Patents

Literature

164results about How to "Realize automatic disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

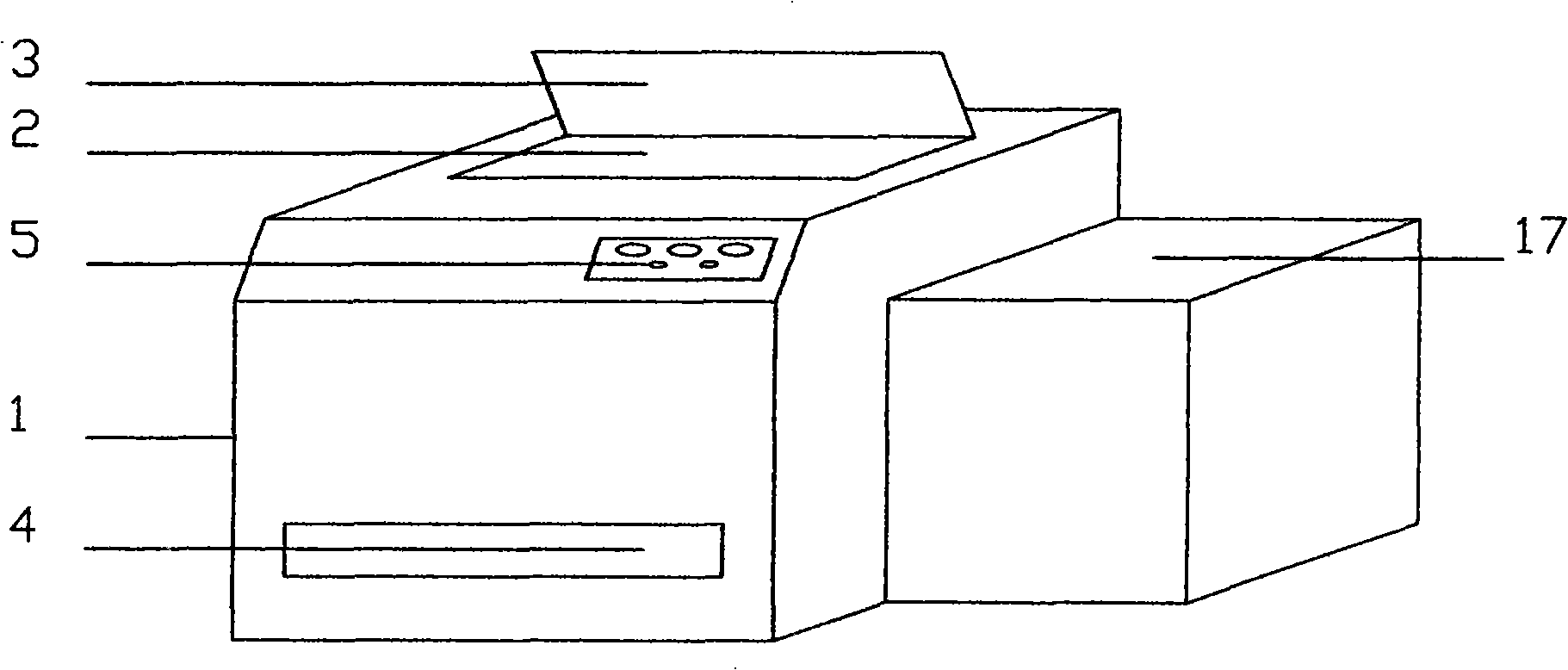

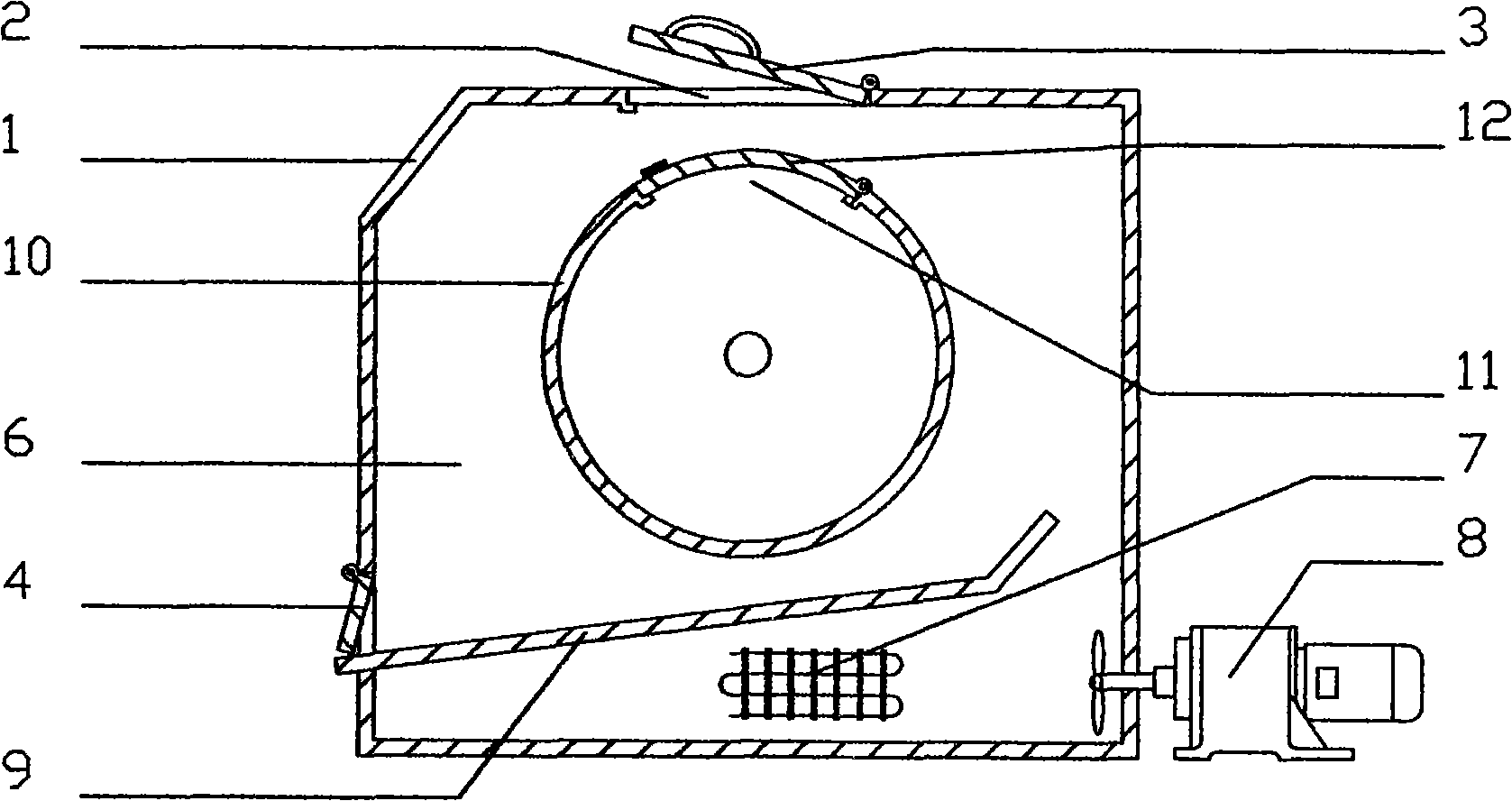

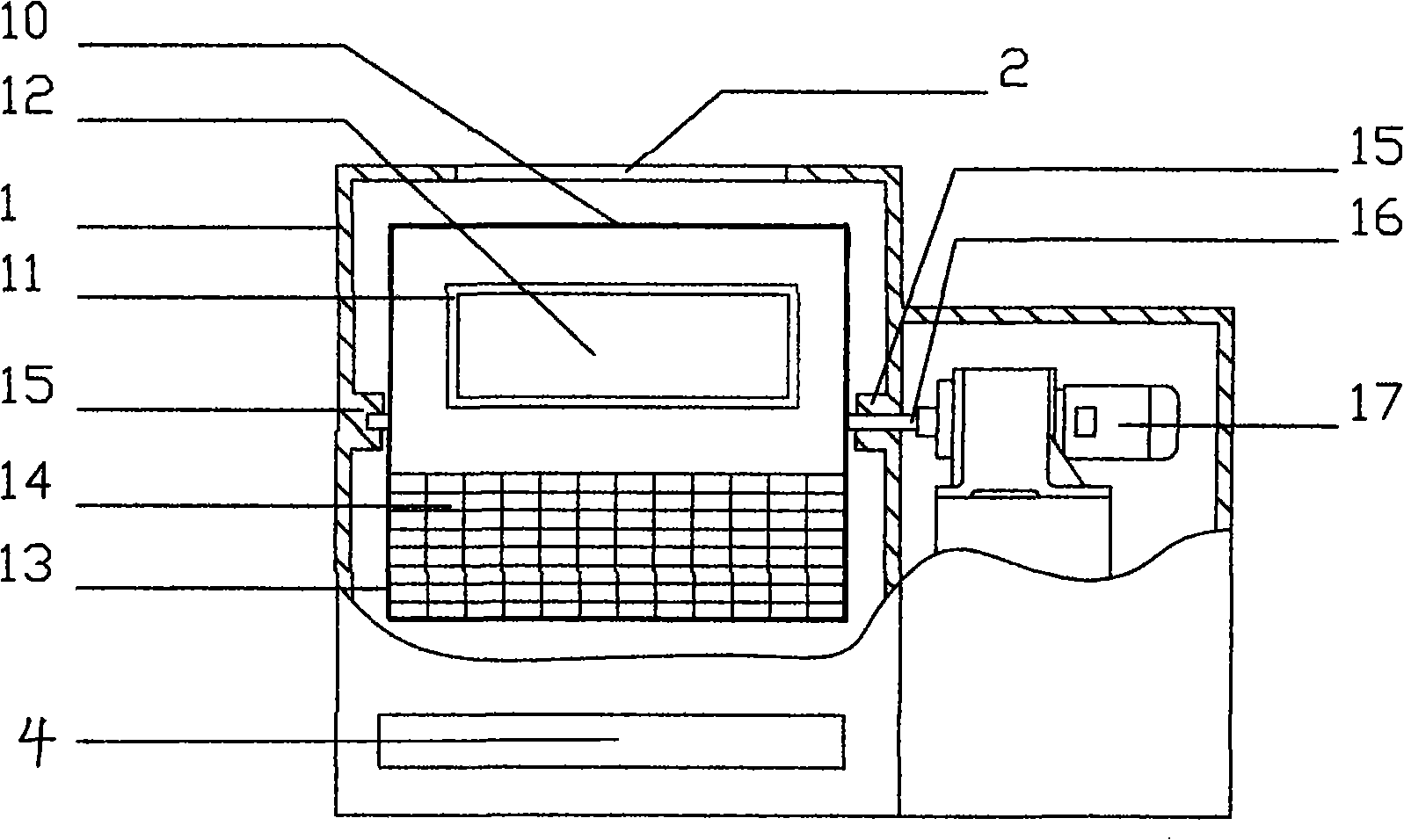

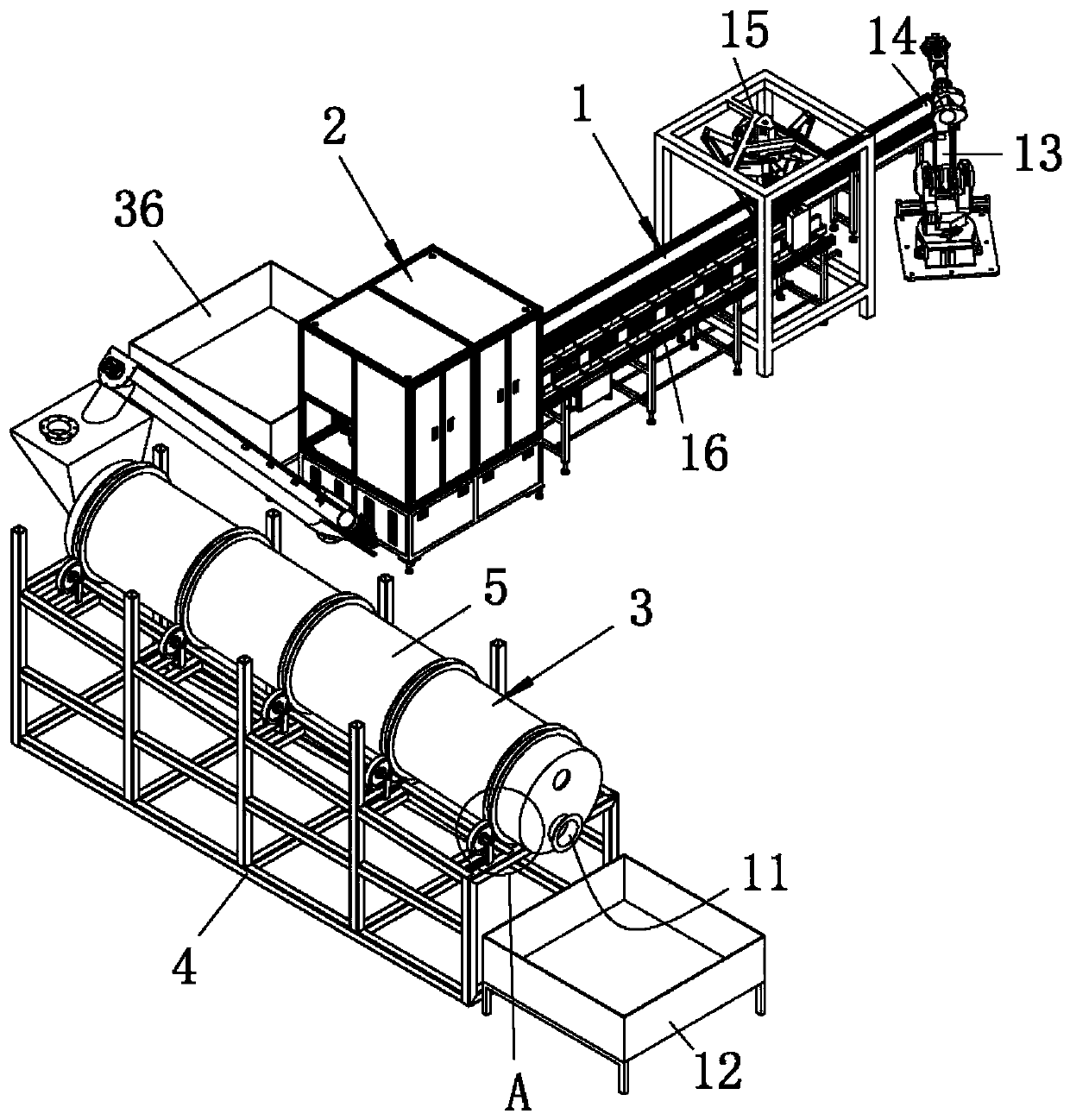

Equipment for dissembling waste and old circuit board

ActiveCN101259555ARealize automatic disassemblyReduce generationSoldering apparatusMetal working apparatusElectricityDecomposition

A device for disassembling a waste circuit board comprises a shell, an electric heater and a fan, which is characterized in that an internal heating space of the device is equipped with a rotatable rotary barrel for placing the waste and old circuit board, and the barrel wall of the rotary barrel is provided with a mesh hole which can be passed by an element. The device can realize the purpose of the automatic disassembly of the waste and old circuit board. The device has the advantages that: compared with the manual disassembly and washing, the efficiency is greatly improved; as the temperature of hot wind of the internal heating space of the device is adjustable and controllable, the set temperature of the hot wind can not only melt a tin point, but also not cause the decomposition of the PCB board and the paint, thus greatly reducing the generation of waste gas; as the internal heating space of the device is near to the closed state when in work, the hot wind is recycled, which can not only save the energy, but can also further reduce the emission of the waste gas to the air.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

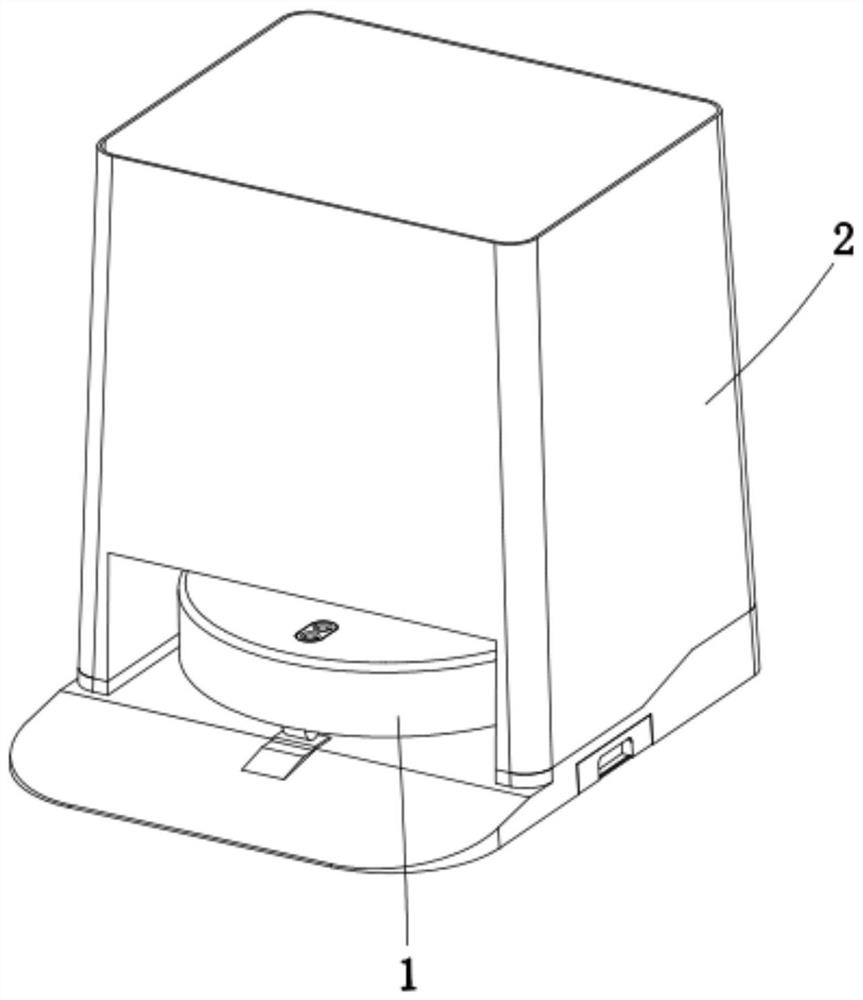

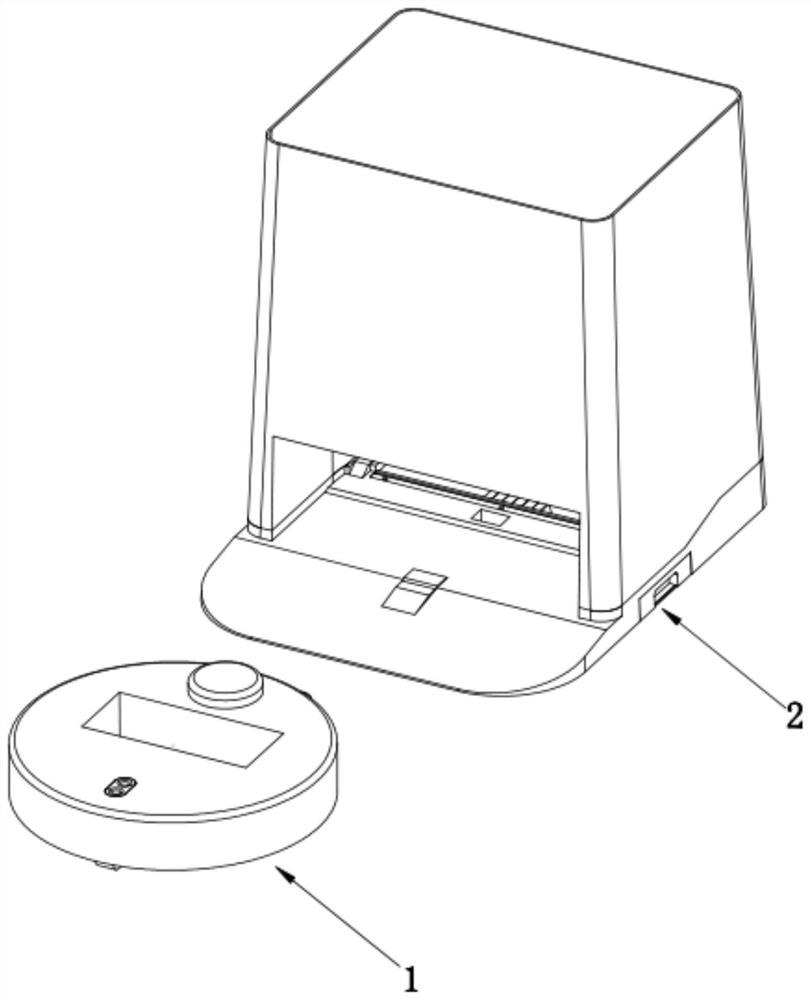

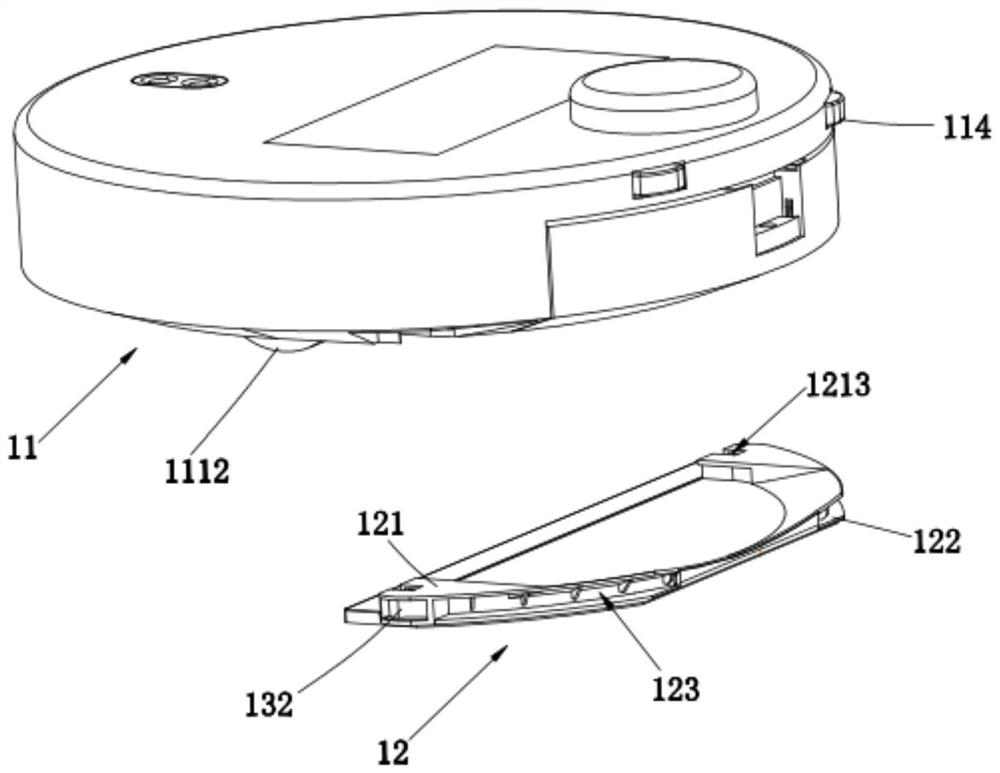

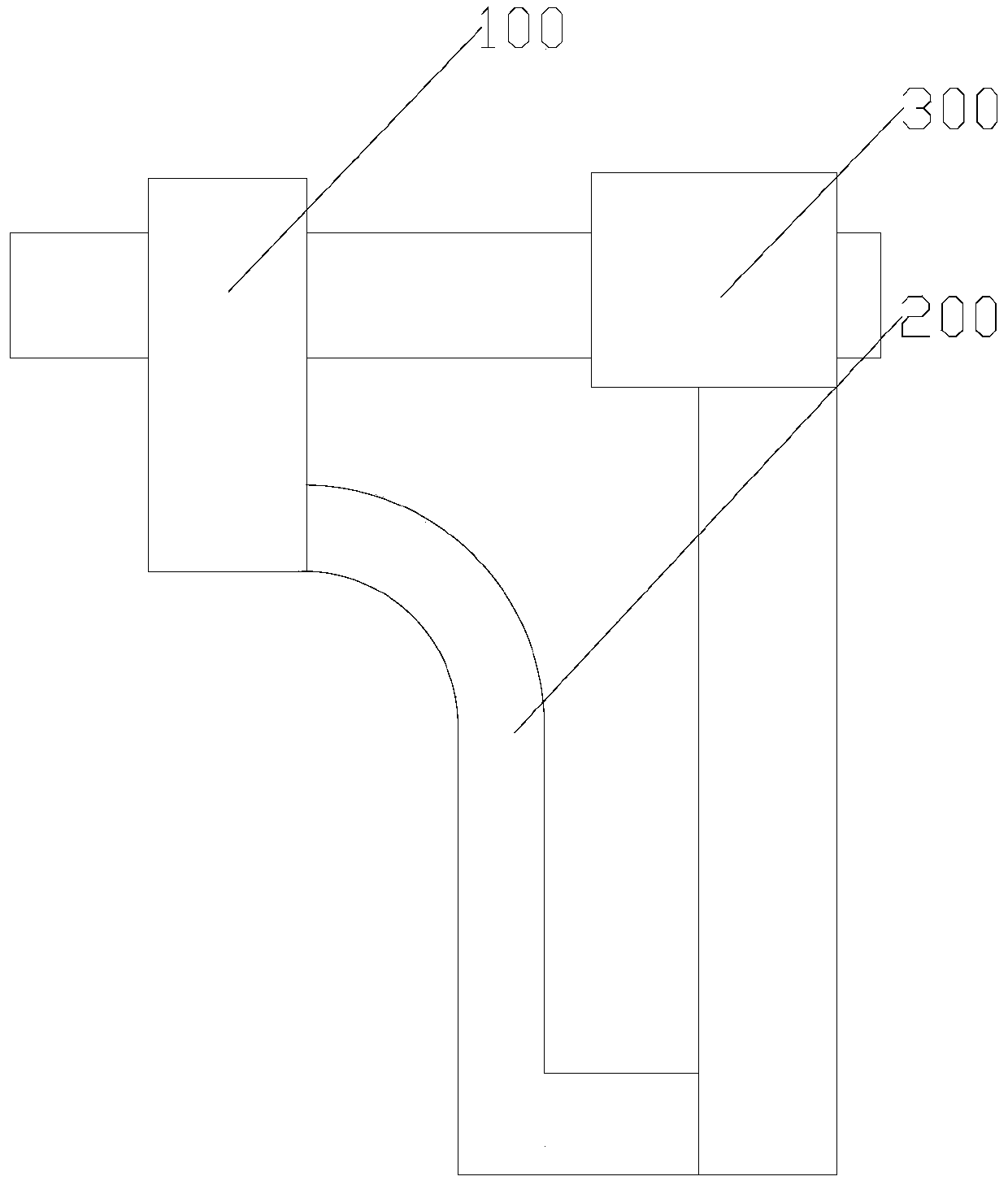

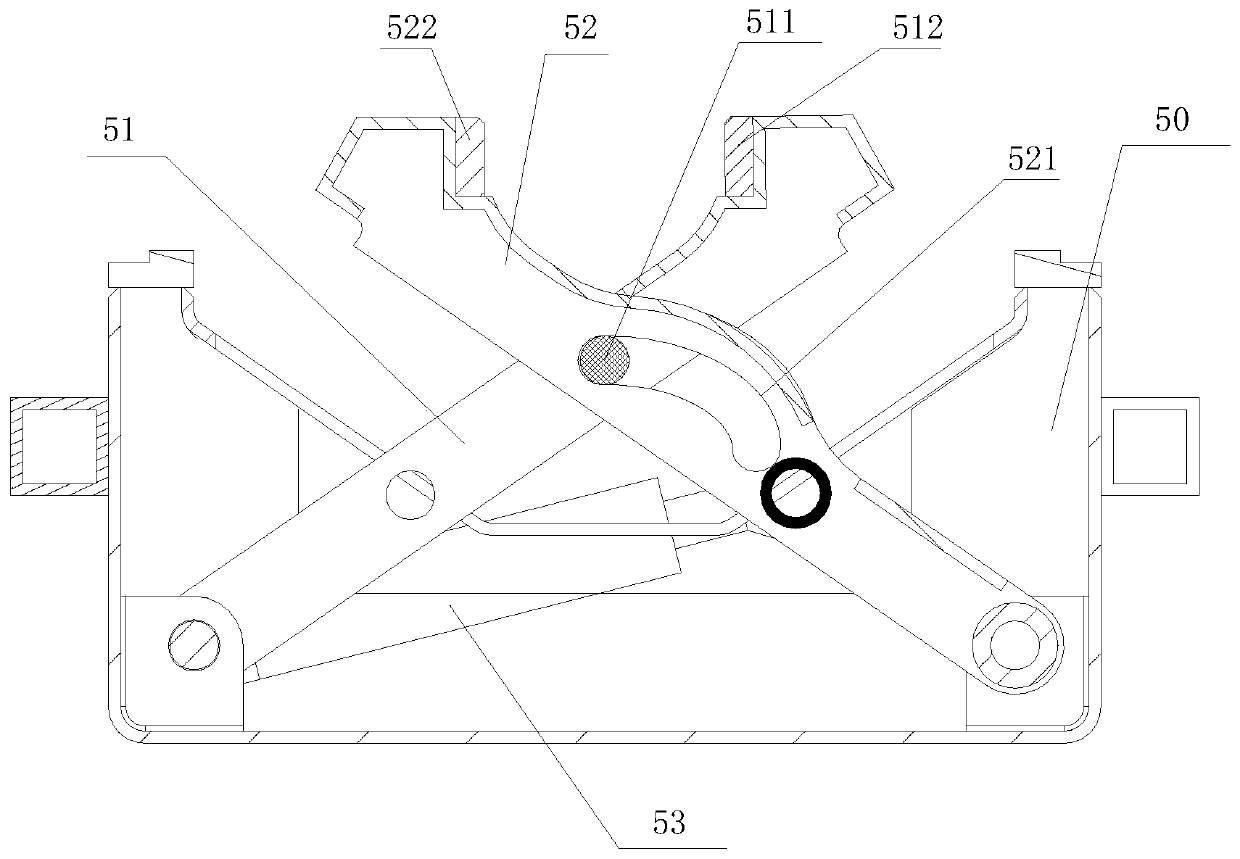

Base and sweeping robot cleaning system

PendingCN112369970ARealize automatic disassemblyImplement automatic installationCarpet cleanersFloor cleanersControl engineeringProcess engineering

The invention is applicable to the technical field of sweeping robots, and provides a base and a sweeping robot cleaning system; the base is used in cooperation with a sweeping robot; the sweeping robot is provided with a mop assembly detachably connected with a robot body through a lock catch mechanism; and the base comprises a base body, a cloth dismounting and mounting mechanism arranged on thebase body, and a first control unit . The cloth dismounting and mounting mechanism can drive the lock catch mechanism to unlock so as to dismount the mop assembly from the robot body, and can drive the lock catch mechanism to lock so as to mount the mop assembly on the robot body; and the first control unit is electrically connected with the cloth dismounting and mounting mechanism. According tothe base, the cloth dismounting and mounting mechanism is arranged, the cloth dismounting and mounting mechanism is matched with the sweeping robot, so that the mop assembly of the sweeping robot canbe automatically dismounting or mounting, the sweeping and mopping functions of the sweeping robot are conveniently switched, the mop assembly does not need to be manually disassembled or assembled, and the base is convenient for a user to use.

