Method for preparing mixed-valent-state iron doped zeolite imidazate skeleton nano-material

A zeolite imidazolate and mixed valence technology, which is applied in the field of preparation of mixed valence iron-doped metal organic framework nanomaterials, can solve problems such as difficulty in regulating the concentration of iron ions, and achieves fewer synthesis regulation parameters, mild conditions, and high production efficiency. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

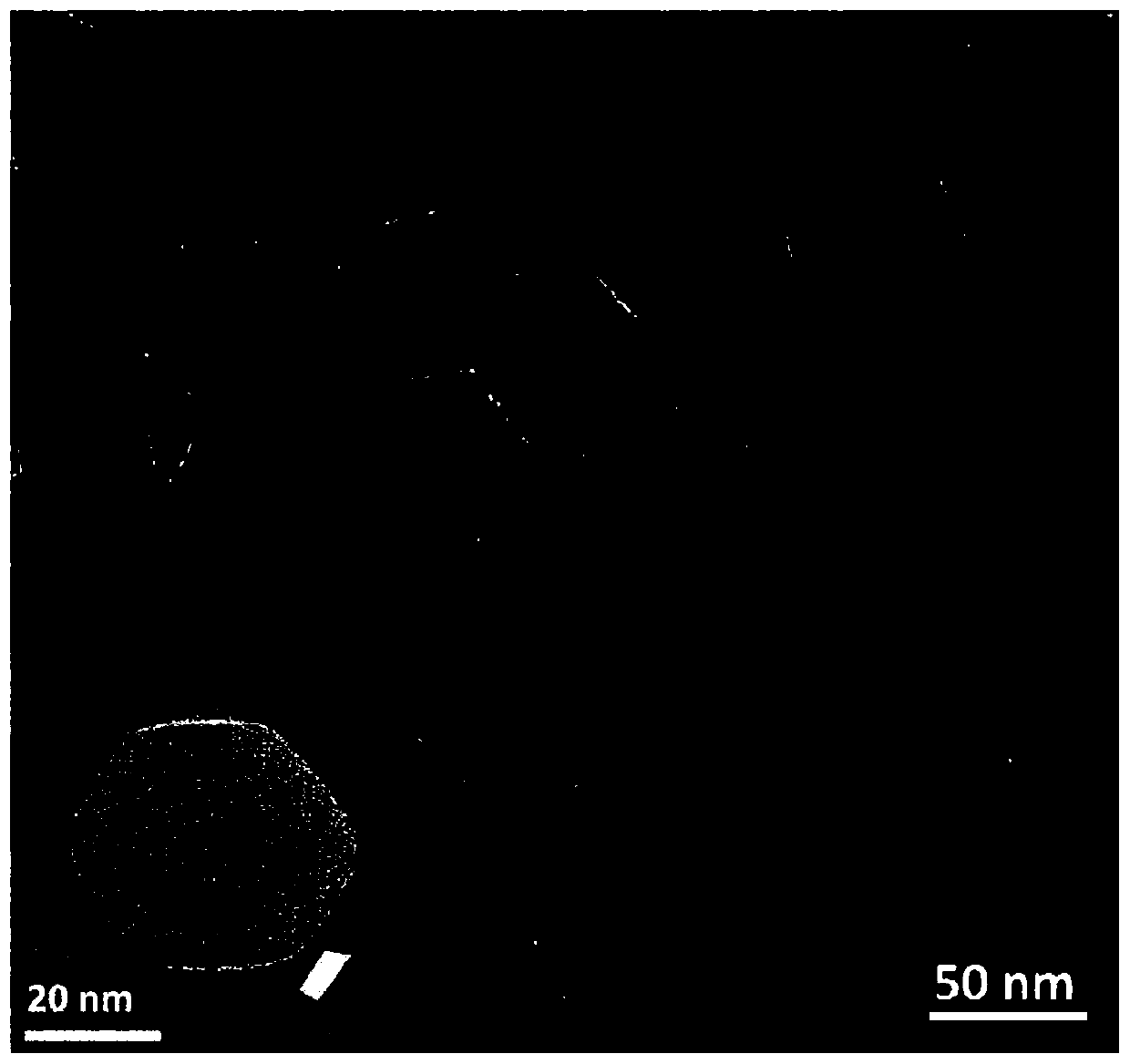

[0034] Weigh 11.65mmol zinc nitrate, 0.124mmol ferrous ammonium sulfate and 0.124mmol ferric ammonium sulfate and disperse in 600mL methanol solvent to form zinc-iron metal cation precursor A solution; weigh 56mmol 2-methylimidazole ligand and disperse in 600mL methanol A solution B is formed in a solvent; the two solutions A and B are mixed, and placed in an oil bath at 60°C, and after 24 hours of magnetic stirring at 300 rpm, the formed product is centrifuged, washed, and vacuum-dried to prepare The final mixed valence iron doping-ZIF-8 nanomaterial, the prepared sample TEM picture is shown in figure 1 . Compared with other embodiments, two metal salts with similar properties are used in this example to obtain a higher iron doping amount. Quantitative analysis of elemental indications shows that the total iron doping amount is calculated to be 50%.

