Patents

Literature

36results about How to "Realize fully automatic conveying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Camera module detection equipment

ActiveCN104967841ARealize fully automatic conveyingHigh degree of automationTelevision systemsTransmission beltEngineering

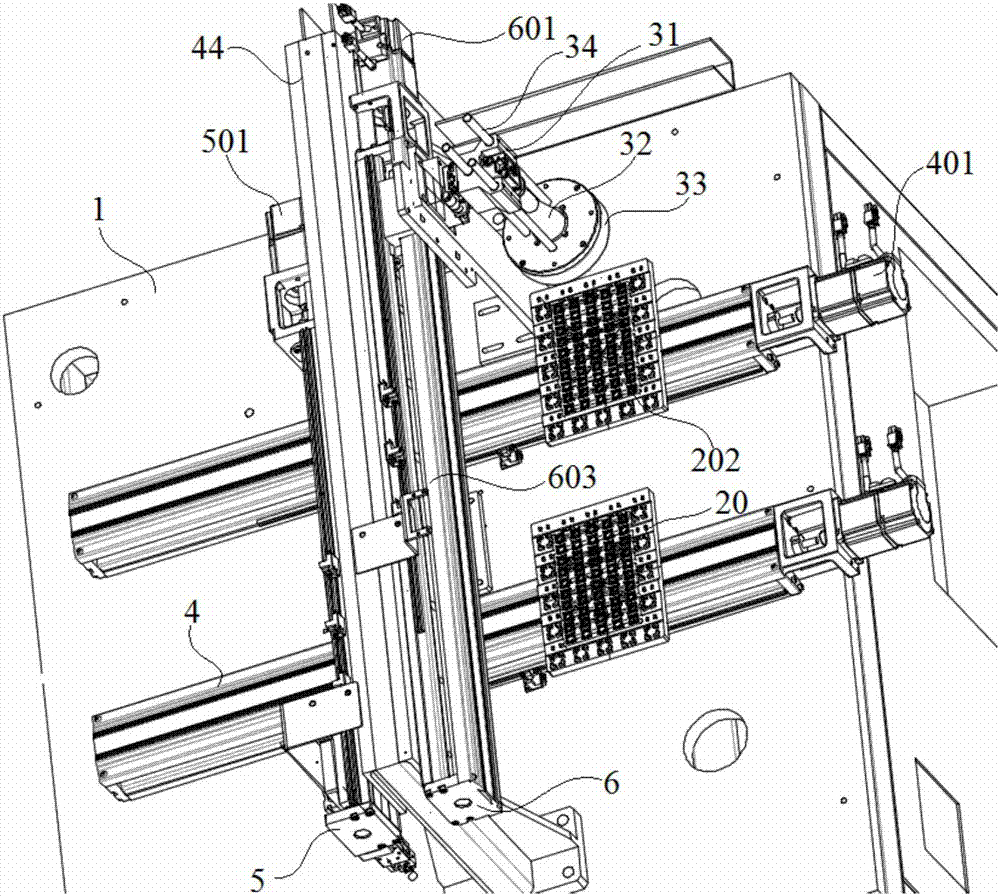

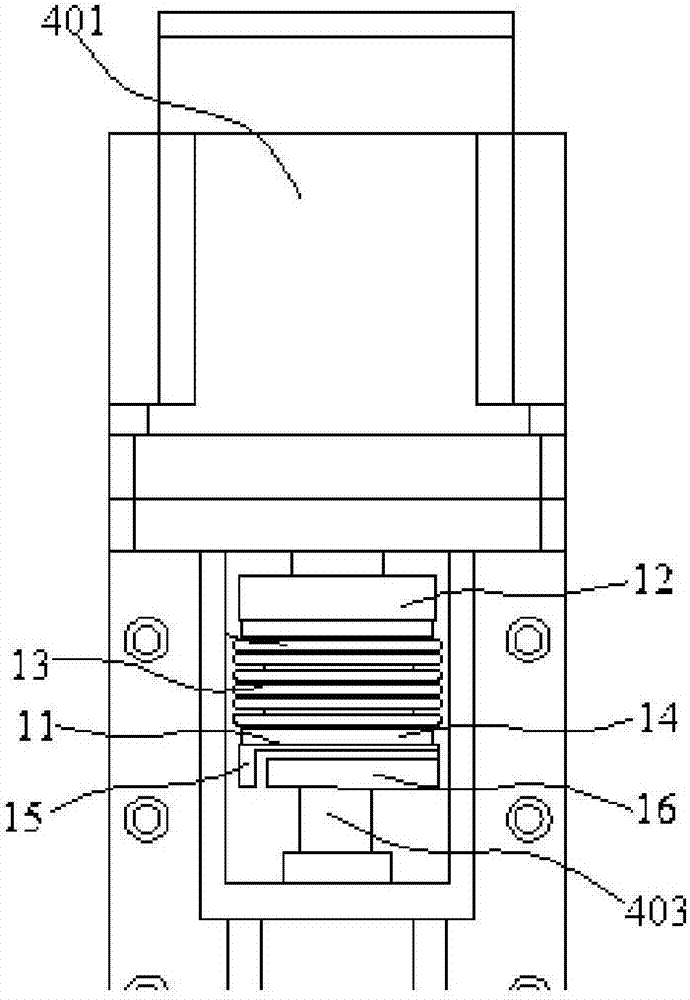

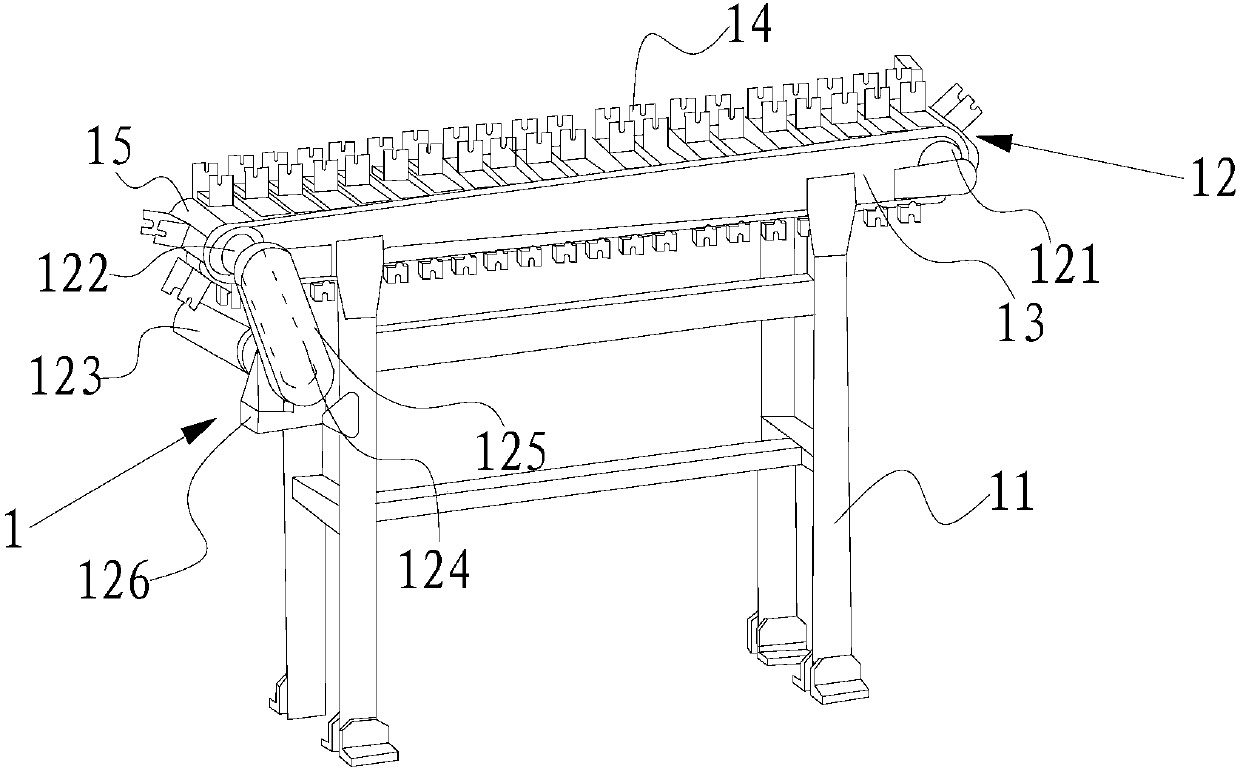

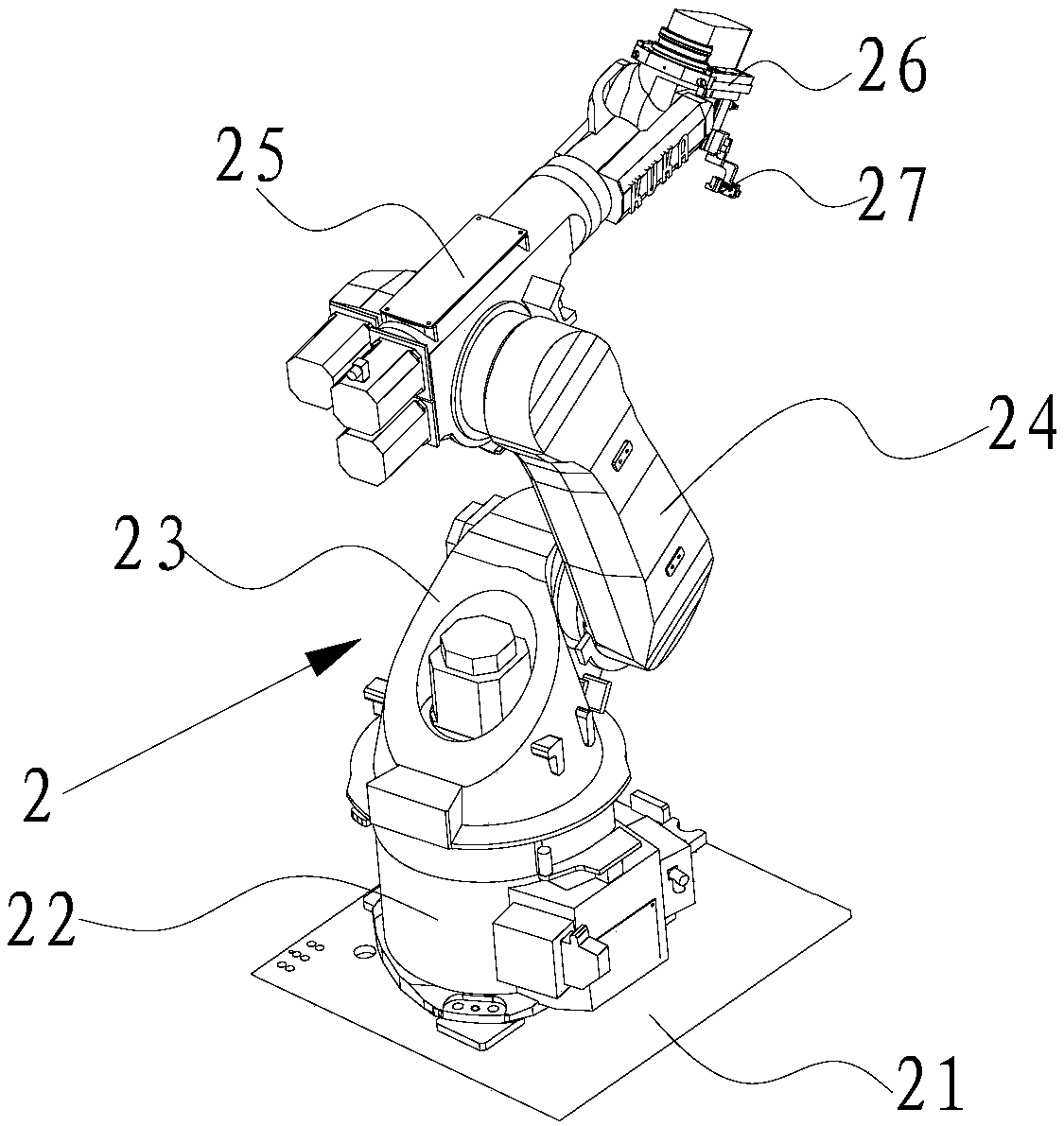

The invention relates to the technical field of mobile phone camera module detection equipment, and particularly relates to camera module detection equipment, which comprises a rack, a transmission device and an optical system. Transmission of a material plate among an input transmission belt, a detection transmission belt and an output transmission belt is realized via a lateral transport mechanism, and output via the output transmission belt is finally carried out. After a camera module is transported on the detection transmission belt, with the help of a first light source group, a second light source group and a third light source group, a first camera and a second camera of the optical system realize detection on a gold wire on a circuit connection substrate on an image sensor group and detection on dust and scratches of the image sensor respectively, and after detection, output via the output transmission belt is carried out. Full-automatic transport of the material plate is realized, the automatic degree of the camera module detection equipment is improved, the working efficiency is improved, automatic detection of the camera module is realized, the detection efficiency is high, the precision is high, and the detection mission rate is low.