Owner:SHENZHEN TOPBAND CO LTD

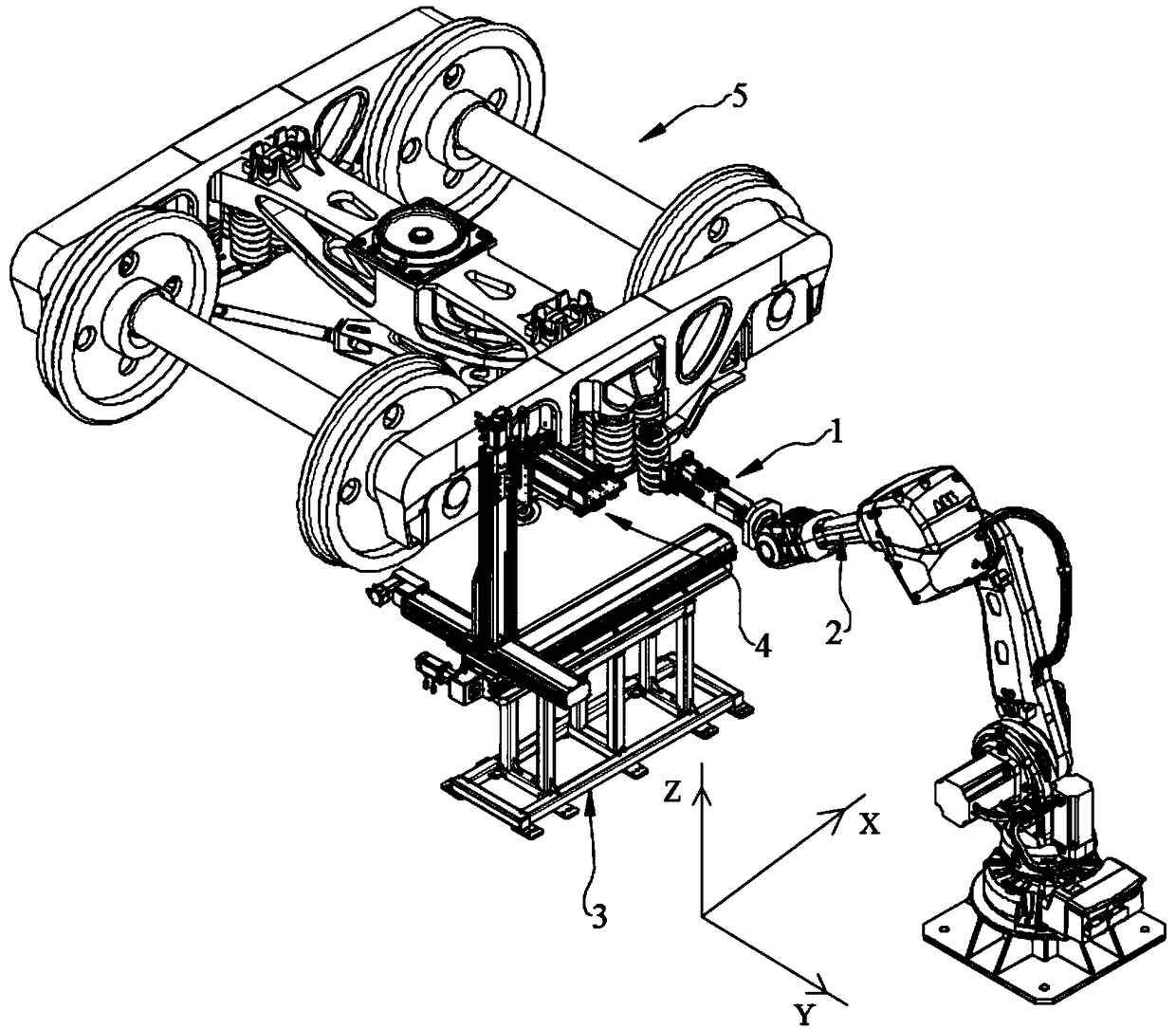

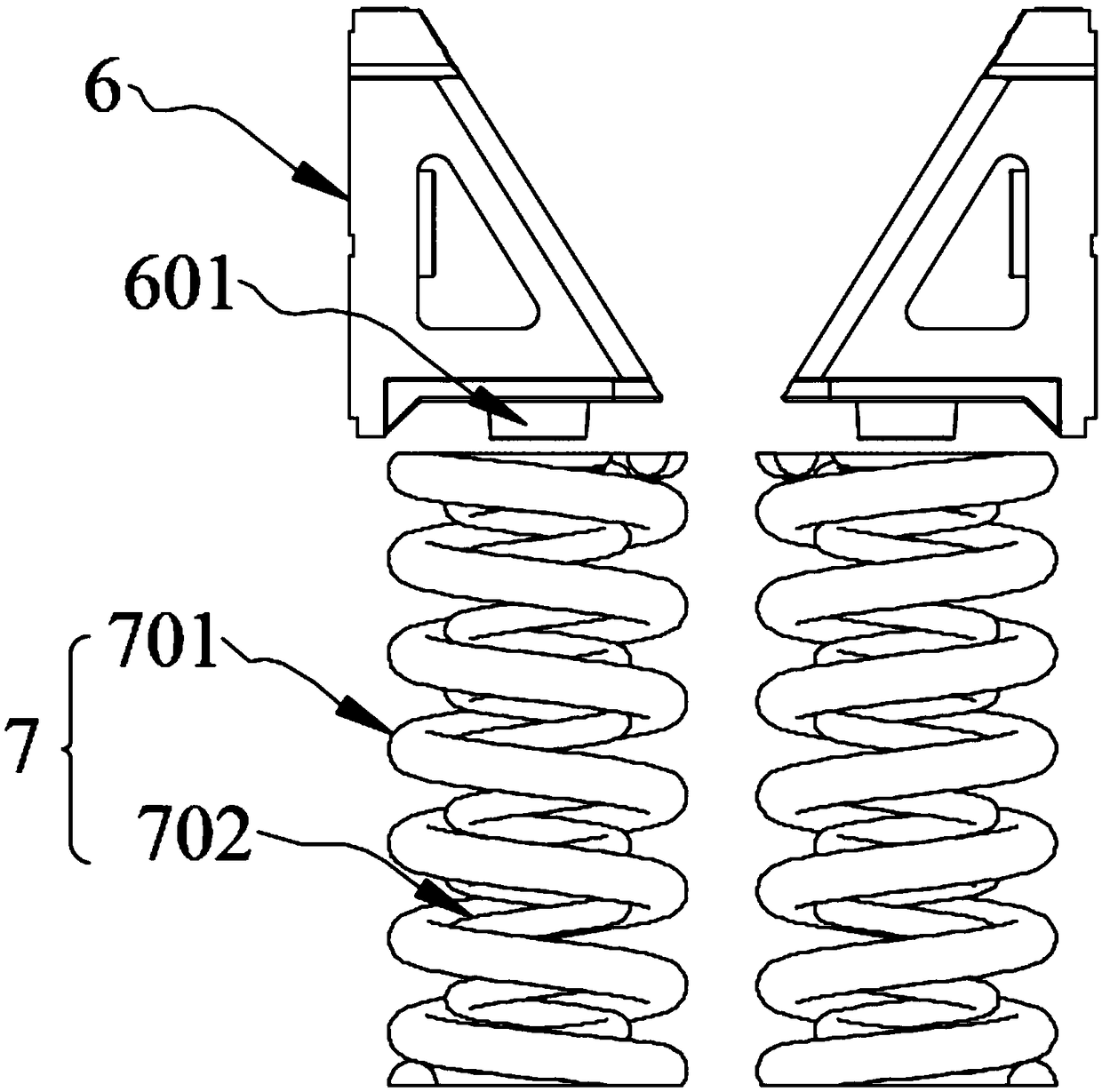

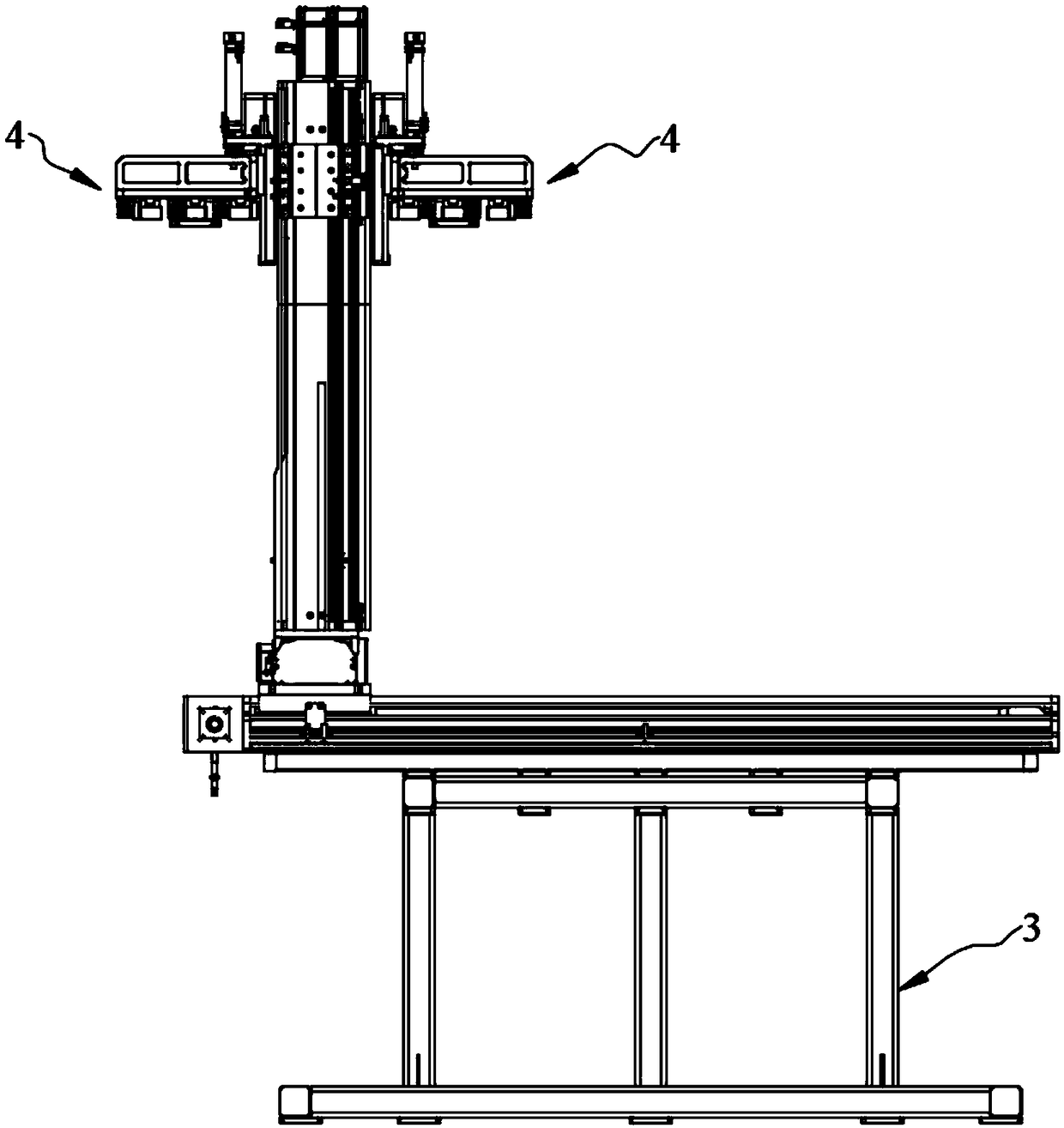

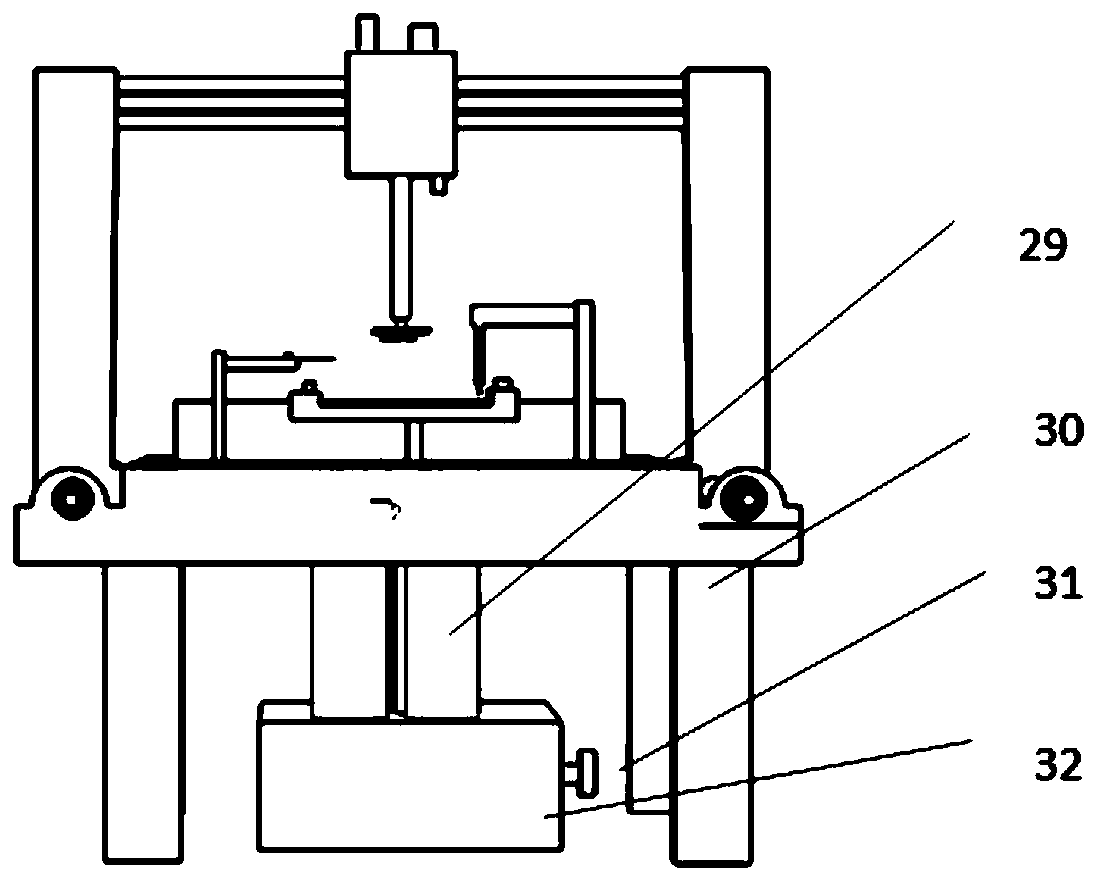

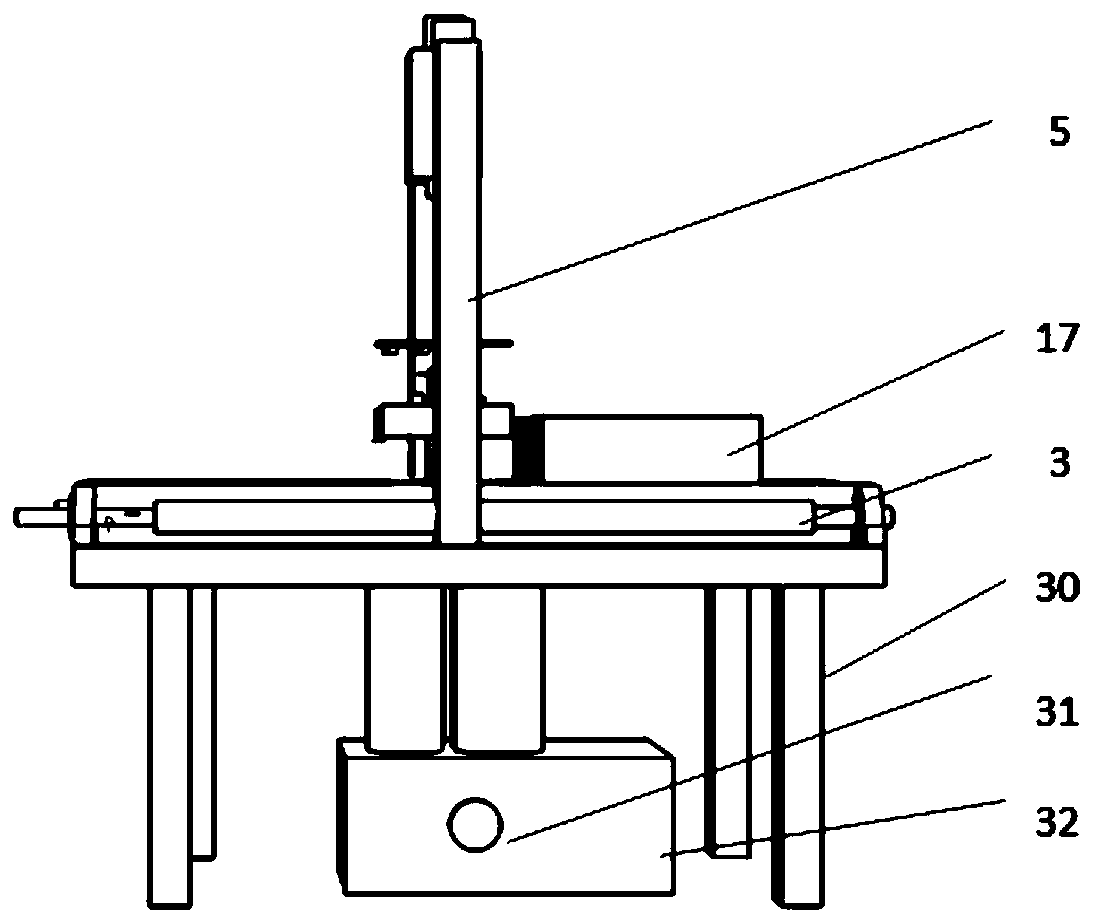

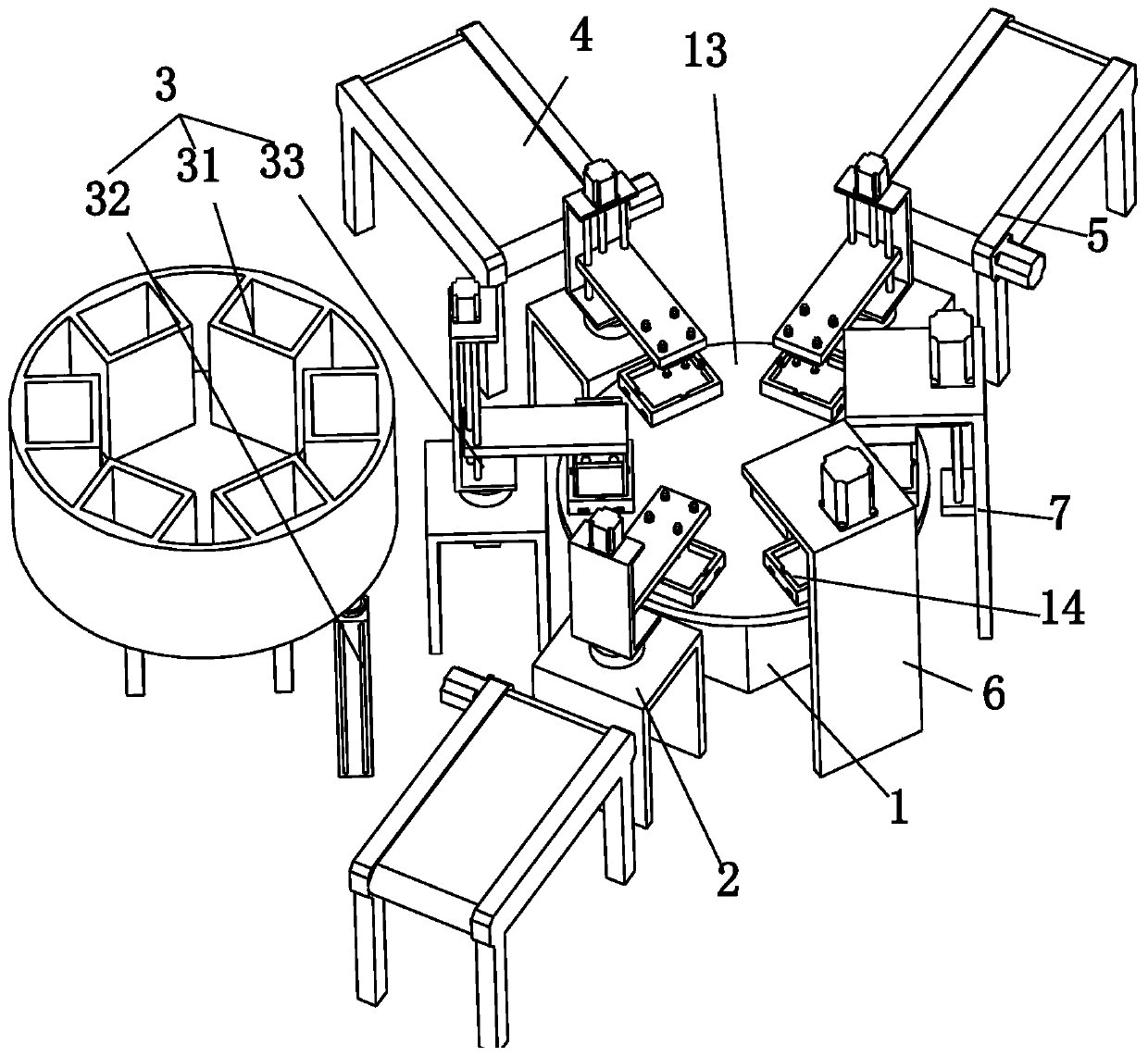

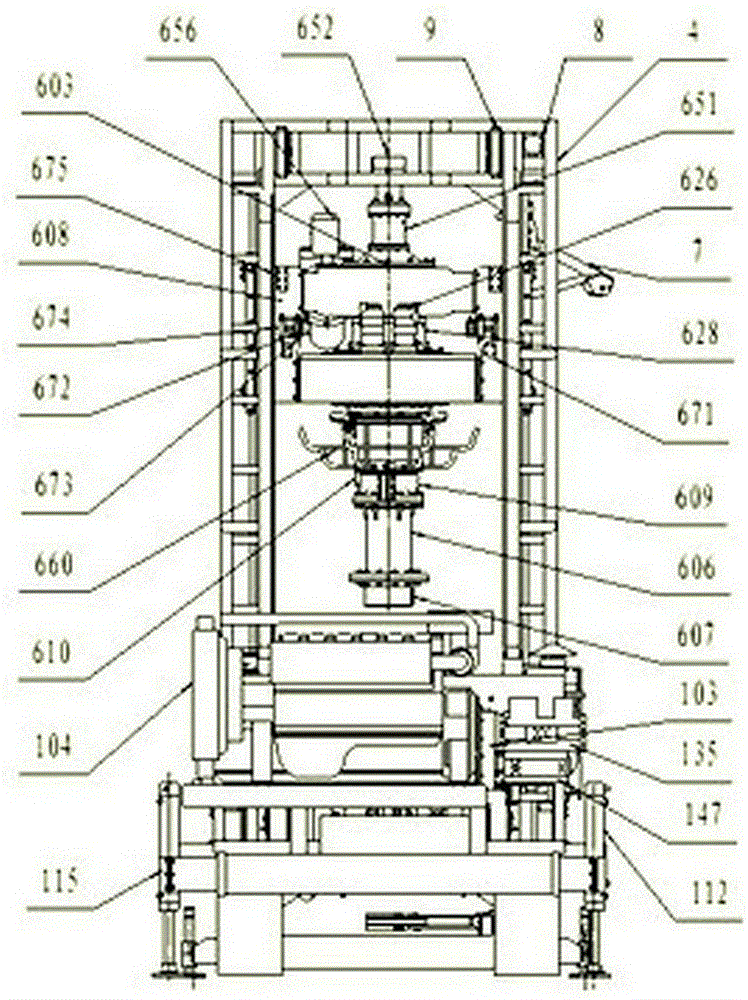

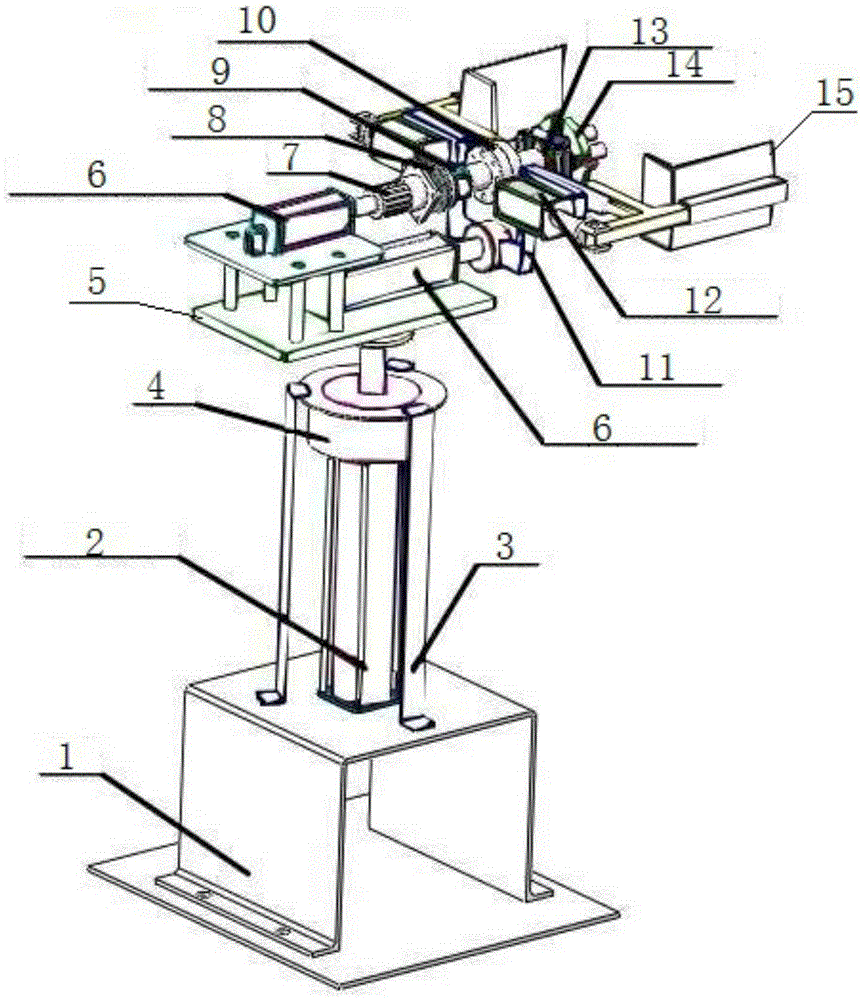

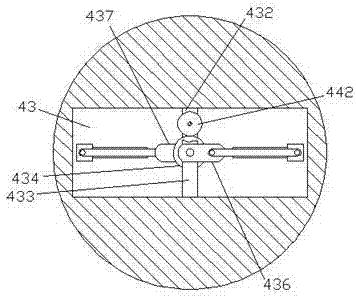

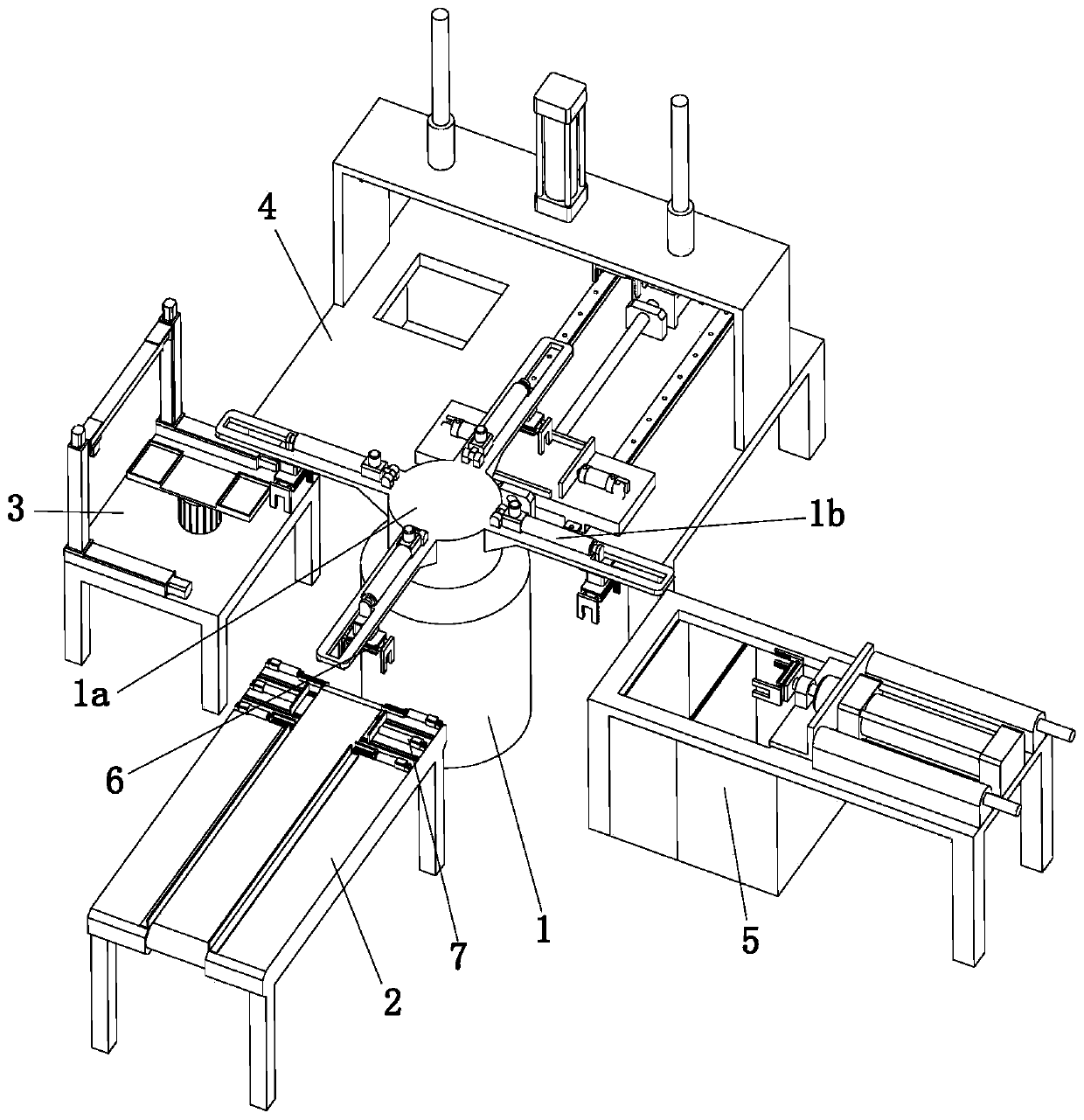

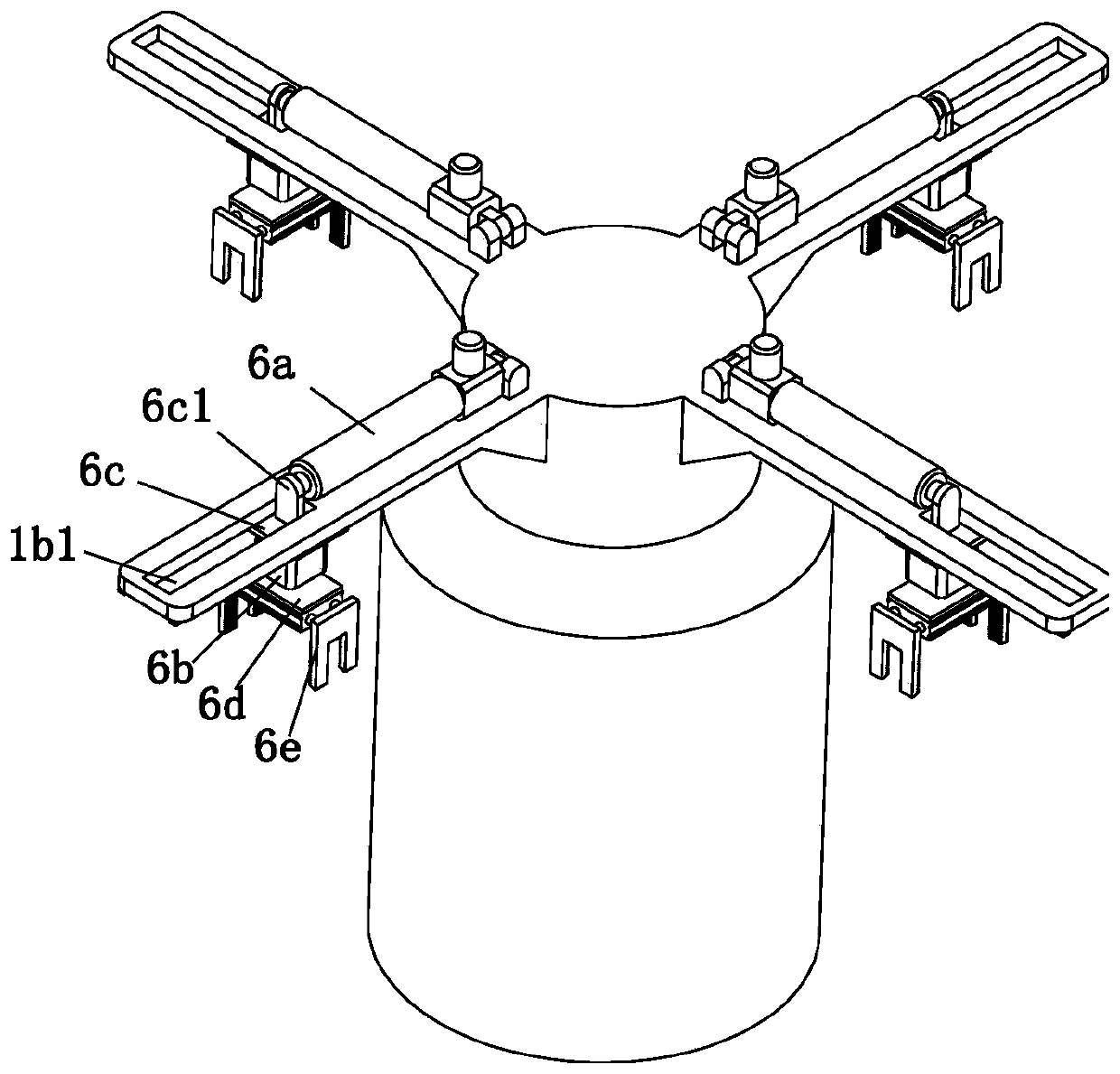

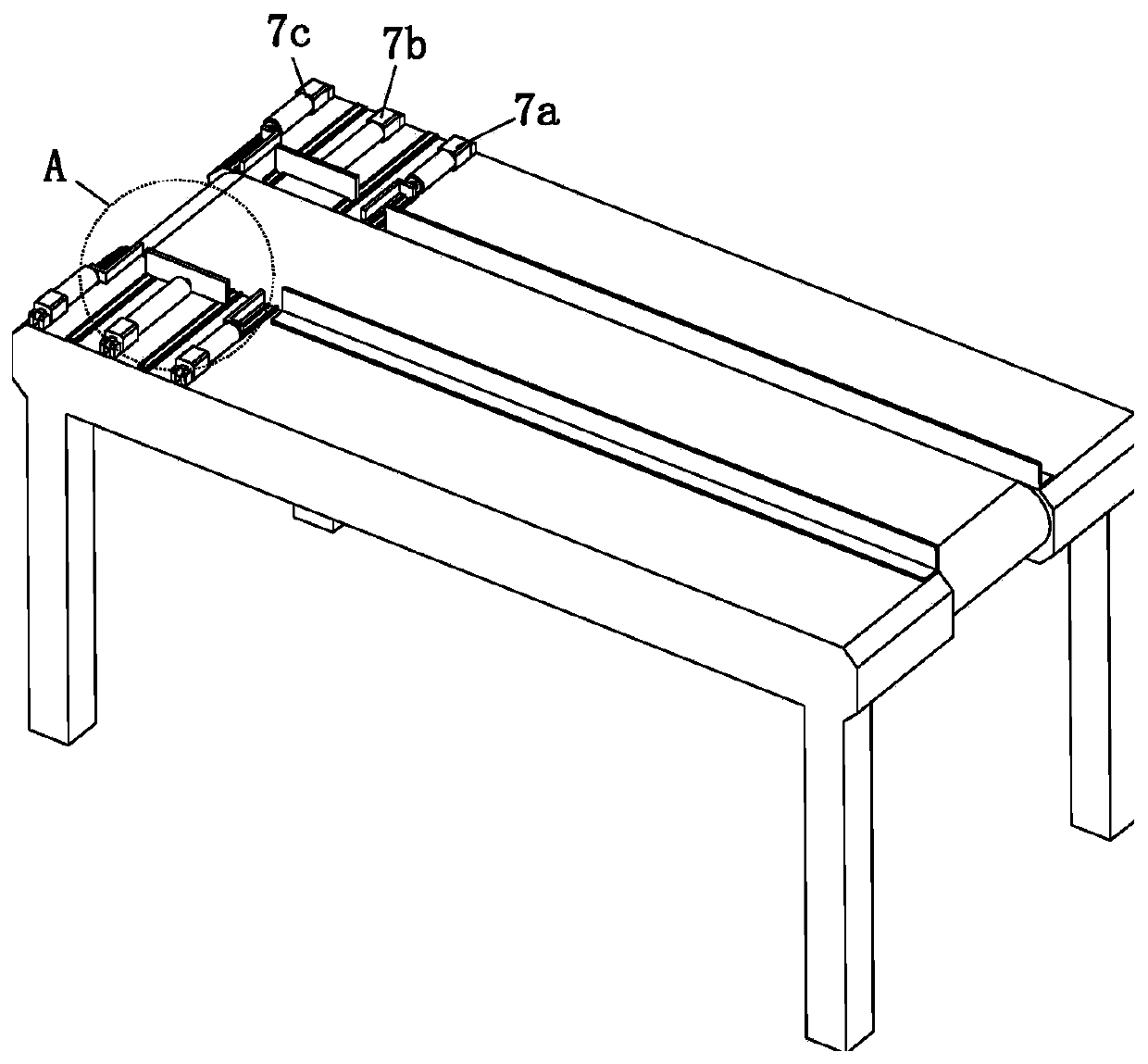

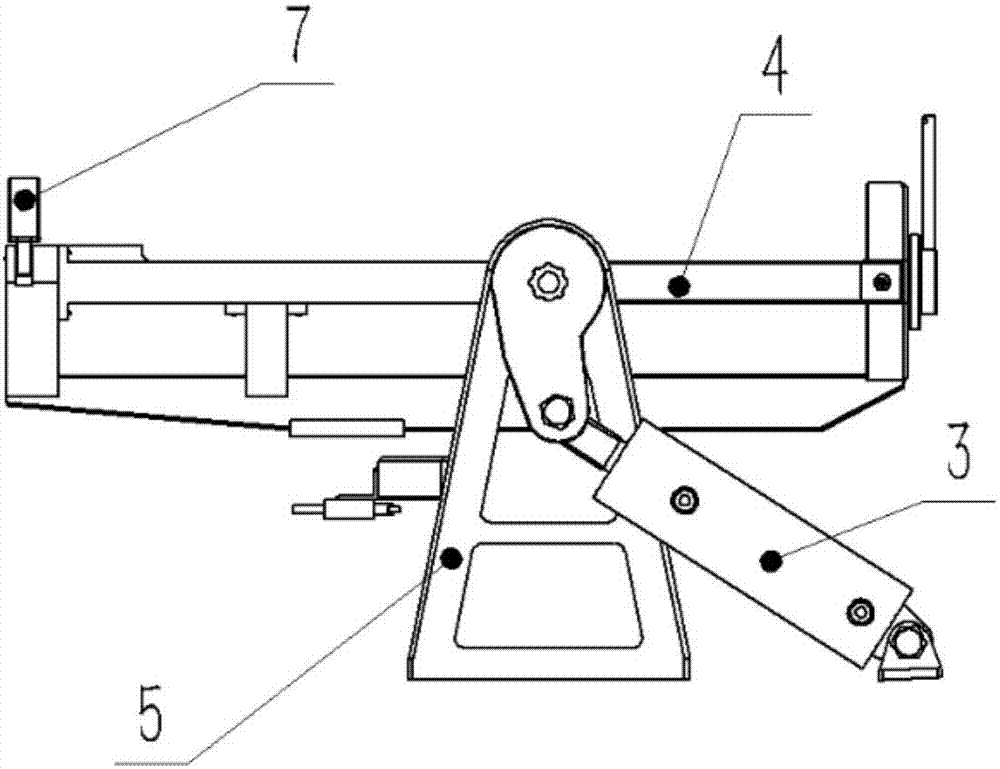

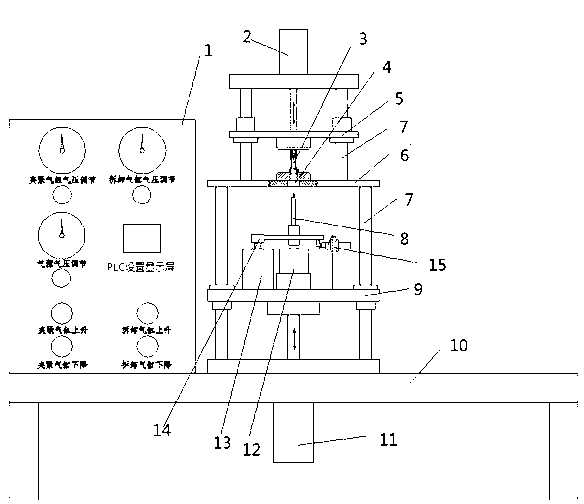

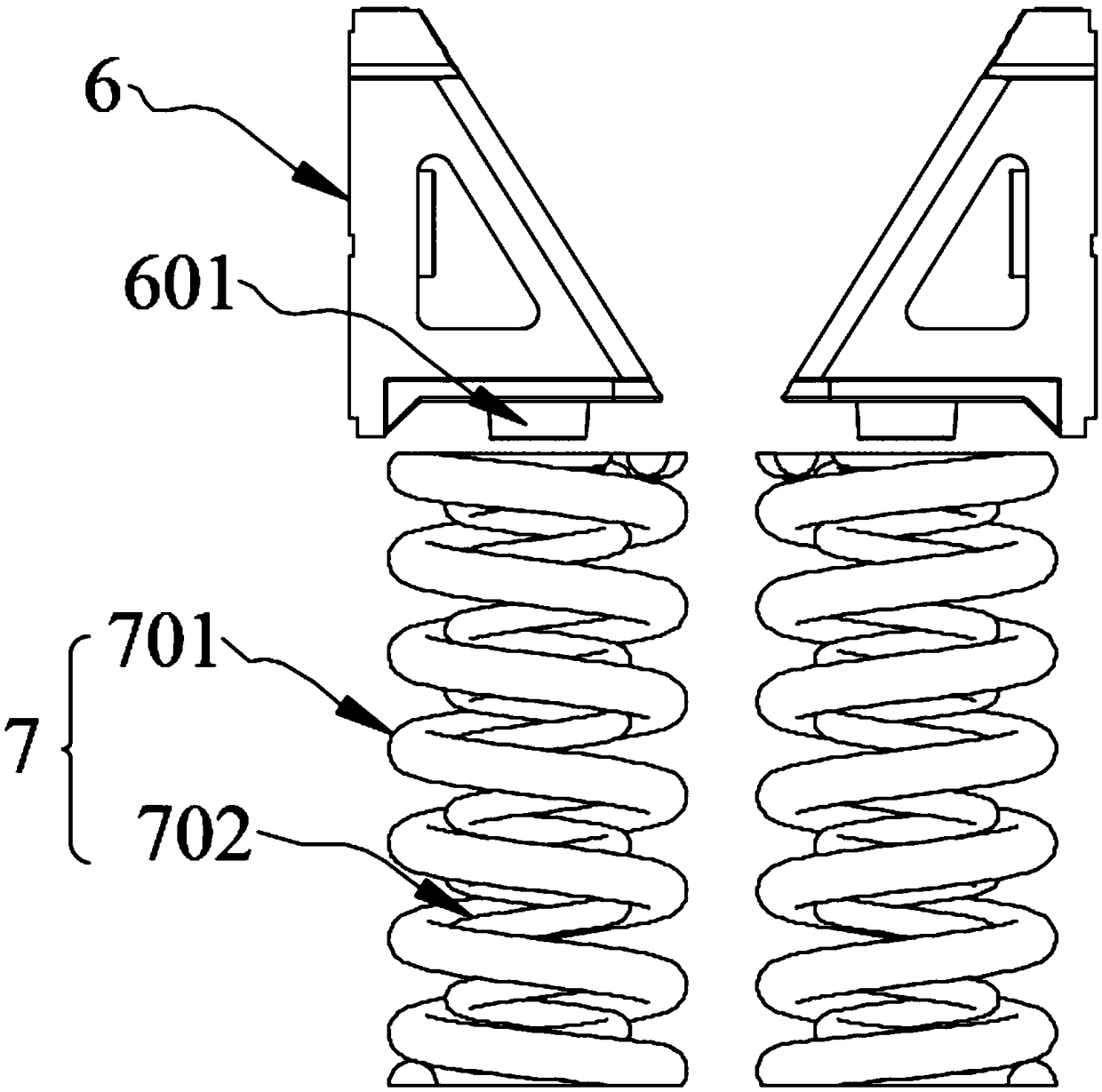

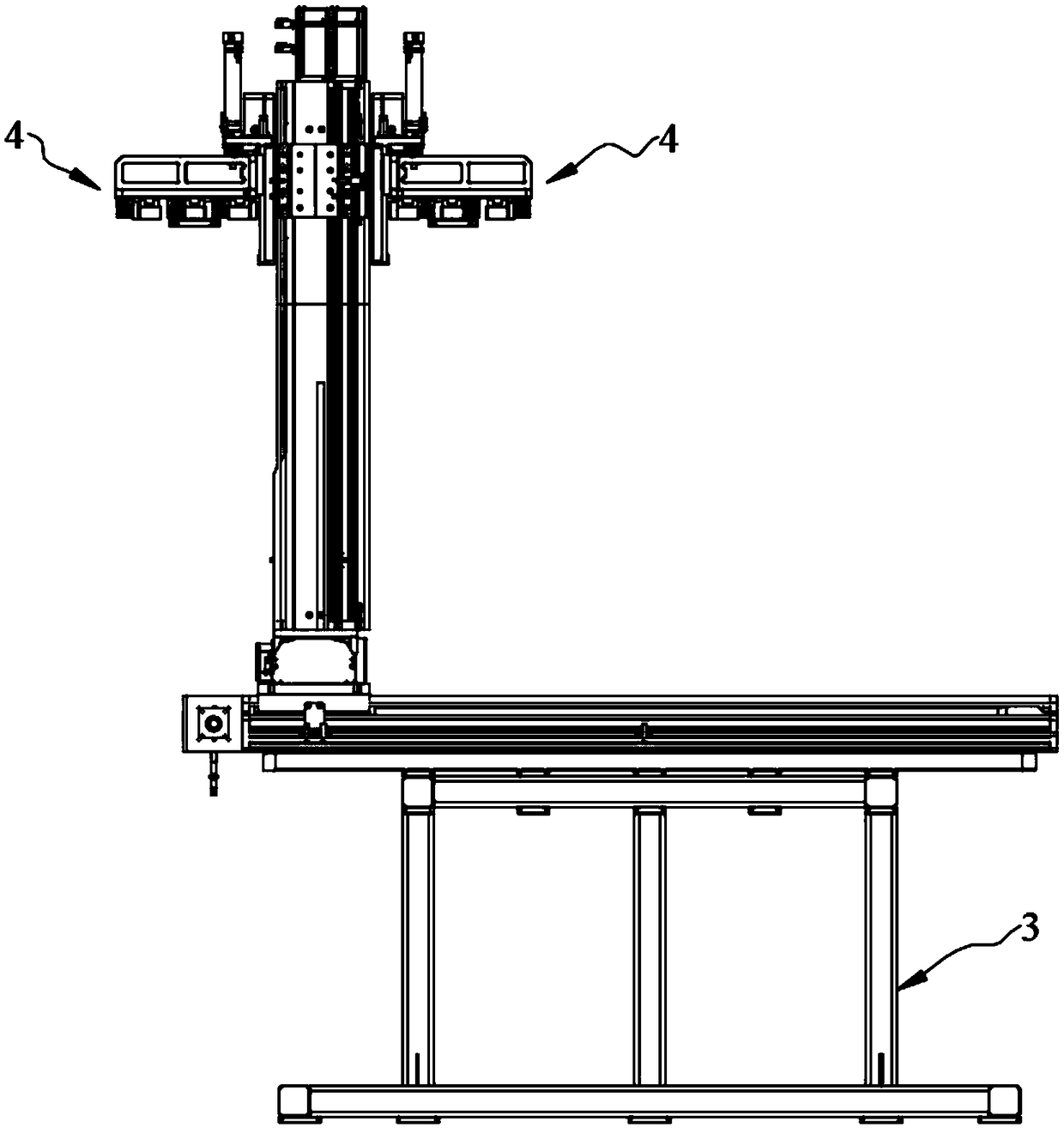

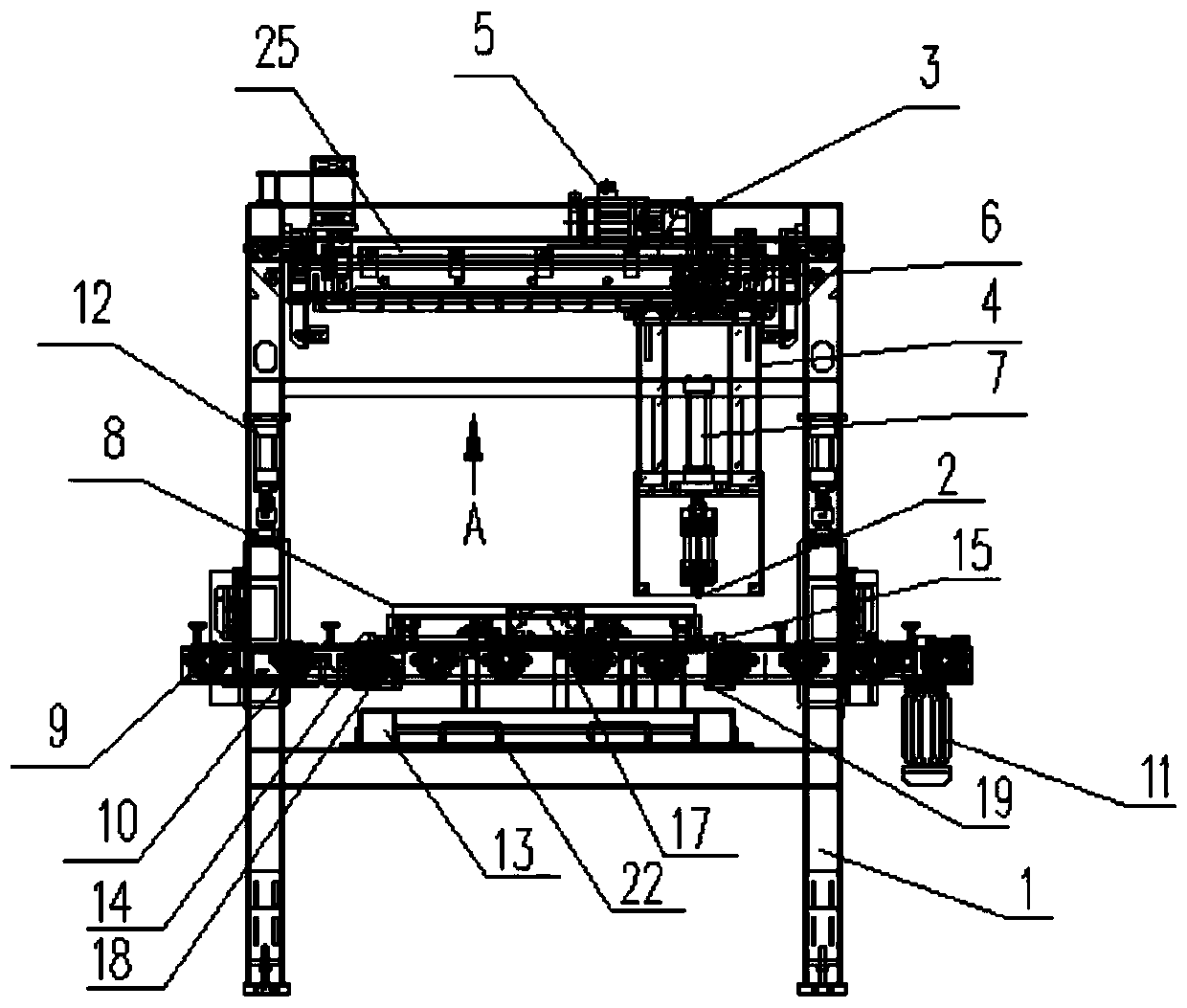

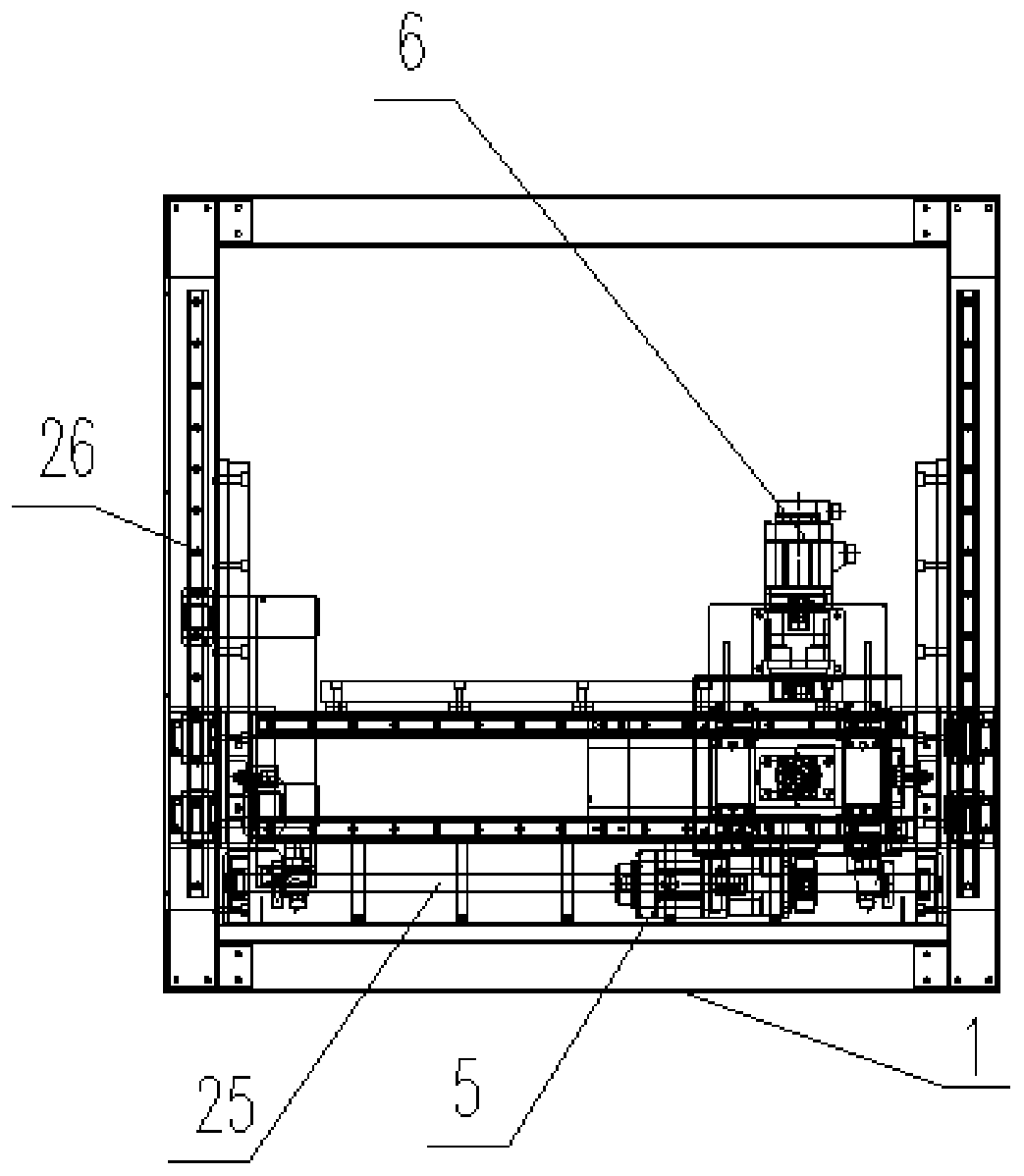

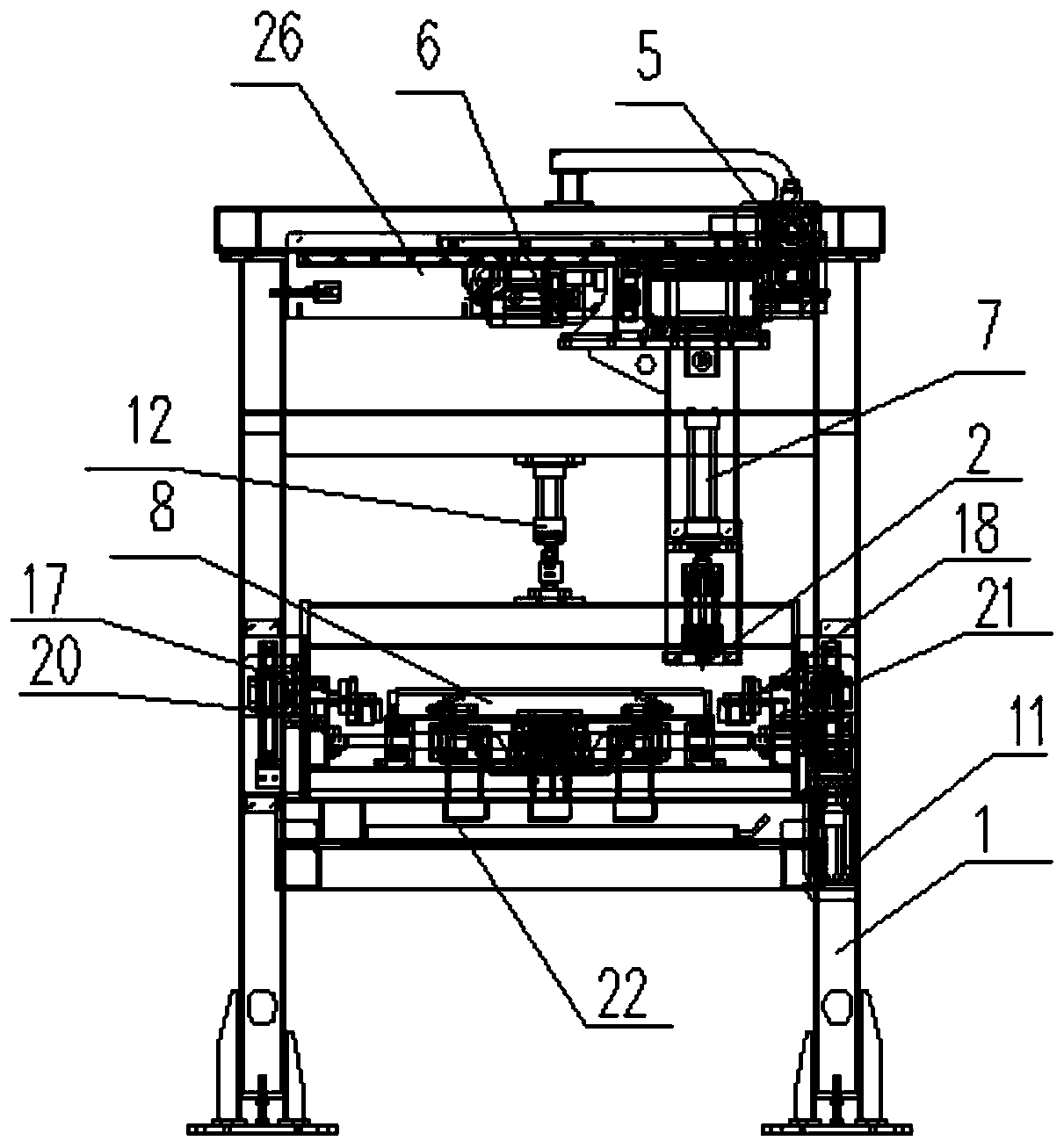

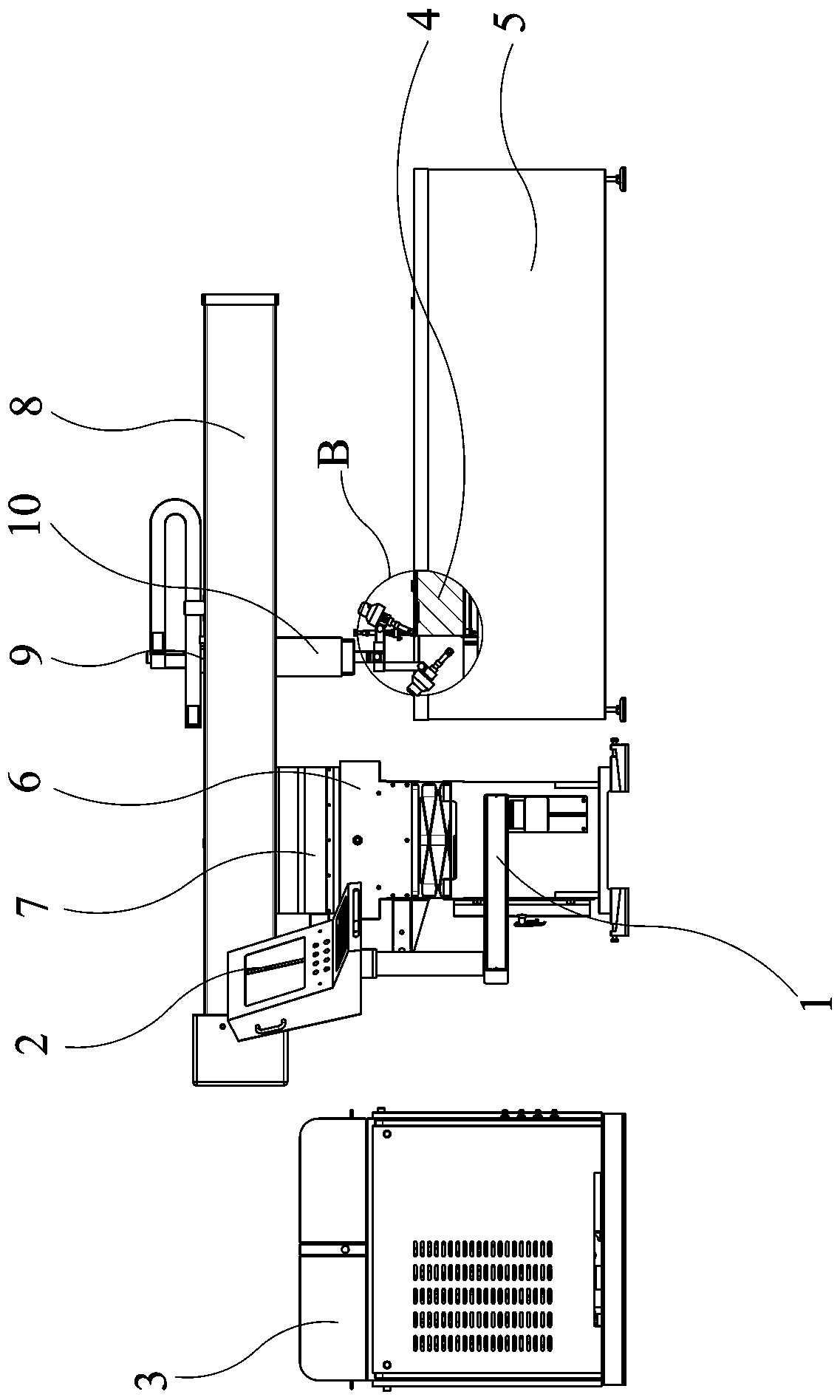

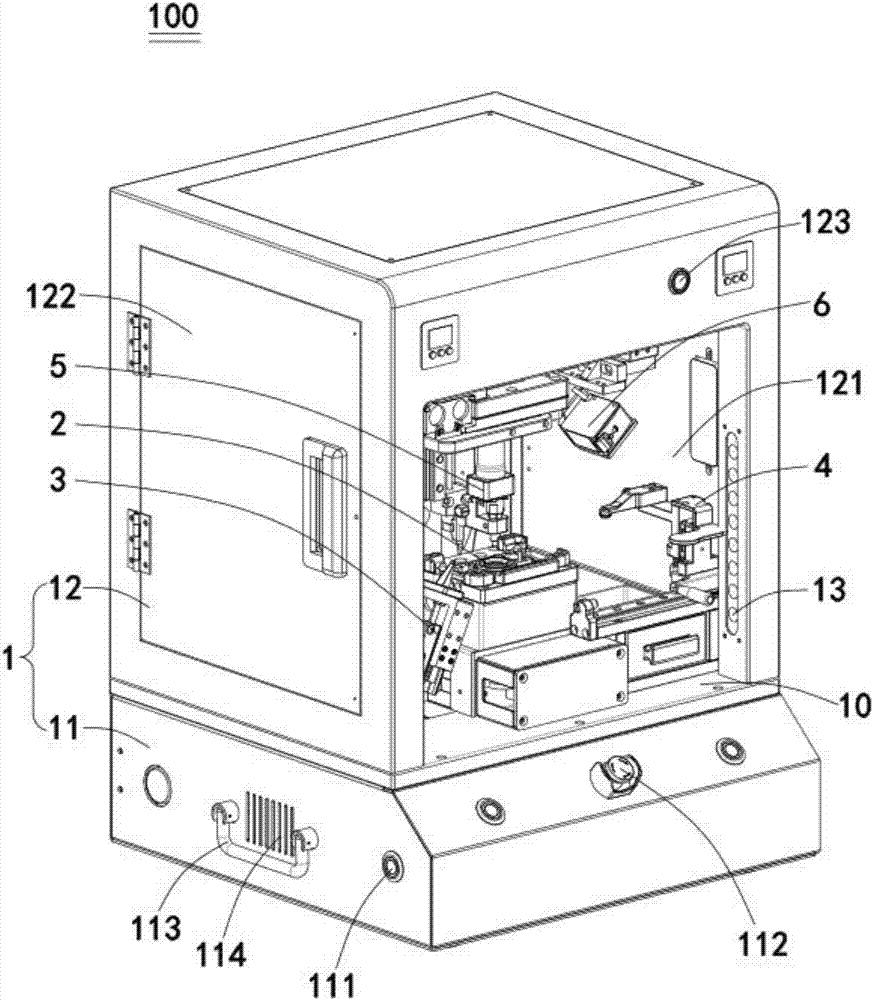

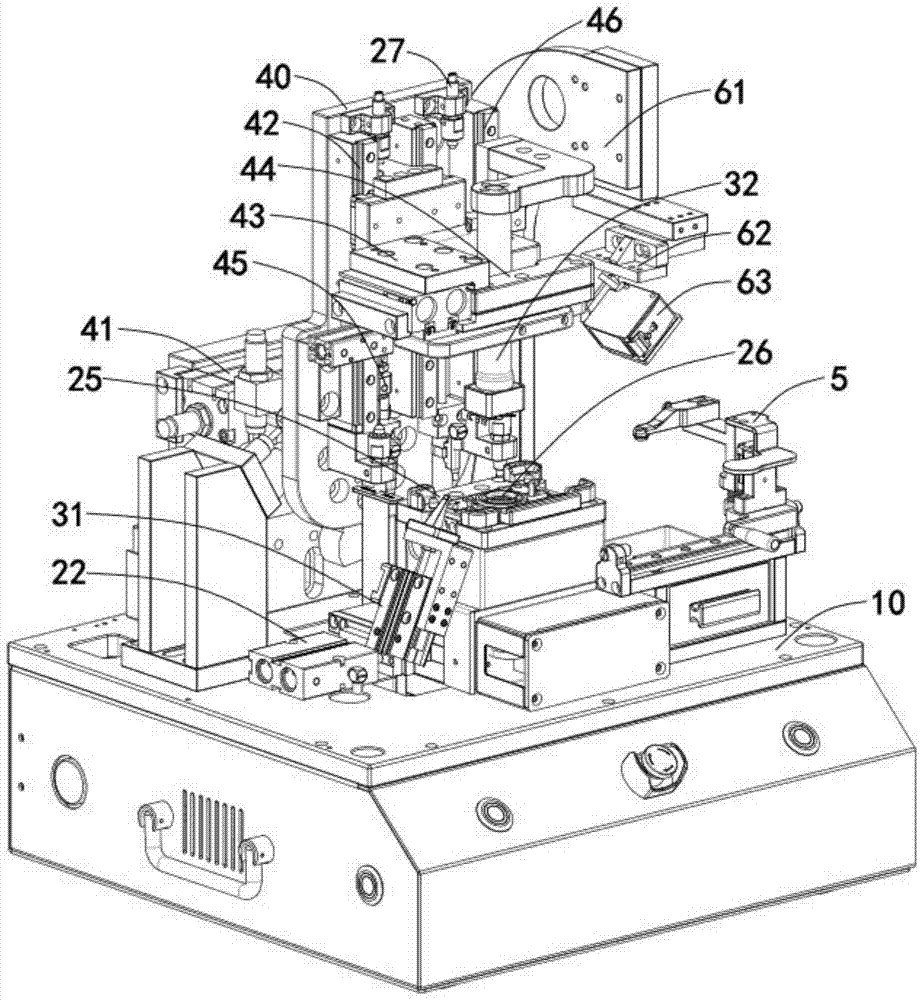

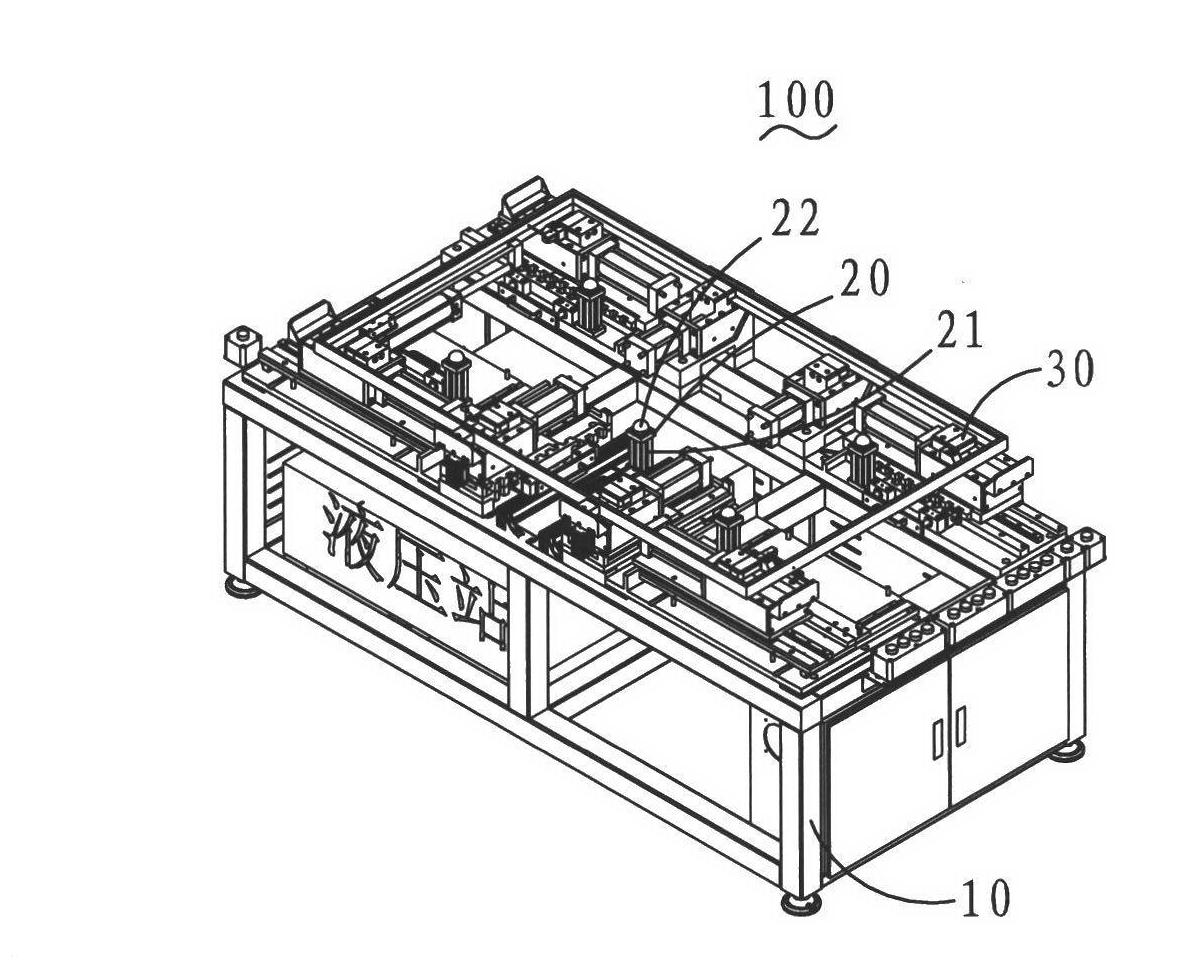

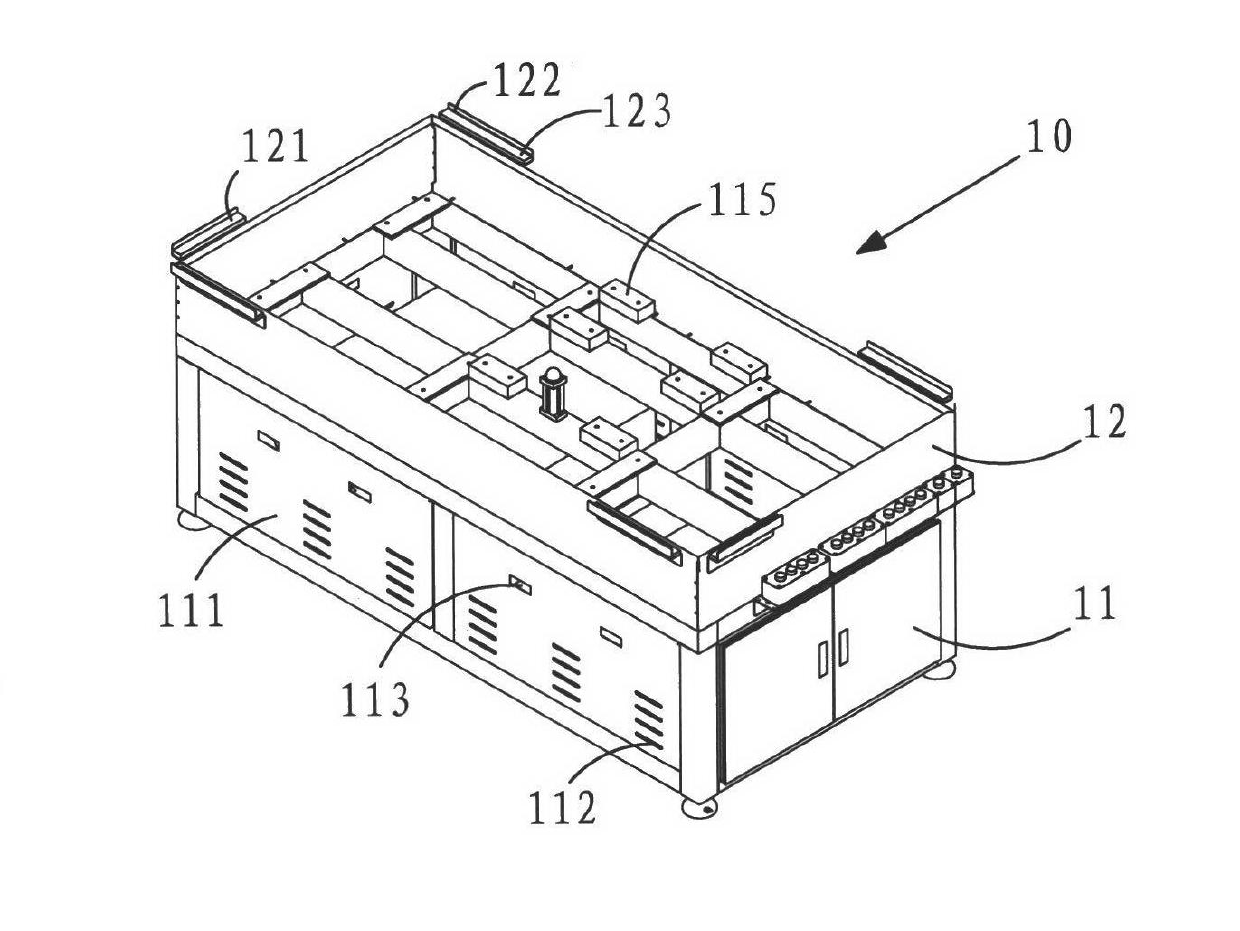

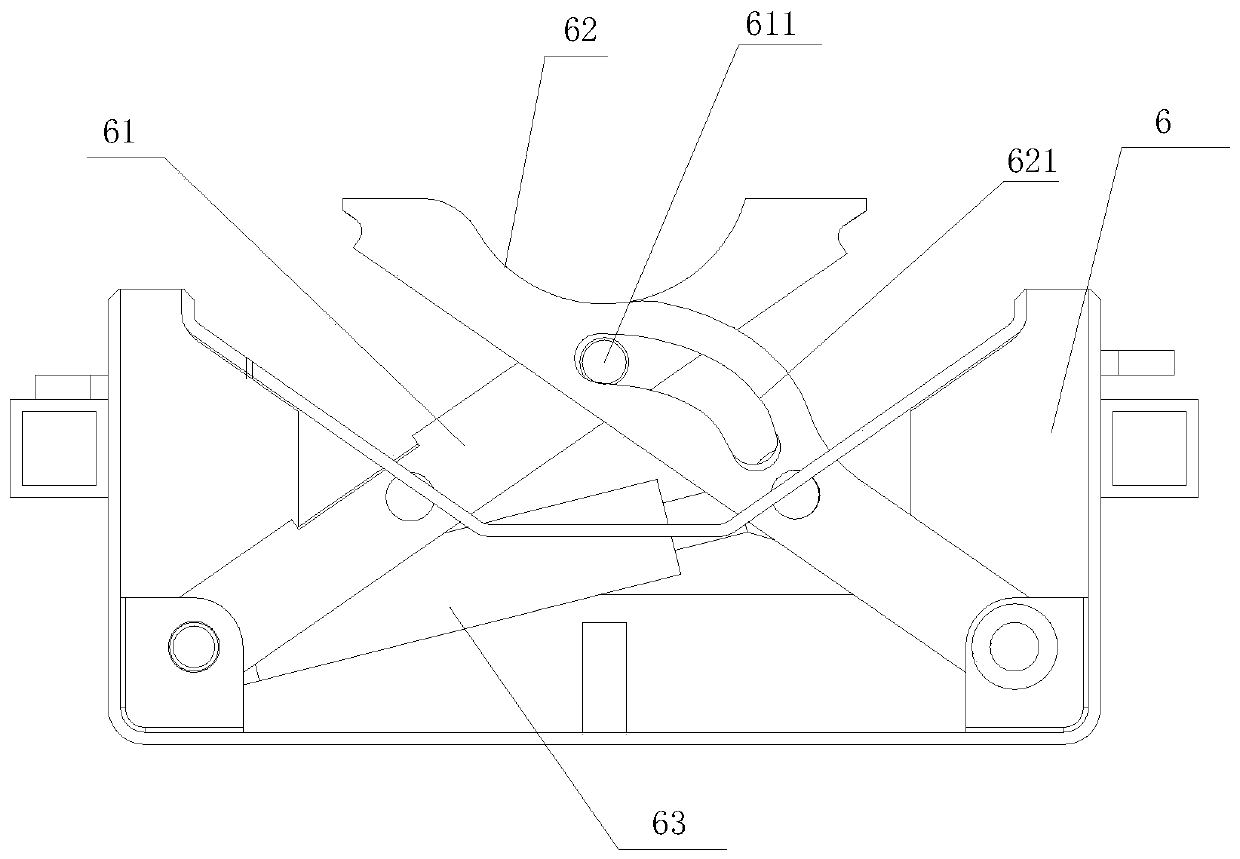

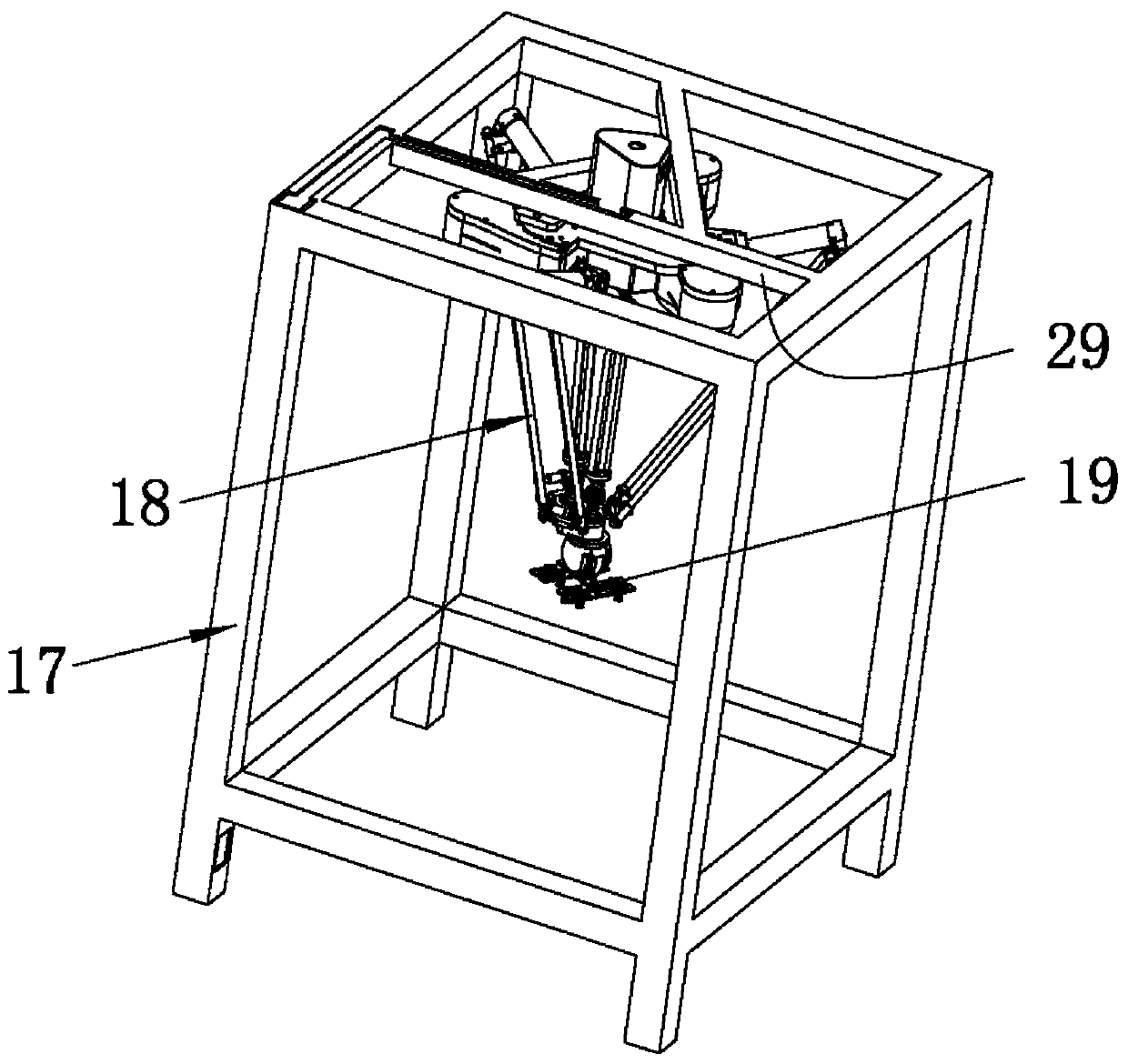

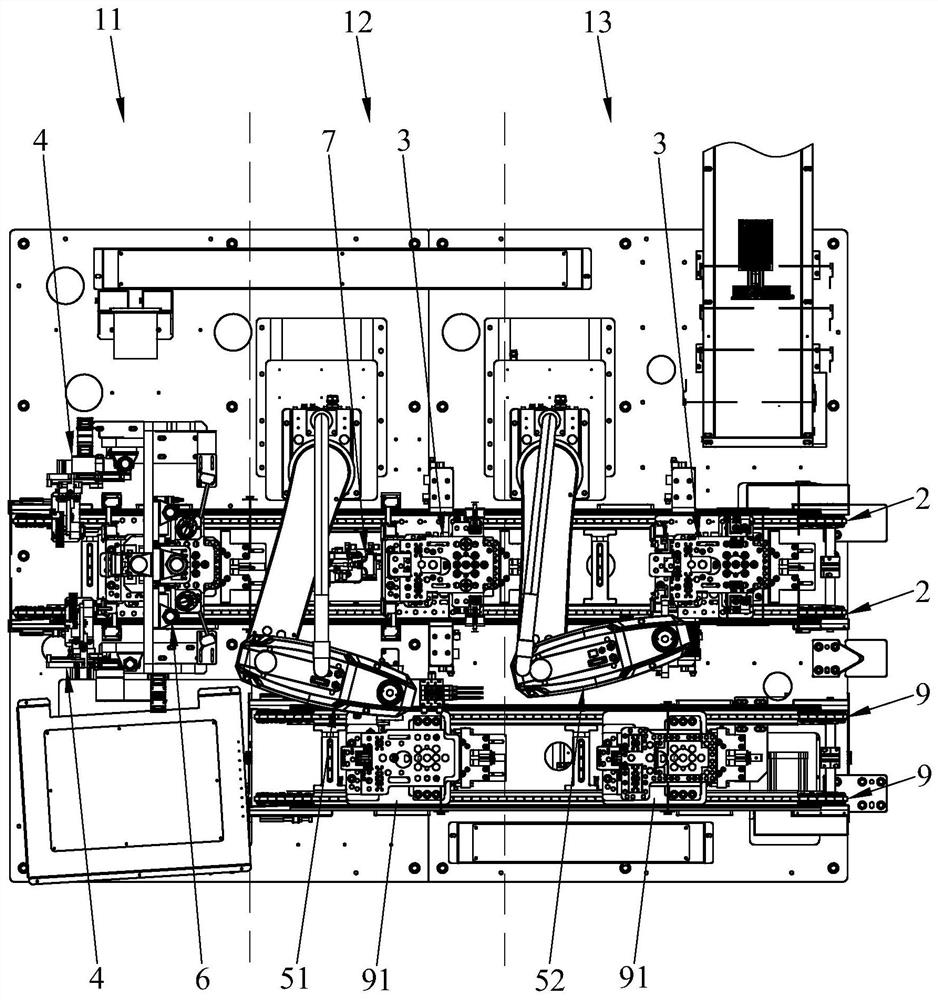

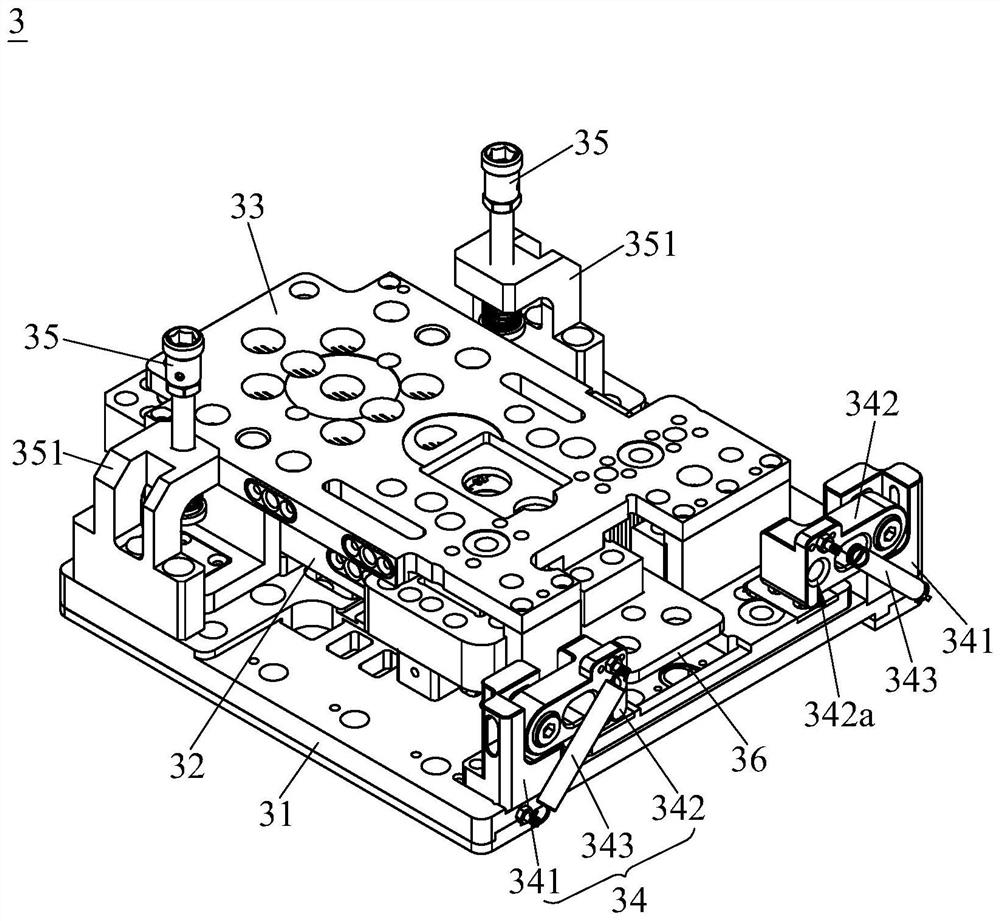

Automatic disassembling system for bogie bearing spring

ActiveCN108637634AAchieve precise positioningImprove disassembly efficiencyMetal working apparatusBogieEngineering

The invention discloses an automatic disassembling system for a bogie bearing spring and belongs to the technical field of bogie disassembling device. The problems that in the existing bogie disassembling process, both a bearing spring and an inclined wedge block need taken out in a manual carrying mode, thus, the labor intensity is high, and the working efficiency is low are solved. The automaticdisassembling system comprises a jacking device and a clamping device; the jacking device comprises a jacking unit used for taking an inclined wedge block out, and the jacking unit is connected witha three-axis cantilever; and the clamping device comprises a clamping head for clamping the bearing spring, and the clamping head is connected with a mechanical arm.

Owner:SOUTHWEST JIAOTONG UNIV

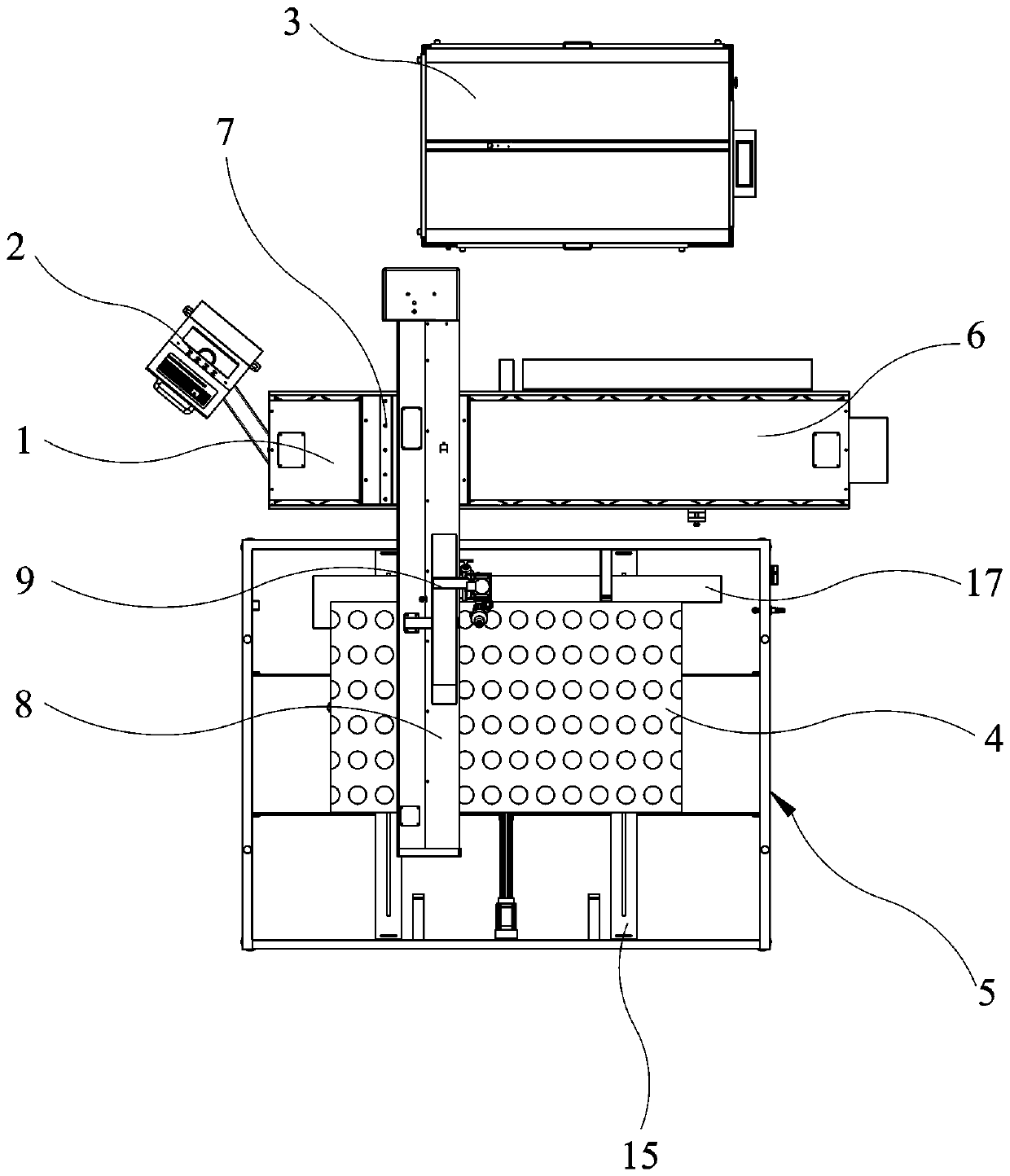

Novel battery disassembling equipment and method

ActiveCN111515644ARealize automatic disassemblyLow risk of explosionWaste accumulators reclaimingMetal working apparatusElectric machineryEngineering

The invention discloses novel battery disassembling equipment which characterized by comprising a worktable, a fixed rodpiece A, a Z-axis lifting lead screw, an L-shaped arm A and an L-shaped arm B, and a battery storage box, wherein a mobile phone clamp is mounted on a guide rail through a guide rail slide block, the mobile phone clamp moves in the guide rail, and grippers at two ends of the mobile phone clamp move on the mobile phone clamp through a motor; a pressure sensor is fixedly mounted on the mobile phone clamp through a bolt; the bottom of the mobile phone clamp is drilled and perforated uniformly, is connected to a nitrogen pipeline through liquid nitrogen pipeline through holes in the bottom of the mobile phone clamp, the connecting parts are sealed by rubber gaskets, the nitrogen