Lithium ion battery silicon cathode material and preparation method thereof

A lithium-ion battery, silicon negative electrode technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of cycle stability, electrochemical reversibility, etc., to improve cycle performance, prolong attenuation speed, and alleviate volume effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

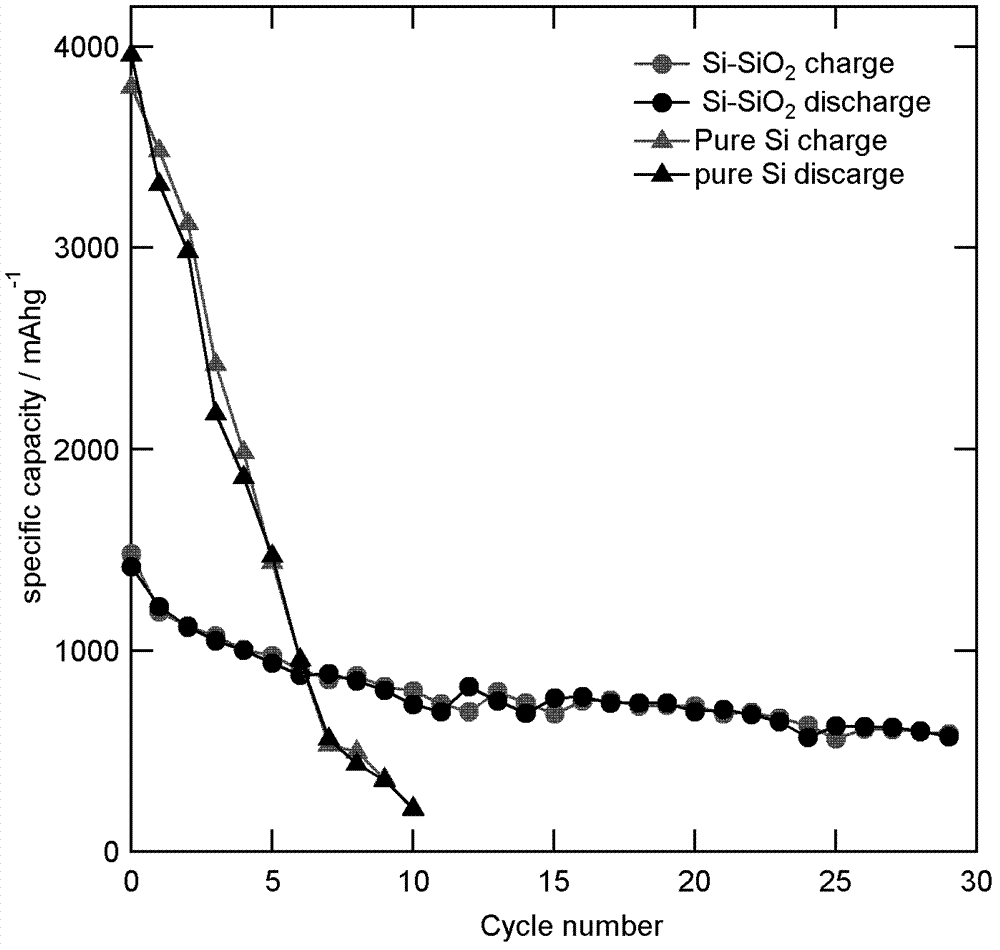

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in further non-limiting detail below in conjunction with preferred embodiments and accompanying drawings.

[0023] A lithium-ion battery silicon negative electrode material, which includes nano-silicon powder and a coating layer coated on the surface of the nano-silicon powder, the particle size of the nano-silicon powder is 0.1nm-10μm.

[0024] The cladding layer is silicon dioxide with a layer thickness of 1 nm-1 μm, and the molar ratio of silicon in the silicon negative electrode material of the lithium ion battery is 20-55%. In addition, the above-mentioned covering layer has a sponge network structure with a conductive network in it. The conductive network is graphite and dispersed in the sponge network structure.

[0025] In addition, the present invention also proposes a preparation method of the above-mentioned silicon negative electrode material for lithium ion batteries, which includes the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com