Owner:东莞市升宏智能科技有限公司

Automatic packing machine for diapers

ActiveCN107054729ASimple structureFree laborWrapper twisting/gatheringPackaging machinesEngineeringMechanical engineering

The invention discloses an automatic packing machine for diapers. A diaper is clamped and conveyed from two sides of a conveyer belt; the diaper is clamped by a material clamping mechanism, so that the width of the diaper is smaller than or equal to the width of a side plate in a bag opening and material conveying mechanism; the diaper is pushed into the bag opening and material conveying mechanism through a material pushing mechanism; the bag opening and material conveying mechanism limits a plurality of diapers left and right to a width which is convenient for entering packing bags; the bag opening and material conveying mechanism can slide and enable the side plate to enter a far-end packing bag, so that the packing bag is opened; the packing bag is stopped after being conveyed to a position corresponding to a bag sucking mechanism, and the bag is opened by the bag sucking mechanism; the material pushing mechanism performs material pushing and pushes the diaper into the packing bag smoothly; the packed diaper slides further along with the bag opening and material conveying mechanism to be pushed integrally into a sealing and cutting packing mechanism on the other side of the conveyer belt mechanism; the material pushing mechanism pushes the diaper to the sealing and cutting packing mechanism to finish sealing; automatic conveying and bagging of the diaper are realized; and stability and production efficiency are enhanced.

Owner:ZHEJIANG DINGYE MACHINERY

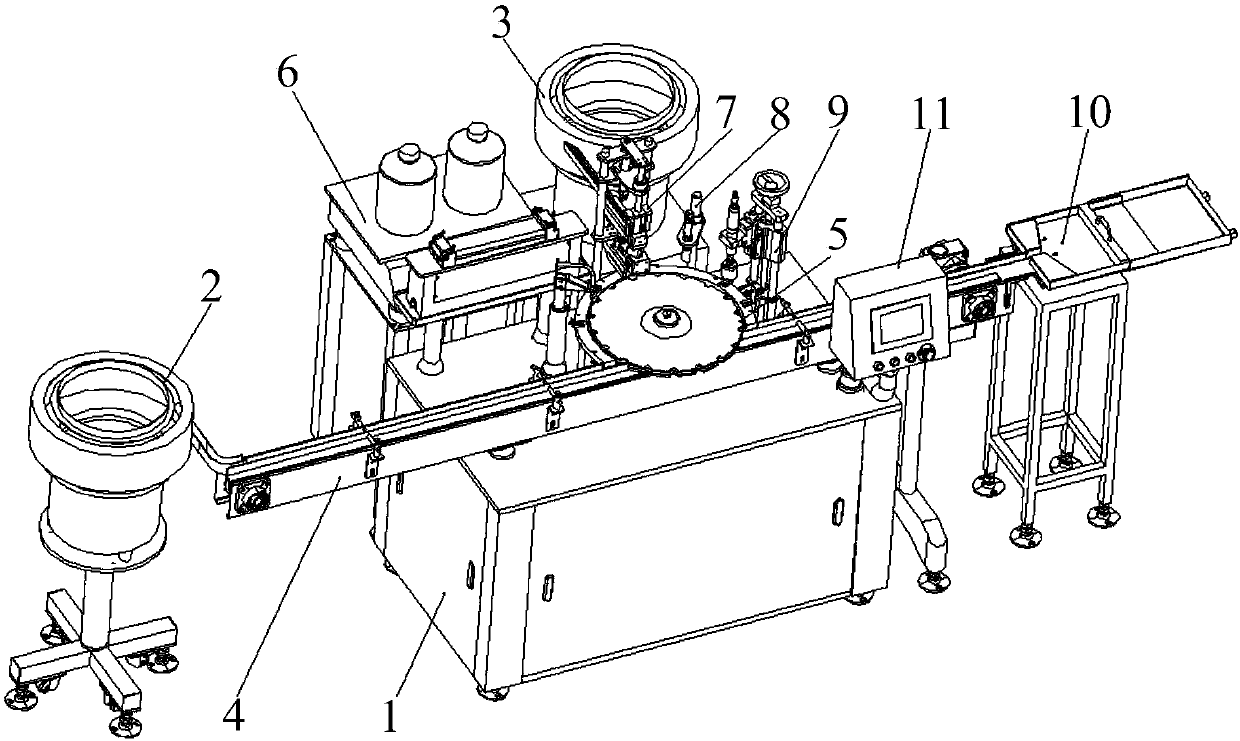

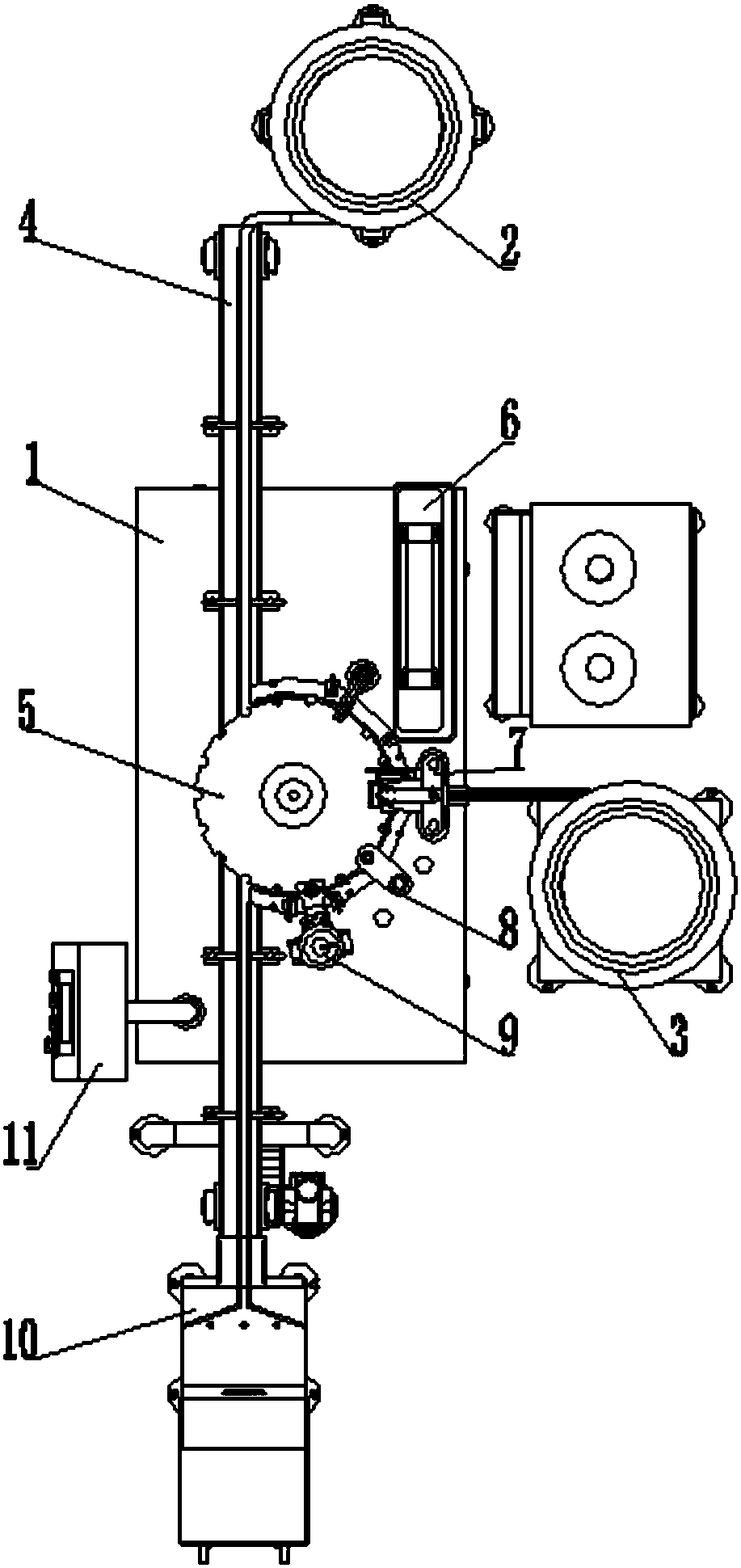

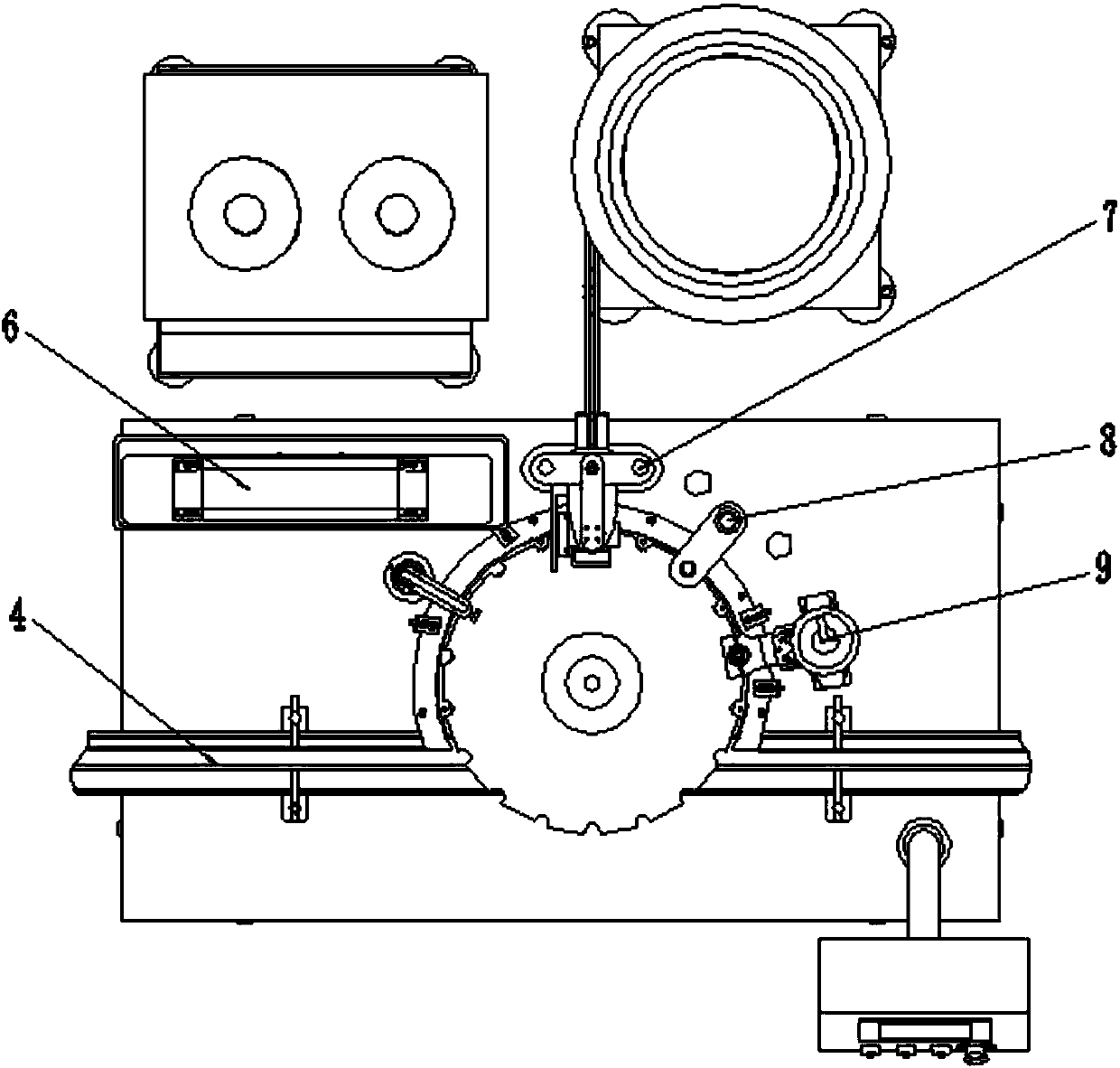

Human red blood cell filling cap screwing machine

PendingCN107777636AImprove filling efficiencyAvoid pollutionClosing machinesCapsPhysicsPeristaltic pump