pipelines are distributed uniformly, and a temperature sensor is mounted on the mobile phone clamp through a bolt. The novel battery disassembling equipment can solve the risk that it may lead toheat loss of an electronic component as the temperature of a hot air gun is relatively high and is not heated uniformly and the battery which is heated may explode in a battery disassembling mode in the prior art, and achieves a technical effect of protecting electronic parts and components such as a main board.

Owner:QINGDAO UNIV OF SCI & TECH

PCB detection and sorting device

The invention relates to the technical field of circuit board detection and sorting, in particular to a PCB detection and sorting device. The device comprises a workbench, wherein the workbench is internally provided with a stepping motor which is vertically arranged, the top of the workbench is provided with a first coupling seat, the output end of the stepper motor is fixedly connected with thefirst coupling seat, a rotating shaft is mounted at the top of the first coupling seat, a rotating disc is arranged at the top of the rotating shaft, six fixing jigs which are evenly distributed in the circumferential direction of the rotating disc are arranged on the rotating disc, a feeding device, a jig replacing device, a first discharging device, a second discharging device, a secondary detecting device and a detecting device are sequentially arranged in the circumferential direction of the rotating disc, and a first auxiliary discharging mechanism located beside the first discharging device and a second auxiliary discharging mechanism located beside the second discharging device are arranged on the outer side wall of the workbench. According to the device, the automatic detection andsorting operation is realized, in addition, the jig can be automatically replaced, and the production efficiency is improved.

Owner:崔亮

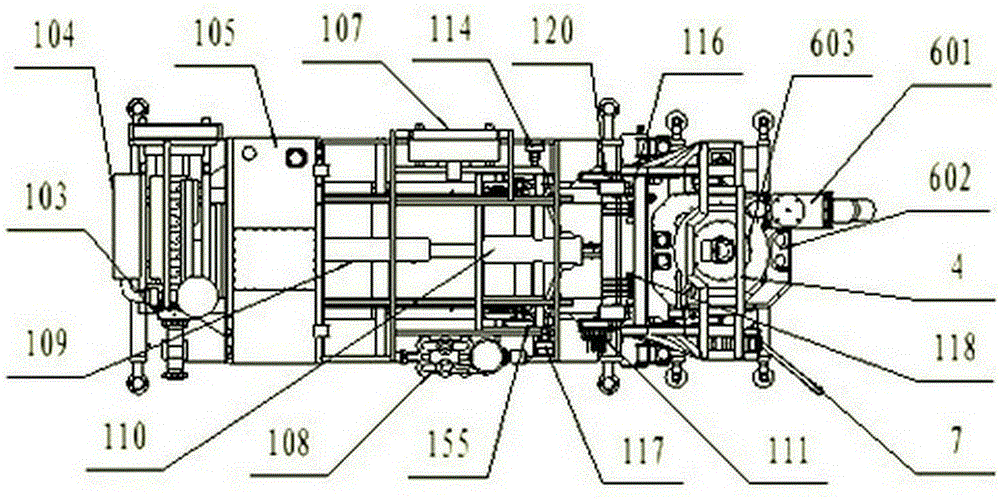

Fully hydraulic reverse circulation drilling machine

InactiveCN105064915AAdapt to the working environmentReduce noiseDrill bitsDrilling rodsGear wheelWinch

The invention provides a fully hydraulic reverse circulation drilling machine, which comprises a walking mechanism, a chassis assembly, a work table frame assembly, a main frame, a main frame turning oil cylinder, a swinging rod assembly, a winch assembly, a drill pipe, a dismounting device, a hydraulic system, a power take-off assembly, an impact drill bit, a rotating wing drill bit, a power assembly and an oil cylinder pulley assembly. A diesel engine or electric power is used for driving; hydraulic motors and oil cylinders are used as executing mechanisms; and the whole process operation of the drilling machine is realized through a hydraulic transmission and control system. The two hydraulic motors and a gear reducer are used for forming a power head to drive a drilling tool to rotate; the hydraulic motors adopt a serial connection or parallel connection mode; and the drill pipe realizes different rotating speeds and can adapt to different-geological-condition and different-hole-diameter operations. The oil cylinders are used for controlling the oil pipe feeding and lifting the drilling tool, so that the power head can vertically move along with the drilling tool and can realize floating, suspension stop and pressurized drilling; the drill pipe can be automatically dismounted and mounted; and the impact drill bit and the rotating wing drill bit are used for realizing the hole drilling of holes with the hole diameter being 2 to 3m and the hole depth exceeding 200m in the pebble bed, the hard rock stratum and the stratum containing large-diameter rock blocks.

