Method for recovering positive electrode material of waste lithium iron phosphate battery

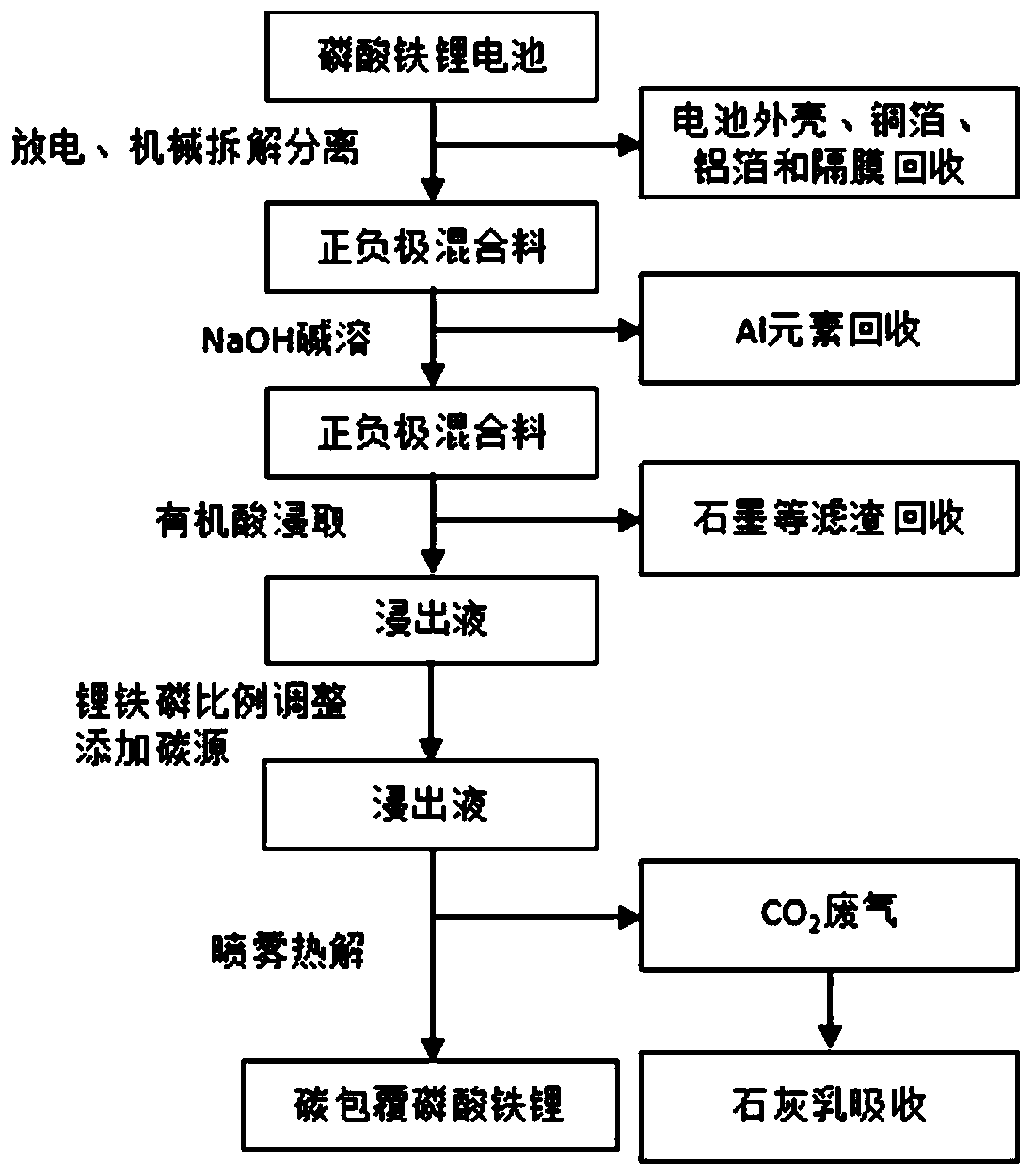

A technology for lithium iron phosphate batteries and positive electrode materials, which is applied in battery recycling, battery electrodes, waste collector recycling, etc. It can solve the problems of difficult industrial production, complicated process, and large acid-base consumption, and achieves controllable particle size. And uniform, wide application prospects, the effect of reducing dismantling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]S1 Discharge the waste lithium-ion battery in 5% NaCl saline solution for 4 hours to make the battery voltage lower than 2V, and then automatically disassemble and separate the positive and negative electrode mixed powder, battery shell, and copper by crushing, magnetic separation, and screening methods. Foil, aluminum foil and separator, the battery casing, copper foil, aluminum foil and separator are directly recycled after dismantling;

[0041] S2 At an ambient temperature of 25°C, add 20mL of 1M NaOH solution to 10g of the separated positive and negative electrode mixed powder, stir in a mixer at a stirring rate of 500rpm for 2h, fully dissolve the positive and negative electrode mixed powder, and separate the solid and liquid, then Al element is recovered from the filtrate;

[0042] S3 At a temperature of 60°C, put the solid powder filtered out in step S2 (the positive and negative electrode mixed powder after removing Al) into 100mL of 1M citric acid to react and s...

Embodiment 2

[0047] S1 discharges the waste lithium-ion battery through the charging and discharging machine for about 4 hours (multiple discharges to ensure that the battery voltage is lower than 1V), and then automatically disassembles and separates the positive and negative mixed powder and the battery through crushing, magnetic separation, and screening methods Shell, copper foil, aluminum foil and separator, the battery shell, copper foil, aluminum foil and separator are directly recycled after dismantling;

[0048] S2 At a temperature of 40°C, add 20 g of the separated positive and negative electrode mixed powder into 50 mL of 1M NaOH solution, and stir in a mixer at a stirring rate of 500 rpm for 1 hour to fully dissolve the positive and negative electrode mixed powder. Al element is recovered in the filtrate;

[0049] In S3, at a temperature of 60°C, put the positive and negative electrode mixed powder filtered out in step S2 after removing Al into 200mL of 1M malic acid to react a...

Embodiment 3

[0053] S1 discharges the waste lithium-ion battery for about 4 hours with a charge-discharge machine (multiple discharges to ensure that the battery voltage is lower than 1V), and then automatically disassembles and separates the positive and negative electrode mixed powder, battery by crushing, magnetic separation, and screening methods Shell, copper foil, aluminum foil and separator, the battery shell, copper foil, aluminum foil and separator are directly recycled after dismantling;

[0054] S2 At a temperature of 50°C, add 10 g of the separated positive and negative electrode mixed powder into 100 mL of 1M NaOH solution, and stir in a mixer at a stirring rate of 500 rpm for 1 hour to fully dissolve the positive and negative mixed powder, and separate the solid and liquid from Al element is recovered in the filtrate;

[0055] In S3, at a temperature of 80°C, put the mixed positive and negative electrode powder filtered out in step S2 into 66.7mL of 1M tartaric acid for 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com