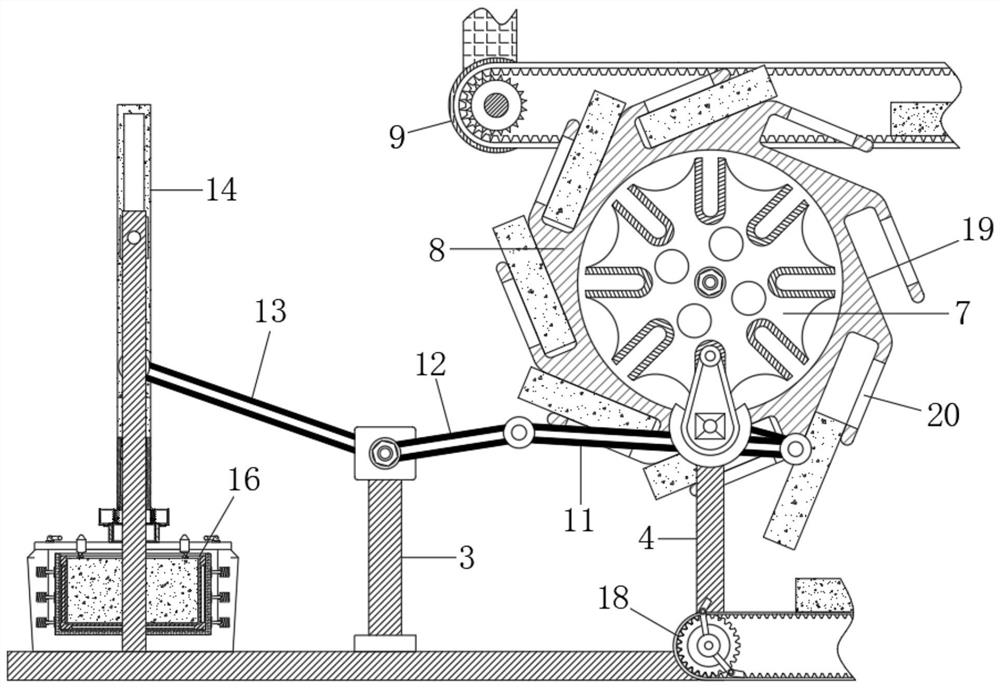

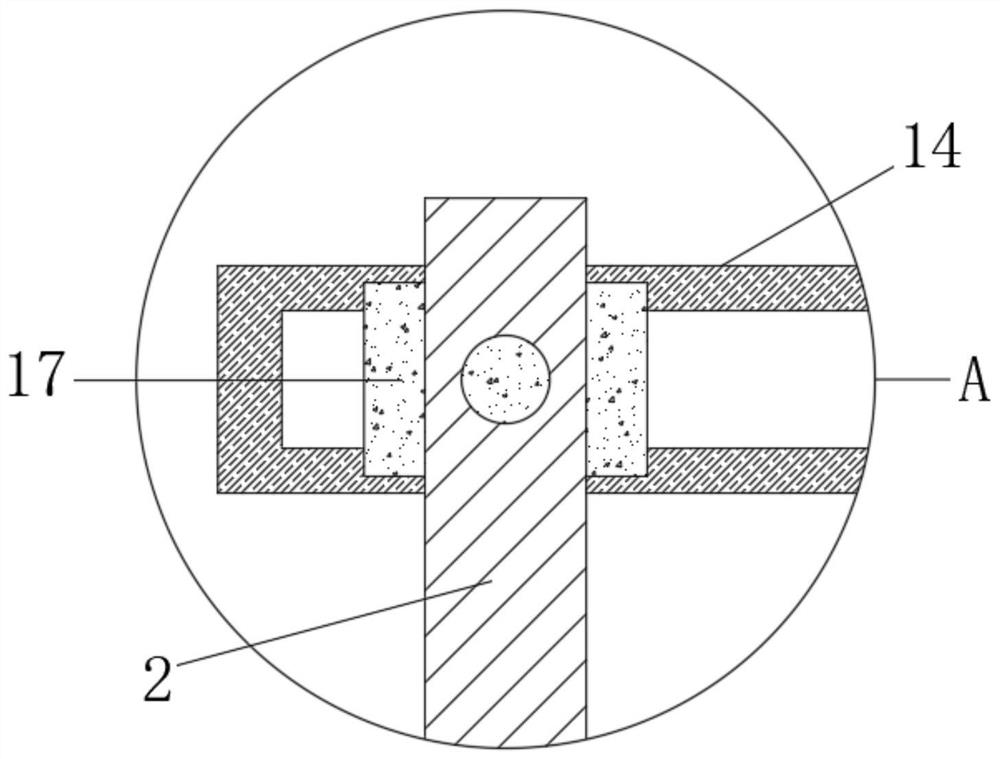

The invention discloses a human red blood cell filling cap screwing machine which comprises a conveying device, a bottle feeding device in butt joint to the front end of the conveying device and a bottle discharging device in butt joint to the back end of the conveying device; a main driving device is in butt joint to the middle of the conveying device and comprises a disc-shaped equal spacing rotating disc, fixed grooves for fixing bottle bodies are formed in an equally spaced manner in the outer circumferential face of the equal spacing rotating disc; a filling station, a cap hanging station, a cap covering correcting station and a cap screwing station are successively arranged on the outer circumference of the equal spacing rotating disc, and the cap hanging station is in butt joint tothe tail end of the cap feeding device; a filling device is arranged on the filling station and comprises a linear peristaltic pump, and a peristaltic pump hose is arranged in a pipe ditch of the linear peristaltic pump; the inlet section of the peristaltic pump hose is inserted into a liquid supply container; and the port of the outlet section of the peristaltic pump hose is connected to a filling needle. The human red blood cell filling cap screwing machine disclosed by the invention can increase the production efficiency of a human red blood cell filling cap screwing process and ensure theproduction quality, and increases the space utilization ratio.

