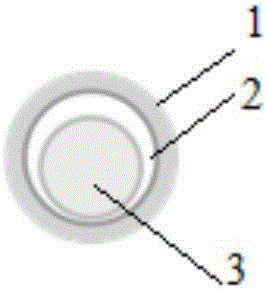

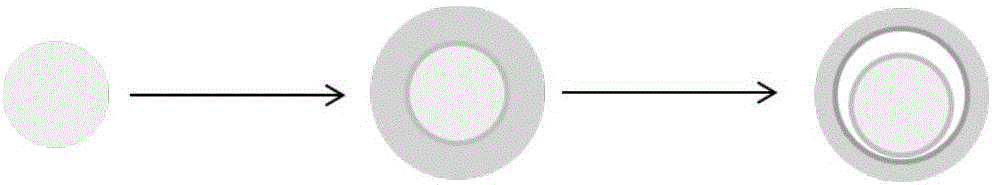

Polymer and nanometer sulfur composite material with shell and egg yolk structure and preparation method

A composite material and polymer technology, applied in the field of electrochemistry, can solve the problems of active material loss, unstable structure, low electrochemical activity, etc., and achieve the effects of preventing agglomeration, alleviating volume change, and inhibiting dissolution and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

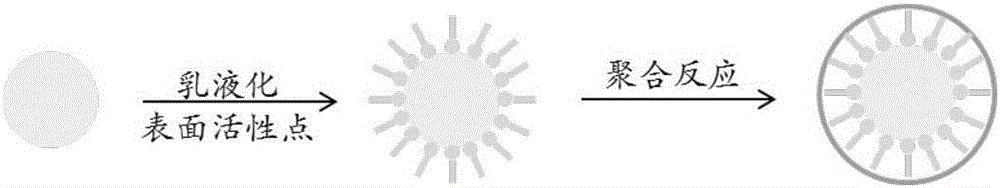

[0087] Weigh 15g of sublimed sulfur element and place it in a high-pressure reactor, add 100g of deionized water, raise the temperature to 150°C, control the pressure to 0.5Mpa, stir at high speed or ultrasonically disperse for 2 hours, and obtain an emulsion of elemental sulfur and water.

Embodiment 2

[0089] Weigh 15g of sublimated sulfur and place it in a high-pressure reactor, add 100g of ethylene glycol, raise the temperature to 150°C, control the pressure to 0.1Mpa, stir at high speed or ultrasonically disperse for 2 hours, and obtain an emulsion of elemental sulfur and ethylene glycol.

Embodiment 3

[0091] Carboxylate, sulfonate, benzenesulfonate (such as sodium alkyl carboxylate, sodium tetradecylsulfonate, sodium dodecylbenzenesulfonate, etc.) Anionic surfactant to obtain stable emulsions of sulfur and water solvents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com