Owner:王乐康

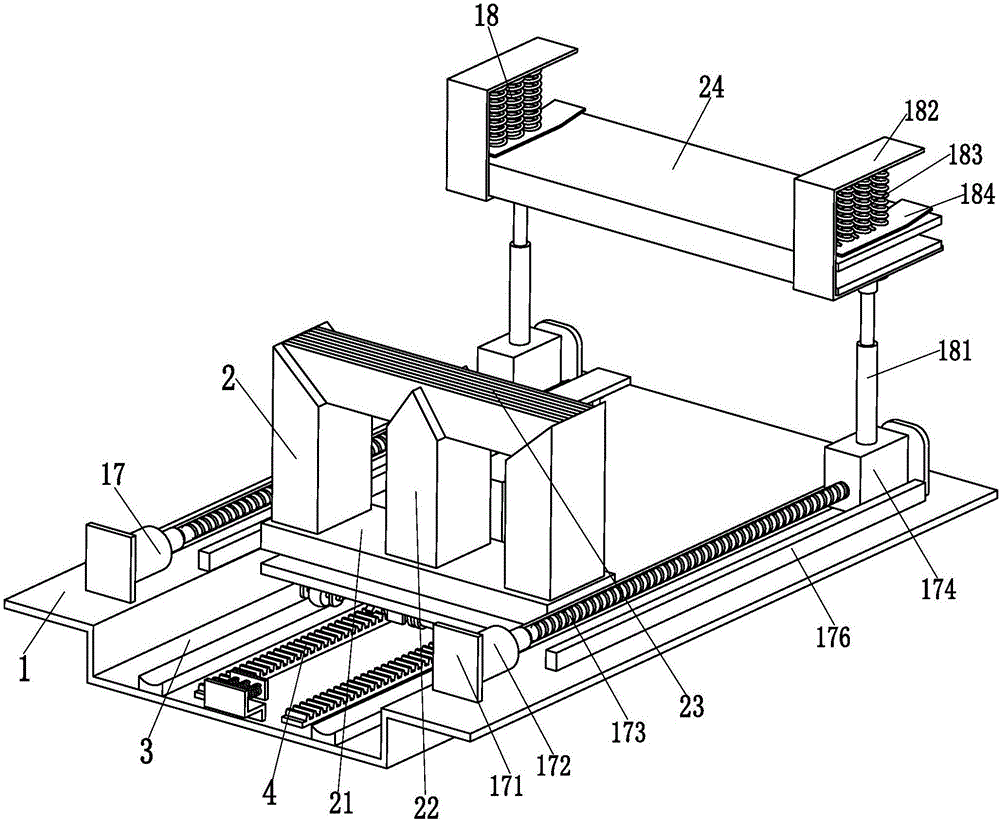

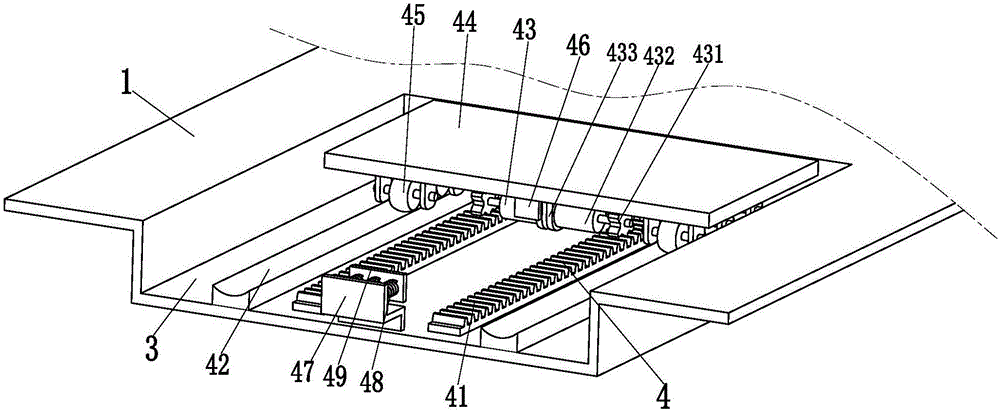

Upper clamp assembly and disassembly device with automatic carrying function for dry-type transformer

ActiveCN106548862ASmooth transmissionGood transmission effectInductances/transformers/magnets manufactureConveyor partsTransformerEngineering

The invention relates to an upper clamp assembly and disassembly device with an automatic carrying function for a dry-type transformer. The upper clamp assembly and disassembly device comprises a bottom plate and an iron core, wherein a concave installation groove is arranged in the front side of the upper end surface of the bottom plate; a sliding carrying mechanism is arranged on the upper end surface of the installation groove; the iron core is put on the upper end of the sliding carrying mechanism and a limiting mechanism is arranged in the middle of the bottom plate; after the sliding carrying mechanism automatically carries the iron core to a specified position, the iron core is locked through the limiting mechanism, so that the iron core does not move when the transformer is manufactured, and the condition that the iron core moves to affect the manufacturing efficiency of the transformer is avoided; two power mechanisms are symmetrically arranged at the left side and the right side of the upper end surface of the bottom plate; each power mechanism is provided with a clamping branch chain for clamping an upper clamp; and the two clamping branch chains are driven to move back and forth through the two power mechanisms. According to the upper clamp assembly and disassembly device, automatic carrying of the iron core of the transformer and the automatic assembly and disassembly function on the upper clamp can be achieved and manual operation is not needed.

Owner:HENGSHUI POWER SUPPLY BRANCH OF STATE GRID HEBEI ELECTRIC POWER

Small-size automatic dismounting system for car tire

A disclosed small-size automatic dismounting system for a car tire comprises a pedestal, and an upgradable support member fixedly disposed on the pedestal; the upper end of the support member is fixedly provided with a horizontal support which is connected with a tire dismounting apparatus through a horizontal push rod, and the tire dismounting apparatus comprises a clamping part used for fixing the tire and an unscrewing device used for dismounting tire bolts. The small-size automatic dismounting system for the car tire is small in volume and low in cost, and possesses the clamping part for clamping the tire, and the clamping part possesses the function of taking off the tire through a clamping arm after the bolt automatic dismounting mechanism positions the bolt and dismounts the bolt.

