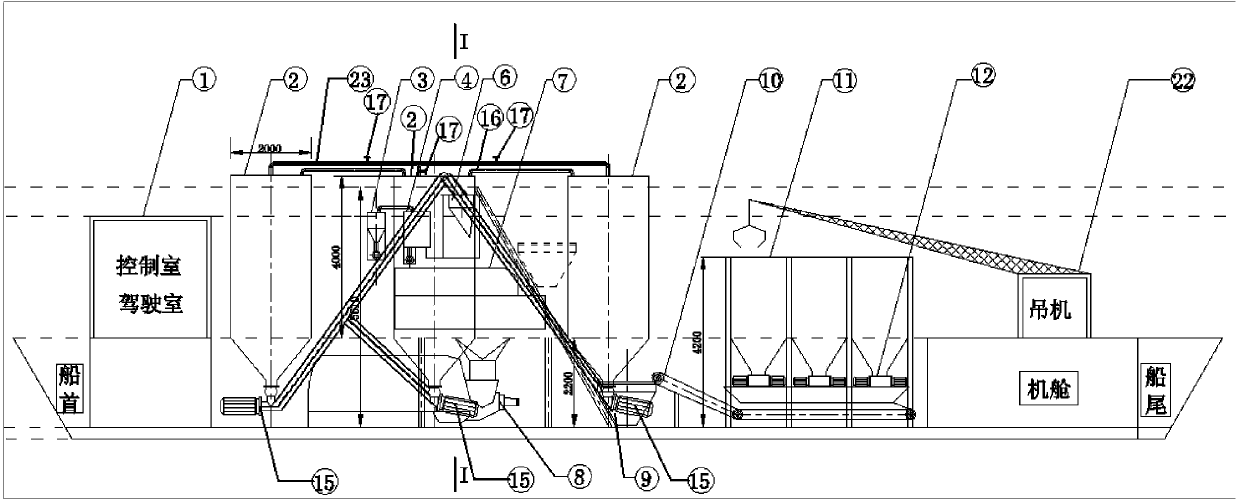

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0024] Such as Figure 1-3 As shown, a mobile concrete mixer ship for inland waterways, the water mobile concrete mixer ship for inland waterways is designed according to the inland waterway level 4 standard, the water mobile concrete mixer ship for inland waterways is mainly composed of a mixing system, a material batching system, a material conveying system, The material metering system, electrical control system, dust removal device and other auxiliary facilities are composed of seven systems, which are respectively arranged in the cabin and on the deck. The main equipment of each system is arranged symmetrically along the horizontal direction or on the longitudinal central axis. Among them: the cab And the control room 1 is set on the central axis of the front part of the bow, the four pressurized water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com