Automatic PIN disassembly machine

An automatic, rack-mounted technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of high labor intensity, low efficiency, easy to damage circuit boards, etc., and achieve the effect of high disassembly efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

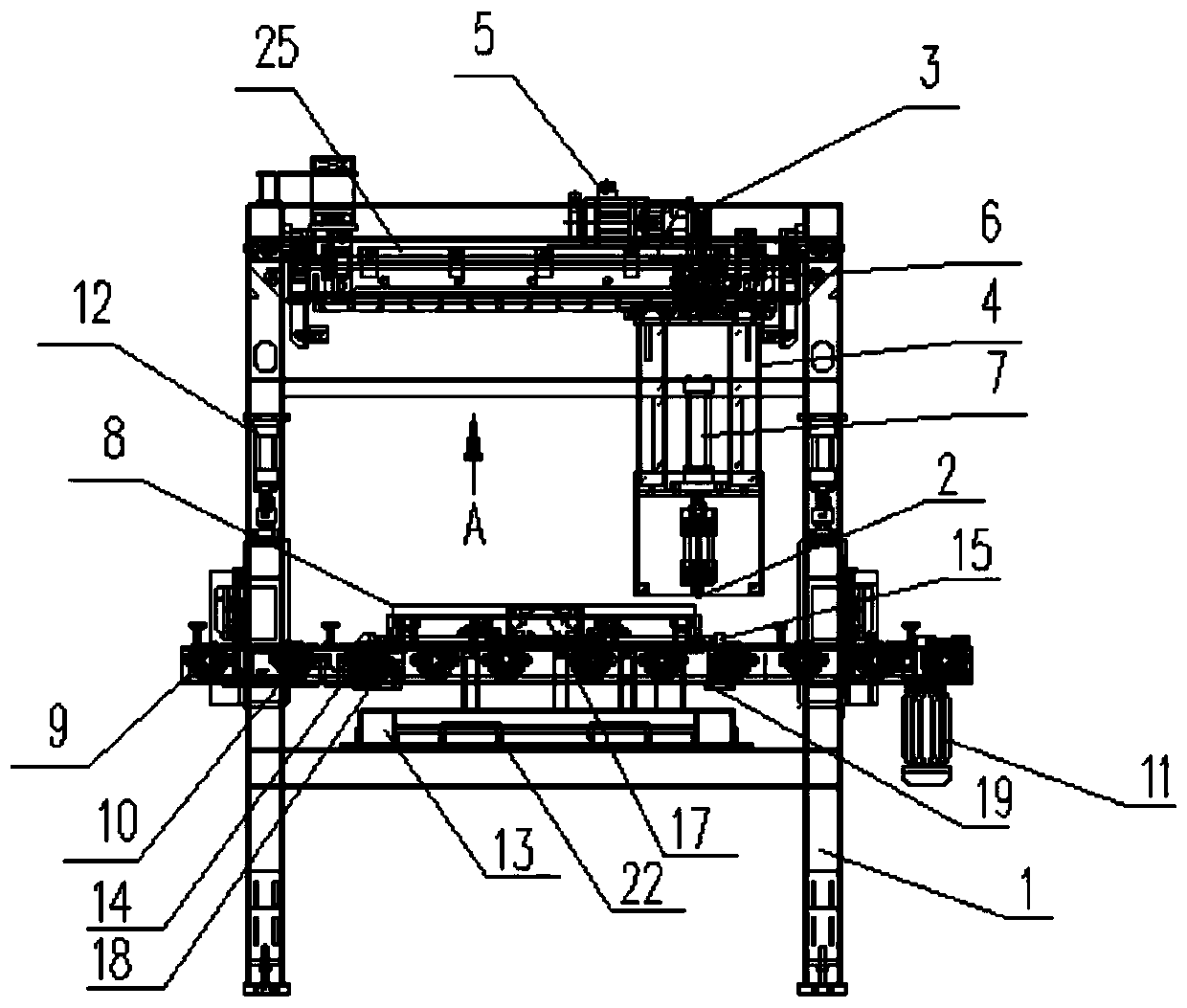

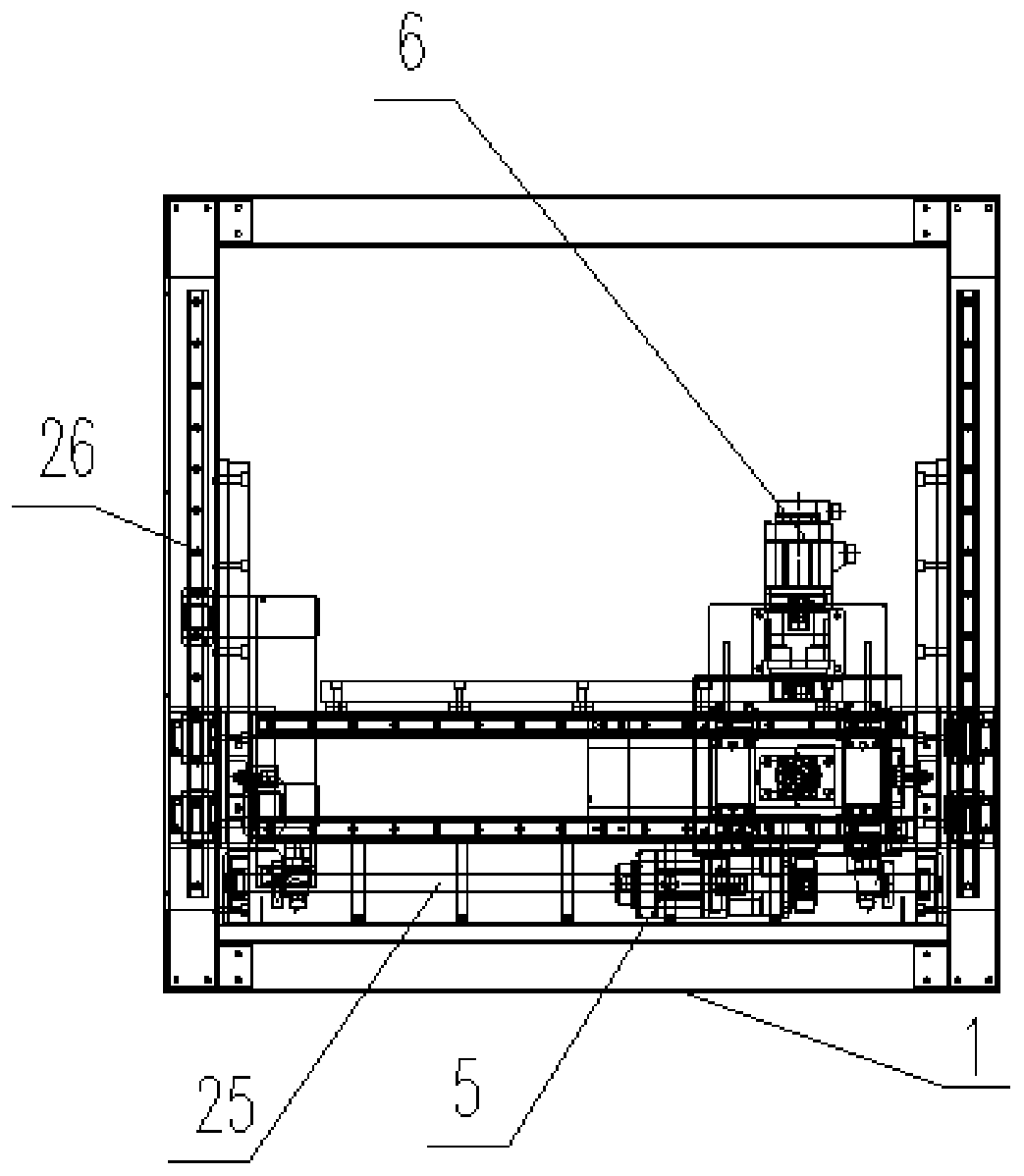

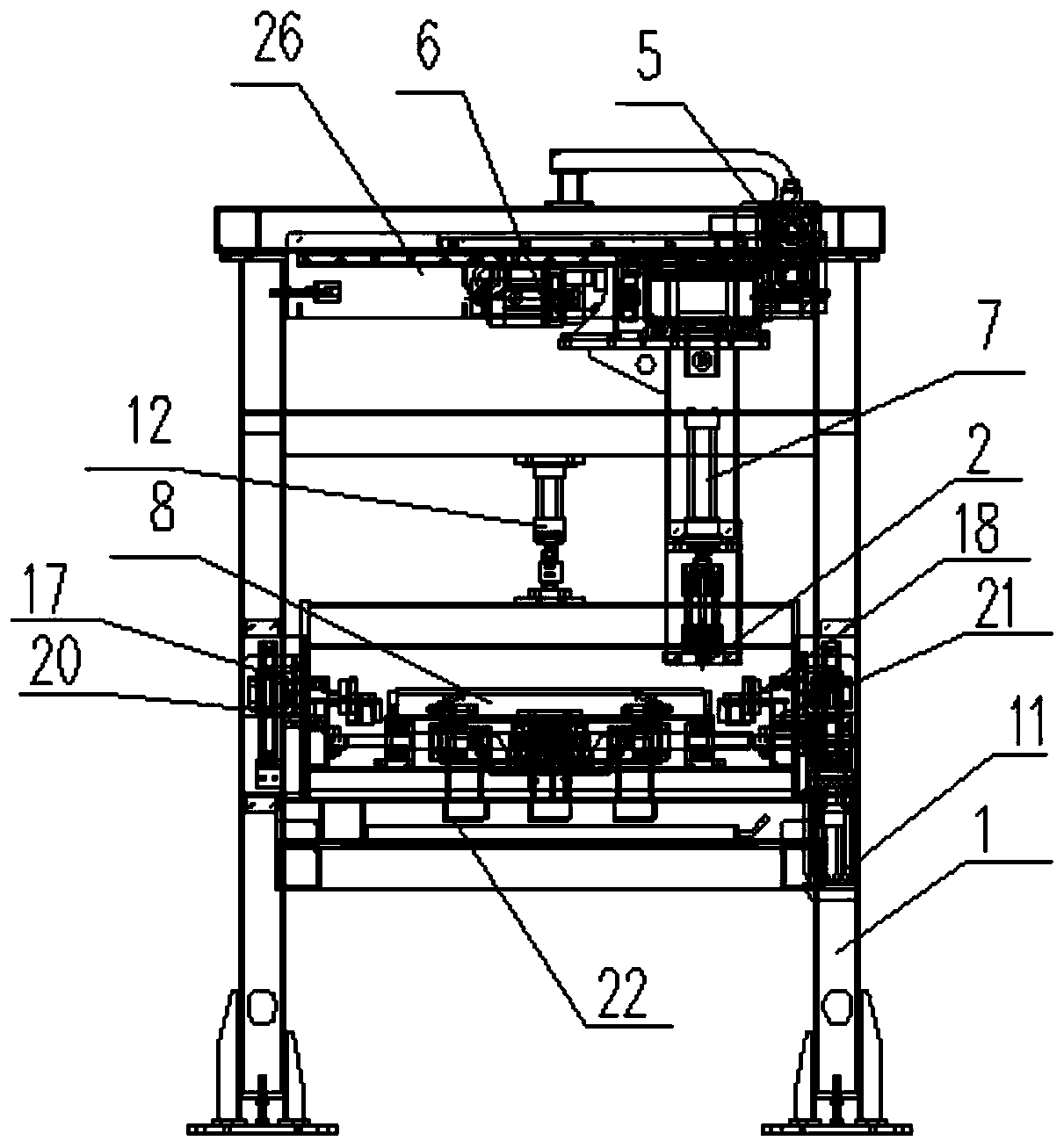

[0021] Embodiment: An automatic PIN needle dismantling machine, including a frame 1, a ejector pin 2, a slider 3 in the X direction, a slider 4 in the Y direction, a plate position correction device, a code scanner, a drive device in the X direction 5, and a The driving device 6, the longitudinal driving device 7 and the control system, the X direction and the Y direction are two directions perpendicular to each other on the horizontal plane, the X direction slider 3 is positioned on the frame 1 that can slide along the X direction, and the Y direction slides The block 4 can be slid along the Y direction and positioned on the X direction slider 3, and the ejector pin 2 can be longitudinally slid on the Y direction slider 4, and the plate position correction device is installed on the frame 1, and the plate position correction device can Calibrate the position of the PIN plate 8 to be removed in the rack 1, the code scanner can read the information in the barcode 27 on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com