Owner:HENAN INST OF SCI & TECH

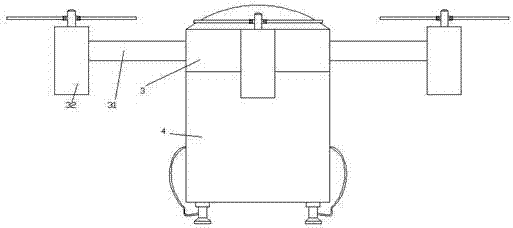

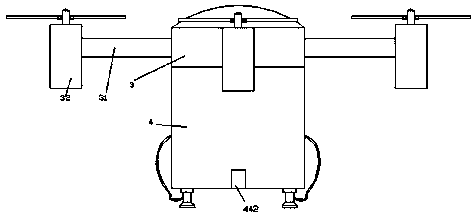

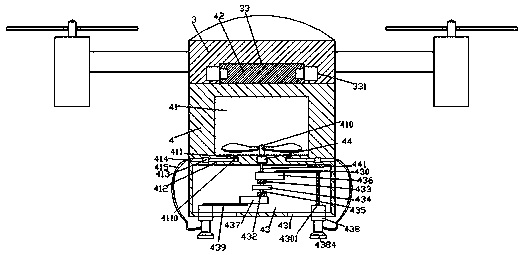

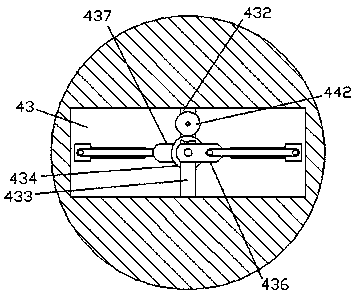

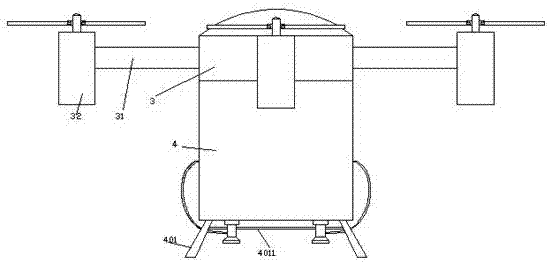

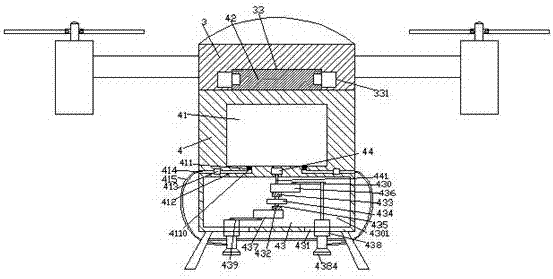

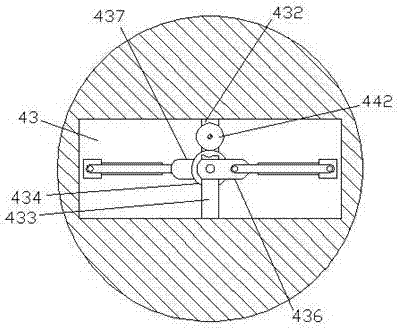

Rotary wing type unmanned aerial vehicle for spraying pesticides

ActiveCN107323671AEasy to separate workEasy to assembleAircraft componentsInsect catchers and killersEngineeringRotary wing

The invention discloses a rotary wing type unmanned aerial vehicle for spraying pesticides. The rotary wing type unmanned aerial vehicle comprises a main body and a spraying rack body arranged at the bottom of the main body, wherein a pesticide storage cavity is formed in the spraying rack body; stirring blades are arranged on the inner bottom wall of the pesticide storage cavity; the bottoms of the stirring blades are in fit connection with a motor which is embedded in the inner bottom wall of the pesticide storage cavity and is fixedly connected with the inner bottom wall of the pesticide storage cavity; a transmission cavity is formed in the position, below the pesticide storage cavity, in the spraying rack body; guide grooves are symmetrically formed in the left and right sides of the inner bottom wall of the transmission cavity; guide blocks are arranged in the guide grooves; a first supporting plate and a second supporting plate which are symmetrically arranged up and down are arranged in the middle in the transmission cavity; the first supporting plate and the second supporting plate extend to the front and back sides; a rotating shaft which extends up and down is arranged in the middle position between the first supporting plate and the second supporting plate; and an extension section of the top of the rotating shaft penetrates through the end face of the top of the first supporting plate and is in rotational fit connection with the end face of the top of the first supporting plate. According to the rotary wing type unmanned aerial vehicle, the structure is simple, automatic disassembly and assembly can be achieved, later maintenance and carrying are facilitated, the service life is prolonged, the pesticide spraying covering area is increased, and pesticide concentration is uniform.

Owner:江苏大成航空科技有限公司

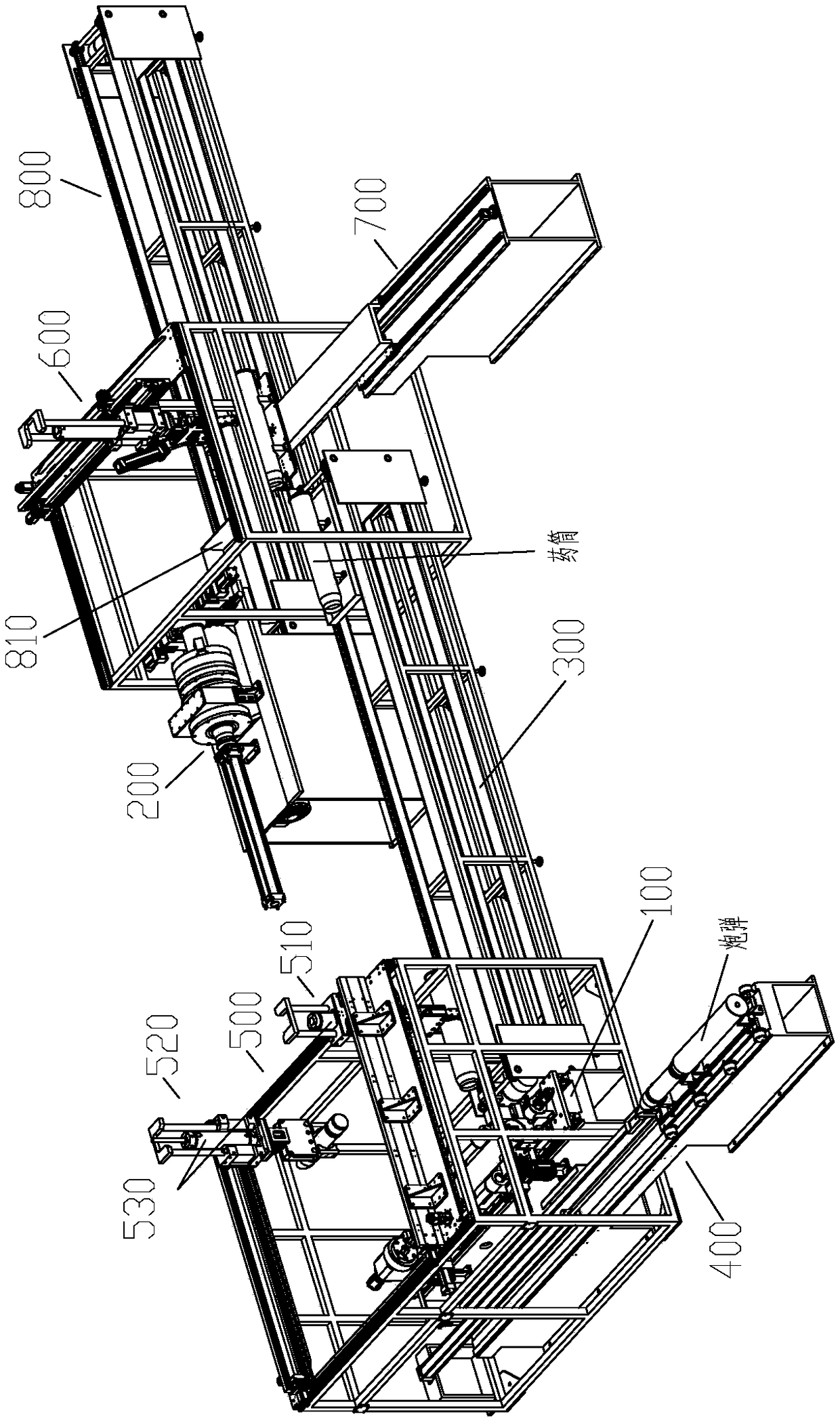

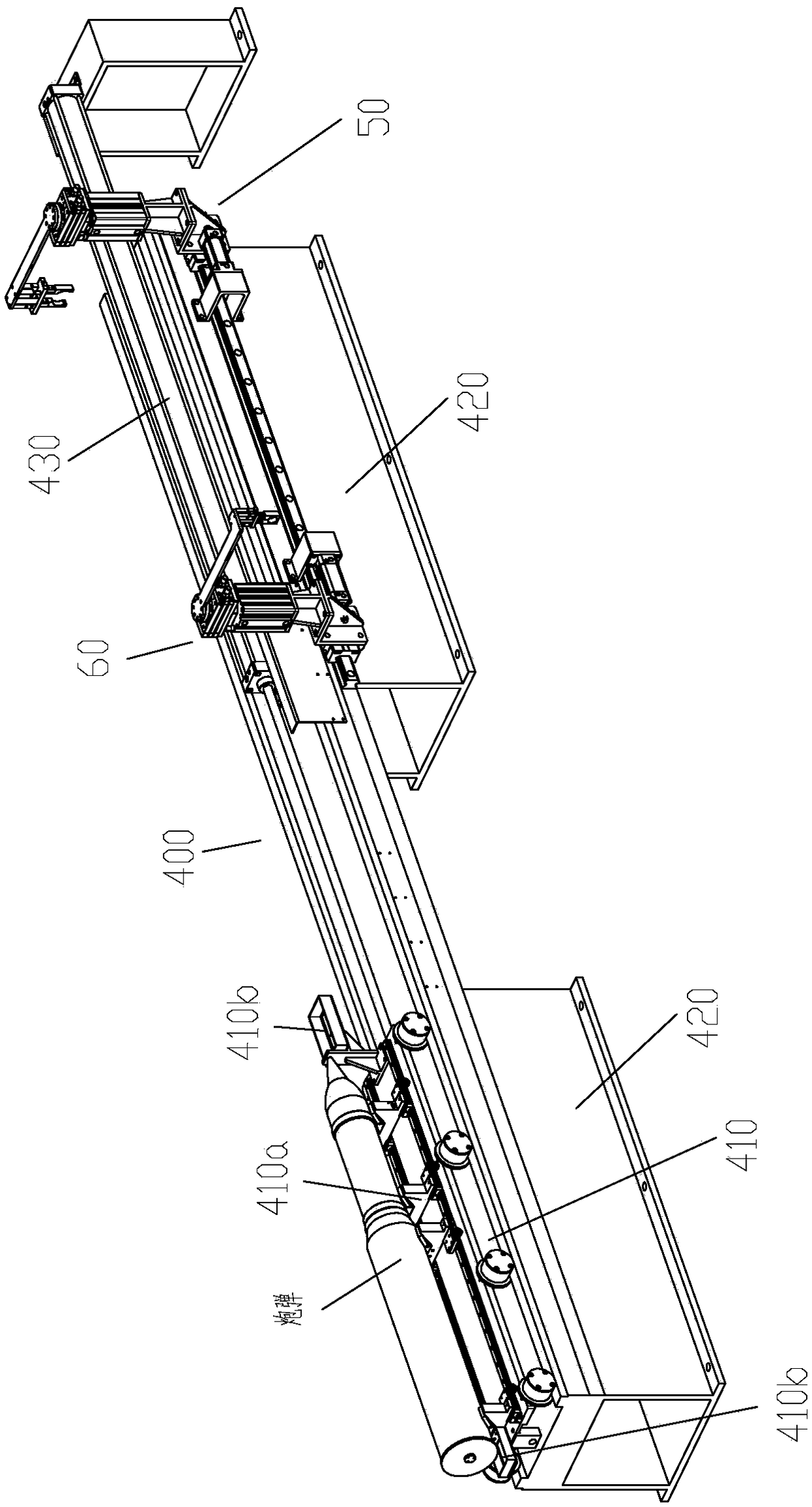

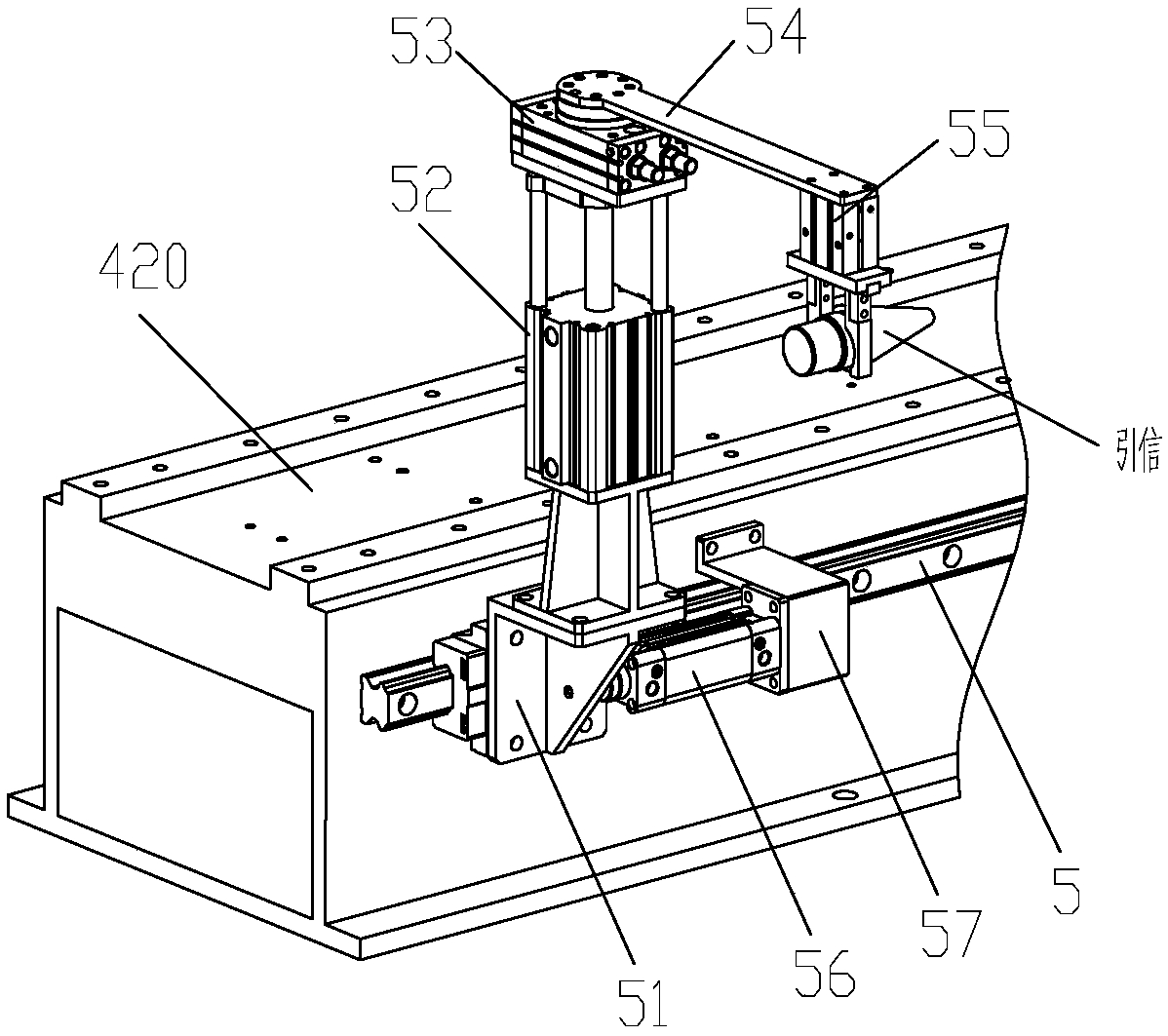

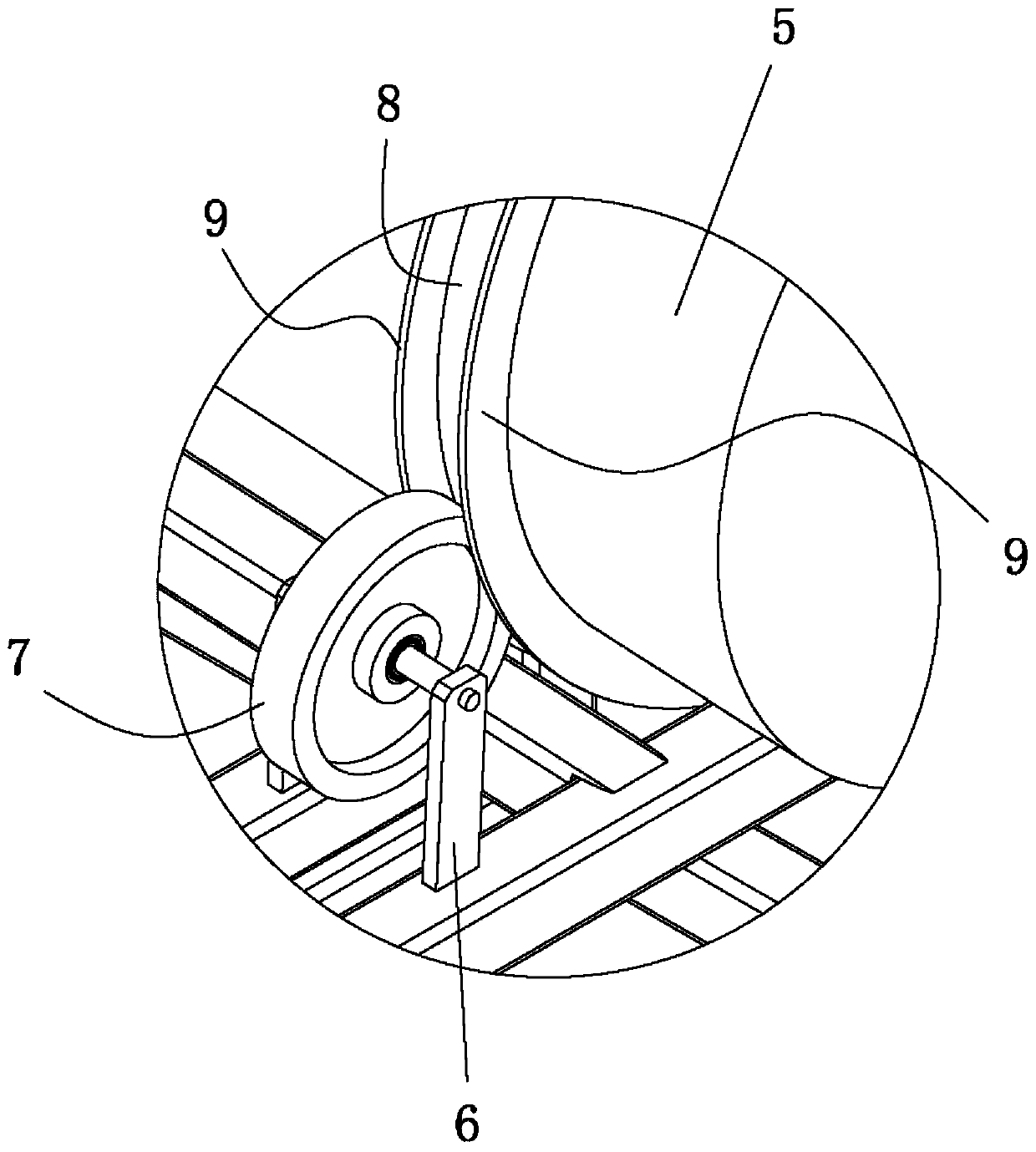

Cannonball dismantling line

The invention discloses a cannonball dismantling line. The cannonball dismantling line comprises a rotary dismantling separator and a cartridge case turning separator. The rotary dismantling separatoris used for dismantling cannonballs into fuses, bullets, cartridge cases and primers. The cartridge case turning separator is used for cutting off the bottoms of cartridge cases and separating explosives from the cartridge cases. The cartridge cases are conveyed between the rotary dismantling separator and the cartridge case turning separator through a cartridge case conveying line, a cannonballconveyor is arranged at the front end of the rotary dismantling separator, and a first truss manipulator is arranged above the combination portion of the rotary dismantling separator, the cannonball conveyor and the cartridge case conveying line. A cartridge case conveyor and an explosive conveying line are arranged at the rear end of the cartridge case turning separator. A second truss manipulator is arranged above the combination portion of the cartridge case conveying line, the cartridge case turning separator, the cartridge case conveyor and the explosive conveying line. The cannonball dismantling line has the beneficial effects that due to the reasonable configuration, the dismantling line can achieve the cannonball dismantling function and the explosive removing function and is compact in layout; and on the basis of the existing industrial control technology, automatic dismantling of cannonballs can be achieved, the cannonball dismantling line has high dismantling efficiency andgood safety, and dismantling cost is low.

Owner:重庆航天工业有限公司

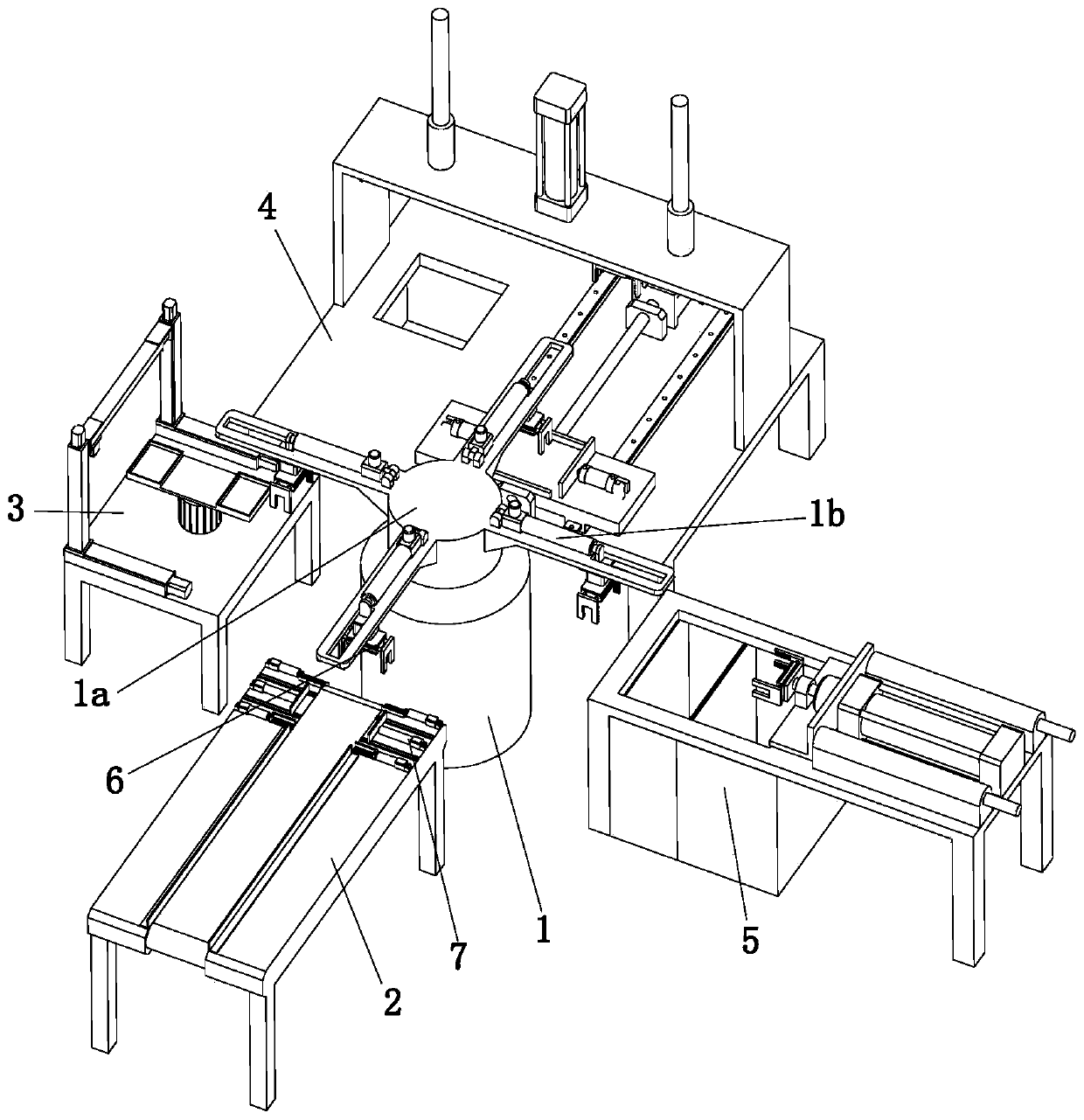

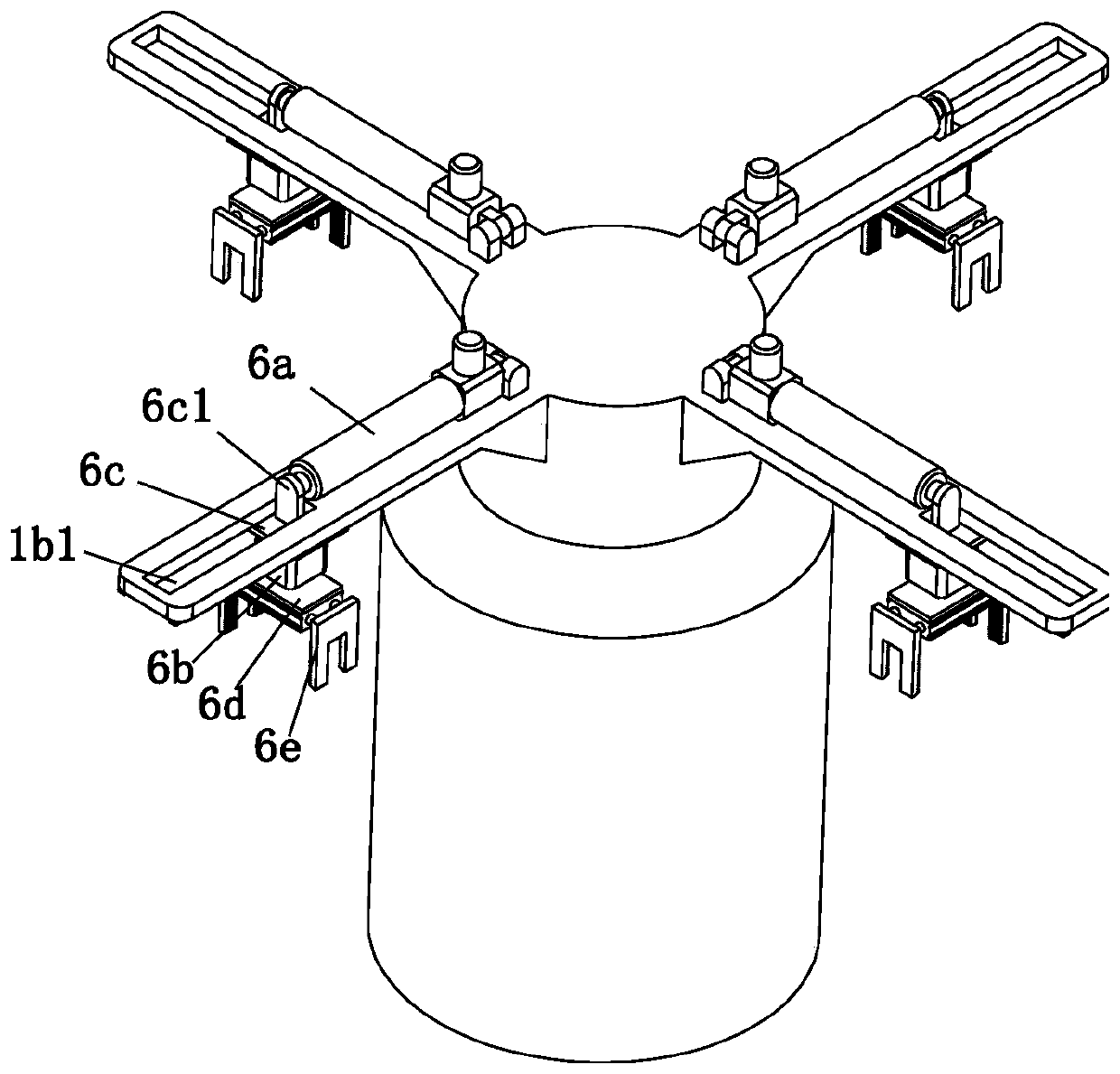

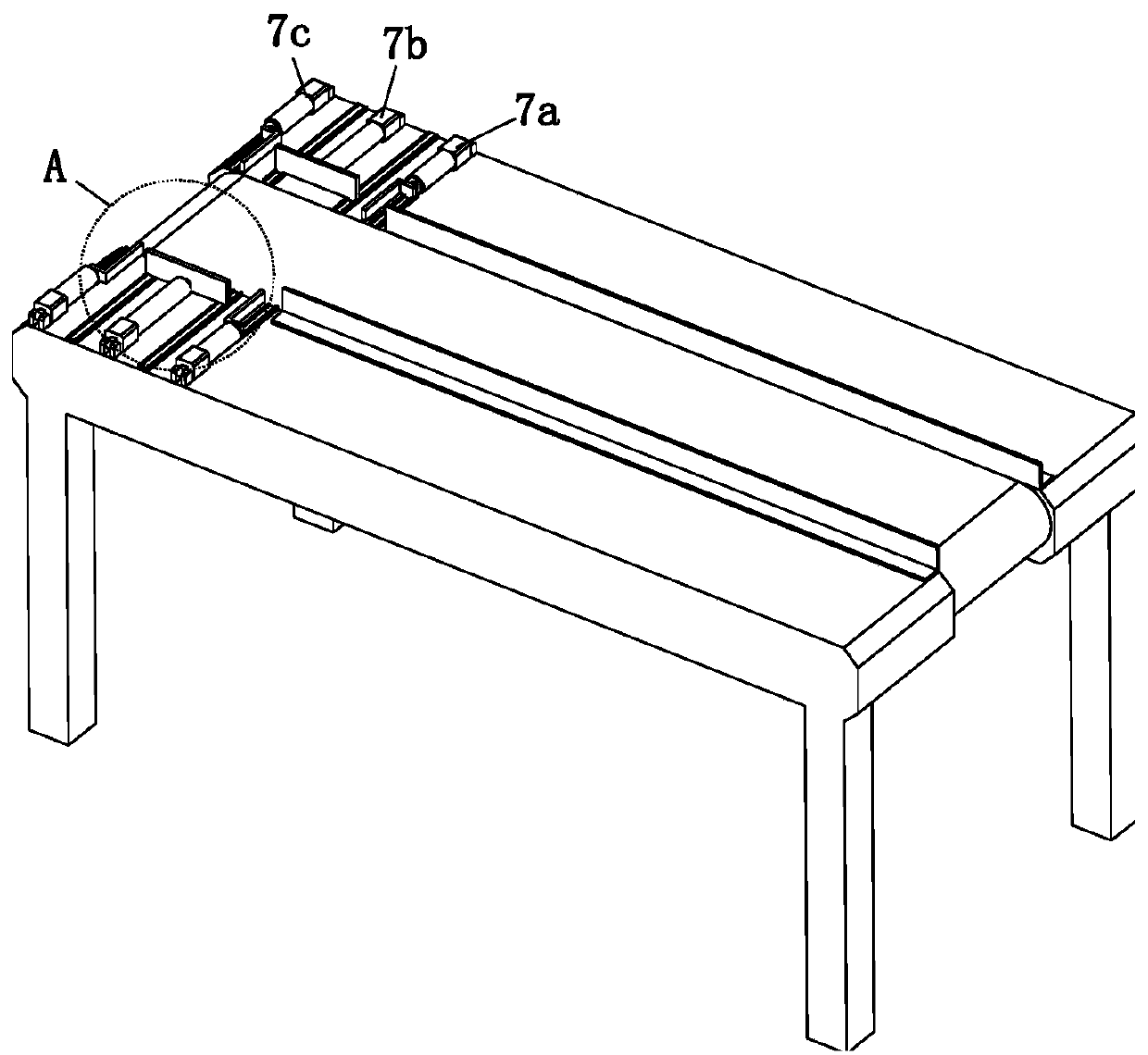

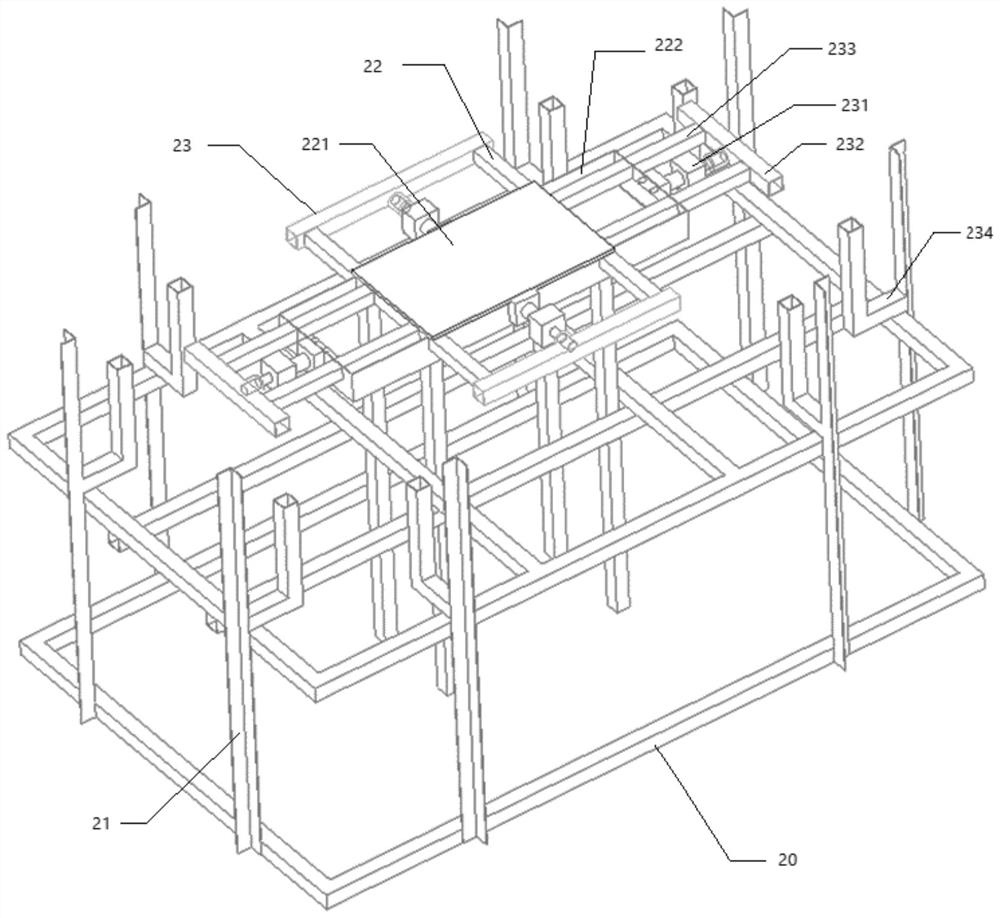

Method of disassembling waste power batteries

ActiveCN109746247ARealize automatic disassemblyHarm reductionSolid waste disposalWaste accumulators reclaimingPower batteryEngineering

The invention discloses a method of disassembling waste power batteries, and belongs to the field of waste power battery treating equipment. The disassembling method is realized based on a battery disassembling device. The battery disassembling device comprises a rotating platform, a feeding conveyer belt, a screw removing device, a box cover removing device and a discharging device, wherein the feeding conveyer belt, the screw removing device, the box cover removing device and the discharging device are uniformly distributed around the rotating platform; a step motor is arranged in the rotating platform; the output end of the step motor penetrates through the top of the rotating platform; a mounting circular housing is arranged at the output end of the step motor; four mounting brackets which are uniformly distributed in the circumferential direction are arranged on the mounting round housing; a handling device is arranged on each mounting bracket; and a limiting device is arranged onthe feeding conveyer belt. According to the battery disassembling device disclosed by the invention, waste accumulator type power batteries are automatically disassembled, manual operation is avoided, labor intensity is reduced, and damage to human body health is reduced.

