Waste lithium ion battery disassembling system

A lithium-ion battery and waste technology, which is applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of low recycling efficiency of waste lithium-ion batteries, improve recycling efficiency, reduce pollution, and realize recycling The effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

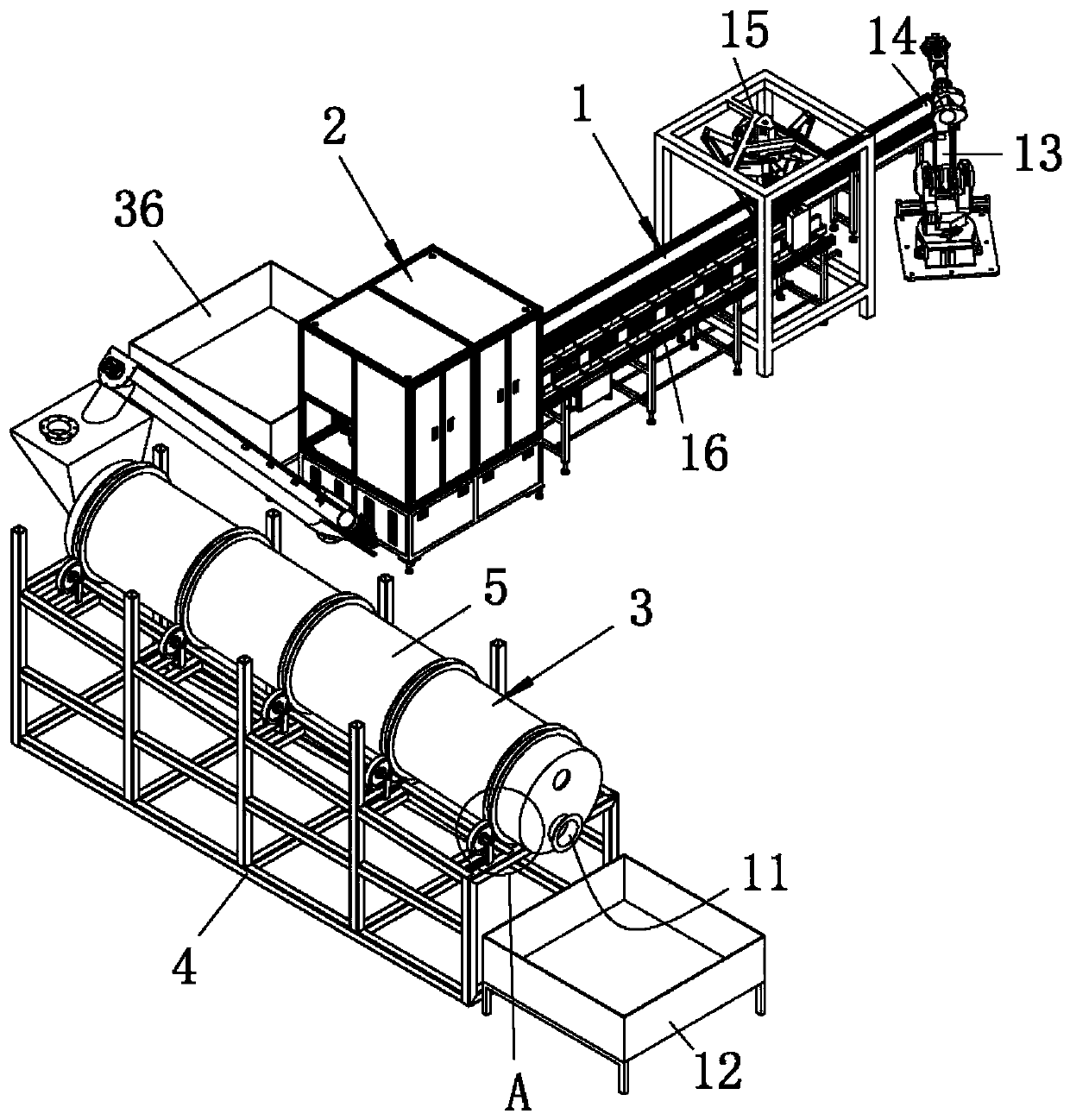

