Prussian blue flower-like nano-structure material as well as preparation and application thereof

A Prussian blue, structural material technology, applied in structural parts, positive electrodes, ferricyanide, etc., can solve problems such as large size and affect the structural stability of electrode materials, achieve high rate performance, and be conducive to market promotion and circulation. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

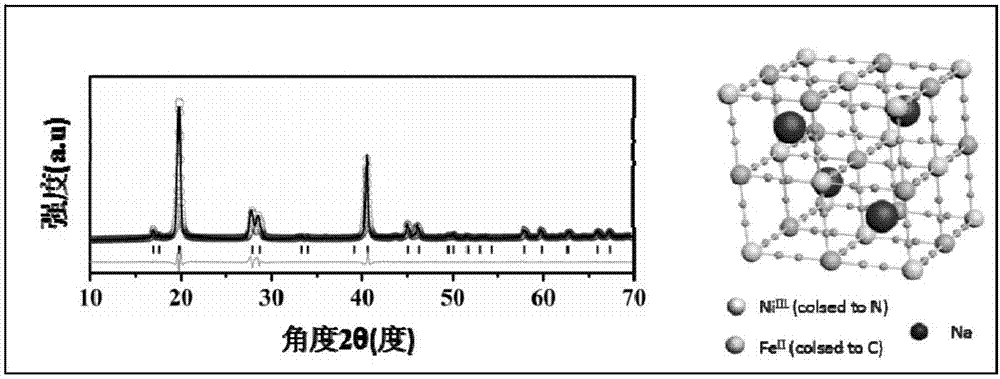

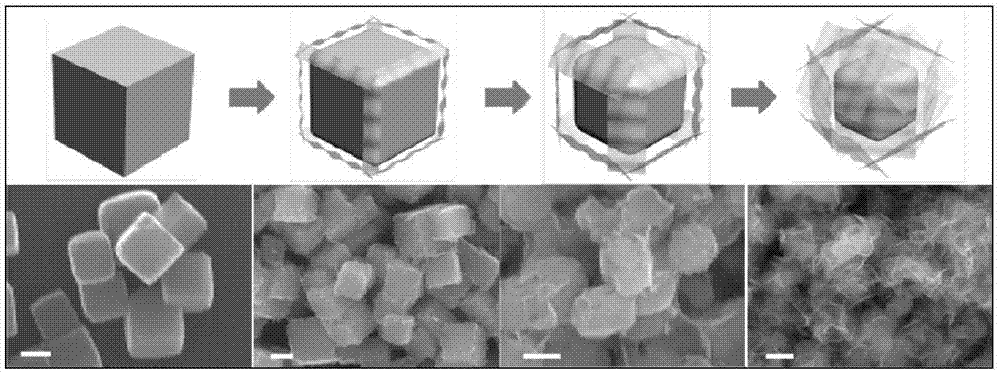

[0030] Prussian Blue (Na 1.11 NiFe(CN) 6 ) The preparation method of nano flower structure electrode material, it comprises the following steps:

[0031] 1) First take 4mmol nickel chloride hexahydrate (NiCl 6H 2 O) and 20mmol anhydrous sodium citrate (Na 3 C 6 h 5 o 7 ) was dissolved in 250mL deionized water;

[0032] 2) Take 5mmol sodium ferrocyanide decahydrate (Na 4 Fe(CN) 6 10H 2 O) be dissolved in another 250mL deionized water;

[0033] 3) Pour the solution obtained in step 2) into the mixture of nickel chloride and sodium citrate obtained in step 1) and stir at room temperature for 5 minutes;

[0034] 4) The mixed solution obtained in step 3) was left to stand at 25°C for 48 hours;

[0035] 5) The precipitate was collected by centrifugation, washed three times with water and absolute ethanol, and dried in vacuum at 80°C for 24 hours to obtain the precursor powder;

[0036] 6) Dissolve 16mmol of sodium hydroxide in 40mL of deionized water;

[0037] 7) Add 10...

Embodiment 2

[0044] 1) First take 3mmol nickel chloride hexahydrate (NiCl 6H 2 O) and 20mmol anhydrous sodium citrate (Na 3 C 6 h 5 o 7 ) was dissolved in 250mL deionized water;

[0045] 2) Take 5mmol sodium ferrocyanide decahydrate (Na 4 Fe(CN) 6 10H 2 O) be dissolved in another 250mL deionized water;

[0046] 3) Pour the solution obtained in step 2) into the mixture of nickel chloride and sodium citrate obtained in step 1), and stir at room temperature for 5 minutes;

[0047] 4) The mixed solution obtained in step 3) was left to stand at 25°C for 48 hours;

[0048] 5) The precipitate was collected by centrifugation, washed three times with water and absolute ethanol, and dried in vacuum at 80°C for 24 hours to obtain the precursor powder;

[0049] 6) Dissolve 16mmol of sodium hydroxide in 40mL of deionized water;

[0050] 7) Add 100mg of precursor powder into sodium hydroxide solution and ultrasonicate for 6h;

[0051] 8) The product was collected by centrifugation, washed thr...

Embodiment 3

[0054] 1) First take 4mmol nickel chloride hexahydrate (NiCl 6H 2 O) and 20mmol anhydrous sodium citrate (Na 3 C 6 h 5 o 7 ) was dissolved in 250mL deionized water;

[0055] 2) Take 5mmol sodium ferrocyanide decahydrate (Na 4 Fe(CN) 6 10H 2 O) be dissolved in another 200mL deionized water;

[0056] 3) Pour the solution obtained in step 2) into the mixture of nickel chloride and sodium citrate obtained in step 1), and stir at room temperature for 5 minutes;

[0057] 4) The mixed solution obtained in step 3) was left to stand at 25°C for 48 hours;

[0058] 5) The precipitate was collected by centrifugation, washed three times with water and absolute ethanol, and dried in vacuum at 80°C for 24 hours to obtain the precursor powder;

[0059] 6) Dissolve 16mmol of sodium hydroxide in 40mL of deionized water;

[0060] 7) Add 100mg of precursor powder into sodium hydroxide solution and ultrasonicate for 6h;

[0061] 8) The product was collected by centrifugation, washed thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com