Owner:SHINVA MEDICAL INSTR CO LTD +1

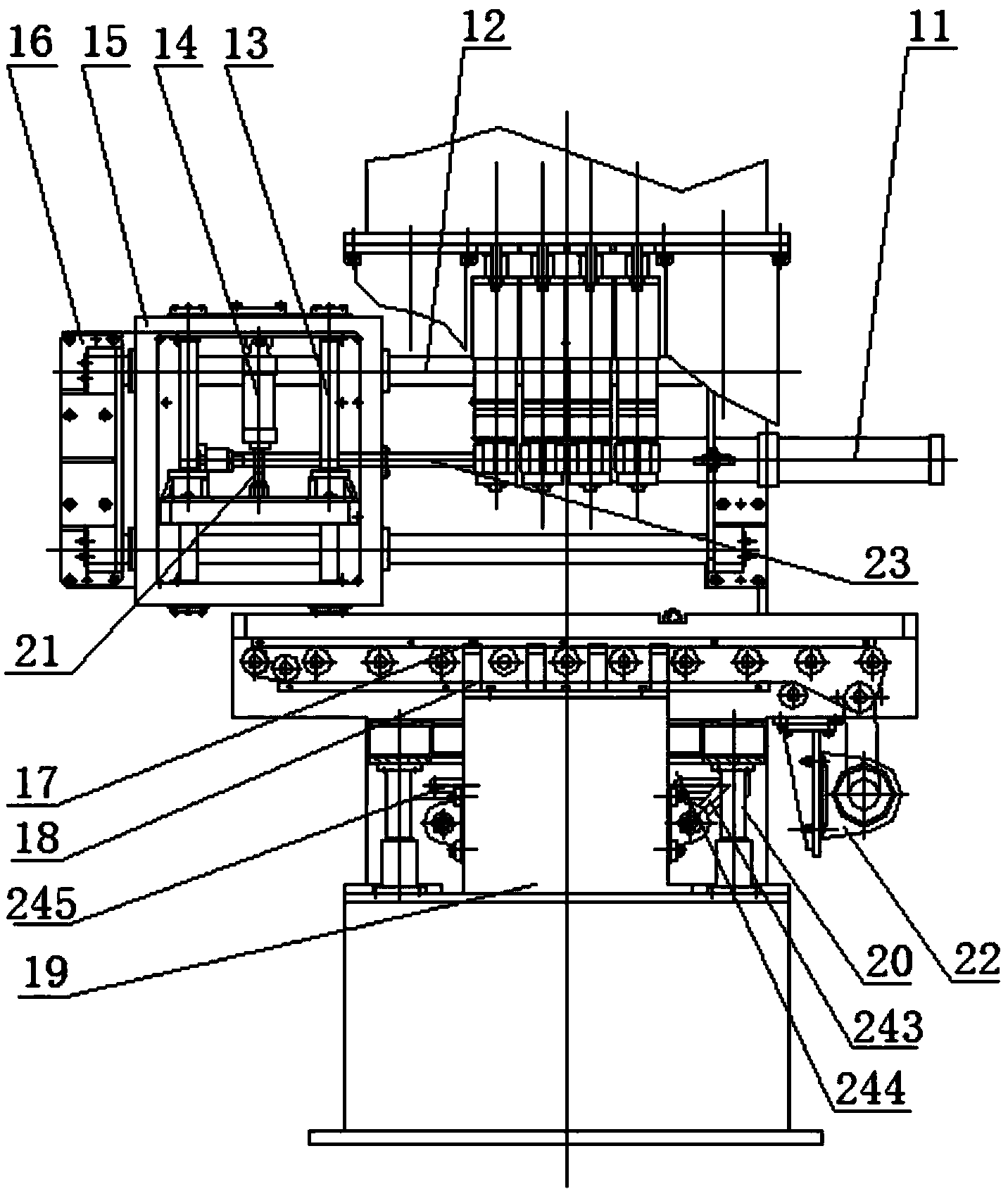

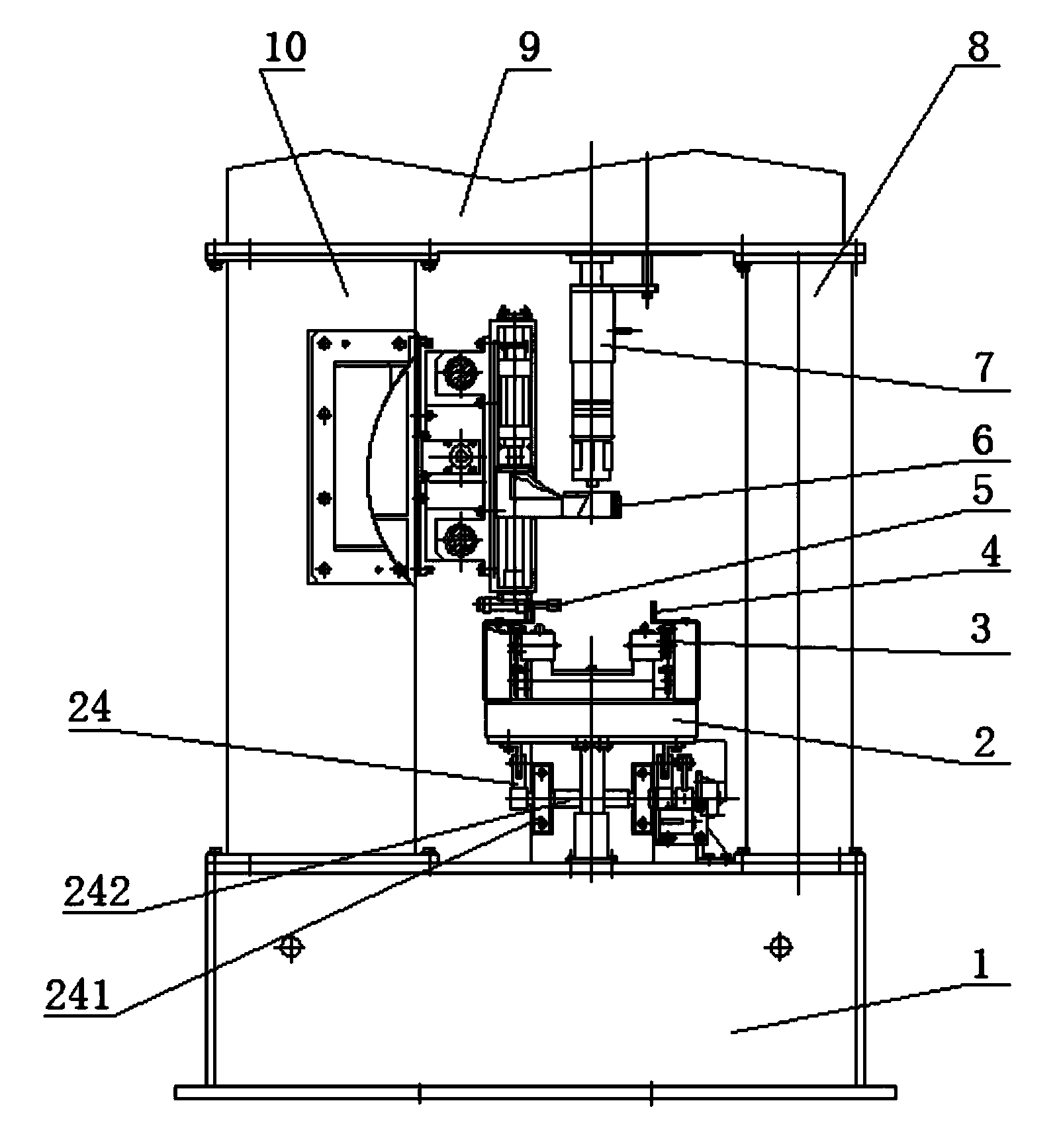

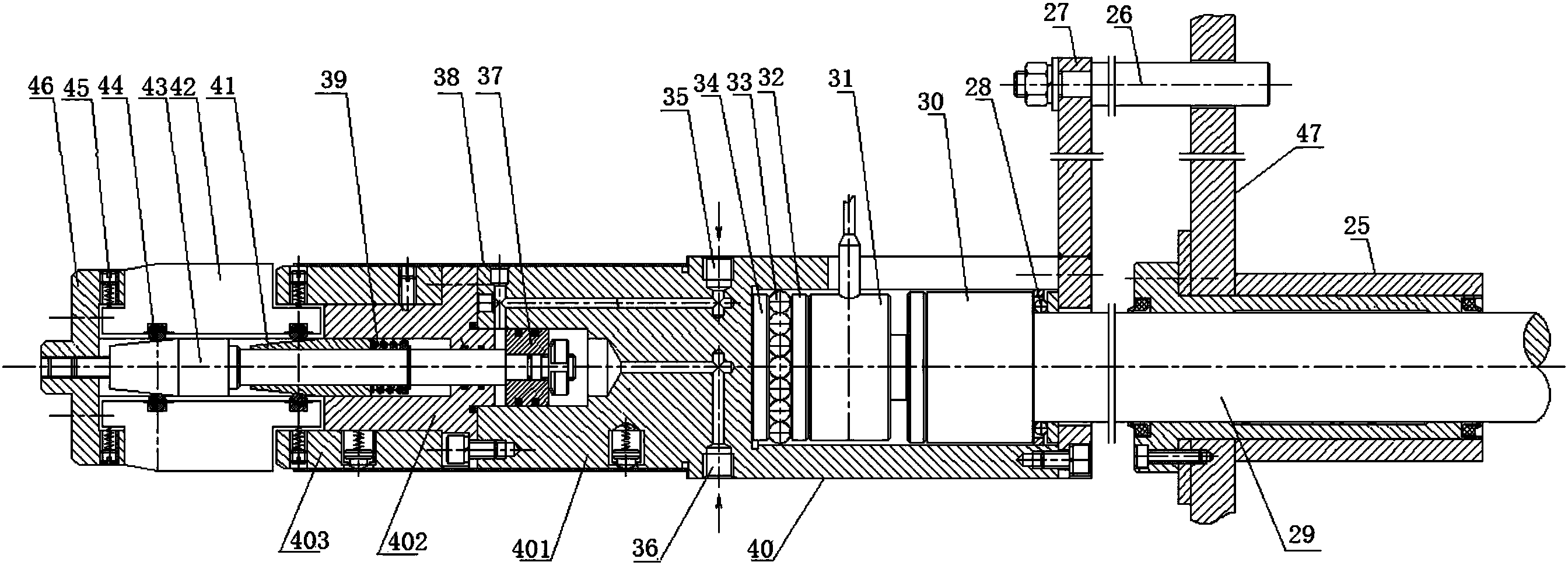

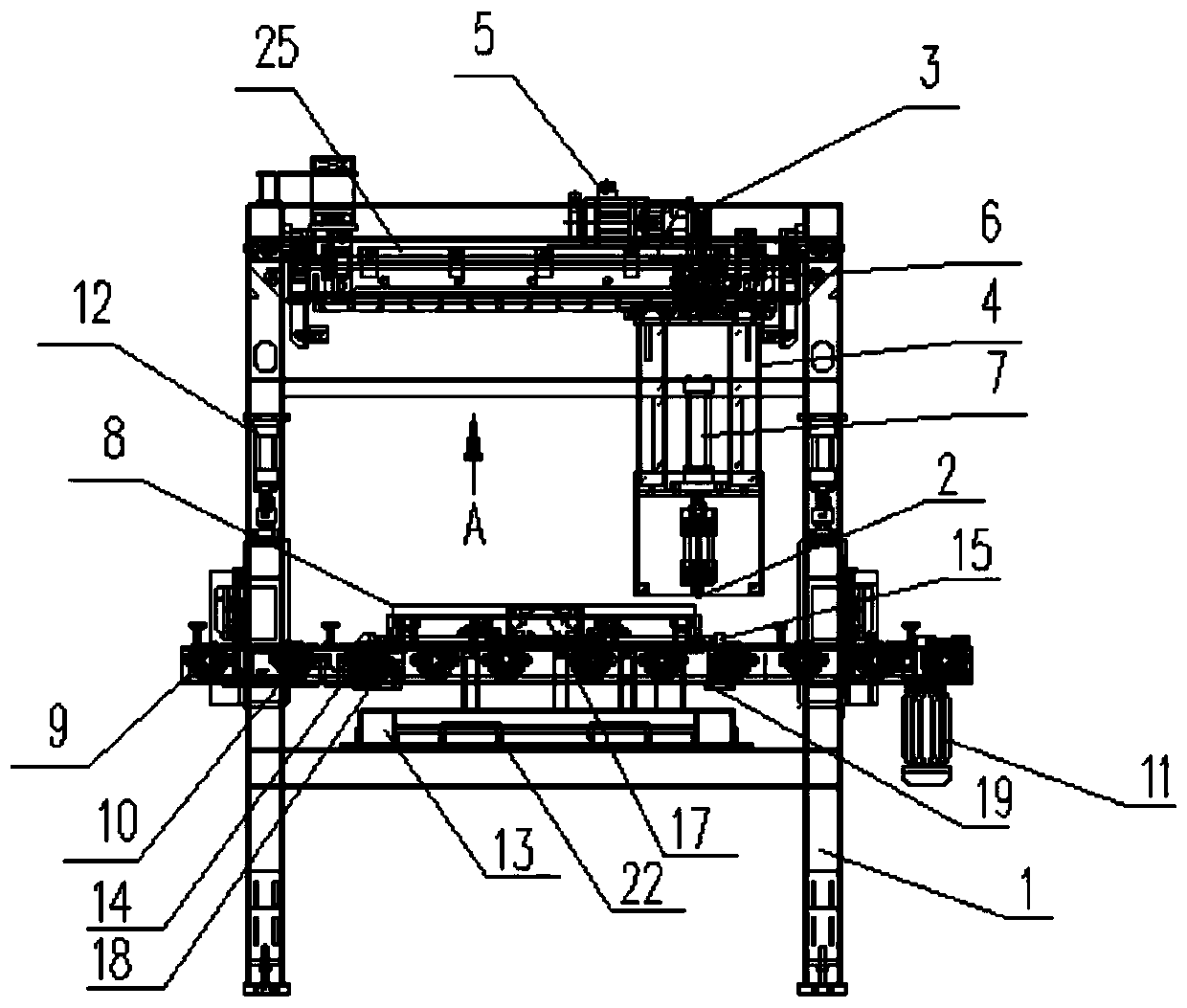

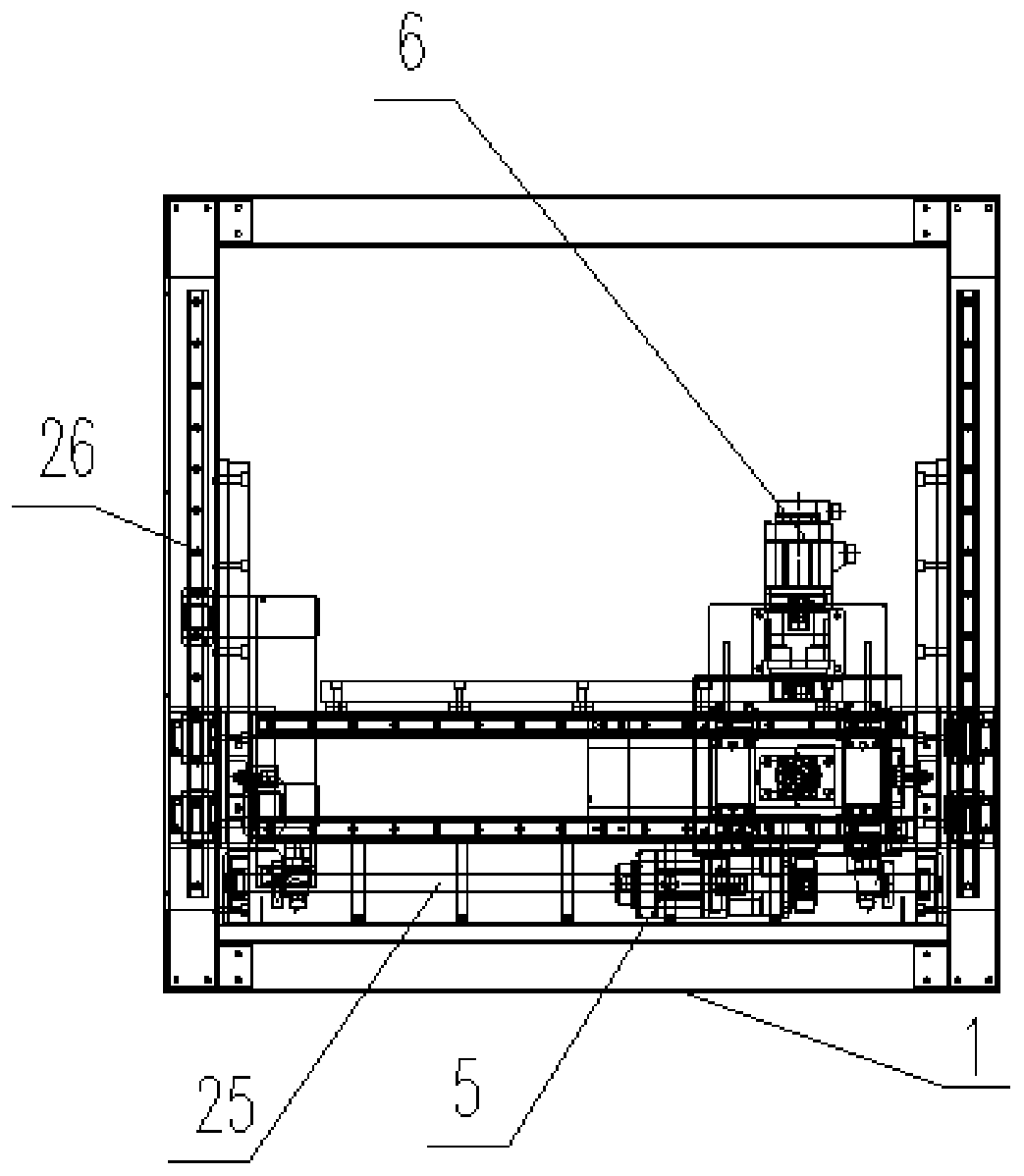

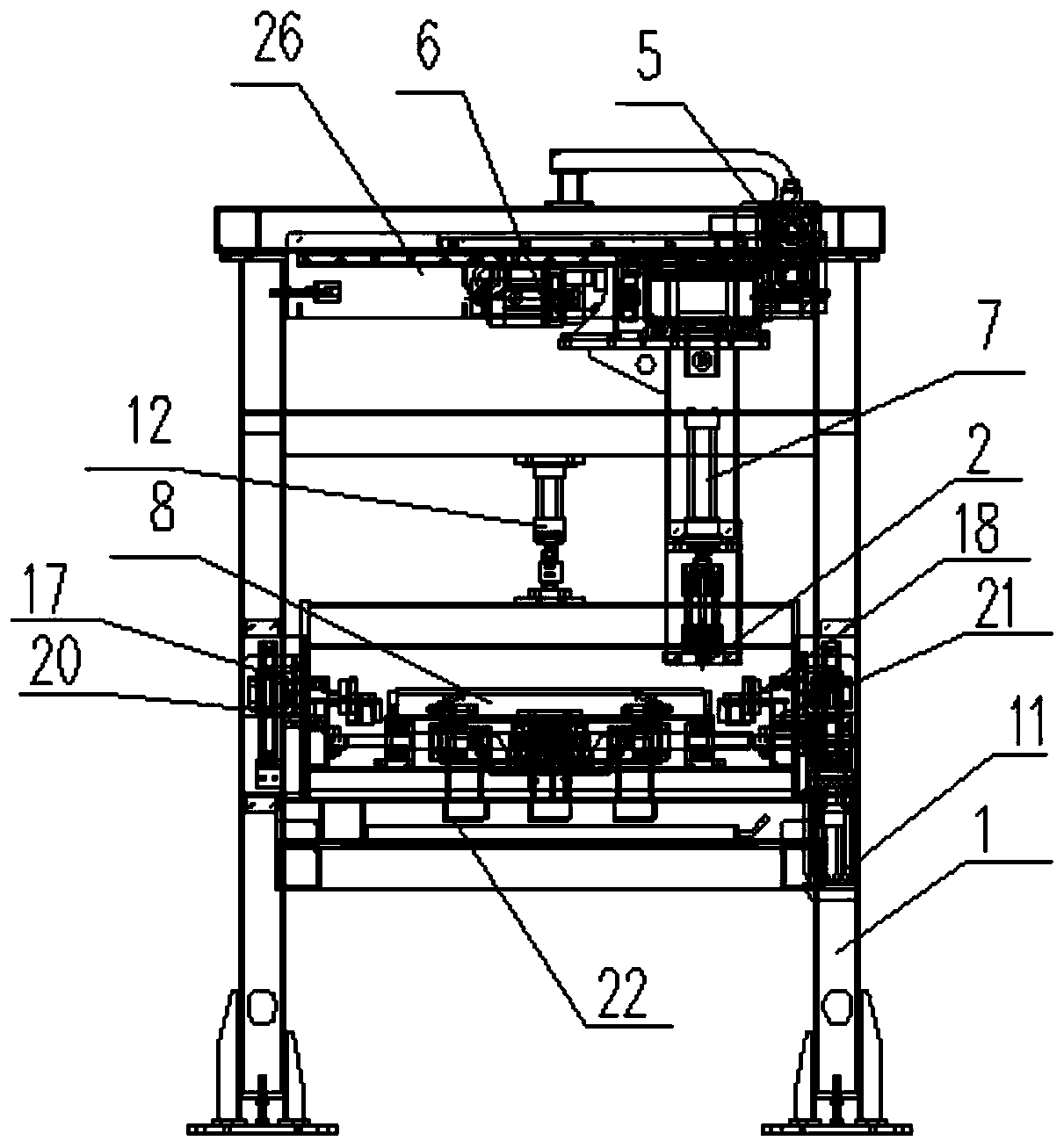

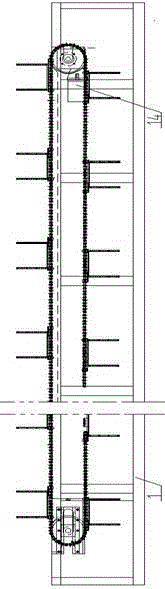

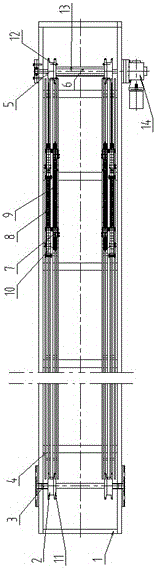

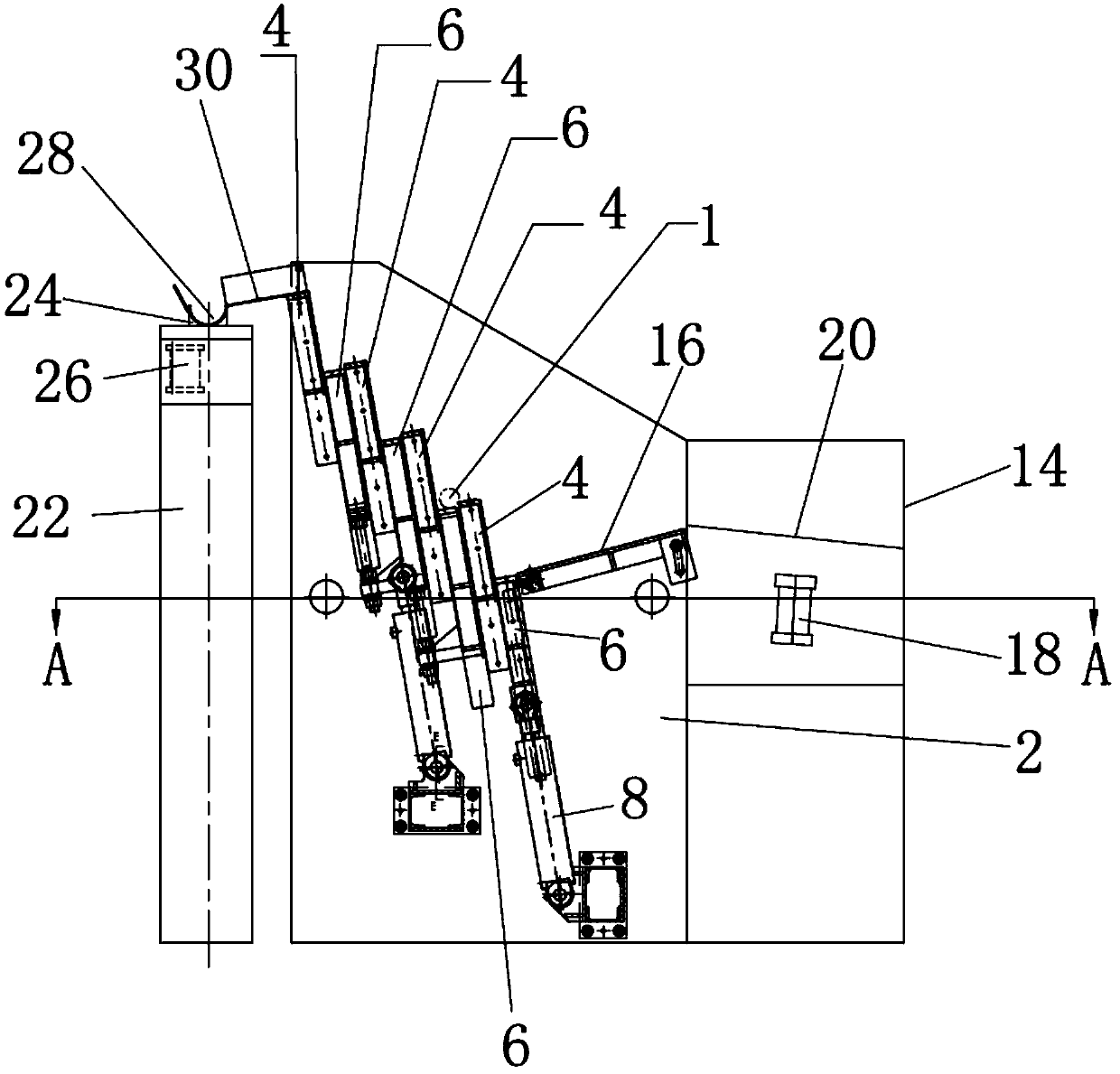

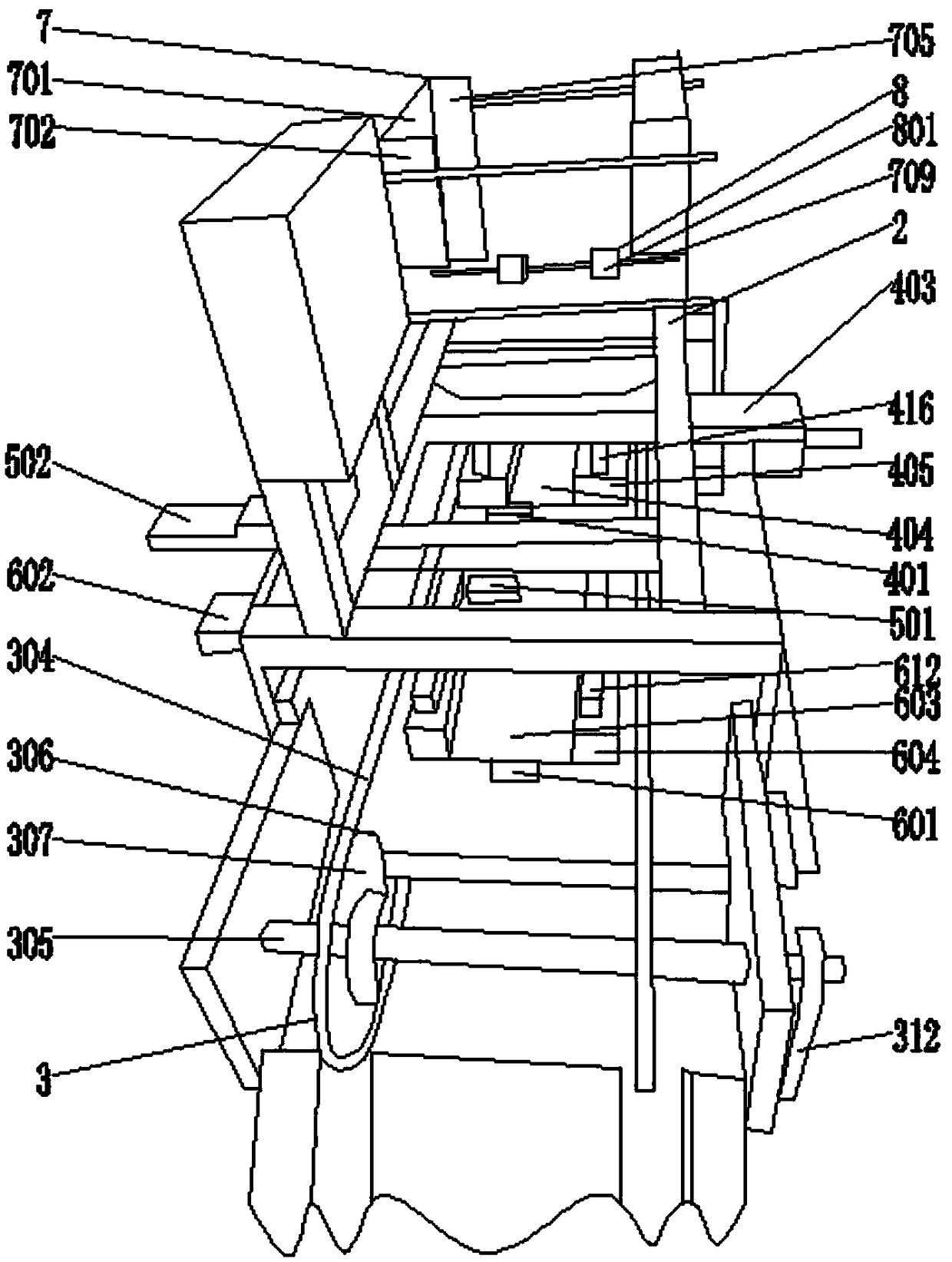

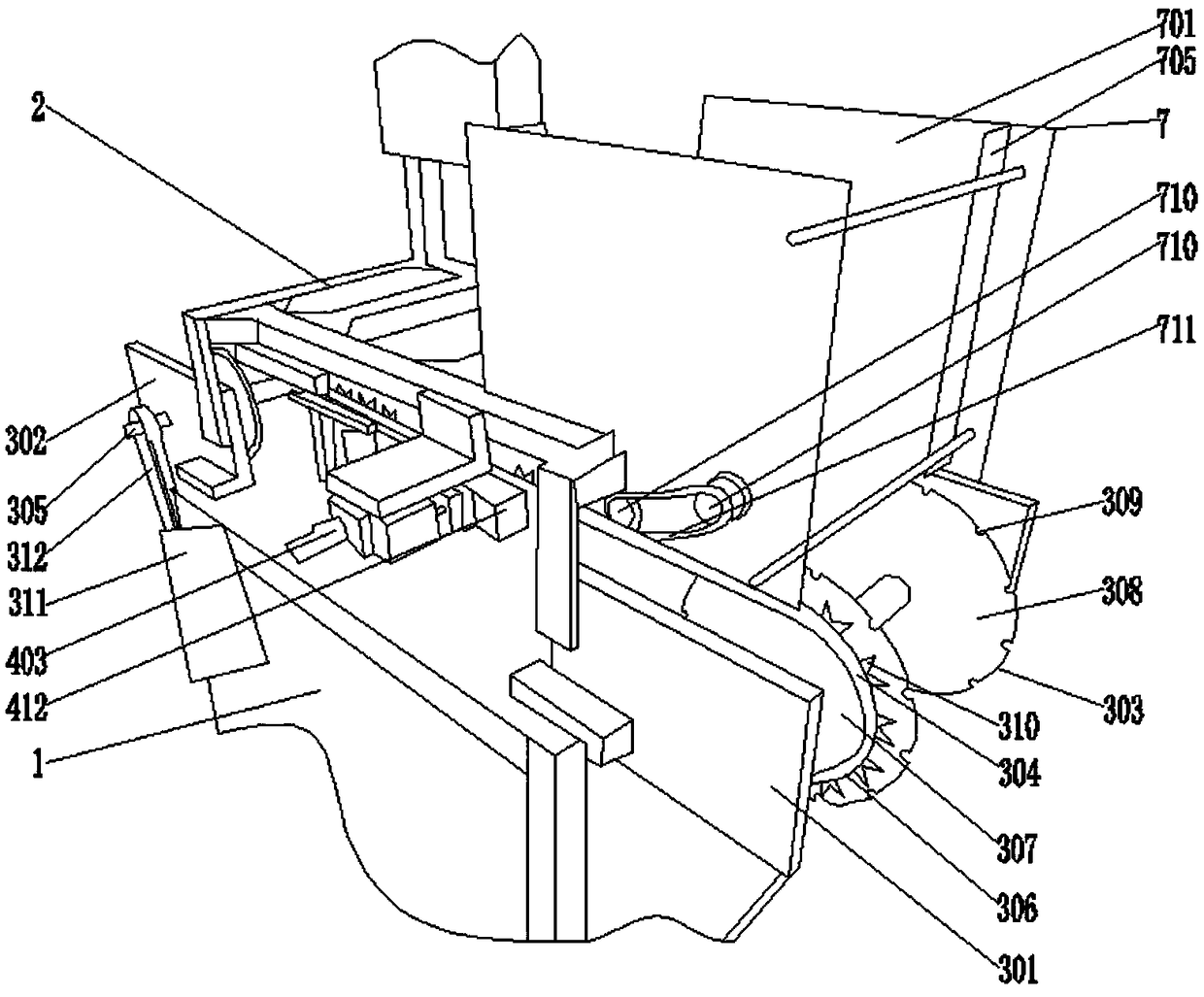

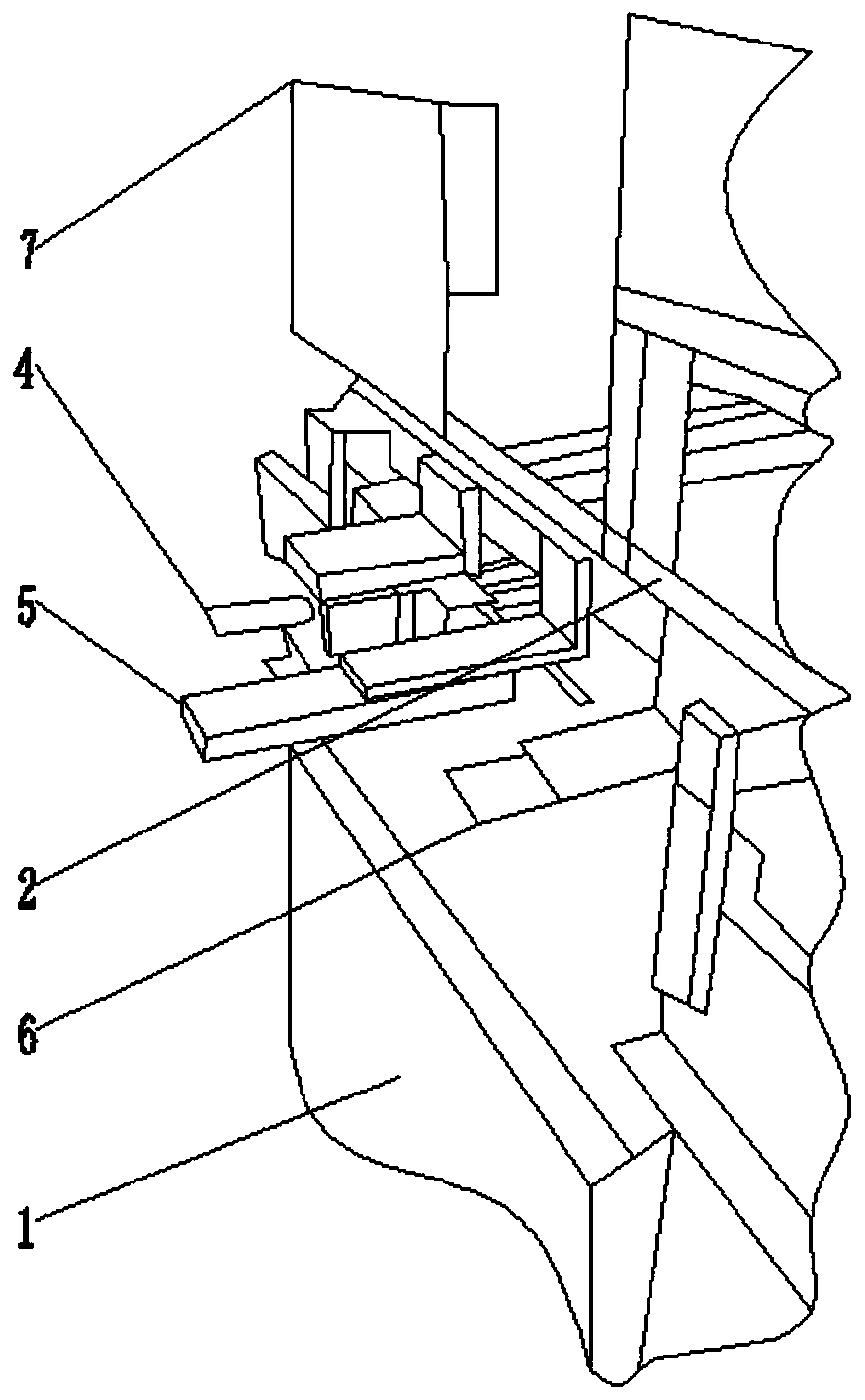

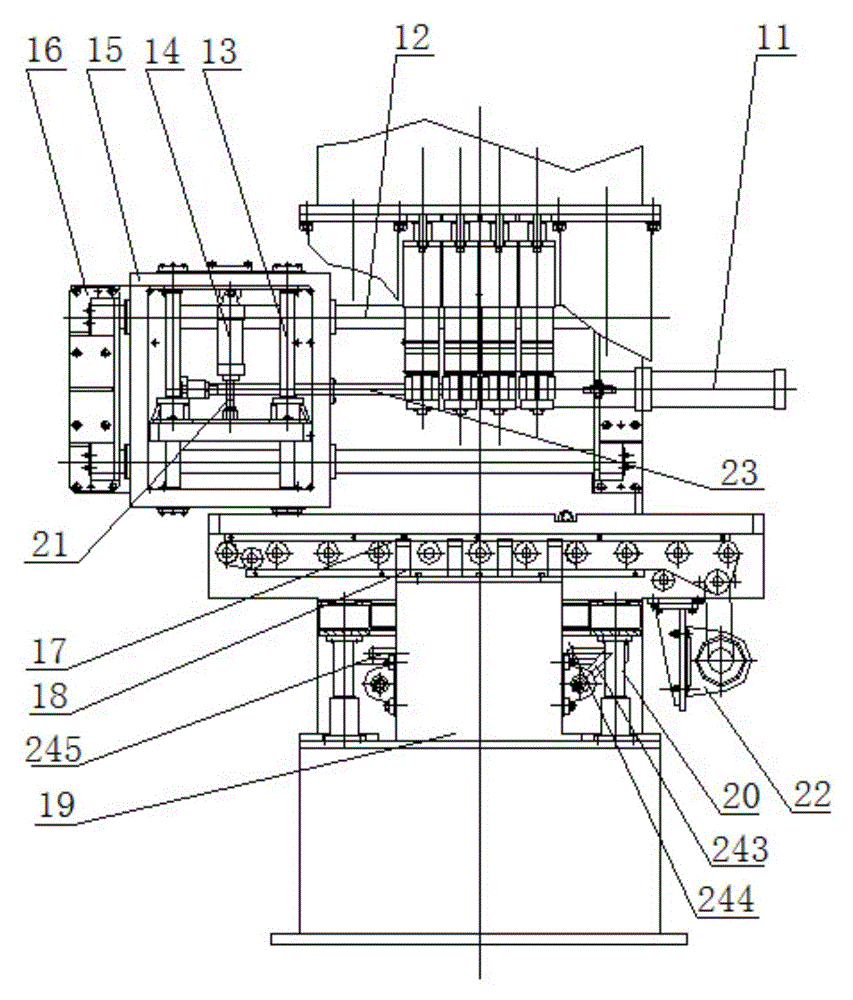

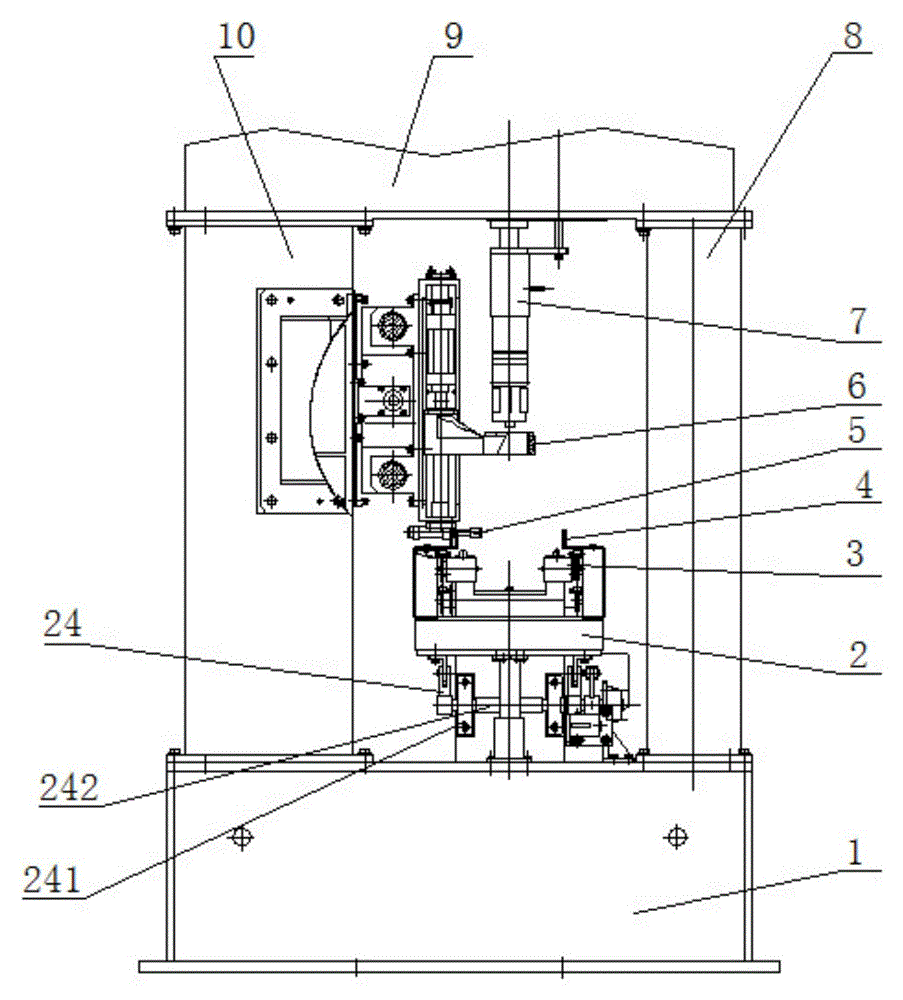

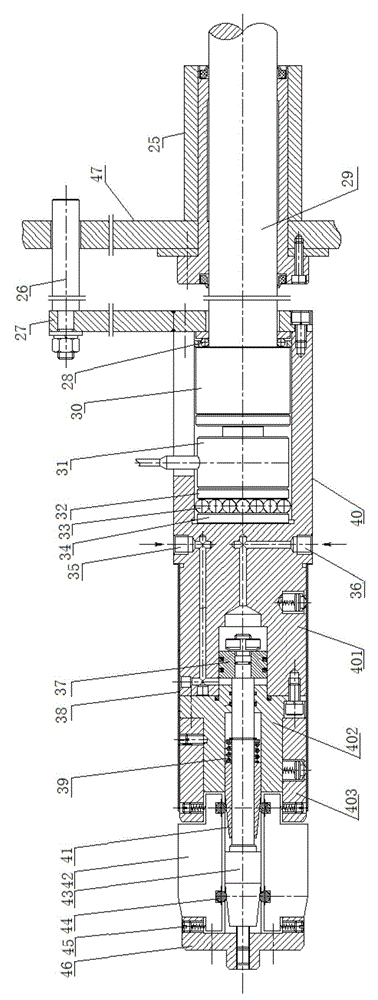

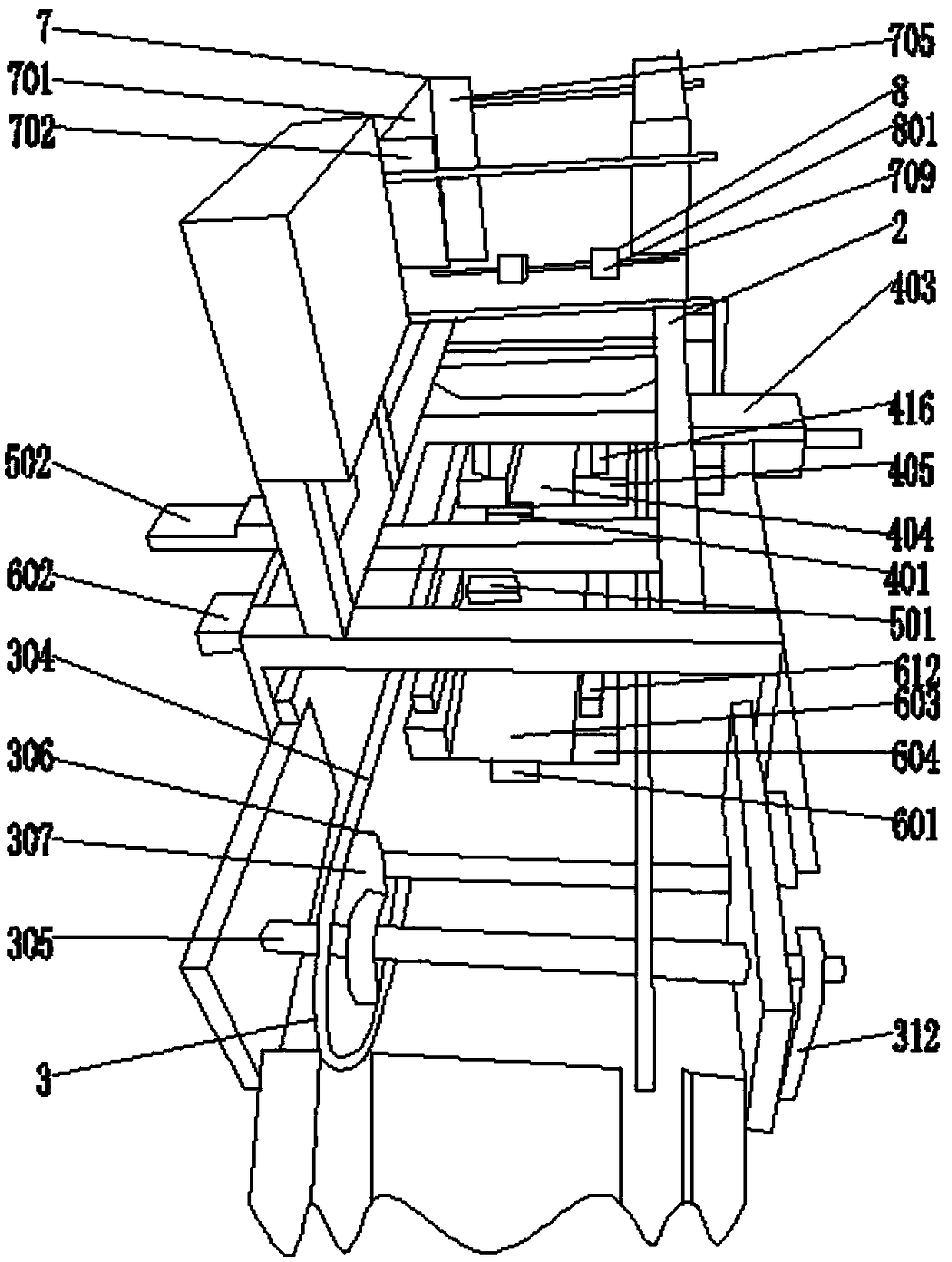

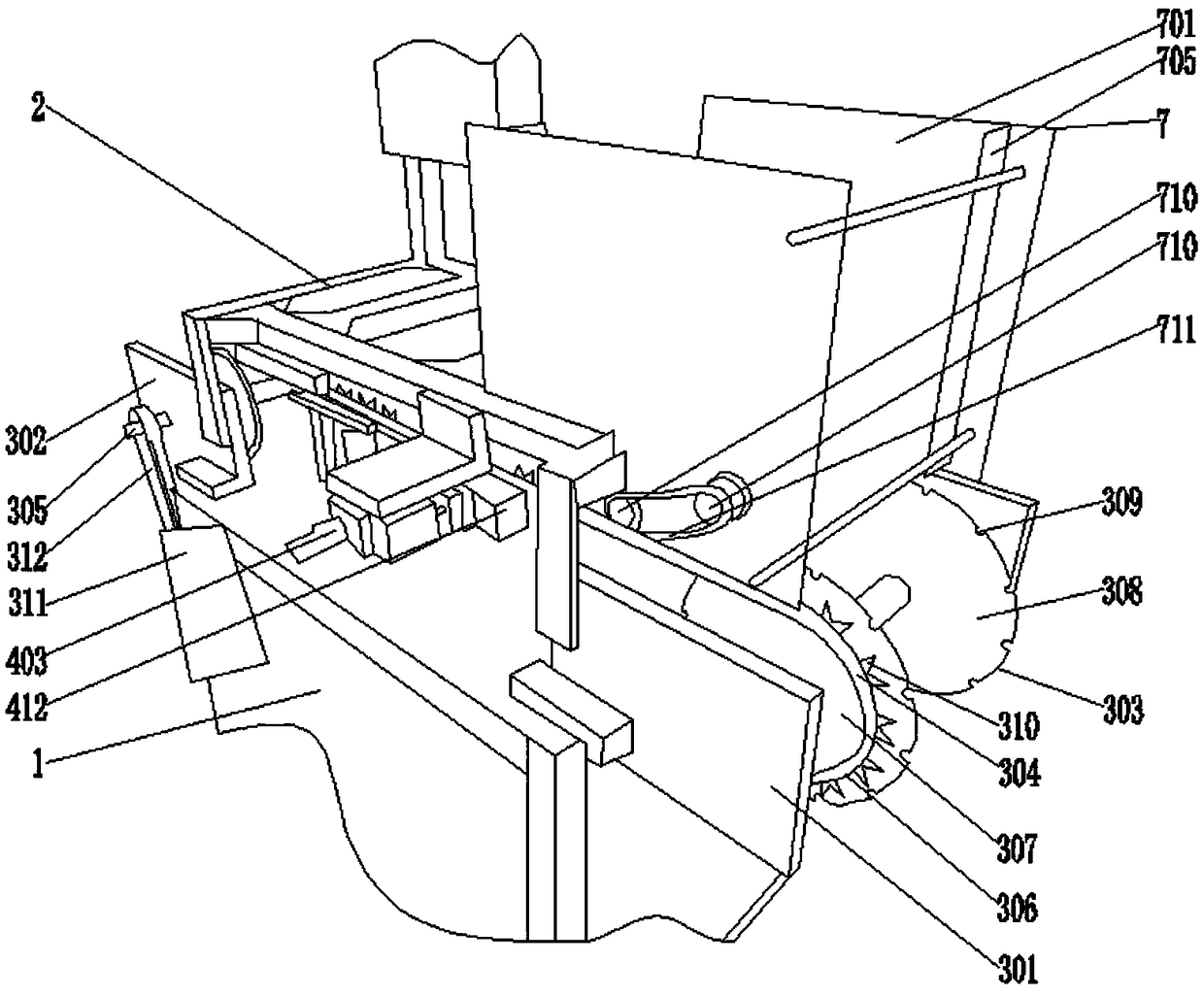

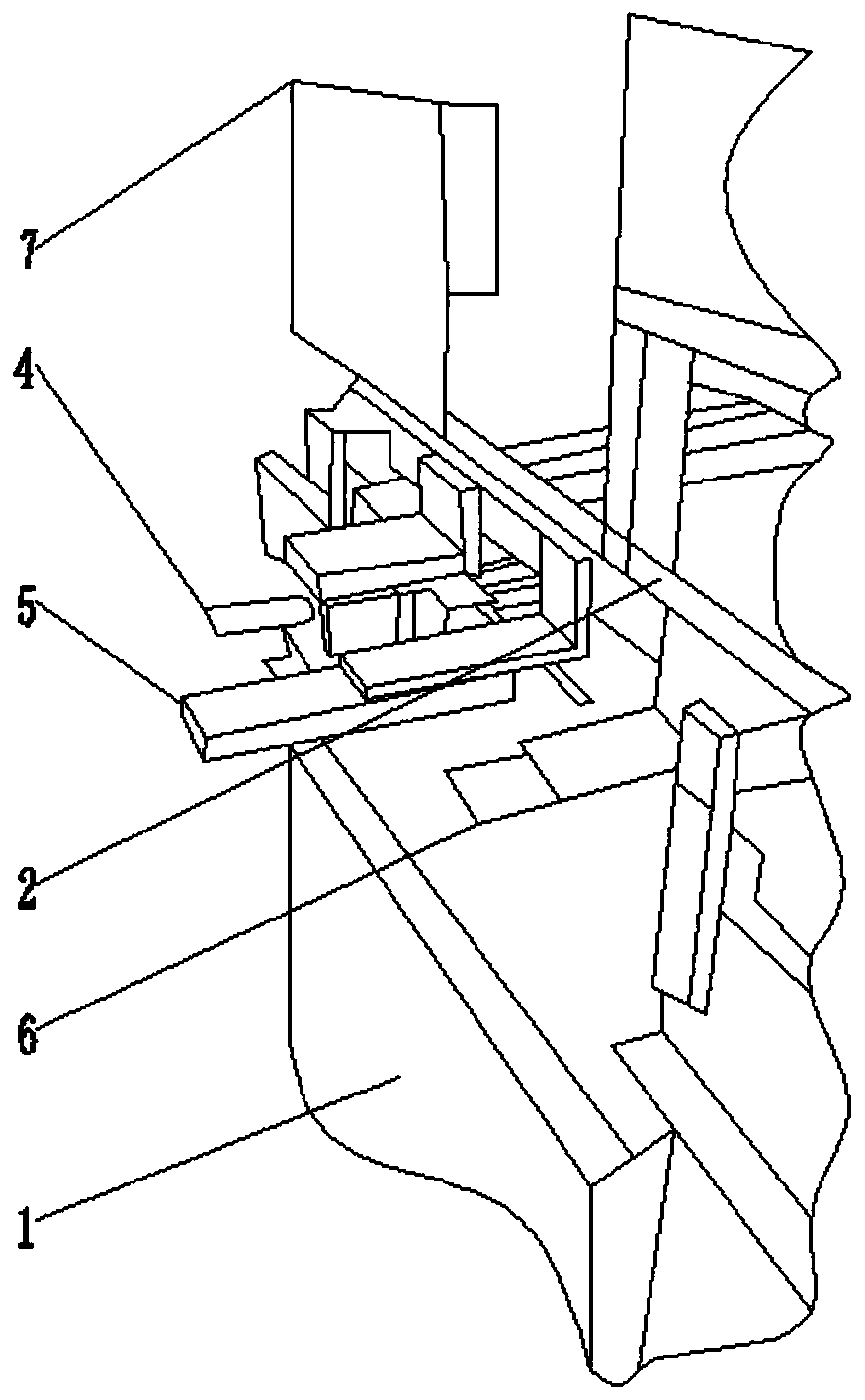

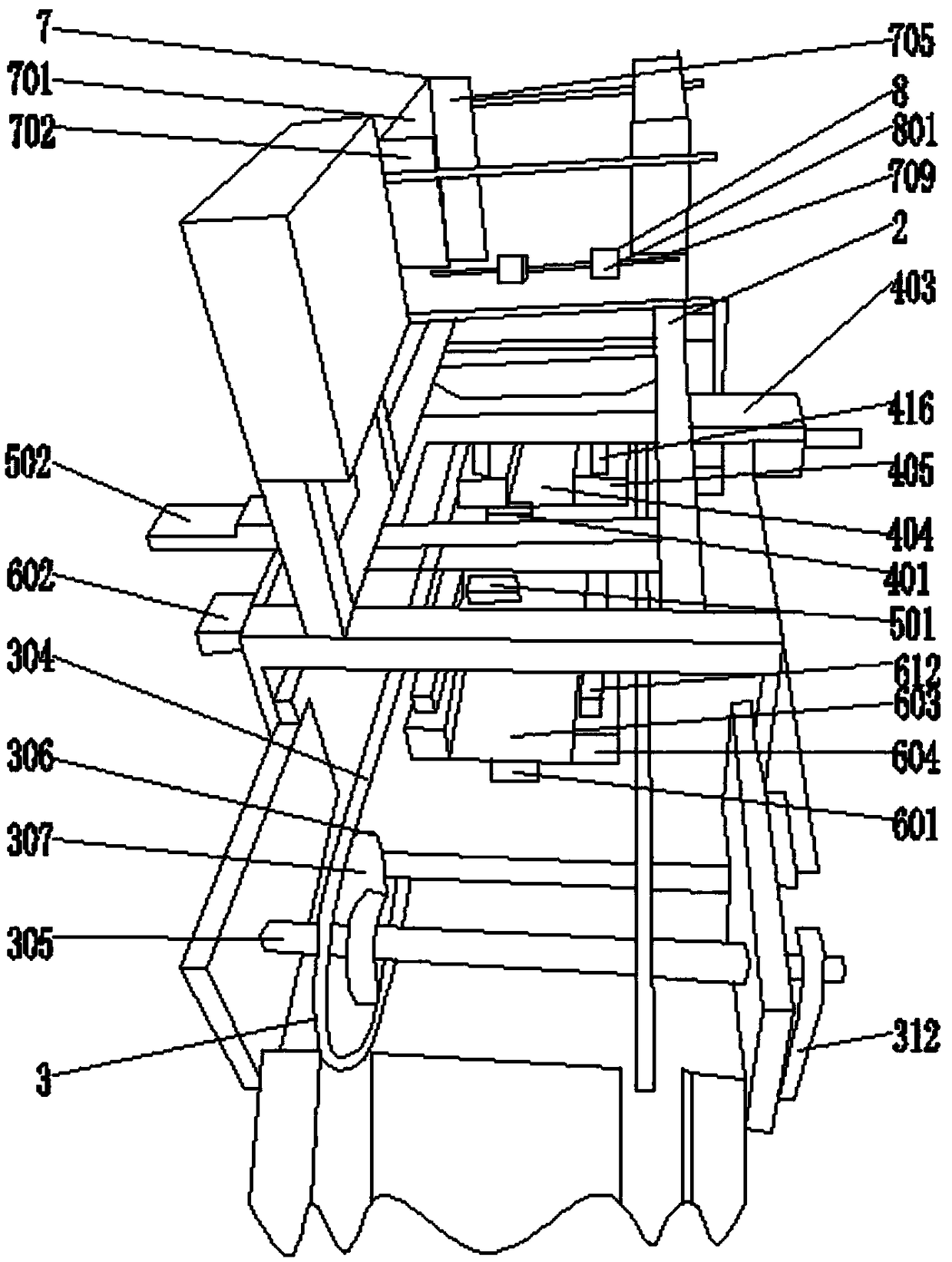

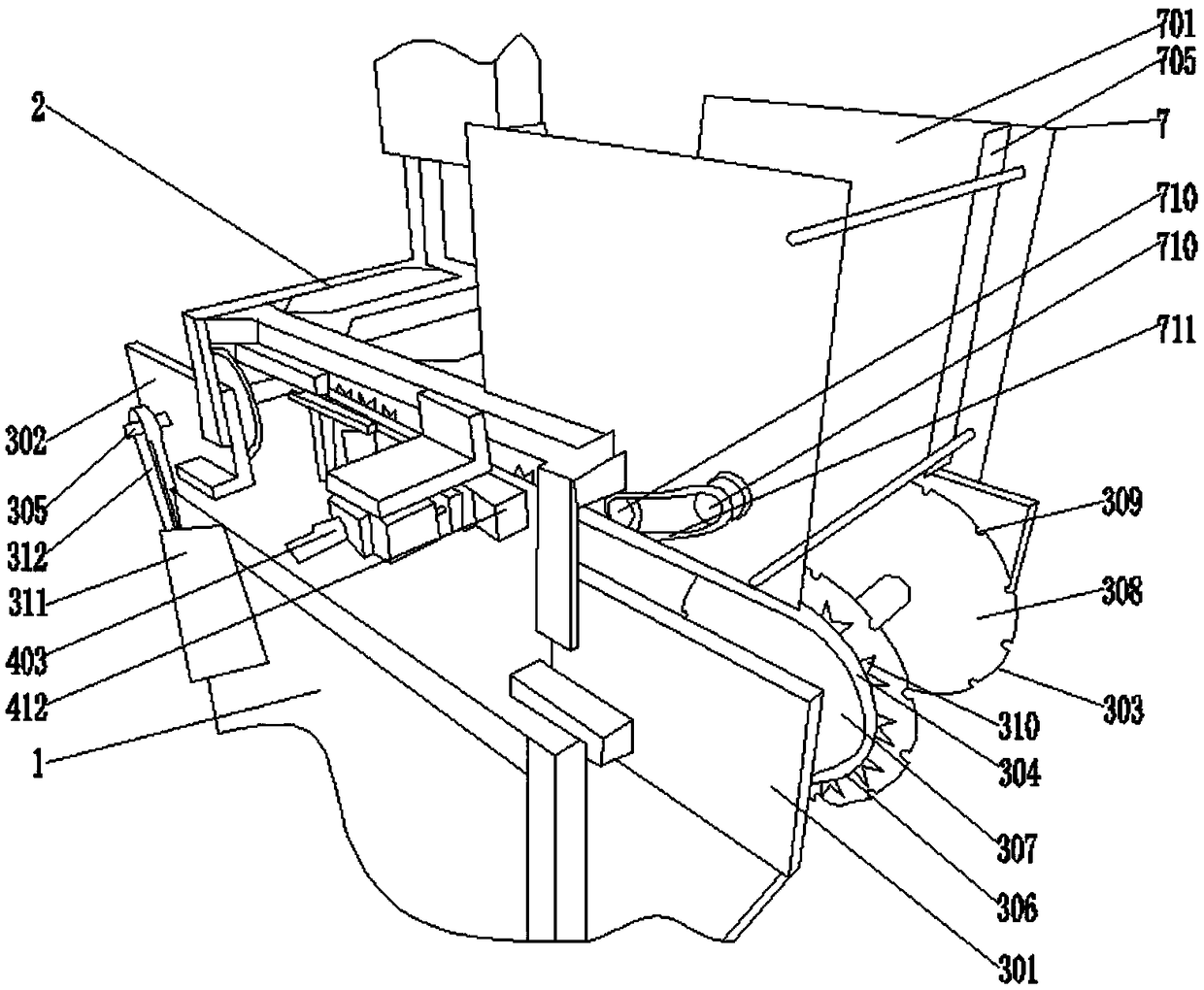

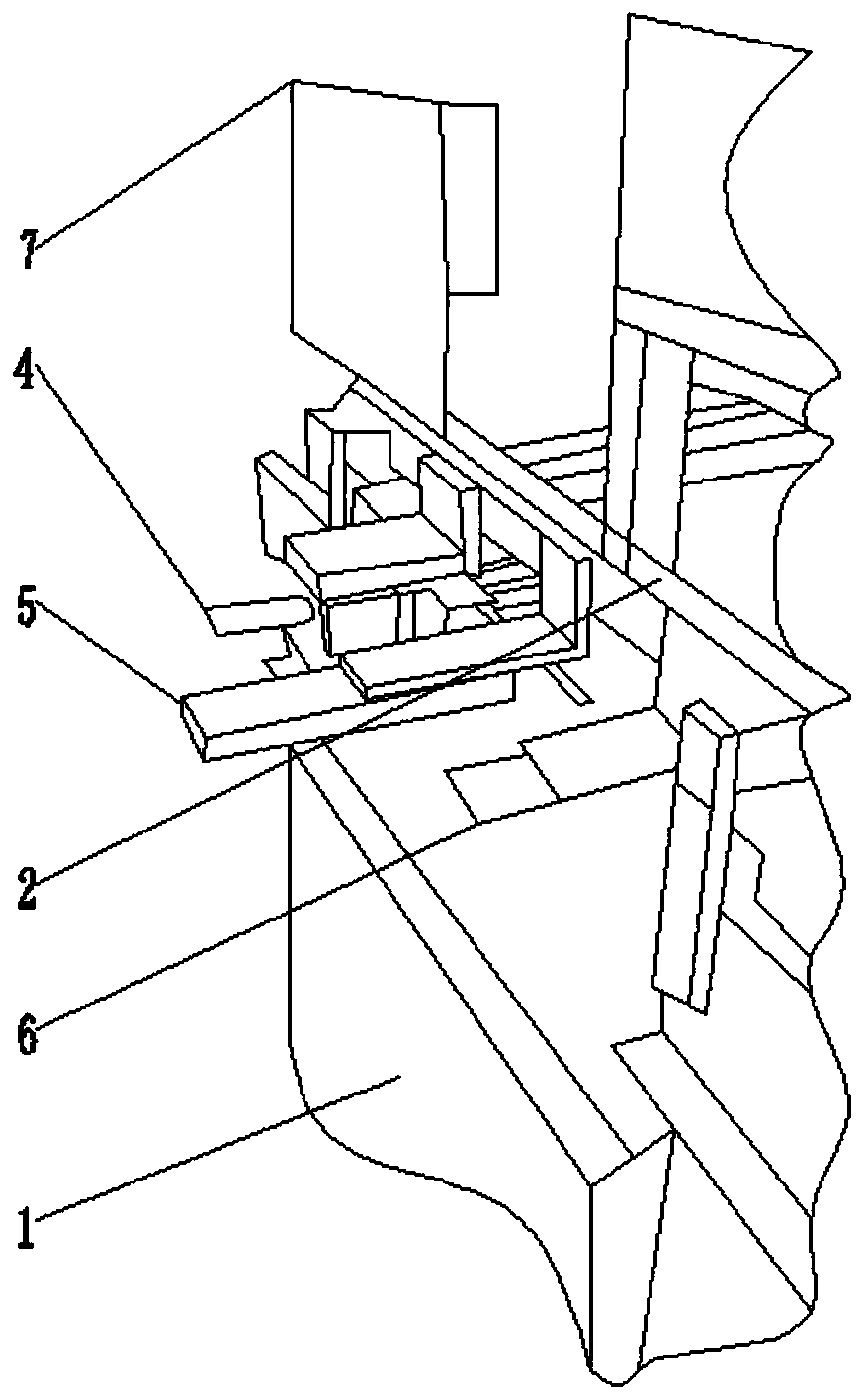

Engine cylinder liner press

ActiveCN103481053ARealize fully automatic feedingRealize high-precision automatic positioningMetal working apparatusCarrying capacityCylinder block

The invention discloses an engine cylinder liner press and belongs to the field of machinery. The engine cylinder liner press comprises a base, a top seat, a rear pillar, a front pillar, a cylinder liner feeding mechanism, a cylinder feeding mechanism, a cylinder liner head pressing device and a positioning and carrying device. The front of the base is connected with the front of the top seat through the front pillar. The rear portion of the base is connected with the rear portion of the top seat through the rear pillar, the