Preparation method of lithium iron phosphate, lithium iron phosphate and lithium ion battery

A technology of lithium iron phosphate and phosphorus source, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low ion conductivity and electronic conductivity of lithium iron phosphate, irregular morphology of lithium iron phosphate particles, and particle size distribution. Non-uniformity and other problems, to achieve the effect of improving electrochemical performance, good electrochemical performance, and wide use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to one aspect of the present invention, a kind of preparation method of lithium iron phosphate is provided, and this preparation method comprises the following steps:

[0037] (a) uniformly mixing the iron source, phosphorus source, lithium source and carbon source, and calcining under a protective atmosphere to obtain a calcined product;

[0038] (b) after grinding the calcined product, drying;

[0039] (c) Calcining the dried material again under a protective atmosphere to obtain lithium iron phosphate.

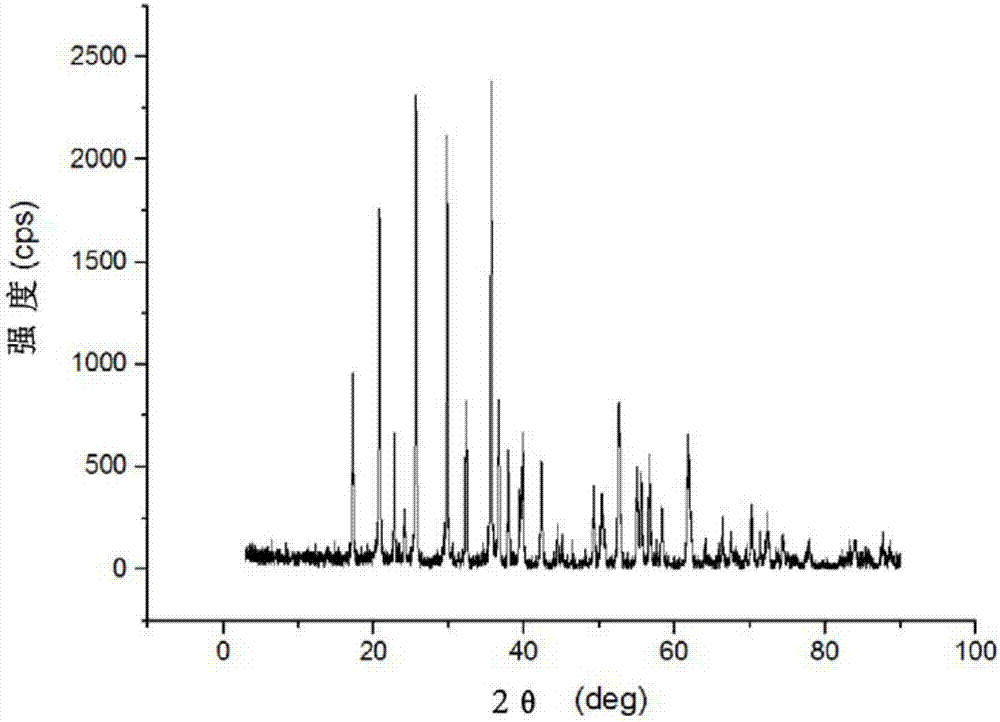

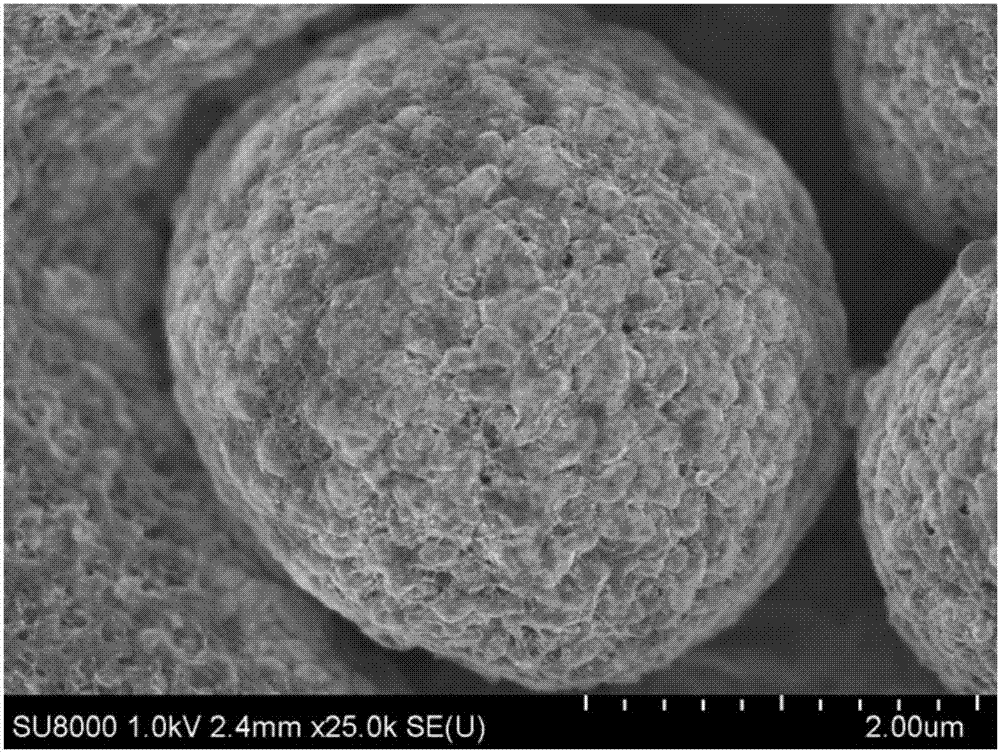

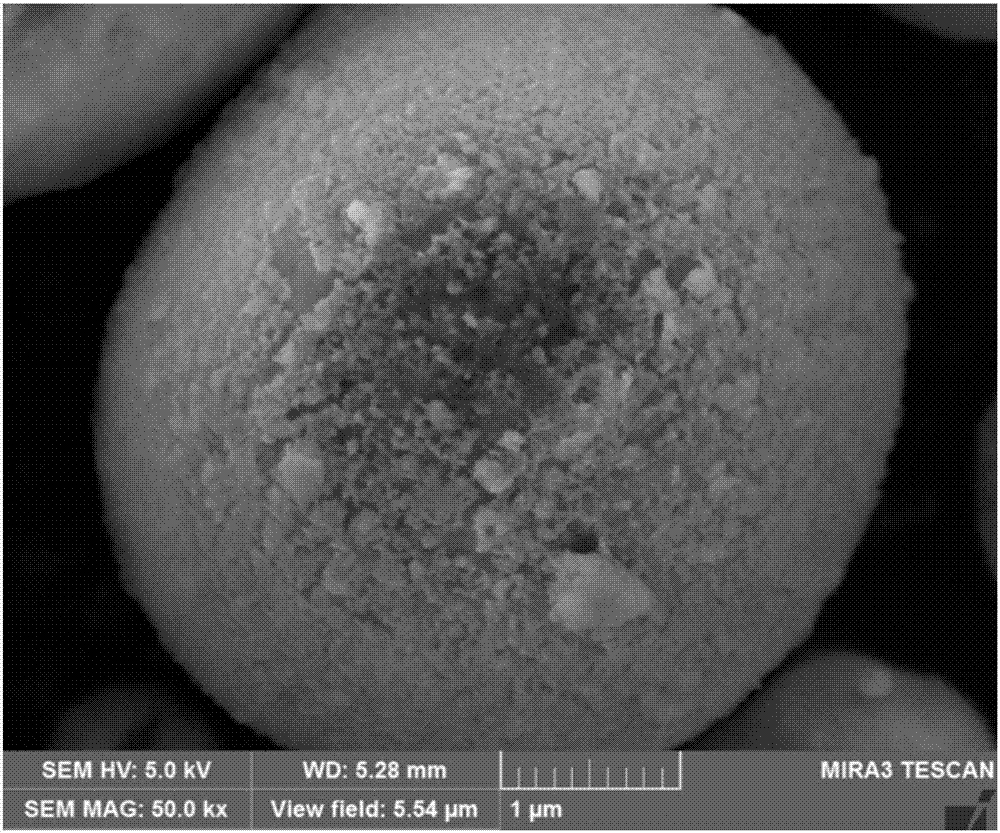

[0040] The invention provides a preparation method of lithium iron phosphate, which comprises mixing iron source, phosphorus source, lithium source and carbon source, calcining, grinding, drying and then calcining again to obtain lithium iron phosphate. By adopting the above-mentioned specific process, the particles of the prepared lithium iron phosphate are spherical, the particle size is at the micron or nanometer level, the particle size is uniform and ...

Embodiment 1

[0080] A preparation method for lithium iron phosphate, comprising the following steps:

[0081] (a) mix the iron source, phosphorus source, lithium source and carbon source evenly, put them into an atmosphere furnace and perform calcining under a protective atmosphere of helium to obtain a calcined product;

[0082] Among them, the iron source is iron oxide, the phosphorus source is diammonium hydrogen phosphate, the lithium source is lithium hydroxide, the carbon source is sucrose, the carbon source accounts for 0.5% of the total weight of the iron source, phosphorus source and lithium source, and the calcination temperature is 750°C , the calcination time is 8h;

[0083] (b) After the calcined product is wet ground, it is dried in an oven at a temperature of 110° C. for 12 hours;

[0084] Among them, the time of wet grinding is 3h, and the solvent of wet grinding is deionized water;

[0085] (c) Calcining the dried material again in a protective atmosphere of helium at a ...

Embodiment 2

[0087] The preparation method of lithium iron phosphate provided in this example is the same as that of Example 1, except that graphene is used as the carbon source in step (a), and the specific steps can refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com