Owner:山西亿晨环保科技有限公司

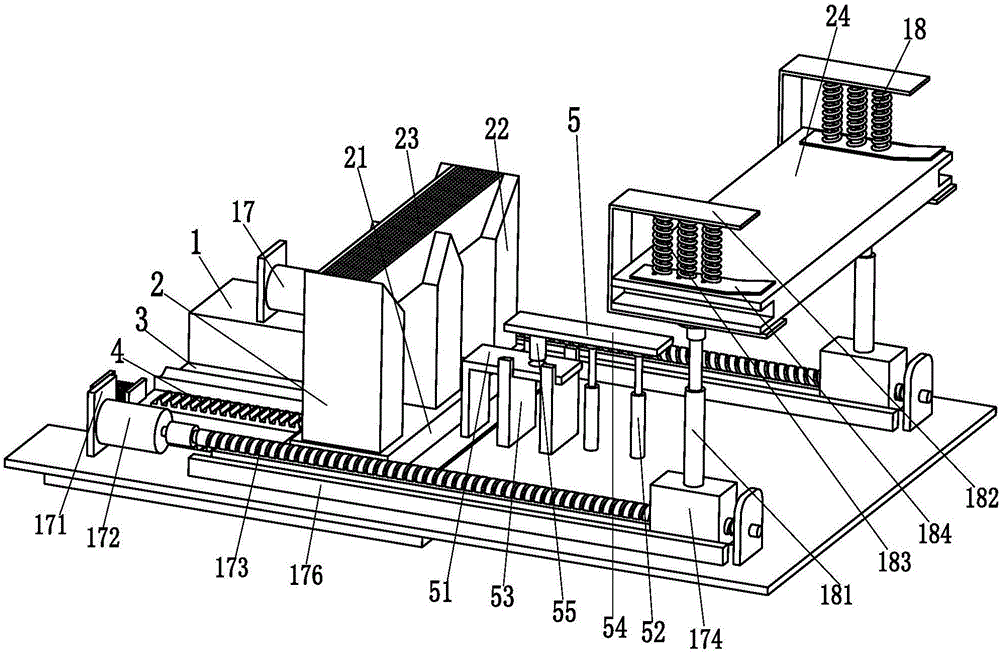

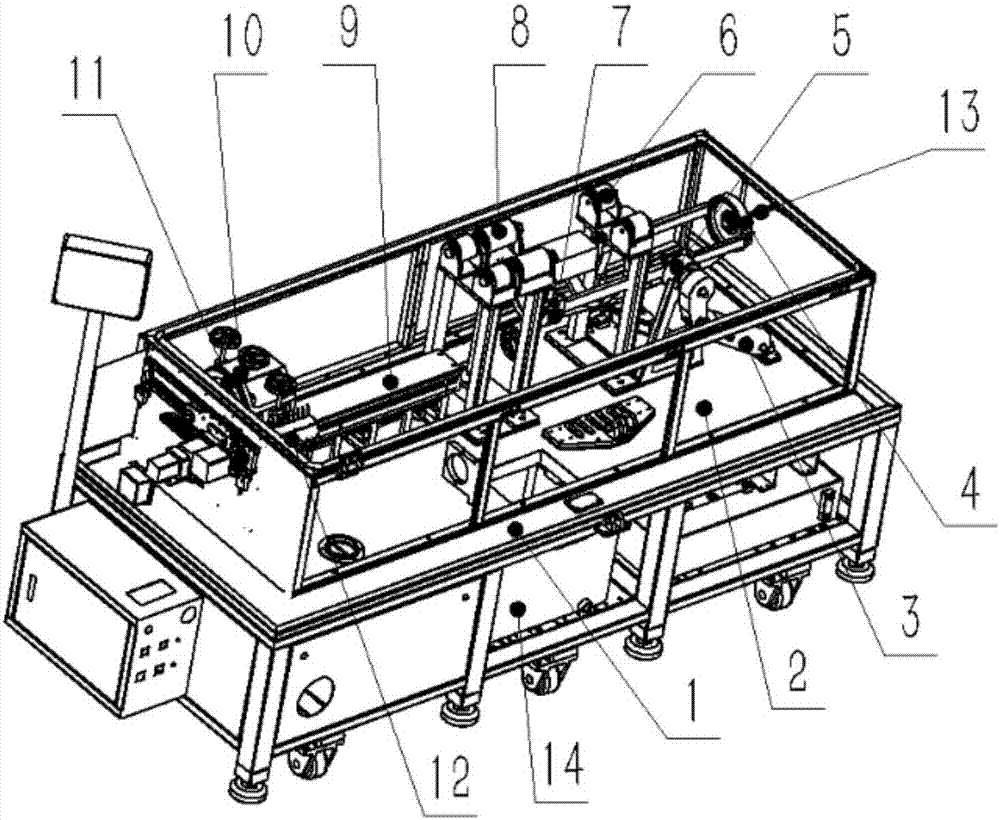

Full-automatic bolt and nut cleaning machine

ActiveCN107442460AEasy clampingRealize automatic disassemblyDrying gas arrangementsCleaning using toolsEngineeringLiquid storage

The invention discloses a full-automatic bolt and nut cleaning machine. The full-automatic bolt and nut cleaning machine comprises a supporting seat, a liquid storage box body and a sealed box body with a transparent window. A bolt locking and overturn mechanism and a bolt rotary supporting mechanism are arranged on the right side of a cleaning machine main body, the bolt locking and overturn mechanism is used for hydraulically driving a bolt to topple and overturn, the middle is locked by using a locking ring, the bolt rotary supporting mechanism adopts a V-shaped structure composed of a pair of rubber rollers and two pairs of nylon rollers, and the rubber rollers drive the bolt to rotate through driving of a motor; a nut dismounting and mounting mechanism and a nut cleaning and air drying mechanism are arranged at the left end of the cleaning machine main body, the nut dismounting and mounting mechanism is installed on a lead screw, and the nut cleaning and air drying mechanism is fixed to a cylindrical gear, matched with a linear gear, at the right end of the cleaning machine; and an oiling mechanism is located on the upper portion of a thread cleaning rolling brush, and cameras are arranged above threads at the two ends of the bolt correspondingly to monitor the cleaning state in real time. According to the full-automatic bolt and nut cleaning machine, full-automatic bolt and nut synchronous cleaning, air drying and oiling operation can be achieved, real-time monitoring can be achieved, operation is convenient, and the efficiency is high.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI +1

Automatic replacing device for drill rod of tapping machine and operation method of automatic replacing device

InactiveCN111996321AIncrease success rateHigh degree of automationBlast furnace componentsBlast furnace detailsEconomic benefitsStructural engineering

The invention discloses an automatic replacing device for a drill rod of a tapping machine and an operation method of the automatic replacing device. The automatic replacing device for the drill rod of the tapping machine comprises a drill rod taking assembly, a drill rod replacing assembly, a drill rod preparing assembly and a controller, wherein the drill rod taking assembly comprises a drill rod warehouse and an automatic drill rod frame arranged above the drill rod warehouse; the drill rod replacing assembly is arranged on a trolley of the tapping machine and comprises a clamping drill rod, a hydraulic push rod driving the clamping drill rod to stretch out and draw back and a hydraulic drive device driving the clamping drill rod to be opened and closed; and the drill rod preparing assembly comprises a guide rail, an RGV trolley and a drill rod bracket arranged on the RGV trolley. In the technical scheme, through seamless connection and cooperation of the drill rod taking assembly,the drill rod replacing assembly and the drill rod preparing assembly, manual work can be replaced to the maximum degree, automatic drill rod dismounting and replacing are achieved, the drill rod replacing automation degree is high, the drill rod replacing operation success rate is high, the automatic production requirement at the present stage is met, economic benefits and use convenience are better, and the automatic replacing device is suitable for application and popularization.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD +1

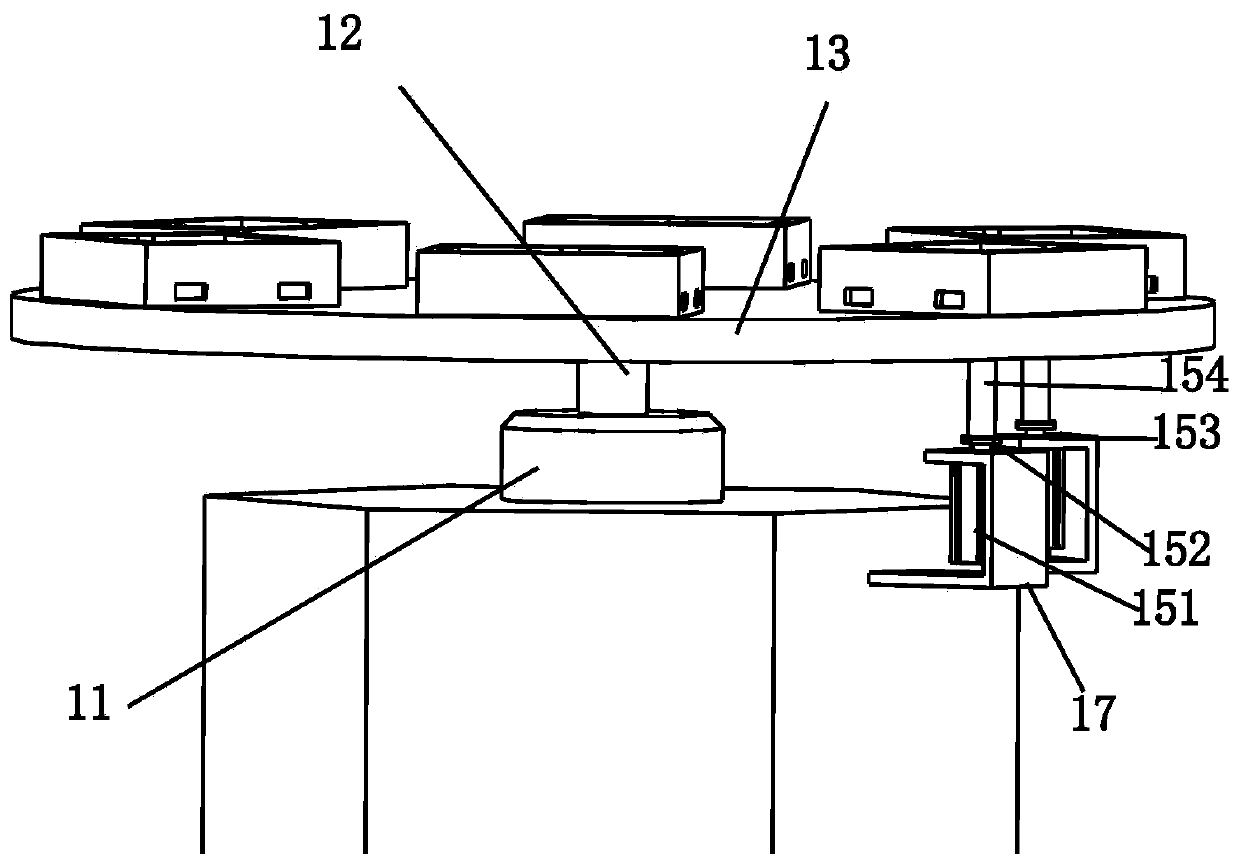

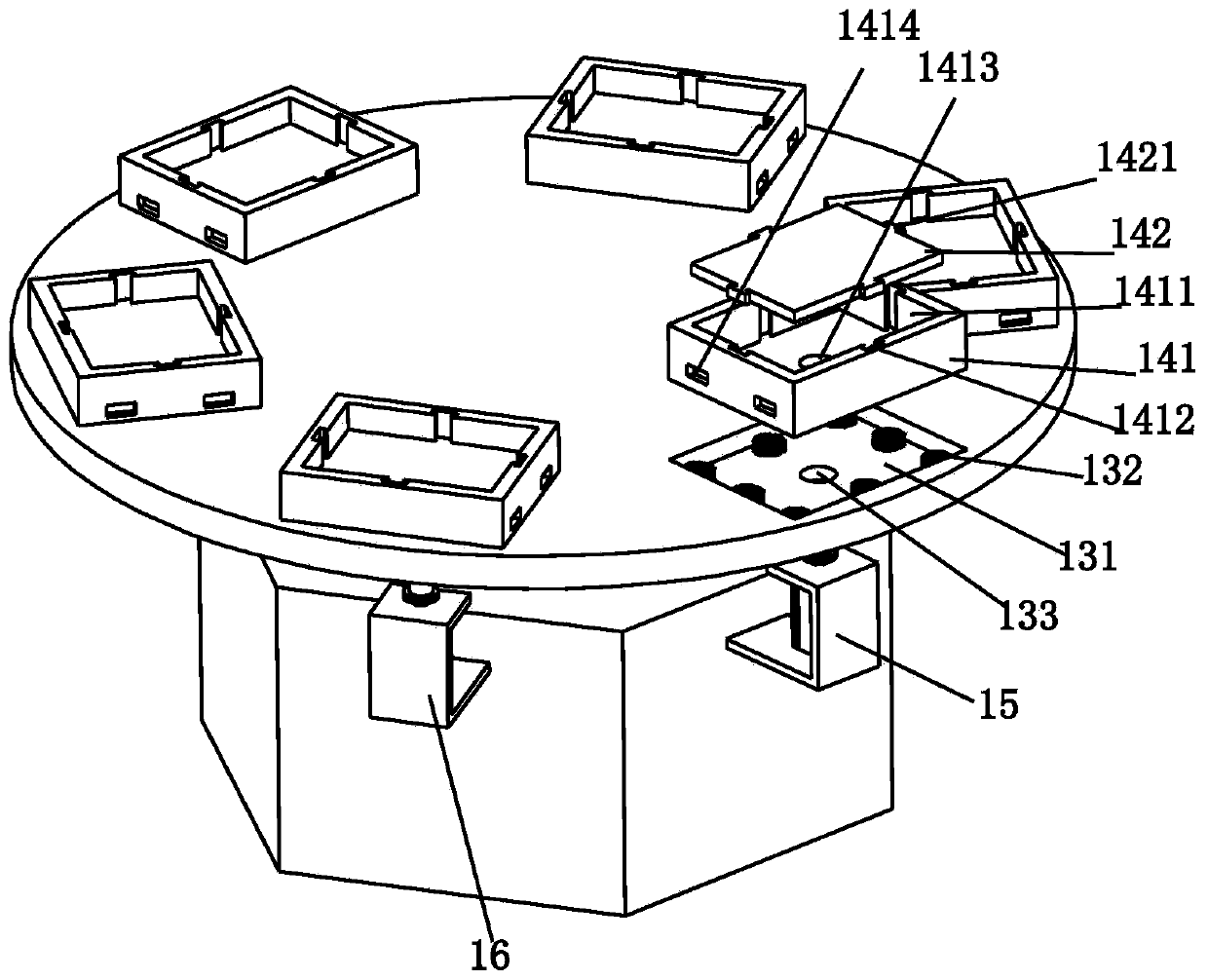

Disassembling device for waste power battery

ActiveCN109773469AAvoid manual operationReduce labor intensityWaste accumulators reclaimingMetal working apparatusElectrical batteryHuman health

The invention discloses a disassembling device for a waste power battery, and belongs to the field of waste powder battery treating equipment. The device comprises a rotating platform, a charging conveying belt, a screw removing device, a box cover removing device and a discharging device, wherein the charging conveying belt, the screw removing device, the box cove removing device and the discharging device are uniformly distributed around the rotating platform; a stepping motor is arranged in the rotating platform, and the output end of the stepping motor penetrates the top part of the rotating platform; a circular mounting housing is arranged at the output end of the stepping motor; four mounting supports are arranged on the circular mounting housing, and the mounting supports are uniformly distributed in the circumferential direction of the circular mounting housing; a carrying device is arranged on each mounting support; and a limiting device is arranged on the charging conveying belt. With the adoption of the device, a power battery in type of a waste storage battery can be automatically disassembled, and manual operation is avoided, so that the working intensity is reduced, and the damage to human health is reduced.

Owner:上海电悦科技有限公司

Water-jet loom nozzle cluster net disassembly machine

ActiveCN103276508AWon't breakImprove the success rate of demolitionLoomsSpraying apparatusSlide plateWater jet

The invention discloses a water-jet loom nozzle cluster net disassembly machine which is used for disassembling a cluster net from a nozzle. The disassembly machine mainly comprises a support, cylinders, a clamping sliding plate, a disassembly sliding plate, a disassembly pull rod, a stepping motor gear pair, a pivotal bearing block and an operating panel, wherein the support is arranged on a worktable. By the aid of the nozzle cluster net disassembly machine, cluster net disassembly success rate is greatly increased, the labor intensity of workers is reduced, and production efficiency is improved.

Owner:ZHENJIANG DONGYI MACHINERY

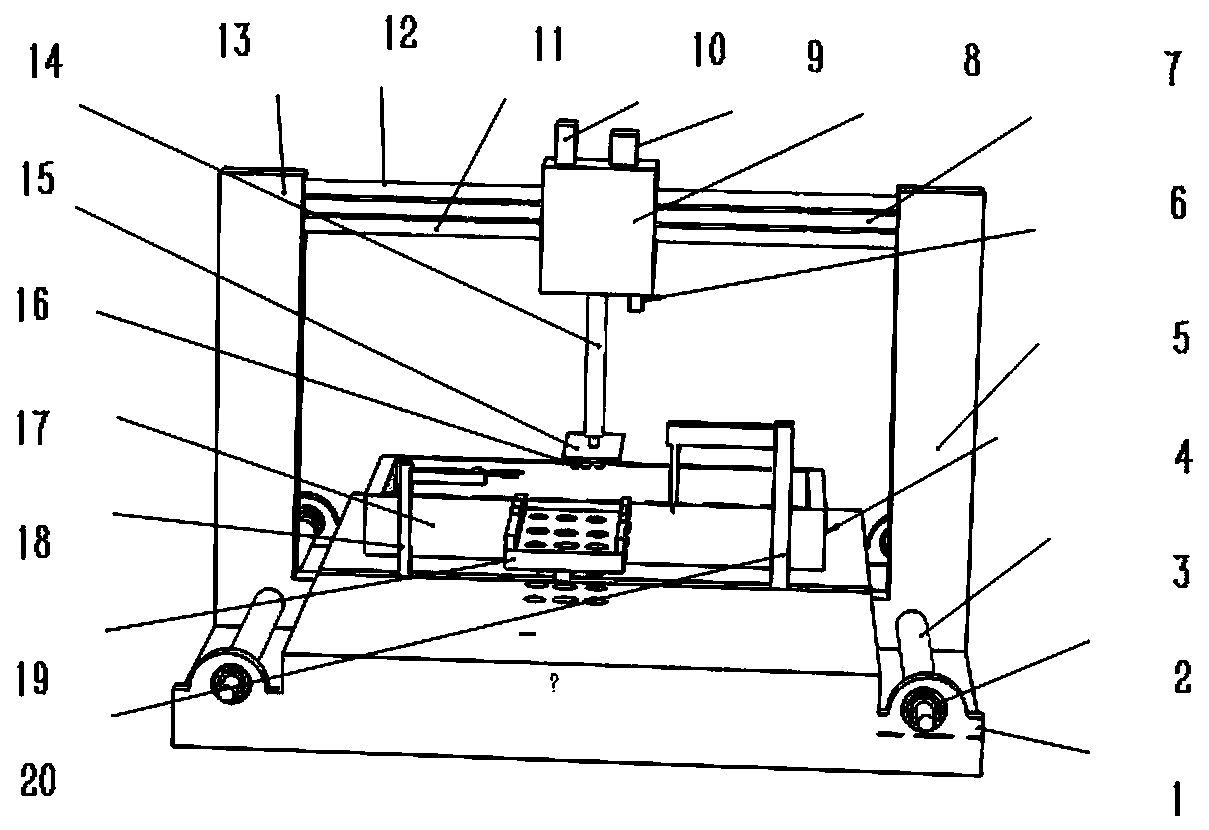

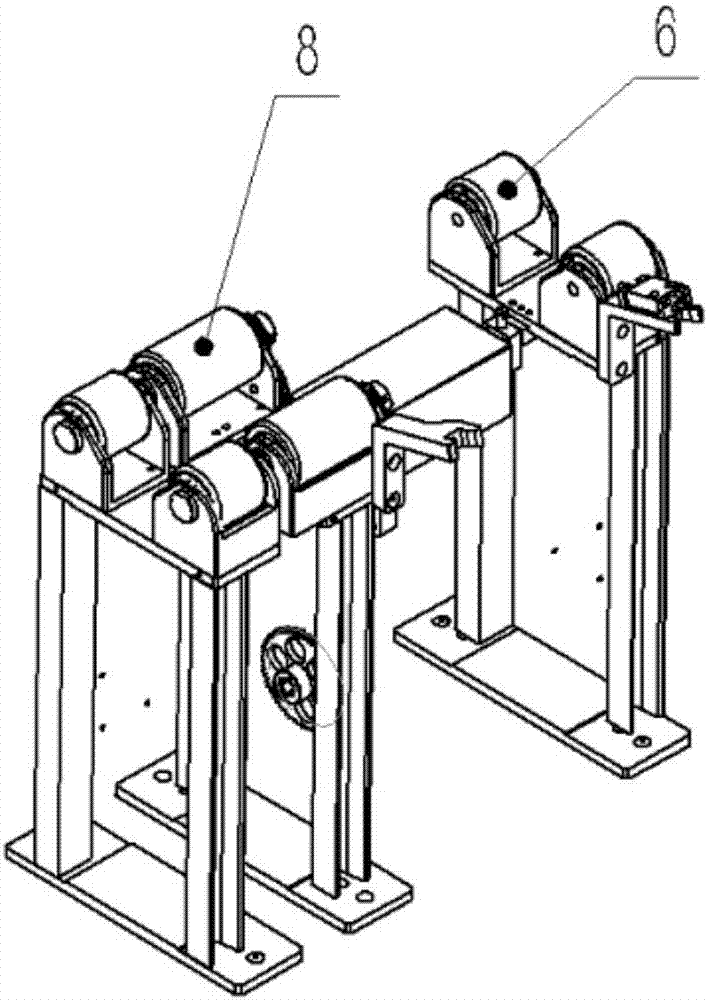

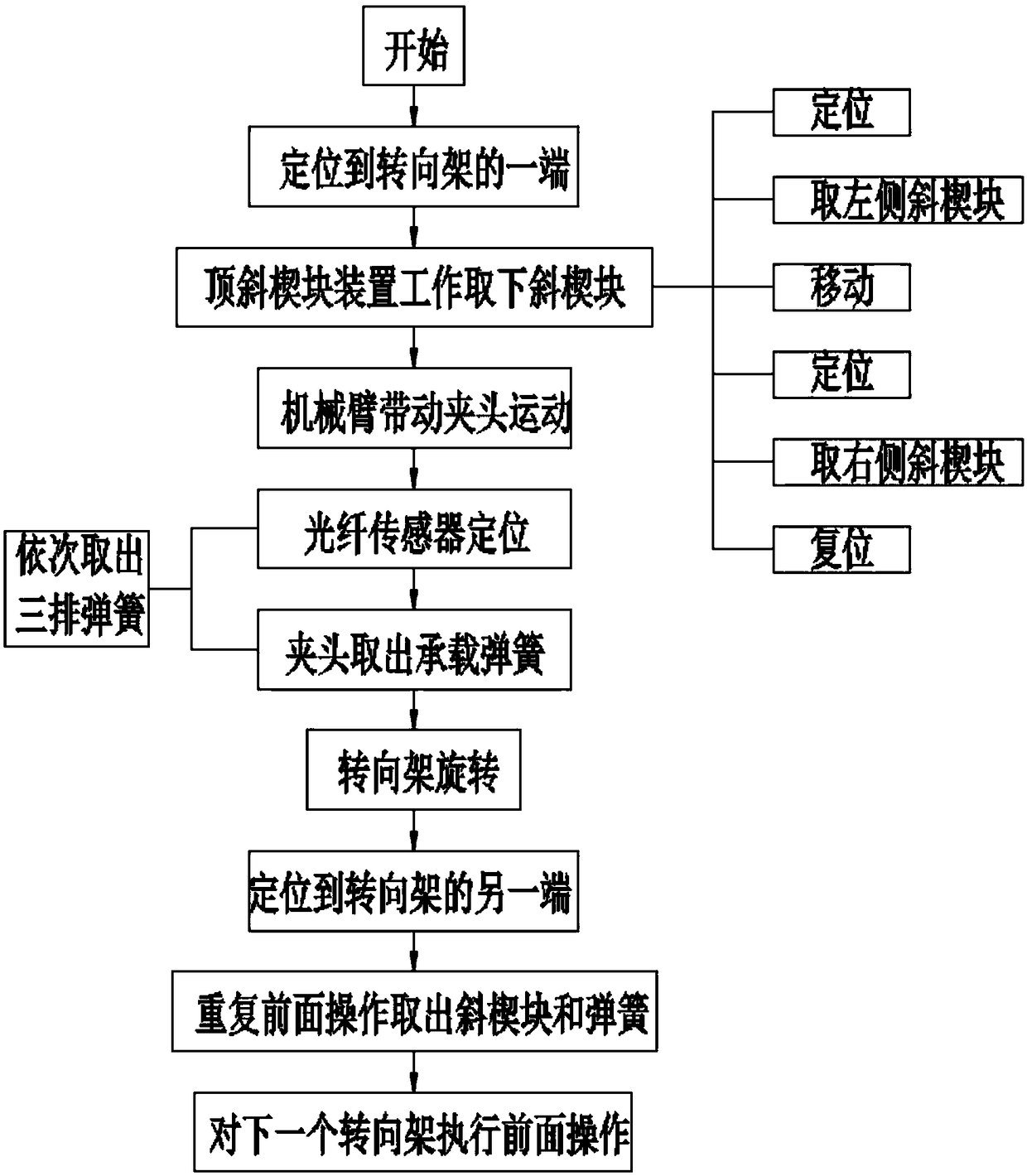

Bogie bearing spring disassembling process

ActiveCN108857312AImprove pick-and-place efficiencyReduce labor intensityMetal working apparatusBogieEngineering

The invention discloses a bogie bearing spring disassembling process, and belongs to the technical field of disassembly of bogie bearing springs. The process is used for solving the problems that in the existing bogie disassembling process, by adopting the mode of manually carrying bearing springs, the labor intensity is large, hidden safety hazards exist in the carrying process, and the work efficiency is low. The process comprises the following steps that S1, one end of a bogie is located; S2, a jacking device works to remove tapered wedges; S3, a mechanical arm drives a chuck to move; S4, alocating device locates bearing springs, and a bijective optical fiber sensor locates outer spring bodies of the bearing springs; S5, the chuck takes out the bearing springs, and three rows of bearing springs are sequentially taken out, the out-taken bearing springs are placed on a transfer frame, and the outer spring bodies and inner spring bodies of the bearing springs are separated; S6, the bogie rotates, and the other end of the bogie is located; S7, the operation of S1 to S5 is repeated, and the tapered wedges and the bearing springs are taken out; S8, the operation of S1 to S7 is repeated for a next bogie.

Owner:成都岁生科技有限责任公司

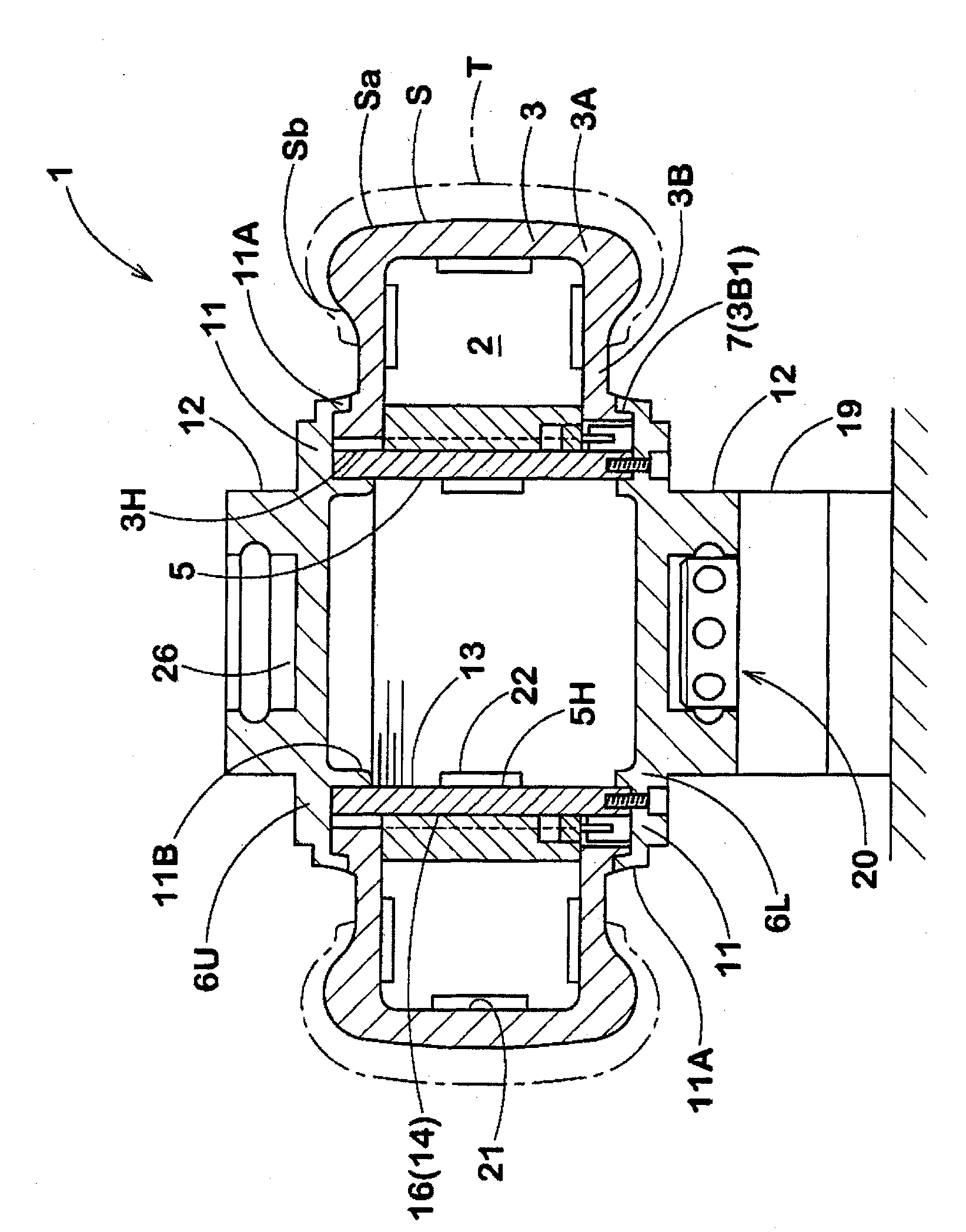

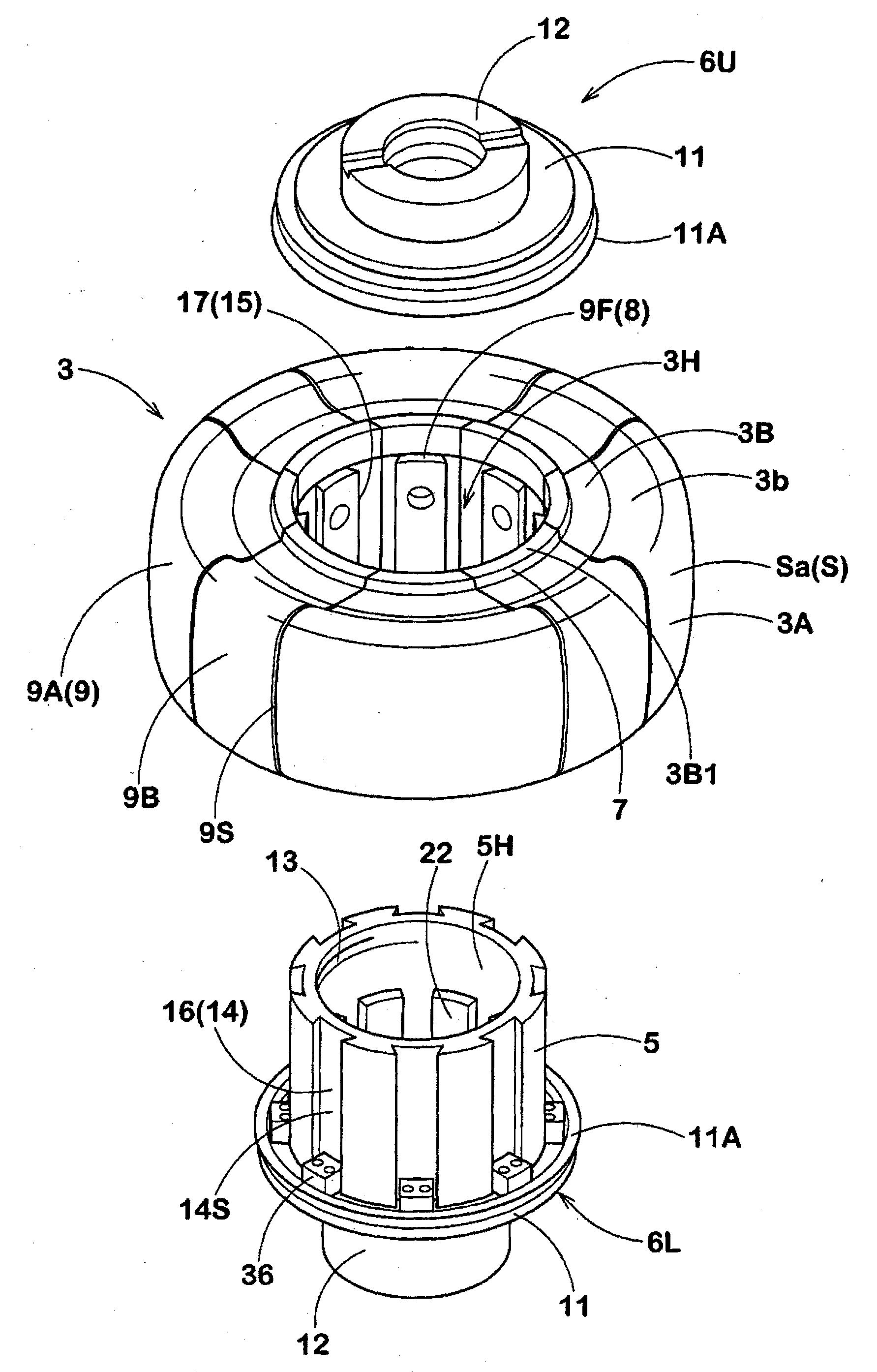

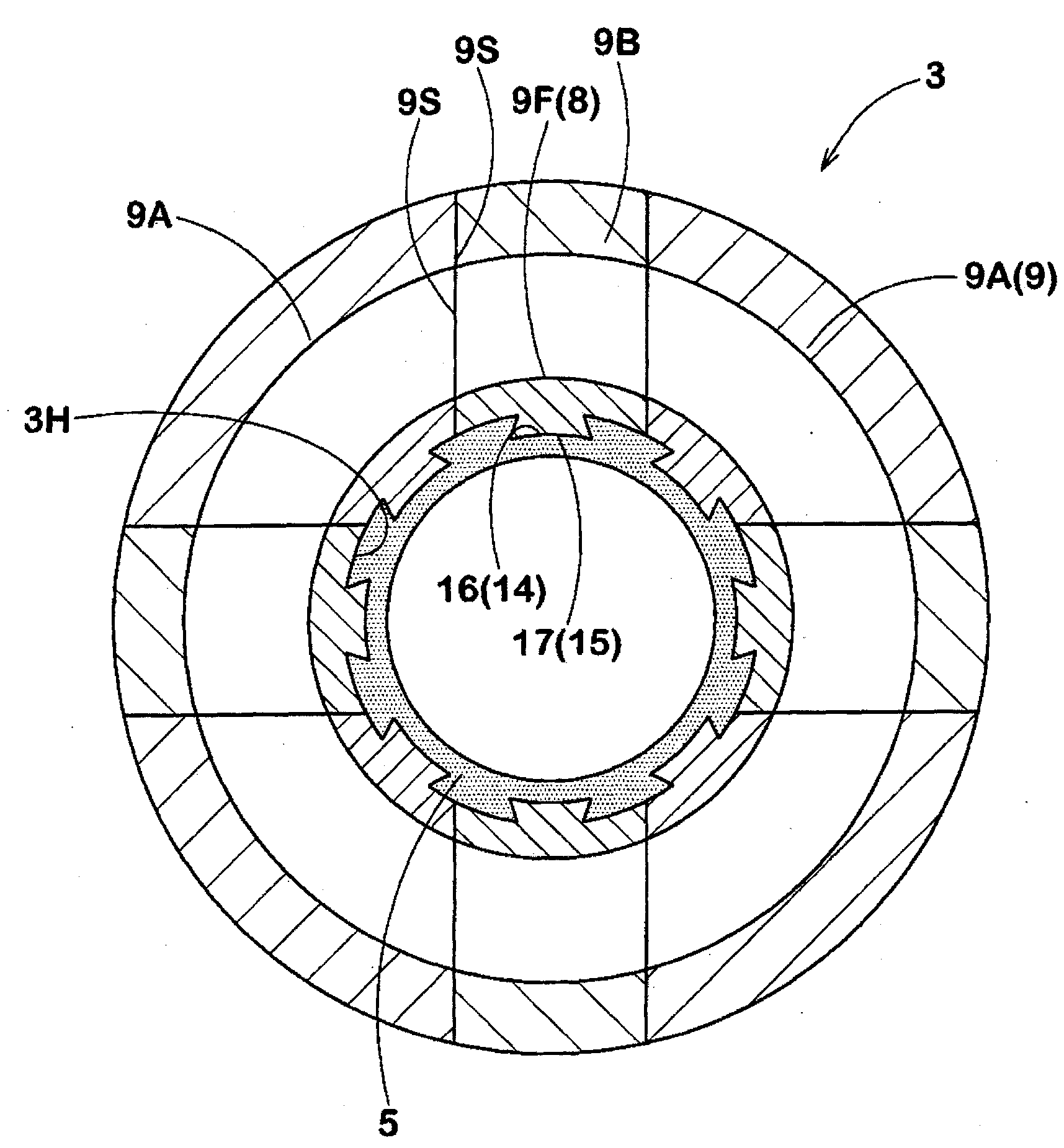

Rigid mold core

InactiveCN102837382ASuppression of difference in degree of sulfidationAvoid position shiftTyresInternal heatingWedge shape