cylinder liner head pressing device is arranged below the top seat and fixedly connected with the same. The cylinder liner feeding mechanism is mounted on the inner side of the rear pillar. The feeding portion of a cylinder liner feeder in the cylinder liner feeding mechanism is arranged right below the cylinder liner head pressing device. The cylinder feeding mechanism and the positioning and carrying device are arranged on the base. Full-automatic feeding of cylinder liners and cylinders is realized, and high-precision automatic positioning and high carrying capacity of the cylinders can be achieved.

Owner:金湖县项目服务中心

Paper tube conveying device

PendingCN110540026ARealize fully automatic conveyingImprove drying efficiencyMetal working apparatusConveyor partsPulp and paper industryUltimate tensile strength

The invention relates to the technical field of conveying equipment, in particular to a paper tube conveying device. The paper tube conveying device comprises a first conveying device, a lifting mechanism, a conveying mechanism, and a third conveying device; the conveying mechanism comprises a second conveying device, a first guiding member, a placing device and a pushing device; the lifting mechanism comprises a storage member, a lifting device and a second guiding member. A paper tube is conveyed by the first conveying device, cut by an external cutting device, guided to the second conveyingdevice by the first guiding member, and pushed to the placing device by the pushing device; and the paper tube is stored by the storage member which is driven by the lifting device to ascend to the second floor