Disassembling method and disassembling line for anti-tank mine

A technology for landmines and tanks, which is applied to weapons accessories, ammunition, offensive equipment, etc., can solve the problems of slow dismantling speed, reliability, safety degradation, and high site conditions, so as to ensure the safety of dismantling, eliminate potential safety hazards, Removes the effect of contact with explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1, see Figure 1 to Figure 15 , a kind of anti-tank landmine dismantling method, comprises the following steps:

[0044] The first step, casing cutting: cut an annular groove on the outer periphery of the mine casing by means of rotary cutting, and the depth of the groove is smaller than the wall thickness of the casing;

[0045] The second step, shell extrusion: form a crack through the wall thickness of the shell at the root of the annular groove by extrusion, so that the mine shell is decomposed into two parts: the shell and the mine cover;

[0046] The third step is to separate the shell: take the groove as the dividing line, and separate the ground shell and the mine cover by pulling;

[0047] The fourth step is to pour the explosives: the explosives remaining in the casing and the mine cover after separation are shaken out by vibration.

[0048] In the casing cutting step of the first step, the section of the annular groove formed by cutting is V-shaped....

Embodiment 2

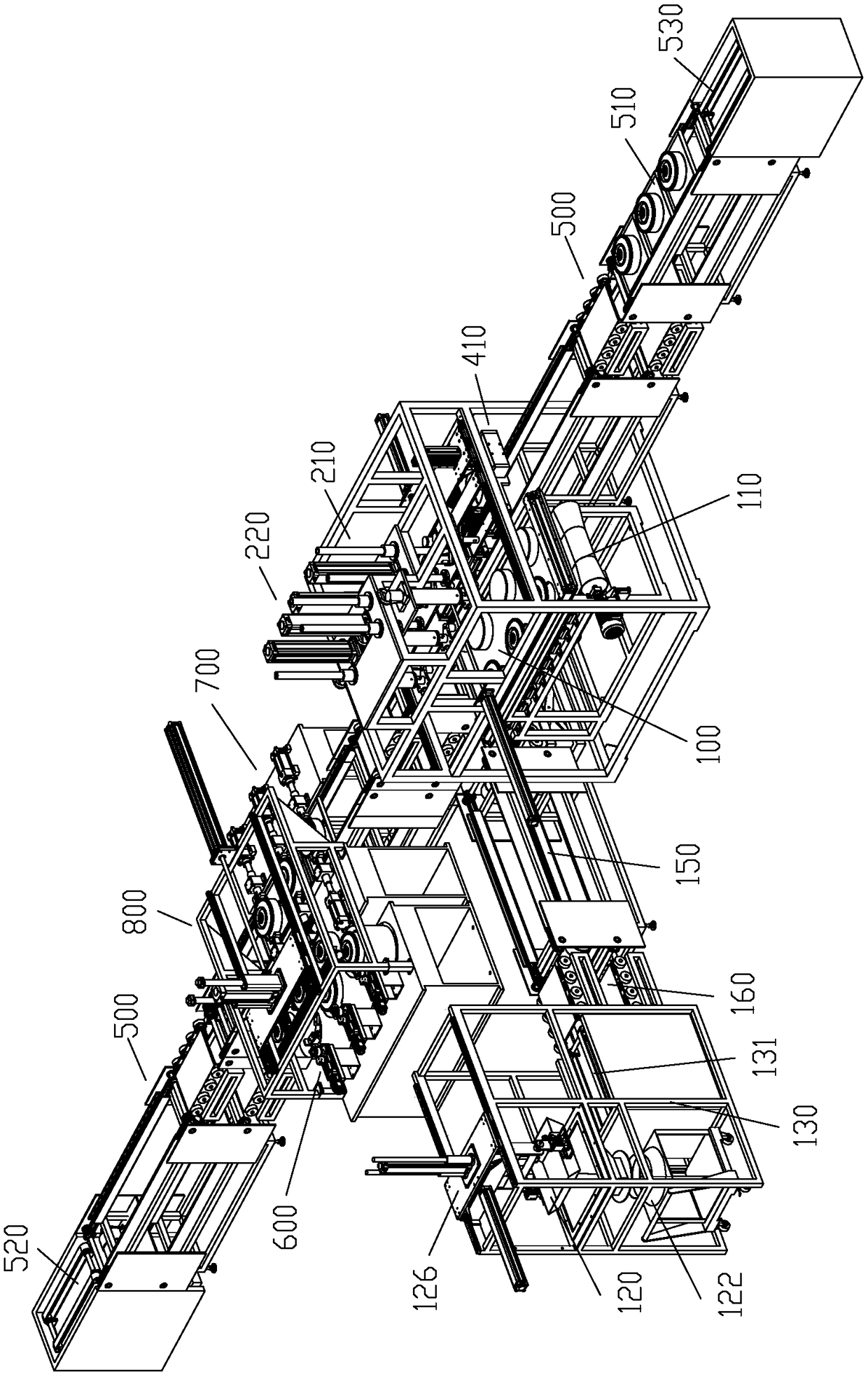

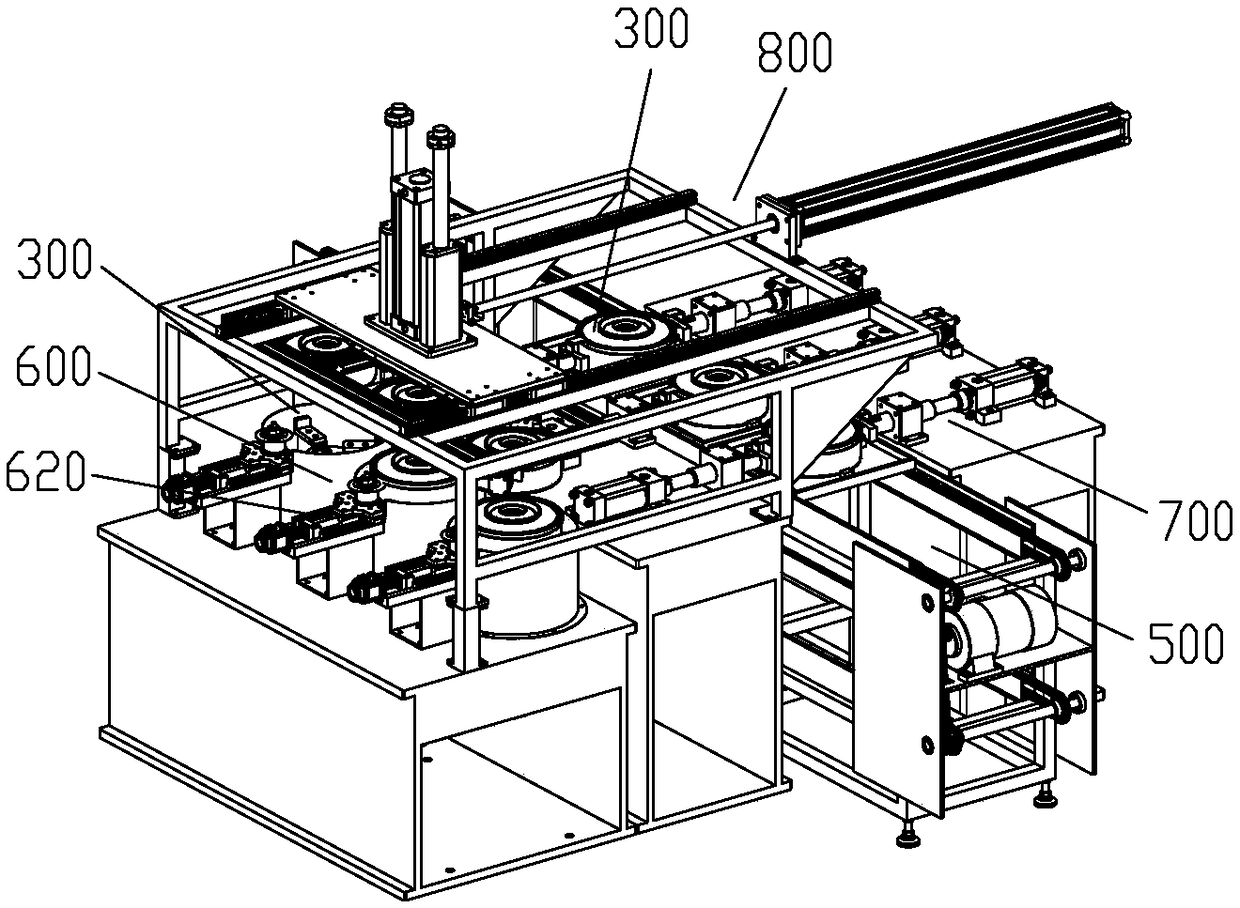

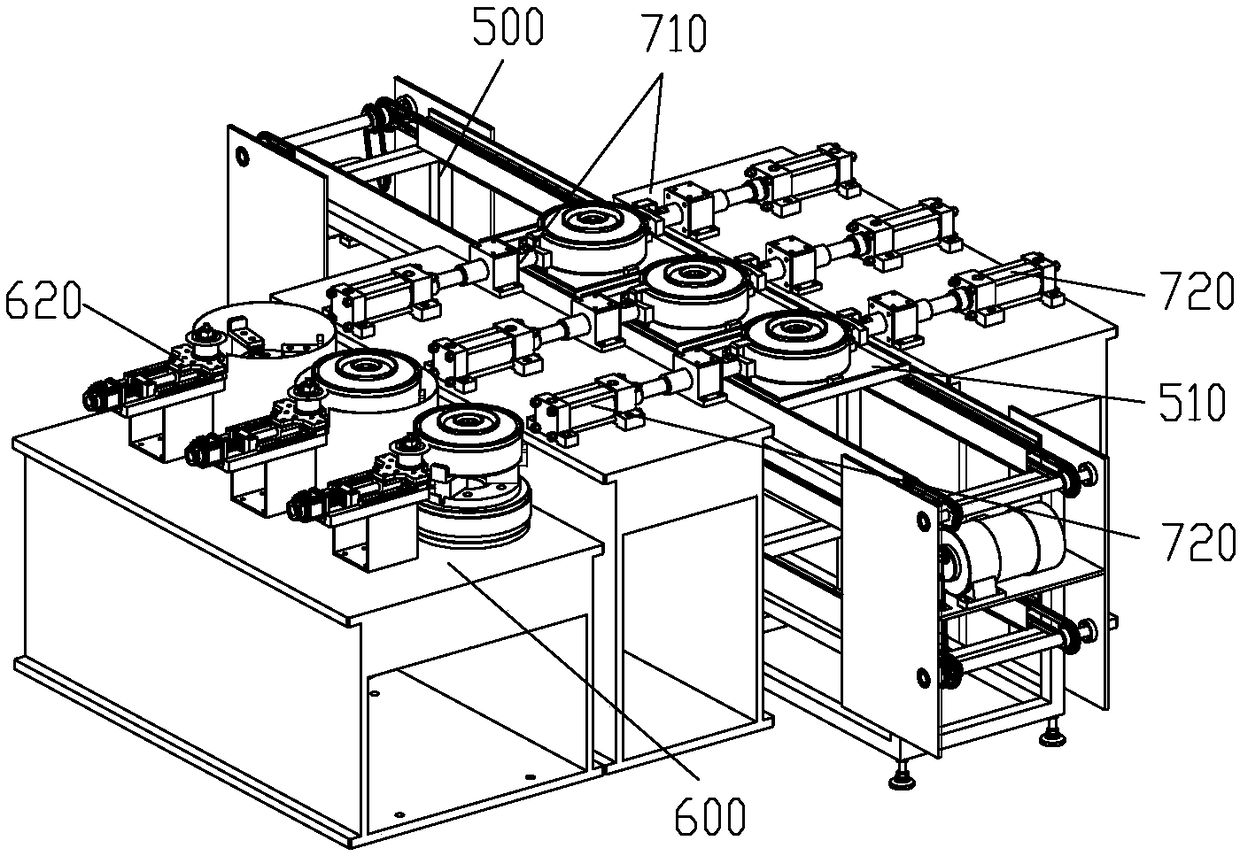

[0050] Example 2, see Figure 1 to Figure 15 , a dismantling line for anti-tank landmines, comprising a shell cutting unit 600, a shell disassembling unit 700, and a vibrating pouring unit connected in sequence by a material delivery unit; the shell cutting unit 600 is composed of a vertical rotary power head 610 and a horizontally moving The cutting tool holder 620 is composed of the shell cutting unit 600 for cutting annular grooves on the shell of the mine; the shell dismantling unit 700 includes at least two hydraulically driven extrusion heads 710 distributed around the circumference, and the shell dismantling unit 700 is used for hydraulically The way of extruding the annular groove forms a penetrating crack at the root of the groove, so that the shell of the mine is separated into the shell and the cover of the mine; The first vibration source 210 and the second vibration source 220 are composed of the first vibration source 210 and the second vibration source 220 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com