Preparation method of 3D sea urchin spherical carbon-based nickel-cobalt bimetallic oxide composite material

A bimetallic oxide and composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high energy consumption, long cycle, complicated operation, etc., and achieve the effect of high activity, simple operation, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

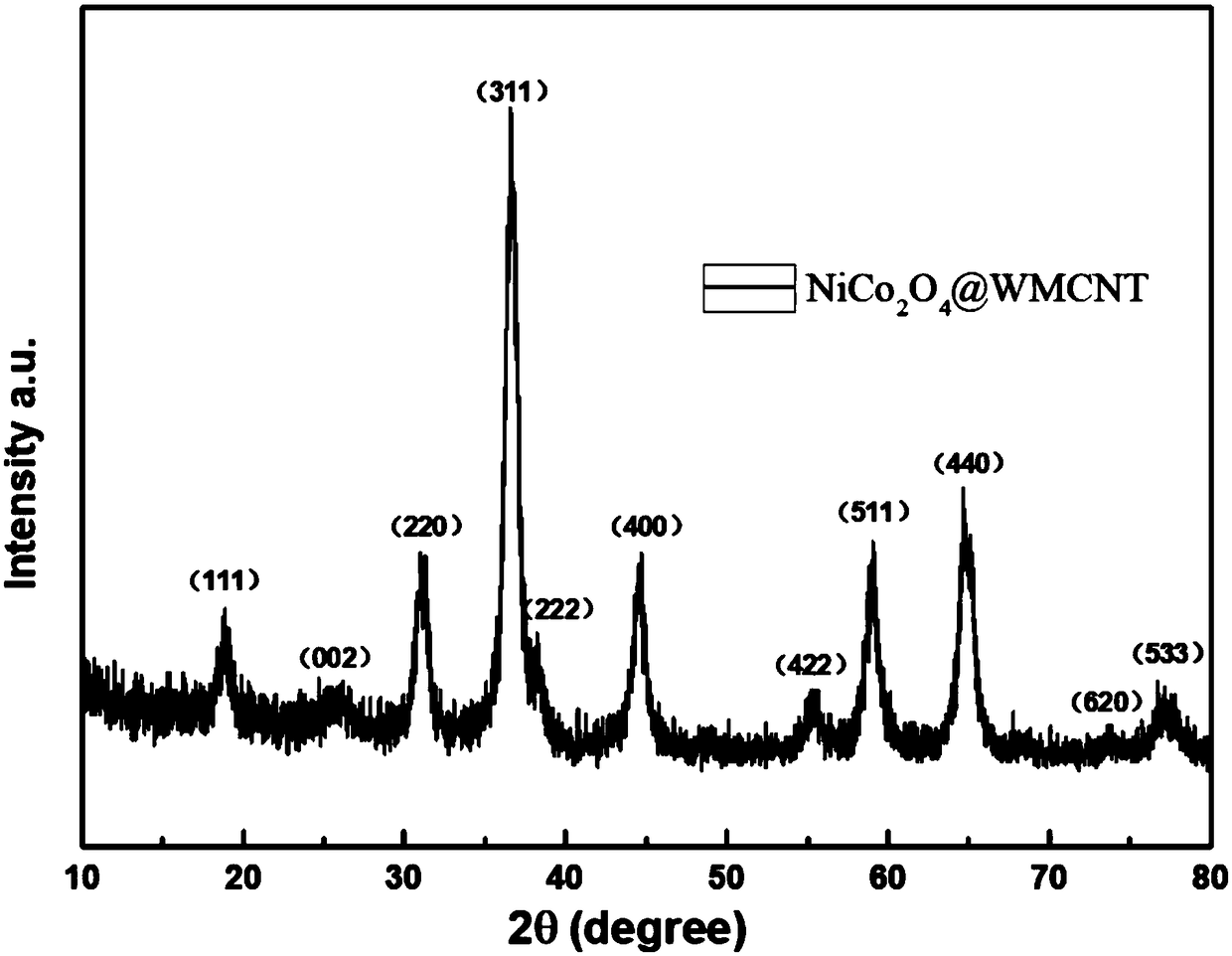

[0045] 1) ultrasonically mix 1 g of multi-walled carbon nanotubes with 80 mL of 40% concentrated nitric acid, treat in an oil bath at 110°C for 2 hours, filter, wash the resulting filter residue with deionized and absolute ethanol until neutral, and dry at 60°C to obtain Acidified multi-walled carbon nanotubes-WMCNT;

[0046] 2) Prepare cobalt nitrate and nickel nitrate in a molar ratio of 2:1 to an ethanol-water solution with a total metal ion concentration of 0.045 mol / L (the volume ratio of ethanol and water is 1:1), according to NiCo 2 o 4 Add 20% of the theoretical mass of the acidified multi-walled carbon nanotube-WMCNT prepared in step 1), after stirring evenly, add a certain amount of urea, adjust the pH to about 11.0, and obtain a black uniform mixed solution;

[0047] 3) Transfer the black homogeneous mixed solution obtained in step 2) into a hydrothermal kettle with a filling rate of 70%, keep it warm at 110°C for 16h, after cooling at room temperature, filter, add...

Embodiment 2

[0050] 1) ultrasonically mix 1 g of multi-walled carbon nanotubes with 50 mL of 50% concentrated nitric acid, treat in an oil bath at 80°C for 3 hours, filter, wash the resulting filter residue with deionized and absolute ethanol until neutral, and dry at 60°C to obtain Acidified multi-walled carbon nanotubes-WMCNT;

[0051] 2) Prepare cobalt nitrate and nickel nitrate in a molar ratio of 2:1 to an aqueous solution with a total metal ion concentration of 0.075mol / L, according to NiCo 2 o 4 10% of the theoretical product quality, add the acidified multi-walled carbon nanotube-WMCNT prepared in step 1), after stirring evenly, add ammonia water dropwise, adjust the pH to about 11.0, and obtain a black uniform mixed solution;

[0052] 3) Transfer the black homogeneous mixed solution obtained in step 2) into a hydrothermal kettle with a filling rate of 70%, heat it at 120° C. for 7 hours, and after cooling at room temperature, filter, add deionized water and absolute ethanol, and ...

Embodiment 3

[0055] 1) ultrasonically mix 1 g of multi-walled carbon nanotubes with 40 mL of 60% concentrated nitric acid, treat in an oil bath at 110 ° C for 1.0 h, filter, and wash the obtained filter residue with deionized and absolute ethanol until neutral, then dry at 60 ° C, Obtain acidified multi-walled carbon nanotube-WMCNT;

[0056] 2) Prepare cobalt acetate and nickel acetate in a molar ratio of 2:1 to an ethanol solution with a total metal ion concentration of 0.09 mol / L, according to NiCo 2 o 4 15% of the theoretical product mass, add the acidified multi-walled carbon nanotube-WMCNT prepared in step 1), after stirring evenly, add ammonia water and urea, adjust the pH to about 11.0, and obtain a black uniform mixed solution.

[0057] 3) Transfer the black homogeneous mixed solution obtained in step 2) into a hydrothermal kettle with a filling rate of 70%, keep it warm at 120°C for 12h, and after cooling at room temperature, filter, add deionized water and absolute ethanol, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com