of a factory, and then the paper tube is guided to the third conveying device by the second guiding member, and is conveyed to an external dryer by the third conveying device. The paper tube conveying device reduces the labor intensity of workers and improves the drying efficiency of the paper tube.

Owner:杭州亚佳宝轻纺科技有限公司

Automatic PIN disassembly machine

PendingCN109874238AWon't hurtRealize automatic disassemblyMultilayer circuit manufactureControl systemEngineering

The invention discloses an automatic PIN disassembly machine, comprising a rack, a lifting pin, an X direction sliding block, a Y direction sliding block, a plate position calibration device, a code scanner, an X direction drive device, a Y direction drive device, a vertical drive device and a control system. The X direction sliding block can be positioned on the rack in a sliding mode along an Xdirection. The Y direction sliding block can be positioned on the X direction sliding block in the sliding mode along a Y direction. The lifting pin can be mounted on the Y direction sliding block inthe sliding mode along a vertical direction. The plate position calibration device on the rack can correct a position of a to-be-disassembled PIN plate in the rack. The code scanner can read information in a bar code on the to-be-disassembled PIN plate. The code scanner communicates with the control system. The control system drives the X direction sliding block, the Y direction sliding block andthe lifting pin to move through control over the X direction drive device, the Y direction drive device and the vertical drive device. The automatic PIN disassembly machine is simple in structure andhigh in disassembly efficiency. Full automatic disassembly of PINs on the plate can be realized. The plate is not damaged.