The invention provides a rigid mold core, which can not cause the leakage of heated fluid, and can be used for the internal heating having the high safety performance. The rigid mold core is provided with a mold core main body constituted by a plurality of mold core composition molds, which are divided along the periphery of the tire, a cylinder-shaped core part inserted in a central hole of the mold core main body, and a pair of side wall bodies disposed on two sides of the mold core main body in an axial direction. First wedge-shaped connection parts are disposed on an outer peripheral surface of the core, and second wedge-shaped connection parts are disposed on the inner peripheral surface of various mold core combination molds. The inner cavity surfaces of the various mold core combination molds are provided with heating devices used for the tire surfaces, the first electric heating devices of the heating devices used for the sides of the tire, the second electric heating devices disposed on the radial inner peripheral surface of the core part. Temperature sensors are embedded in various crown wall parts.

Owner:SUMITOMO RUBBER IND LTD

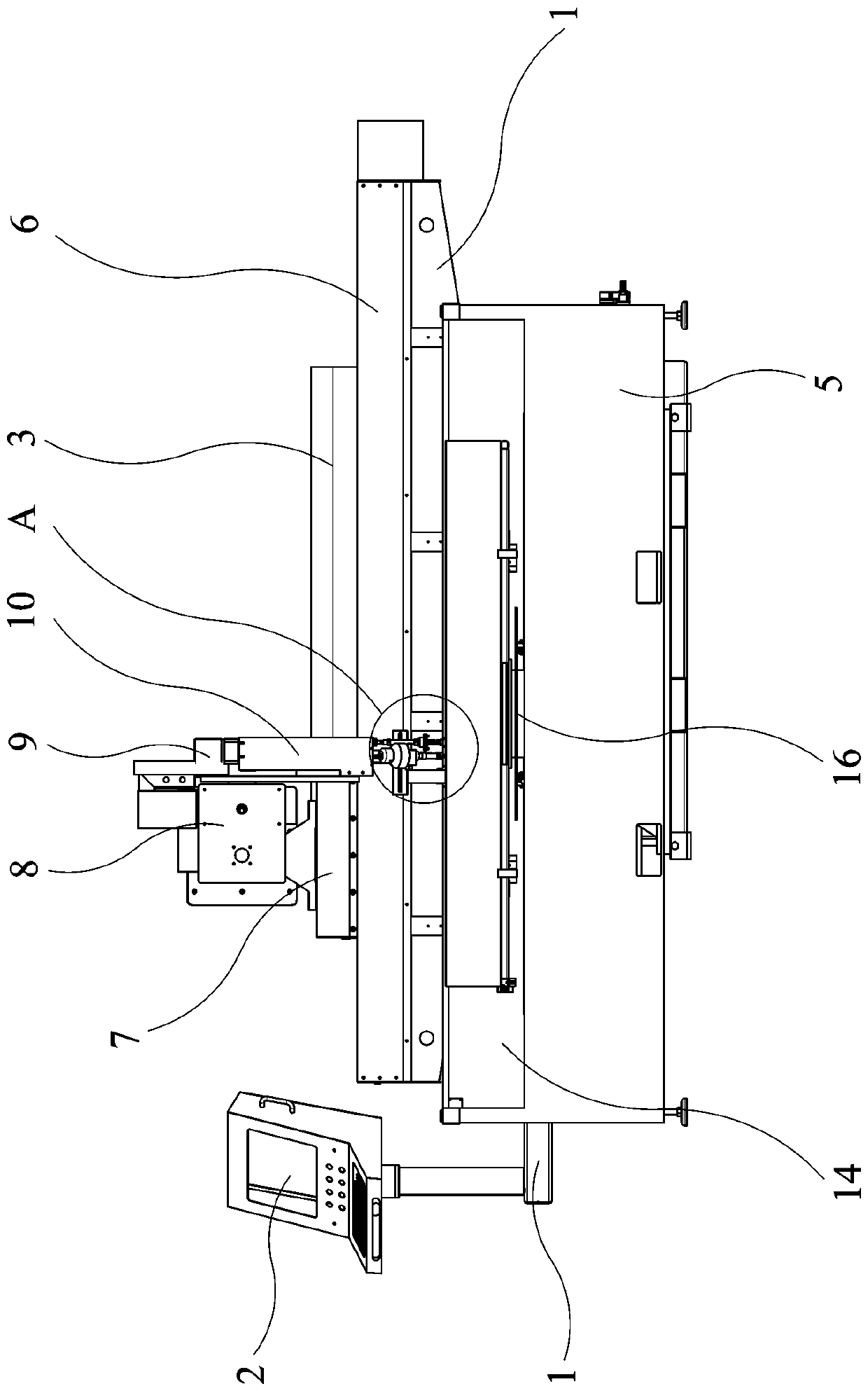

Automatic PIN disassembly machine

PendingCN109874238AWon't hurtRealize automatic disassemblyMultilayer circuit manufactureControl systemEngineering

The invention discloses an automatic PIN disassembly machine, comprising a rack, a lifting pin, an X direction sliding block, a Y direction sliding block, a plate position calibration device, a code scanner, an X direction drive device, a Y direction drive device, a vertical drive device and a control system. The X direction sliding block can be positioned on the rack in a sliding mode along an Xdirection. The Y direction sliding block can be positioned on the X direction sliding block in the sliding mode along a Y direction. The lifting pin can be mounted on the Y direction sliding block inthe sliding mode along a vertical direction. The plate position calibration device on the rack can correct a position of a to-be-disassembled PIN plate in the rack. The code scanner can read information in a bar code on the to-be-disassembled PIN plate. The code scanner communicates with the control system. The control system drives the X direction sliding block, the Y direction sliding block andthe lifting pin to move through control over the X direction drive device, the Y direction drive device and the vertical drive device. The automatic PIN disassembly machine is simple in structure andhigh in disassembly efficiency. Full automatic disassembly of PINs on the plate can be realized. The plate is not damaged.

Owner:KUNSHAN JUHONG MACHINERY TECH

Mattress disassembling device

ActiveCN109732703ARealize dismantlingImprove processing efficiencyMetal working apparatusEngineeringCantilever

The invention discloses a mattress disassembling device. The mattress disassembling device comprises a rack, a control device, a power device, a moving assembly, a cutting assembly and a cutting platform; the control device and the moving assembly are arranged on the rack, the cutting assembly is arranged on the moving assembly, the cutting platform is located below the cutting assembly, the moving assembly comprises a transverse guide rail, and a transverse moving device, the transverse guide rail is fixed to the rack, the transverse moving device is matched with the transverse guide rail, the cutting assembly is fixed to the transverse moving device, the cutting assembly comprises a cantilever, a connecting part and at least two cutters, the cantilever is fixed to the transverse moving device in a suspension manner, the connecting part is fixed to the lower end of the cantilever, the cutters are fixed to the connecting part, and the cutters are arranged in a vertically staggered manner. The mattress disassembling device can achieve mattress disassembling, springs, and steel wires are separated from fabrics, sorting and recycling are facilitated, through the cutters, the upper corner and the lower corner of the edge of the mattress can be cut at the same time, the cutting of the edge of the mattress can be finished at a time, the mattress does not need to be turned over, the treatment efficiency of the waste mattress can be improved, and cost is reduced.

Owner:HUANCHUANG XIAMEN TECH

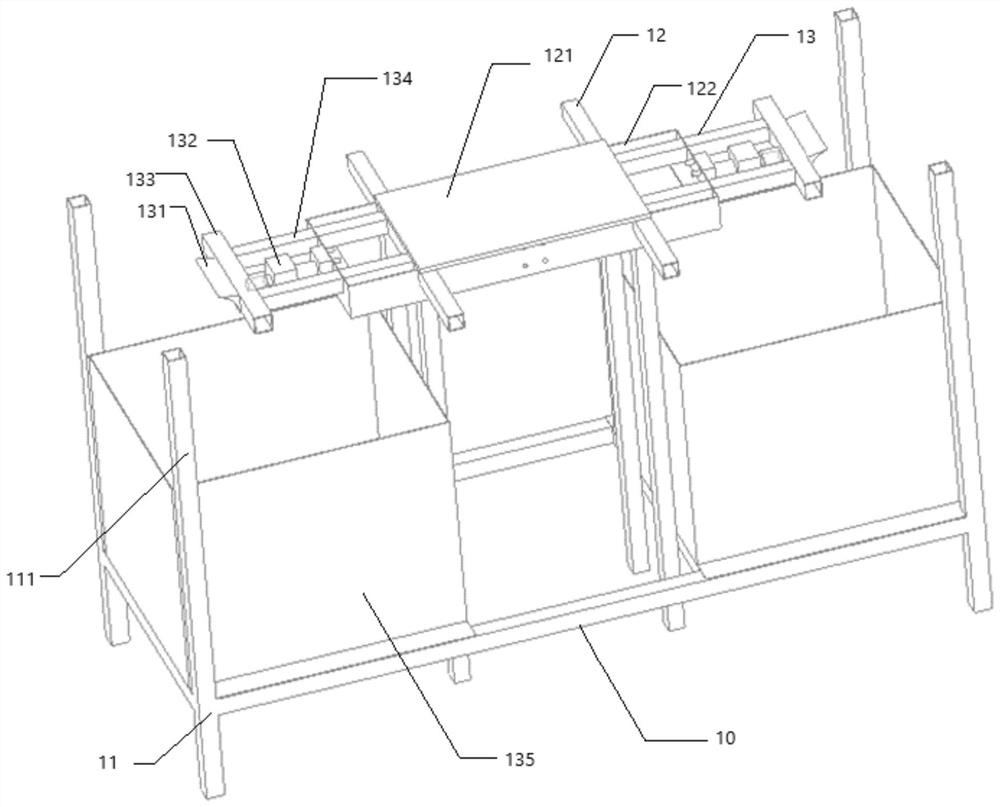

Automatic disassembling device and method for solar photovoltaic module

PendingCN114799832ARealize automatic disassemblyIntegrity guaranteedMetal working apparatusResource recoveryEngineering

The invention discloses an automatic disassembling device and method for a solar photovoltaic module, and relates to the field of resource recovery and regeneration of the solar photovoltaic module, the automatic disassembling device comprises a junction box disassembling device and an aluminum alloy frame disassembling device.The junction box disassembling device comprises a first support, a first working platform and two junction box disassembling mechanisms; a connecting box is shoveled away from a back plate through a scraper knife, a material receiving box is arranged on a support below the corresponding connecting box, the disassembled connecting box can be recycled, the aluminum alloy frame disassembling device comprises a second support, a second working platform and four sets of aluminum alloy frame disassembling mechanisms, an ejector rod is used for abutting against a flange of a frame to disassemble the frame from the back plate, and a material receiving groove is formed in the periphery of the second support. According to the invention, the junction box and the aluminum alloy frame can be automatically disassembled, the disassembly substance can be recycled, full-automatic disassembly of the solar photovoltaic module is realized, the efficiency is high, the positioning is accurate, and the integrity of the back plate, the junction box and the aluminum alloy frame after disassembly can be kept.

Owner:NANJING NORMAL UNIVERSITY

Release paper tearing equipment for taking protective covers

ActiveCN106903501ARealize automatic disassemblyRealize semi-automatic disassemblyMetal working apparatusPaper recyclingWorkbenchIndustrial engineering

The invention provides release paper tearing equipment for taking protective covers. The release paper tearing equipment comprises a rack, a workbench, a positioning mechanism, a carrier disassembling mechanism, a rear cover disassembling mechanism and a protective cover disassembling mechanism, wherein the workbench is arranged on the rack, and the positioning mechanism, the carrier disassembling mechanism, the rear cover disassembling mechanism and the protective cover disassembling mechanism are arranged on the workbench; and the carrier disassembling mechanism is located below the positioning mechanism, the rear cover disassembling mechanism is located above the positioning mechanism, and the protective cover disassembling mechanism is located on one side of the positioning mechanism. The positioning mechanism is used for positioning a product to be machined. The carrier disassembling mechanism is used for disassembling a carrier, then the rear cover disassembling mechanism is used for disassembling a rear cover of a watch dial plate, the protective cover disassembling mechanism then disassembles a protective cover in the watch dial plate, and afterwards, release paper in the watch dial plate is torn manually; and automatic disassembling of the carrier and the watch rear cover is achieved, semi-automatic disassembly of the protective cover is achieved, the automation degree is high, disassembling is efficient and convenient, labor is saved, and production efficiency is improved.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

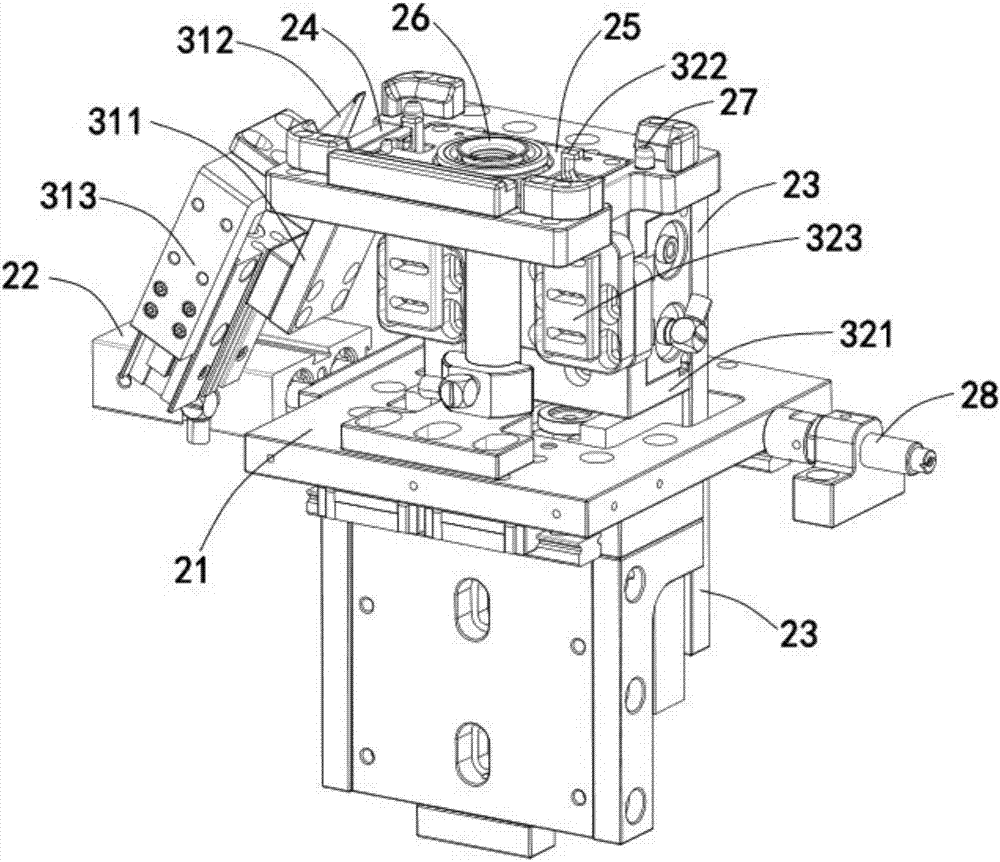

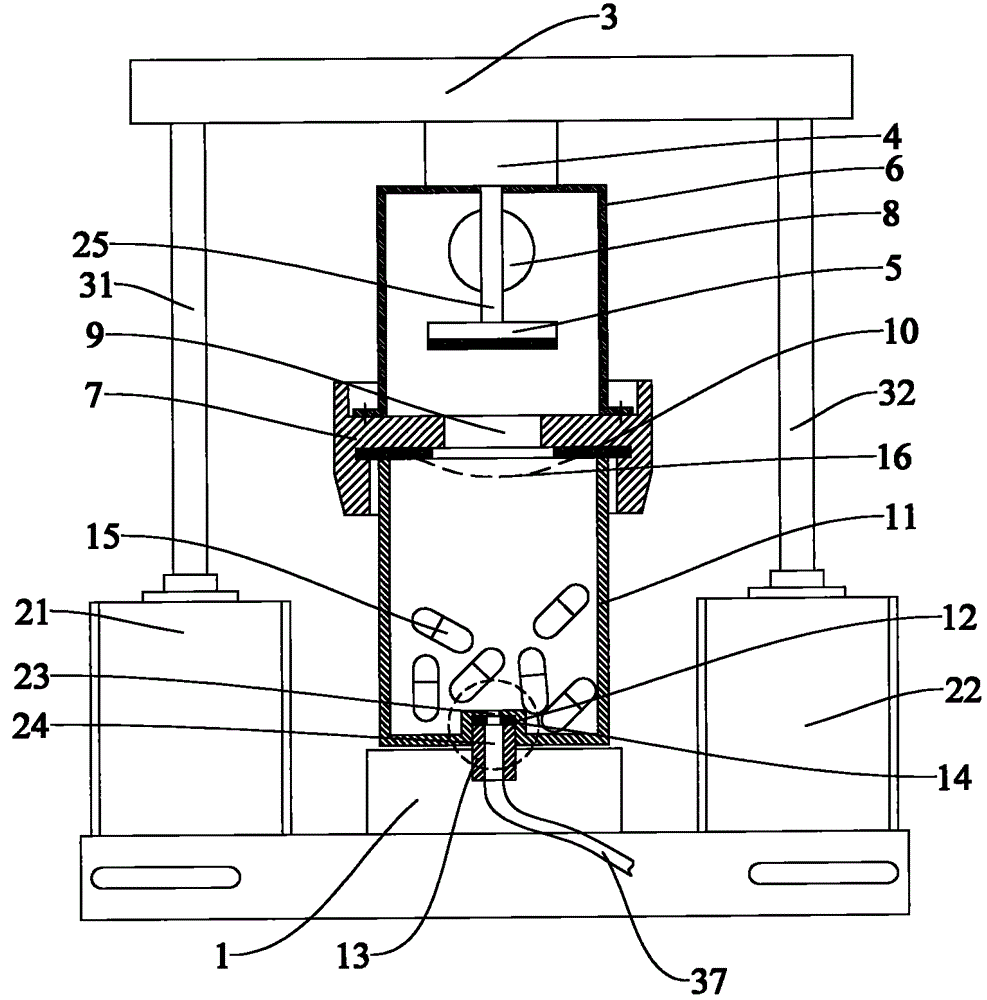

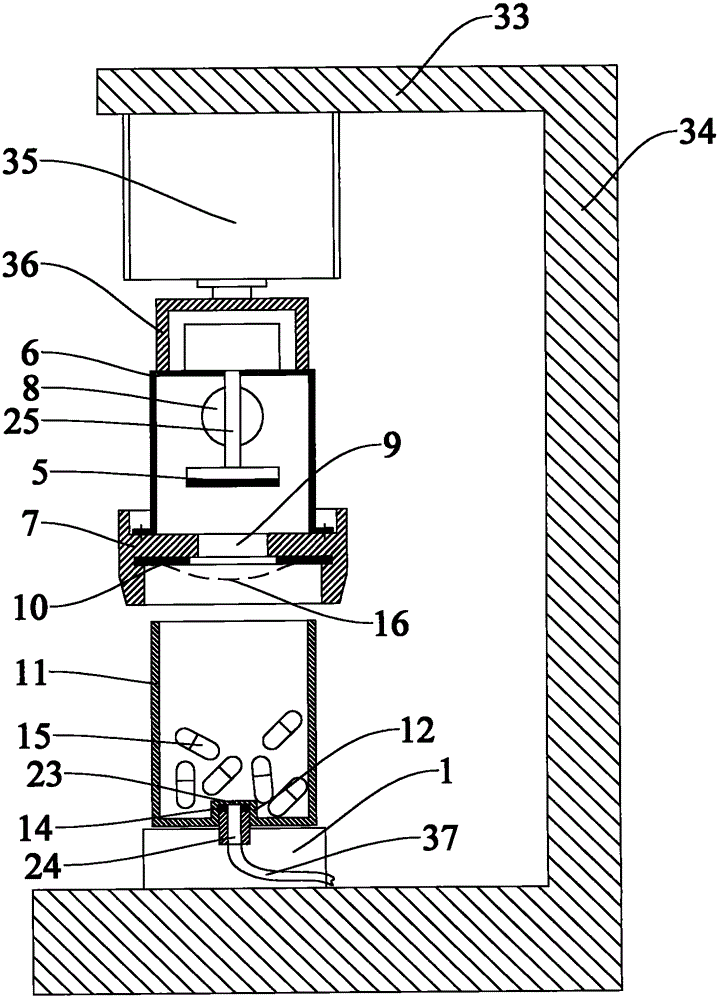

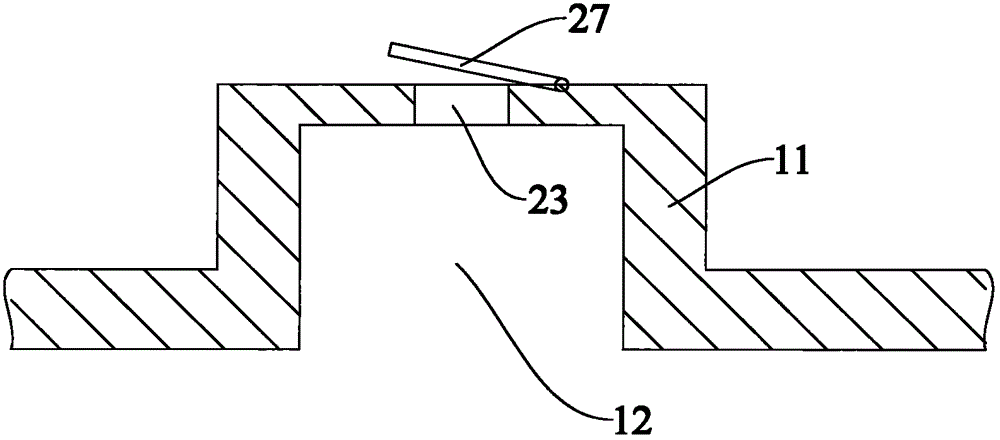

Capsule pulling device

ActiveCN104528085ARealize automatic disassemblyGuaranteed purityArticle unpackingExhaust valveEngineering

The invention provides a capsule pulling device which comprises a working bin used for containing capsules to be disassembled and an exhaust chamber. Air is pressed into the working bin through an air inlet. The exhaust chamber is arranged above the working bin, an exhaust port is formed in the exhaust chamber, a first cylinder is arranged at the end face, away from the working bin, of the exhaust chamber, an output shaft of the first cylinder can stretch into the working bin, and an exhaust valve plate is fixedly connected to the end, stretching into the working bin, of the output shaft. A bin cover which can be sealed with and matched with the working bin is fixedly arranged at the end face, close to the working bin, of the exhaust chamber in a sleeving mode, a through pressure releasing hole is formed in the position, corresponding to the exhaust valve plate, of the bin cover, and the exhaust valve plate can seal the pressure releasing hole. According to the capsule pulling device, automatic disassembly of capsules is achieved through air pressure difference, and the defects that medicine powder is contaminated and the efficiency is low in manual disassembly are overcome.

Owner:韩杰

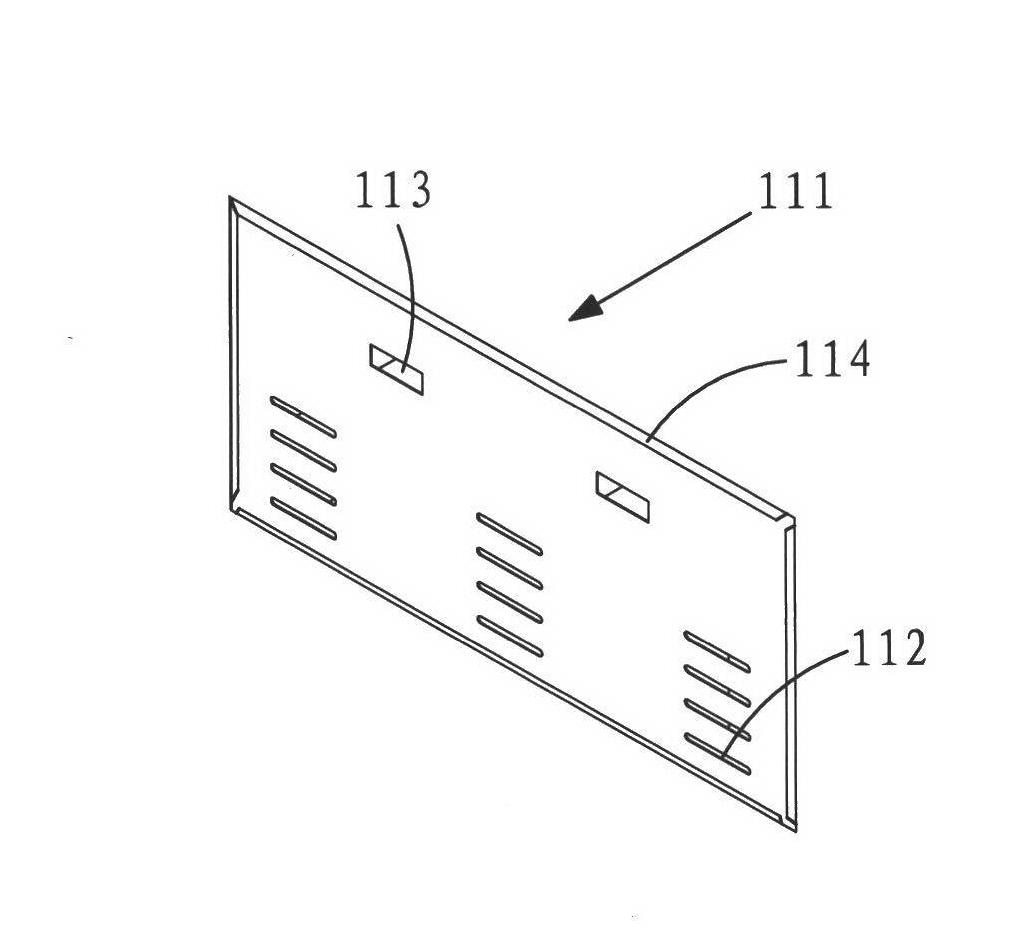

Frame disassembling system of solar cell

InactiveCN102437244ARealize automatic disassemblyFinal product manufactureElectronic waste recyclingEngineeringSolar cell

The invention discloses a frame disassembling system of a solar cell. The frame disassembling system comprises a cabinet body, a support part and a disassembling device, wherein the disassembling device is provided with four vertically-arranged air cylinder devices and four horizontally-arranged air cylinder devices. Compared with the prior art, the frame disassembling system of the solar cell provided by the invention can be used for automatically disassembling the frame of the solar cell.