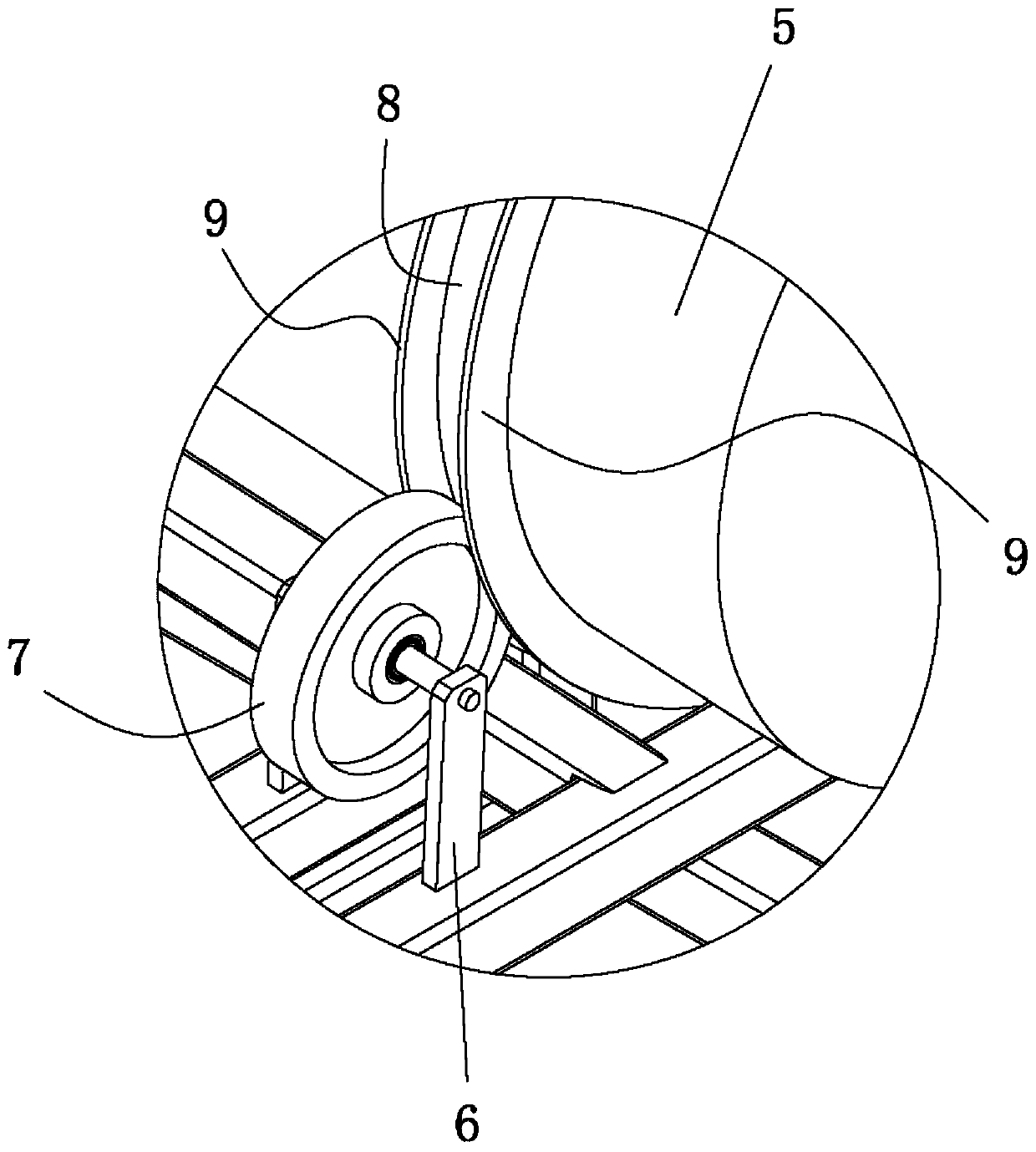

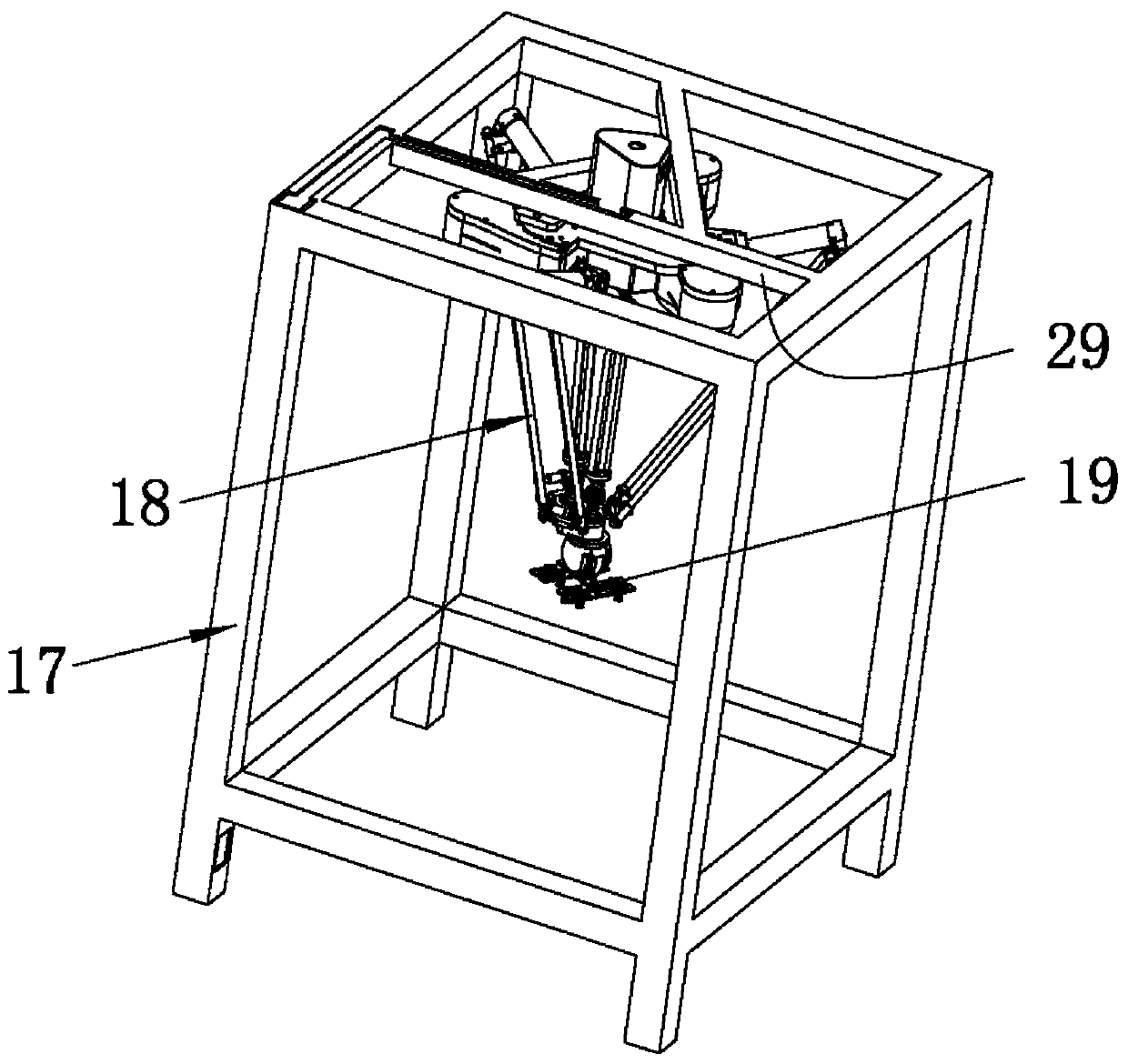

[0037] see figure 1 As shown, a waste lithium ion battery dismantling system of the present invention includes a feeding device 1, a dismantling device 2 and a pyrolysis device 3, and the feeding device 1 automatically transfers the waste lithium ion batteries from the outside to the dismantling device 2 Inside, the dismantling device 2 is used to automatically break open the waste lithium-ion battery transferred by the feeding device 1, and the waste lithium-ion battery broken by the dismantling device 2 is automatically transferred to the pyrolysis device 3, and the pyrolysis device 3 has a heating assembly And the condensing component, the heating component heats the electrolyte ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com