Negative electrode material and preparation method and application of negative electrode material

A negative electrode material and reaction technology, which is applied in the field of negative electrode materials and its preparation, can solve the problems of unsuitable industrial production, limited capacity of negative electrode materials, and low rate performance, and achieve high specific capacity, simple preparation method, and good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

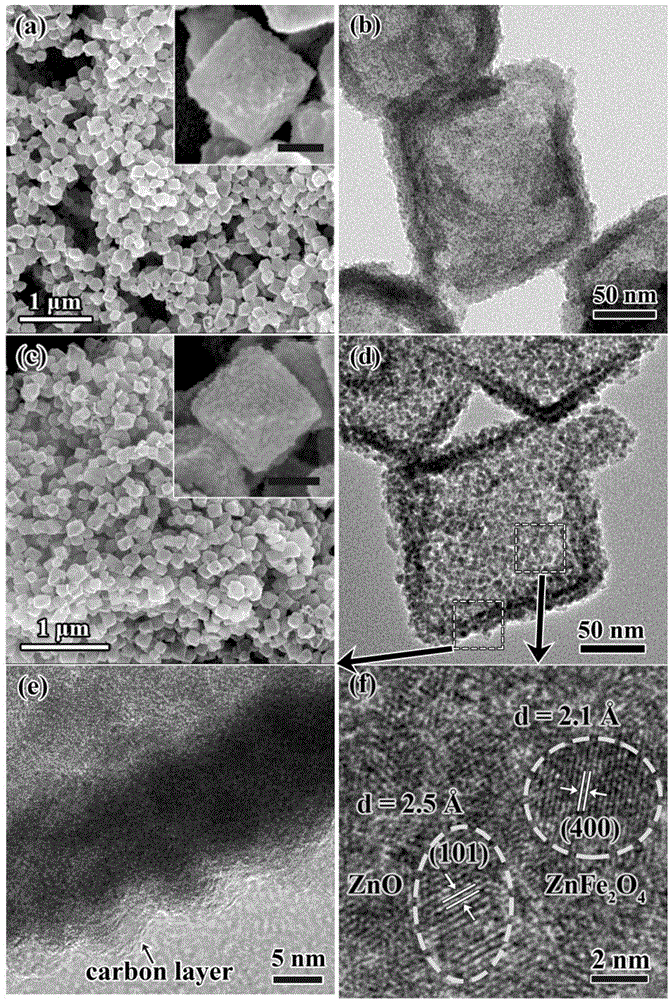

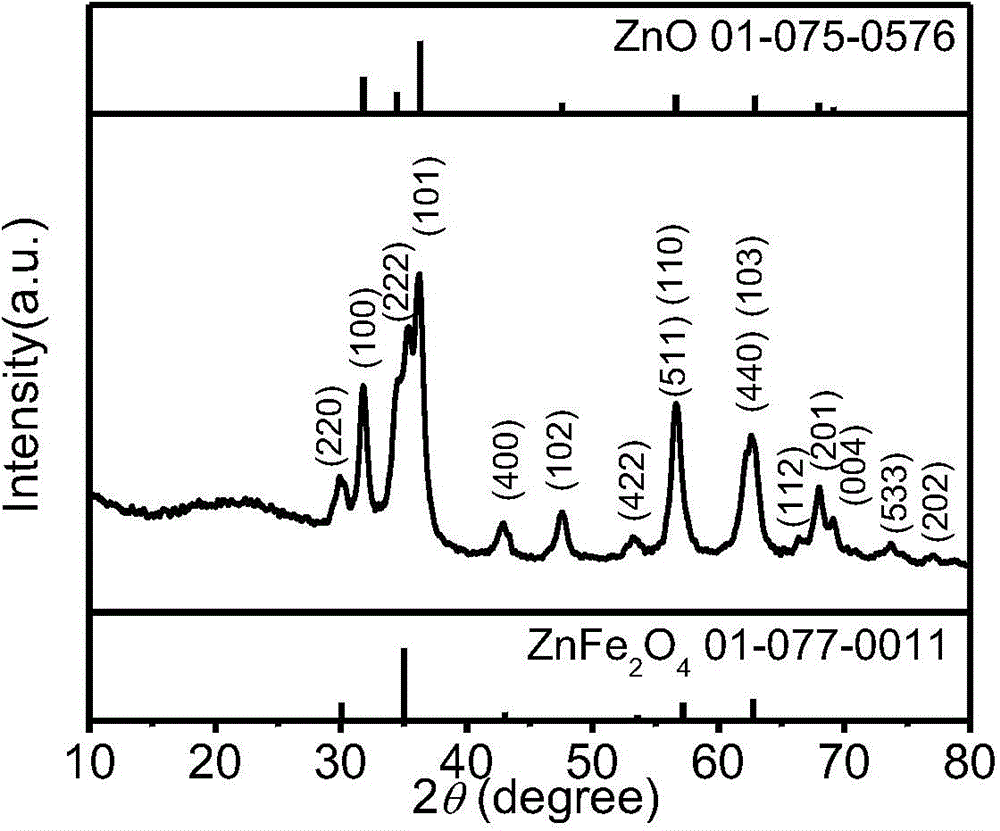

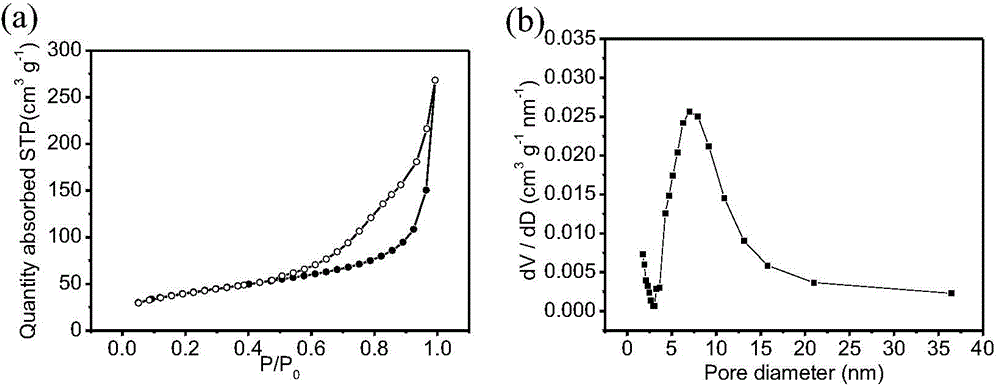

Image

Examples

Example Embodiment

[0027] Example one

[0028] The first step is to prepare the reaction precursor solution: dissolve component A in component B to prepare a reaction precursor solution; wherein component A includes the following raw materials in parts by weight: 14-15 parts of zinc nitrate, 18~ of iron acetylacetonate 20 parts, 2 to 3 parts of terephthalic acid, 63 to 64 parts of polyvinylpyrrolidone with a molecular weight of 30,000 to 60,000; component B is N,N-dimethylformaldehyde prepared in a volume ratio of 4:3 to 2:1 A mixed solution of amide and ethanol; in the prepared reaction precursor solution, the concentration of zinc nitrate is 3.43~3.53g / L.

[0029] As a preference for the above numerical range, the weight ratios of the raw materials of component A are: 14.6 to 14.7 parts of zinc nitrate, 18.9 to 19.1 parts of iron acetylacetonate, 2.9 to 3.1 parts of terephthalic acid, and poly Vinylpyrrolidone is 63-63.5 parts.

[0030] In this embodiment, it is further preferred that the volume of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com