Owner:SIP GOLDWAY TECH

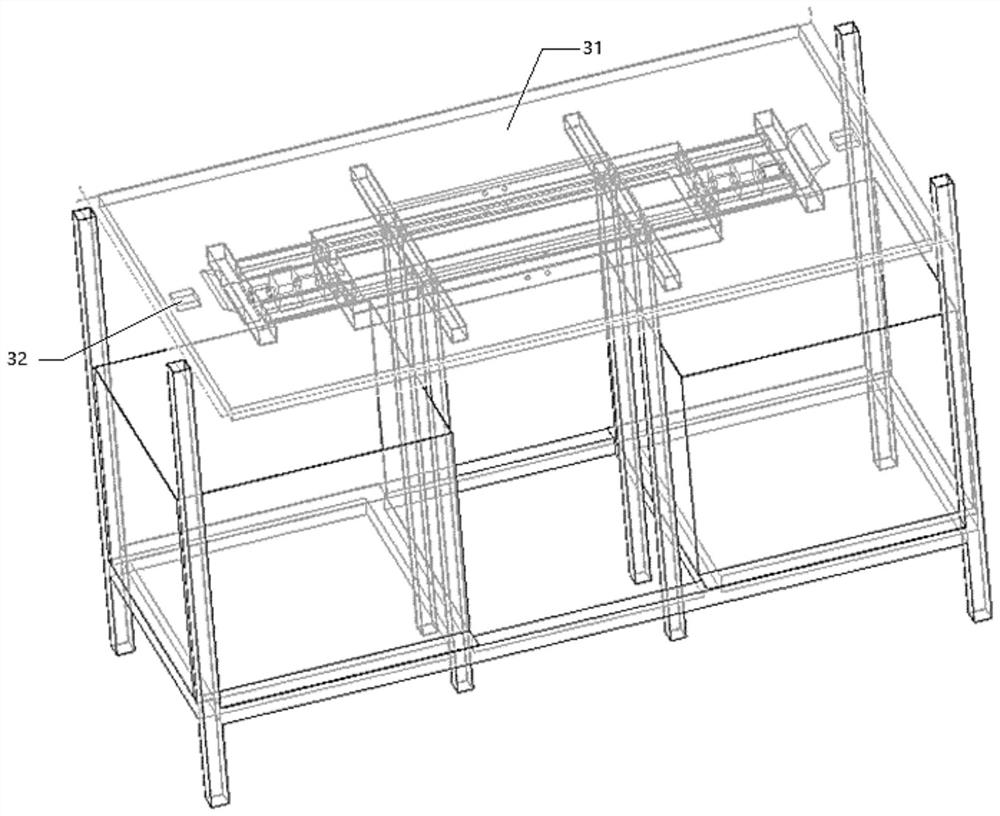

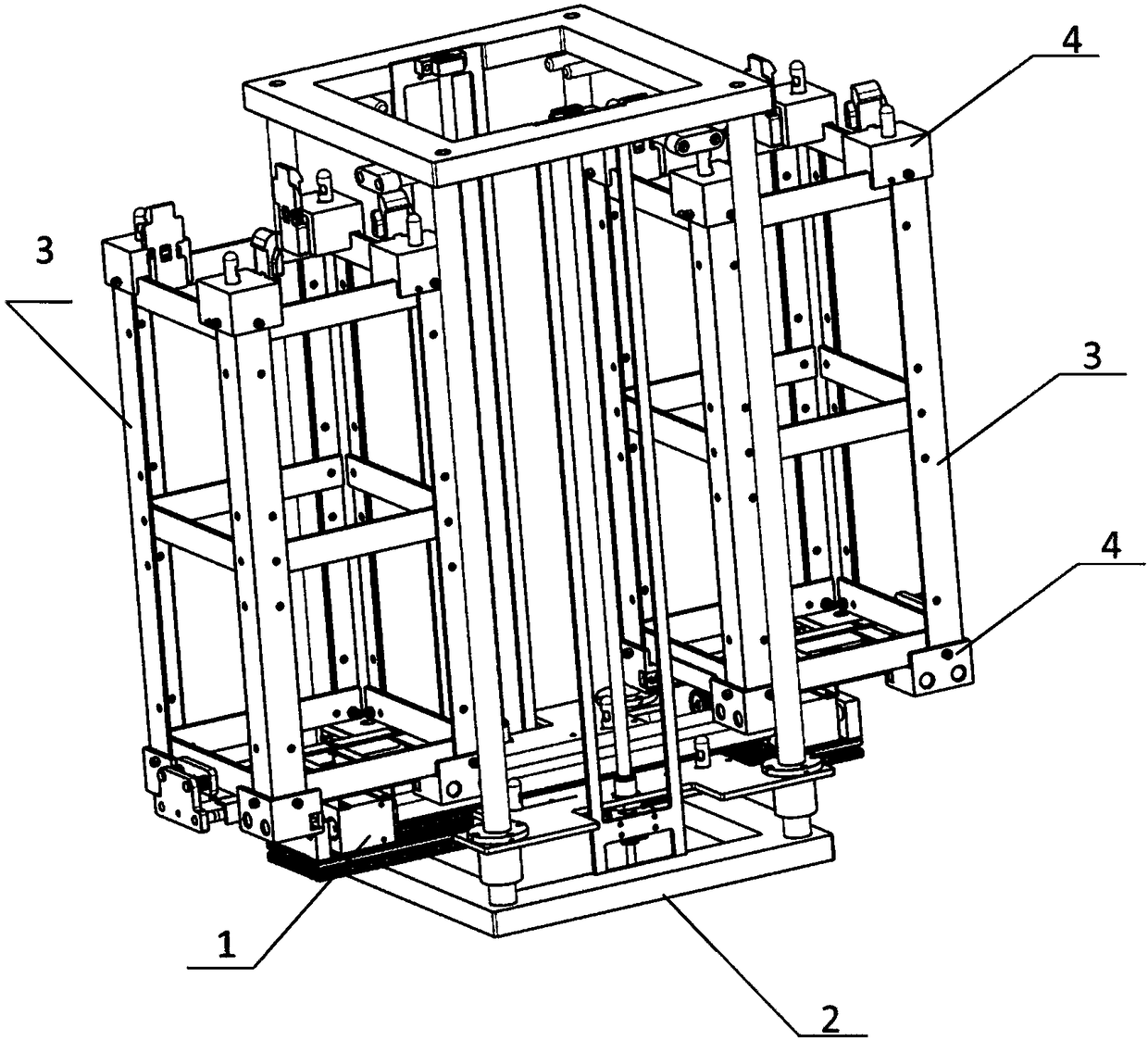

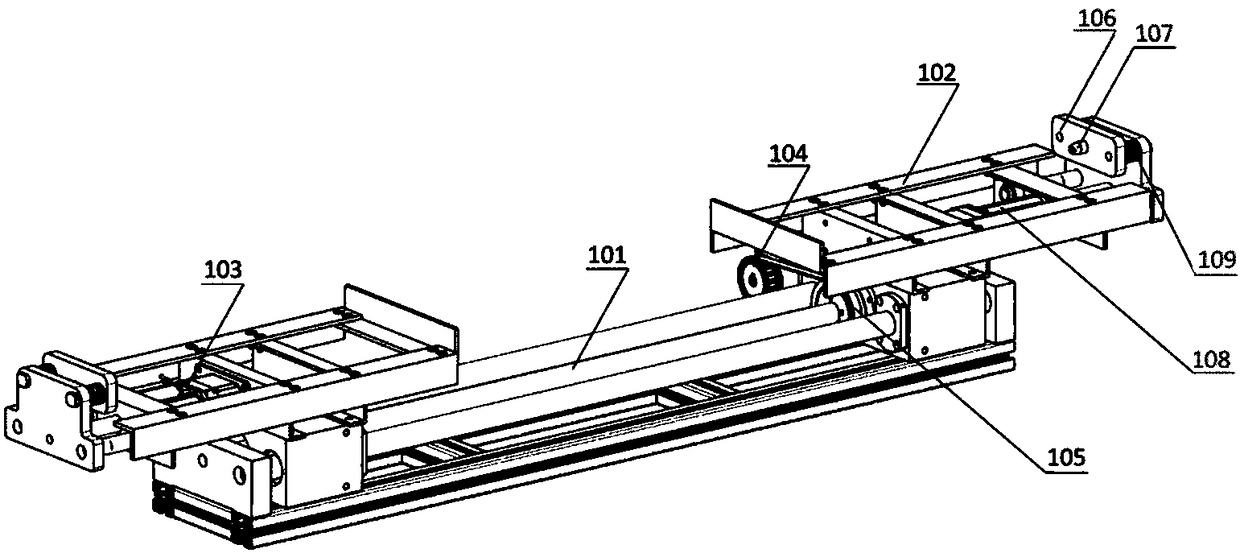

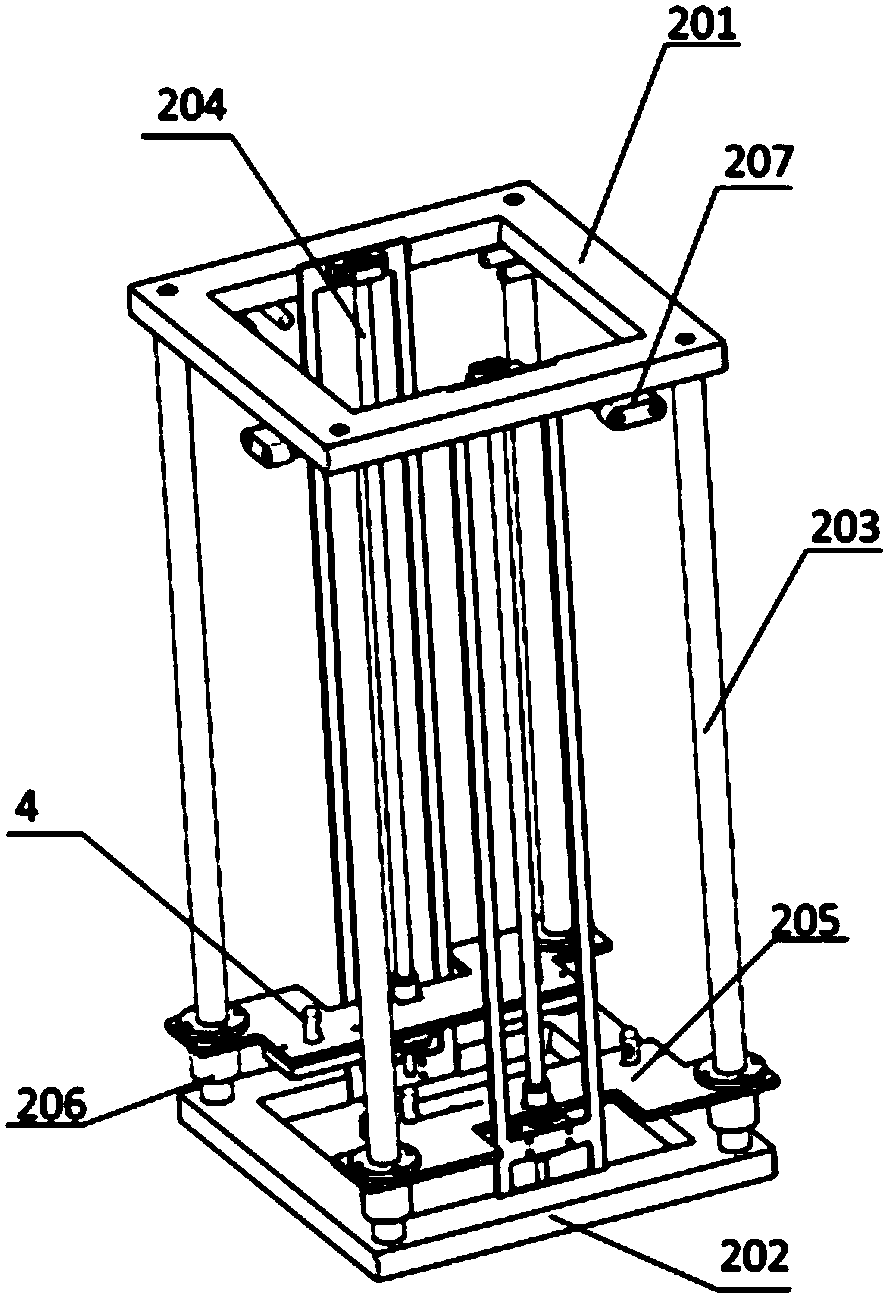

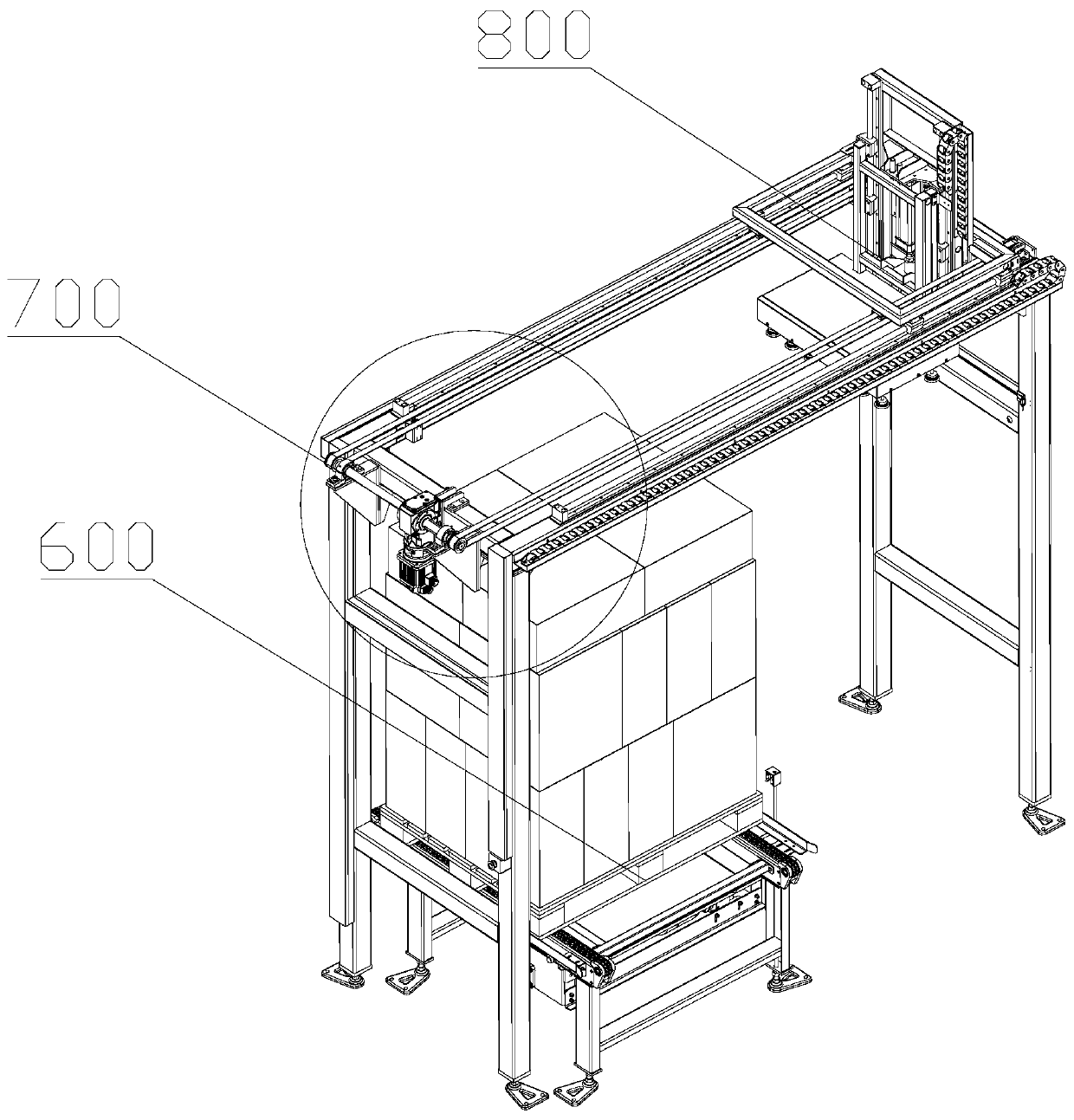

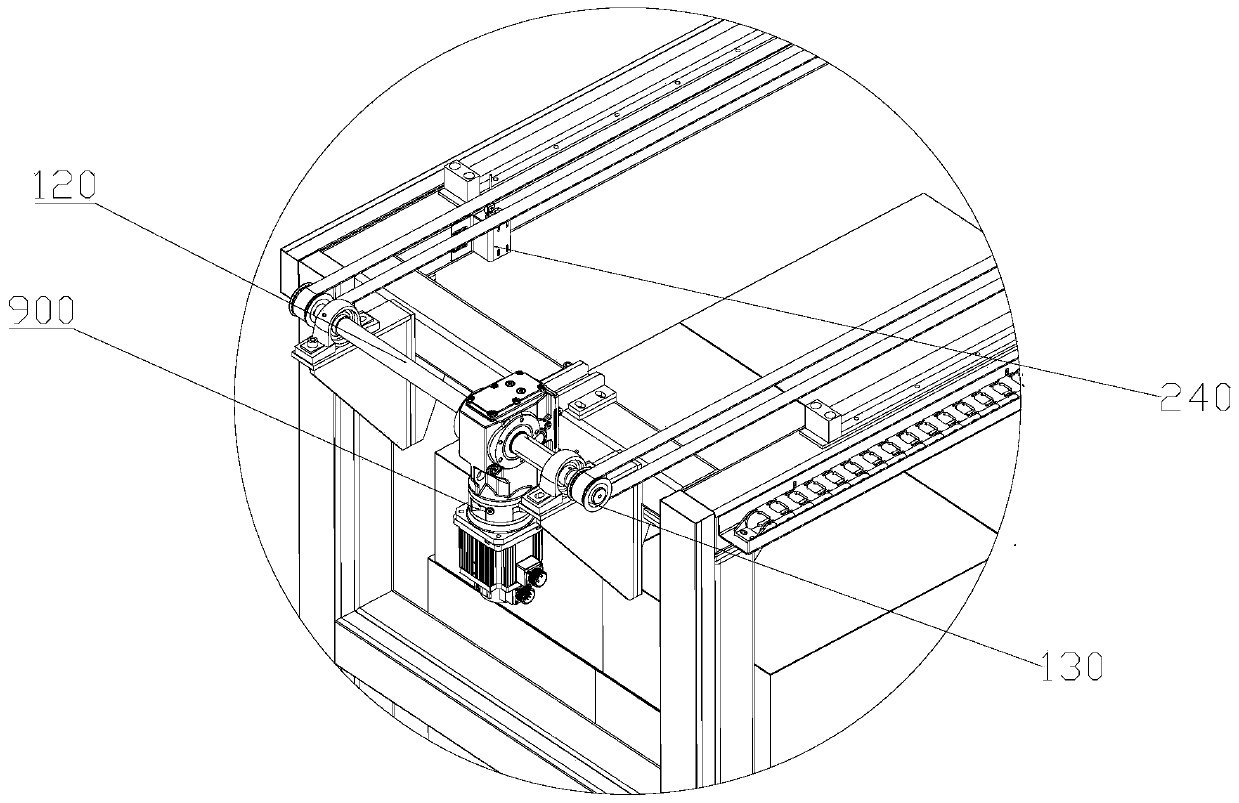

Multi-module automatic dismounting and mounting lifting mechanism and lifting method

ActiveCN108408348AEliminate potential safety hazardsReduce shakingLifting devicesMechanical conveyorsVertical motionEngineering

The invention discloses a multi-module automatic dismounting and mounting lifting mechanism and a lifting method. The mechanism comprises an automatic transverse moving mechanism, an automatic liftingmechanism and multiple modules; the automatic transverse moving mechanism comprises an automatic horizontal moving device and a tray; the tray is arranged on the automatic horizontal moving device, and is used for containing the modules, and the automatic lifting mechanism comprises an automatic vertical motion device and a lifting positioning plate, the lifting positioning plate is arranged on the automatic vertical motion device, multiple first male and female abut-joint devices are fixedly arranged on the upper surface of the lifting positioning plate, a fixing mechanism is arranged on theautomatic vertical motion device, the modules are of frame structures, multiple second male and female abut-joint devices are arranged on the lower end of each module, and multiple third second maleand female abut-joint devices are arranged on the upper end of each module. The lifting mechanism is combined with the automatic transverse moving mechanism, the multiple modules can be automaticallydismounted and mounted, the problem that a current high-altitude work lifting mechanism shakes at high altitude is solved, and the potential safety hazards of manual dismounting and mounting can be removed.

Owner:STATE GRID SHAANXI ELECTRIC POWER RES INST +3

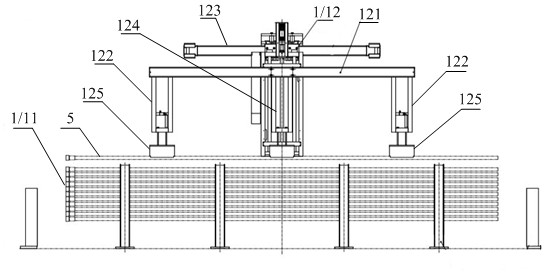

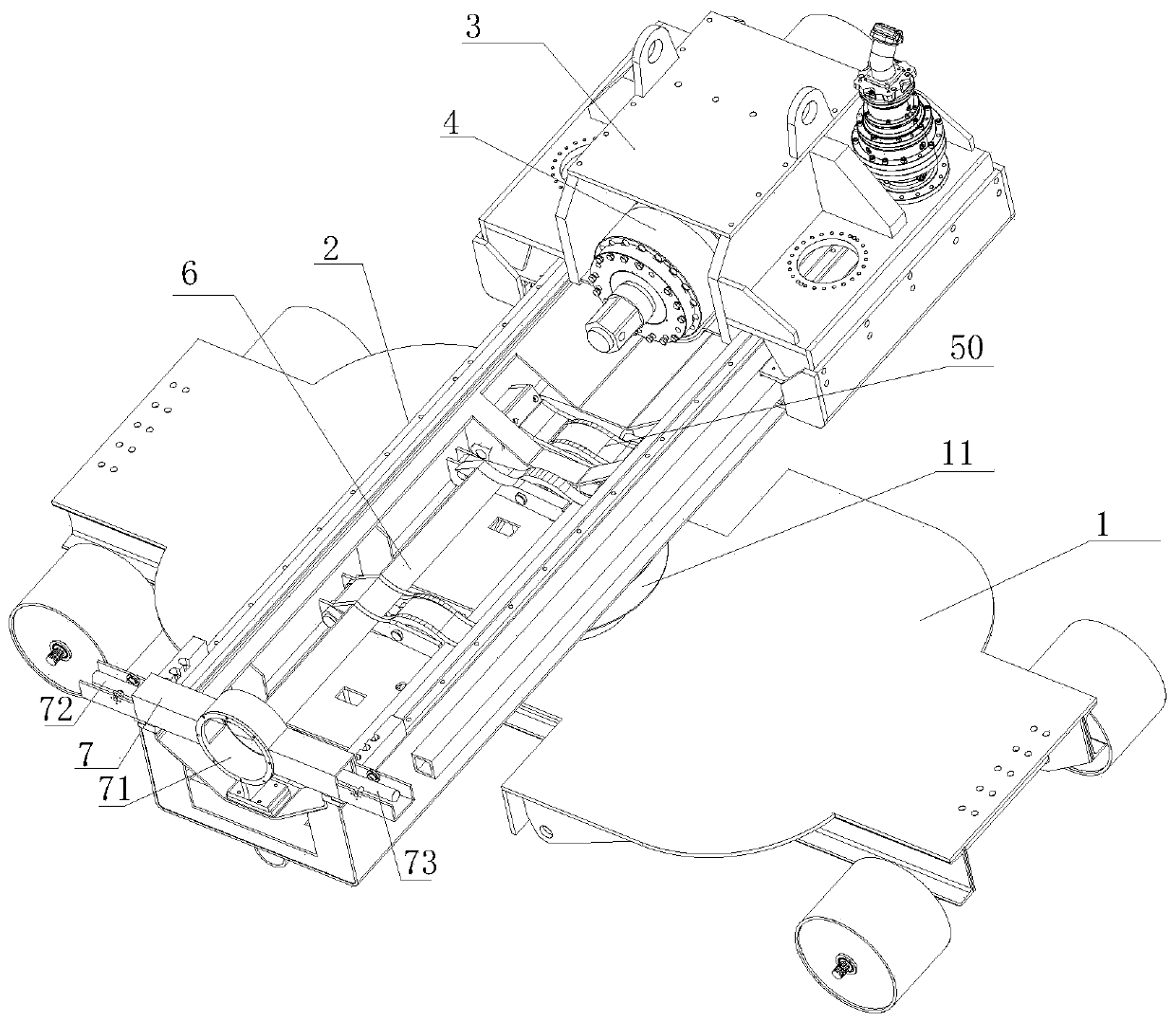

Profiled cigarette unstacker and unstacking assembly line

InactiveCN110902400ARealize fully automatic unstackingSave human effortDe-stacking articlesLogistics managementStructural engineering

The invention provides a profiled cigarette unstacker and a unstacking assembly line, and relates to the technical field of logistics-related equipment. The profiled cigarette unstacker includes a grasping device, a transporting device, a detecting device, a conveying device, and a support frame. The transporting device is disposed on the upper end of the support frame. The grasping device is disposed on the transporting device, and can be moved on the transporting device. The detecting device is configured to detect cigarette boxes laid on a cigarette stack. The grasping device is used for grasping cigarette boxes laid on a pallet, and moving out the laid cigarette boxes of the pallet under the driving of the transporting device. The profiled cigarette unstacker provided by the present invention is used for dismantling the cigarette boxes laid on the sprofiled cigarette stack, and the remaining standard cigarette stacks are transported to a standard cigarette unstacker by the conveying device to be dismantled. Thus, the profiled cigarette unstacker fully-automatically unstacks the cigarette stacks, saves manpower and improves the unstacking efficiency.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

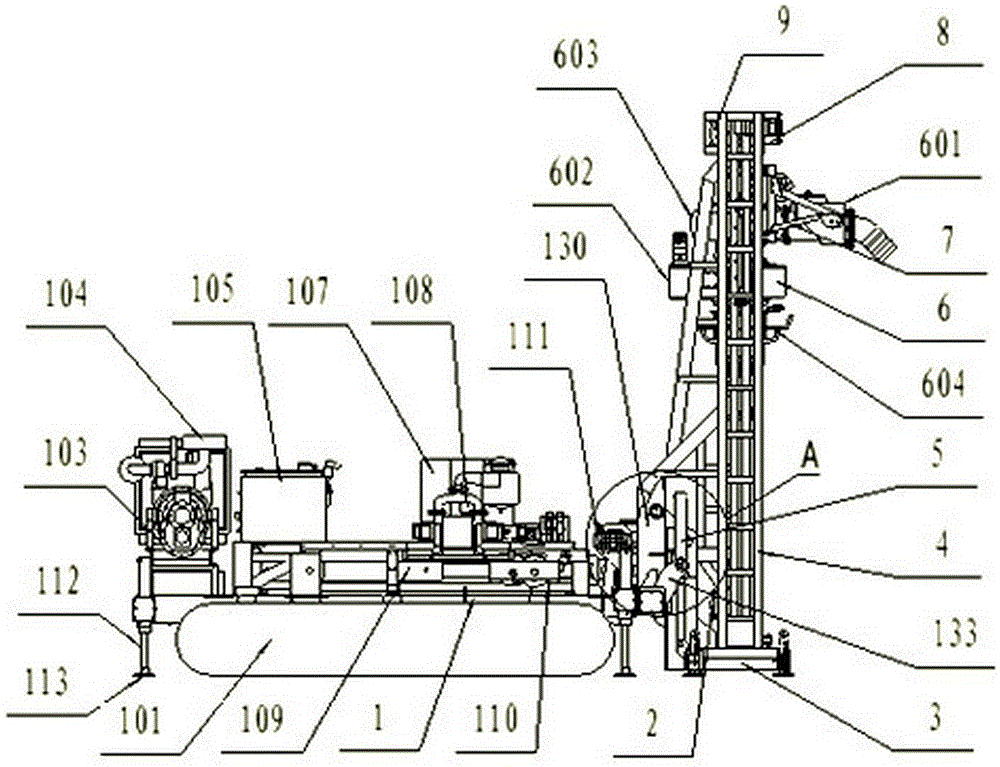

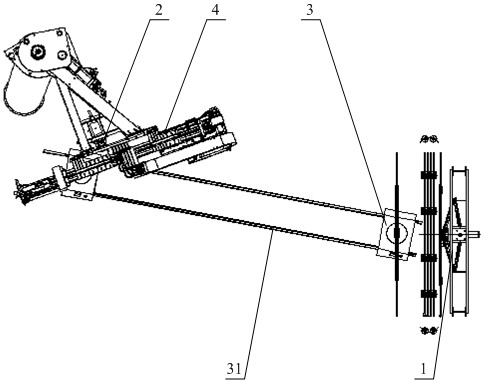

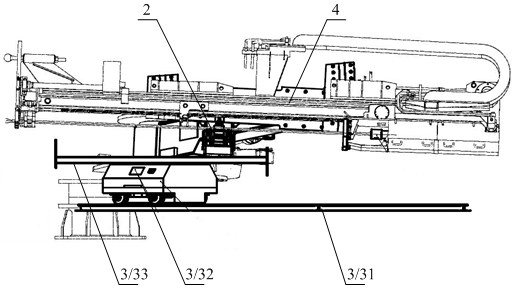

Large-aperture pressure relief drilling machine

ActiveCN110905420ARealize automatic disassemblySave human effortDrilling rodsDerricks/mastsStructural engineeringIndustrial engineering

The invention discloses a large-aperture pressure relief drilling machine, which comprises a movement foundation bed and a track unit, wherein the track unit is provided with a mechanical movement part; the mechanical movement part comprises a working end, wherein the track unit on the same side of the working end is laterally fixedly provided with a front vise of a hollow beam shape; the workingend is provided with an annular ring beam; two sides of the front vise are independently provided with a disassembling device; the track unit is provided with a rear vise for disassembling a drill rod, and a bracket used for supporting the drill rod; and the center of the bracket is positioned on an axial line from the working end to the front vise. The large-aperture pressure relief drilling machine has the beneficial effects that the pushing and the drilling of the drill rod can be realized through the front vise, the bracket and the rear vise of the same structure, automatic disassembling can be realized, manpower is saved, and working efficiency is improved. By use of a mechanical operation, a large-diameter drill rod which exceeds a manpower bearing range can be used, and the efficiency of the pressure relief drilling machine is improved by one level.

Owner:CHINA UNIV OF MINING & TECH

Waste lithium ion battery disassembling system

PendingCN110890603ARealize automatic deliveryRealize automatic disassemblyWaste accumulators reclaimingBattery recyclingElectrolytic agentProcess engineering

The invention relates to the technical field of waste lithium ion battery recovery. The invention discloses a disassembling system, in particular to a waste lithium ion battery disassembling system. The system comprises a feeding device, a disassembling device and a pyrolysis device, the feeding device is used for transferring the waste lithium ion batteries into the disassembling device; the disassembling device breaks the waste lithium ion battery moved by the feeding device; the waste lithium ion battery broken by the disassembling device is transferred into the pyrolysis device, a heatingassembly of the pyrolysis device heats the broken waste lithium ion battery to evaporate the electrolyte, and a condensation assembly reduces the evaporated electrolyte to various different temperatures to realize condensation recovery of different components in the electrolyte; according to the waste lithium ion battery disassembling system, an operator does not need to manually operate recyclingtreatment of the waste lithium ion battery, automatic conveying, automatic disassembling and automatic pyrolysis of the waste lithium ion battery are achieved, then automatic recycling treatment of the waste lithium ion battery is achieved, and the recycling treatment efficiency of the waste lithium ion battery is improved.

Owner:东莞市宏湖智能装备有限公司

Unmanned aerial vehicle for pesticide spraying

InactiveCN107697299AEasy to separate workEasy to assembleAircraft componentsRotary stirring mixersImpellerUncrewed vehicle

Owner:成都千里驹科技有限公司

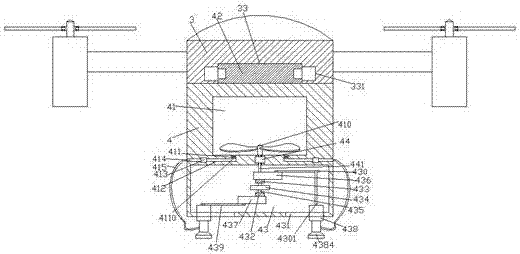

Sewage treatment device

ActiveCN107265550AIncrease the areaImprove spraying efficiencyWater/sewage treatment by sorptionAlumSewage treatment

The invention discloses a sewage treatment device which includes a body and an operation body arranged on the bottom thereof. An alum chamber is arranged in the operation body. A power apparatus is disposed in an internal bottom wall of the alum chamber. A transmitting chamber is arranged in the operation body under the alum chamber. Guide troughs are correspondingly disposed on the left and right sides of an internal bottom wall of the transmitting chamber. Each guide trough is provided with a guide piece therein. A first plate and a second plate are arranged in the interior of the transmitting chamber in a vertically corresponding manner and are both extended to the front side and the back side. A rotary shaft, which extends vertically, is disposed between the first plate and the second plate, wherein an extension portion on the top of the rotary shaft penetrates the top surface of the first plate in a connection manner of revolving fit. The sewage treatment device has simple structure, can achieve automatic assembly and dismounting, has convenience in maintenance and transportation in later period, and is increased in spray coverage area at the same time.

Owner:ENRIC BENGBU COMPRESSOR

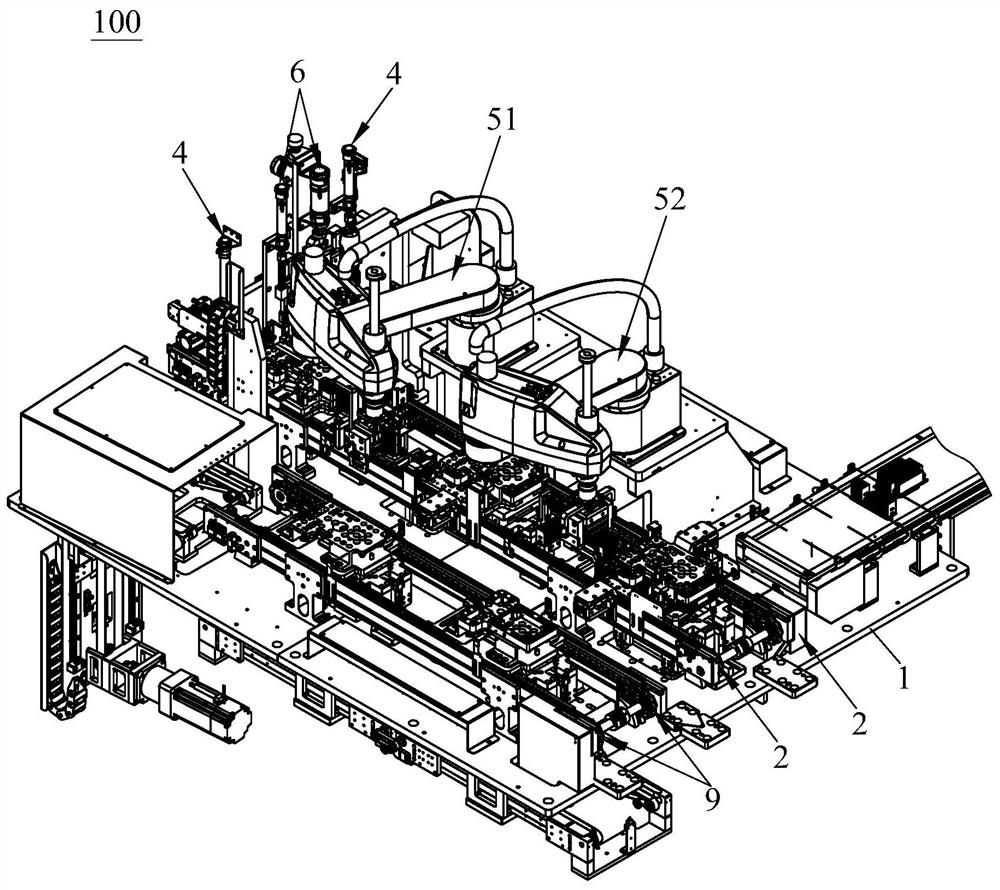

Jig disassembling equipment

PendingCN112296668ARealize automatic disassemblyRealize automatic blankingAssembly machinesMetal working apparatusRobot handEngineering

The invention provides jig disassembling equipment. The jig disassembling equipment comprises a rack, first conveying lines, jigs, pressing plate opening mechanisms, a first manipulator and a second manipulator, wherein the rack is sequentially provided with a first station, a second station and a third station in the conveying direction of the first conveying lines; the jigs are placed on the first conveying lines and comprise jig bottom plates, jig limiting middle frames, jig upper covers and elastic pressing assemblies, the jig bottom plates are provided with placement stations for allowingradiators to be placed, the jig limiting middle frames are detachably stacked in the jig bottom plates, and the jig upper covers cover the jig limiting middle frames and are detachably stacked on thejig bottom plates, and the elastic pressing assemblies comprise first supporting seats, rotary pressing plates and first elastic pieces; the pressing plate opening mechanisms are arranged on the rackand located at the first station, and the pressing plate opening mechanisms can drive the rotary pressing plates to rotate to be disengaged from the jig upper covers; and the first manipulator is used for disassembling the jig upper covers, and the second manipulator is used for disassembling the jig limiting middle frames and taking out the radiators located on the jig bottom plates.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com