Owner:KUNSHAN JUHONG MACHINERY TECH

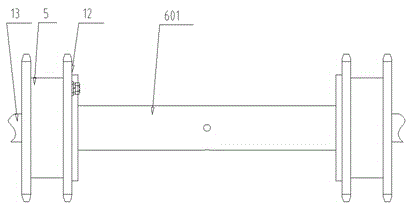

Bundled glass tube conveyer

InactiveCN105383864AReduce labor intensityReduce secondary pollutionConveyorsControl devices for conveyorsEngineeringGlass tube

The invention provides a bundled glass tube conveyer which can transport glass tubes to different procedures to be packaged. The bundled glass tube conveyer comprises a rack, a driving unit, a driving shaft, a driven shaft, a fixed conveying unit, an adjustment conveying unit, a plurality of bundled glass tube movable brackets, a plurality of bundled glass tube fixed brackets, and a glass tube bracket interval adjustment device, wherein the driving shaft is connected with the driving unit; the fixed conveying unit comprises a fixed driving wheel, a fixed driven wheel and a fixed connecting piece; the adjustment conveying unit comprises an adjustment driving wheel, an adjustment driven wheel and an adjustment connecting piece; the bundled glass tube movable brackets are mounted on the fixed connecting piece; the fixed driving wheel and the adjustment driving wheel are mounted on the driving shaft; the fixed driving wheel is positioned on the outer side of the adjustment driving wheel; the fixed driven wheel and the adjustment driven wheel are mounted on the driven shaft; and the fixed driven wheel is positioned on the outer side of the adjustment driven wheel.

Owner:SHANDONG LINUO TECHNICAL GLASS CO LTD