Embodiment 2

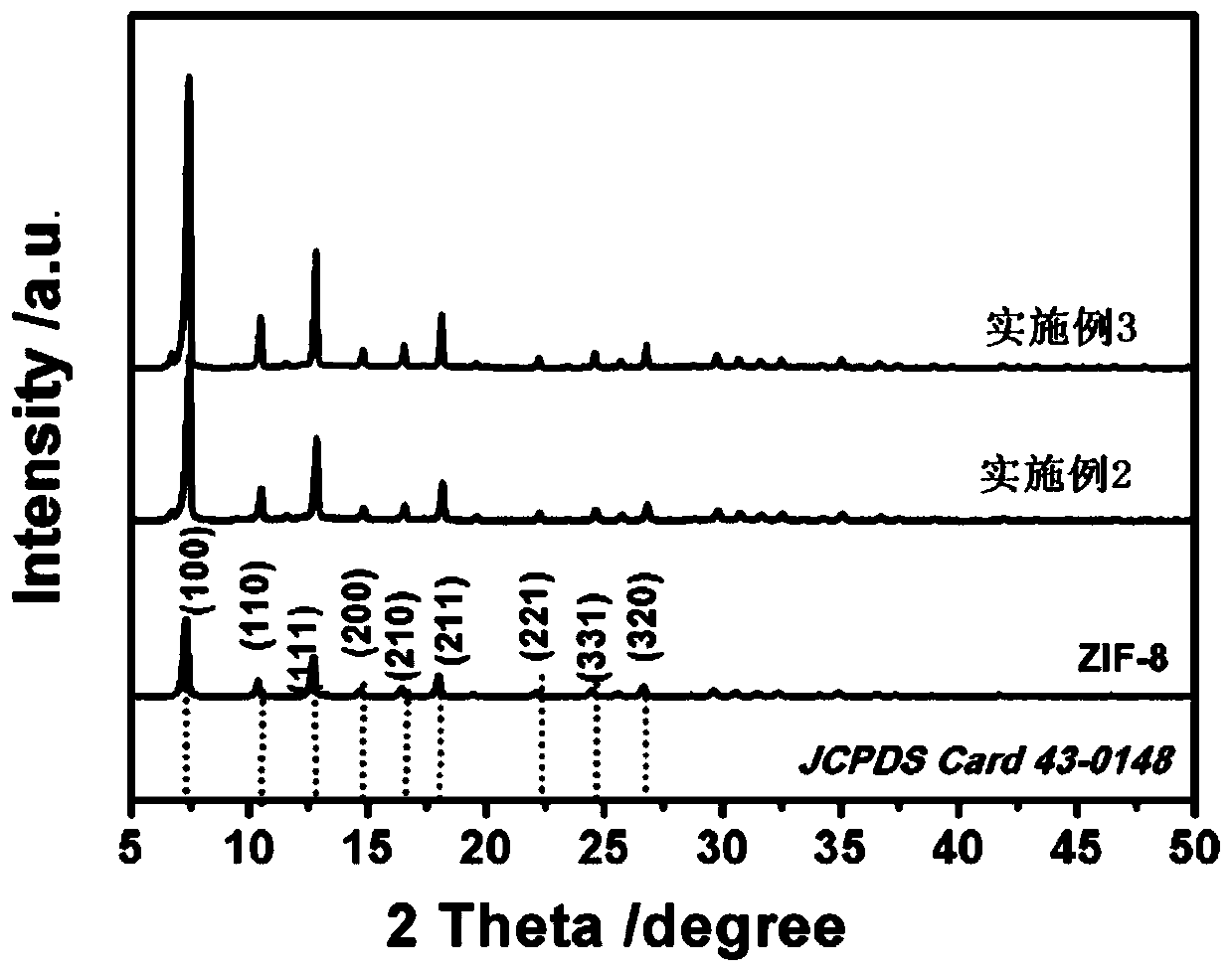

[0036] Weigh 11.65mmol zinc nitrate, 0.124mmol ferrous sulfate and 0.062mmol ferric nitrate and disperse in 300mL methanol solvent to form zinc-iron metal cation precursor A solution; weigh 56mmol 2-methylimidazole ligand and disperse in 300mL methanol solvent Form B solution; mix A and B solutions, place them in an oil bath at 40°C, and react with magnetic stirring at 400 rpm for 36 hours, then centrifuge, wash, and vacuum-dry the formed product to prepare the final Mixed valence iron-doped-ZIF-8 nanomaterial, the XRD pattern of the obtained sample is shown in figure 2 .

Embodiment 3

[0038] Weigh 11.65mmol zinc nitrate, 0.124mmol ferrous sulfate and 0.248mmol ferric chloride and disperse in 200mL methanol solvent to form zinc-iron metal cation precursor A solution; weigh 56mmol 2-methylimidazole ligand and disperse in 200mL methanol solvent Form B solution; mix A and B solutions, put them in an oil bath at 100°C, and react with magnetic stirring at 200 rpm for 16 hours, then centrifuge, wash, and vacuum-dry the formed product to prepare the final product The mixed valence state iron-doped-ZIF-8 nanometer material, the XRD pattern of the obtained sample is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com