Double-outlet large-package full-servo belt feeding type packaging system

PendingCN113086319ARealize fully automatic conveyingReduce manpower outputWrapper twisting/gatheringControl theoryMechanical engineering

The invention provides a double-outlet large-package full-servo belt feeding type packaging system. The double-outlet large-package full-servo belt feeding type packaging system comprises a machine body base frame, a bag taking mechanism, a traction mechanism, a bag opening mechanism, a bag extruding mechanism, a discharging mechanism, an upper sealing and pressing mechanism and a shaping mechanism. The bag taking mechanism and the shaping mechanism are respectively fixedly arranged at two ends of the machine body base frame, the traction mechanism, the bag opening mechanism, the bag extruding mechanism, the discharging mechanism and the upper sealing and pressing mechanism are sequentially arranged between the bag taking mechanism and the shaping mechanism, and the traction mechanism is arranged close to the bag taking mechanism. The bag taking mechanism, the traction mechanism, the bag opening mechanism, the bag extruding mechanism, the discharging mechanism, the upper sealing and pressing mechanism and the shaping mechanism are all located at the same horizontal height and all installed on the machine body base frame, and the double-outlet large-package full-servo belt feeding type packaging system has the effects that the cost of the whole packaging process is saved, and time and labor are saved.

Owner:上海如天包装设备有限公司

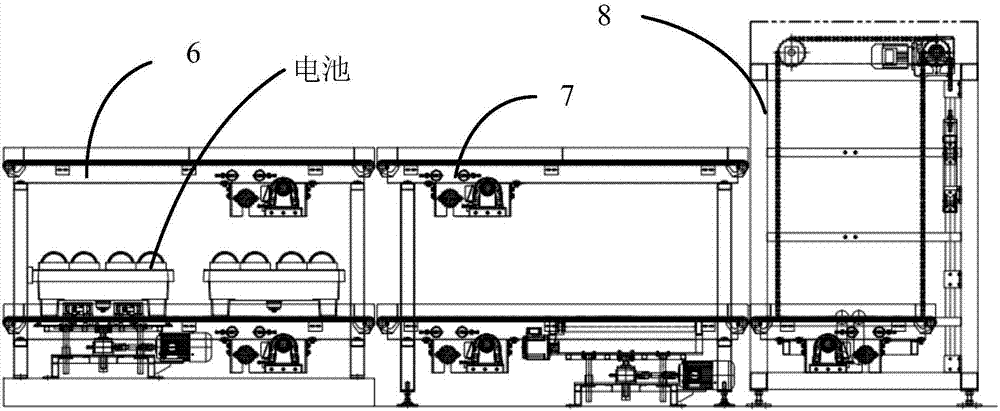

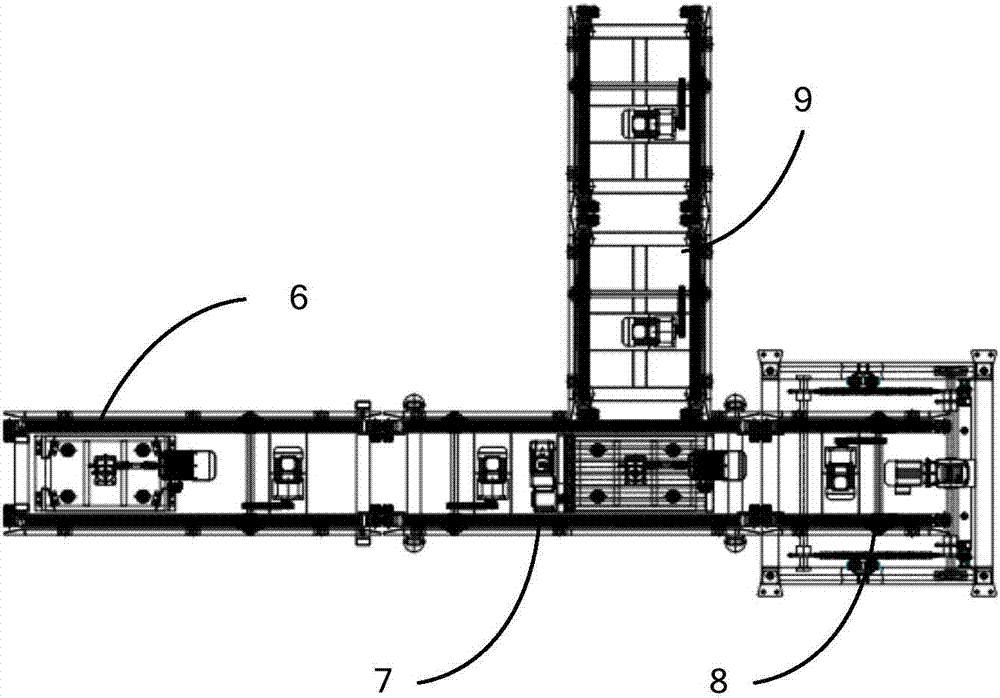

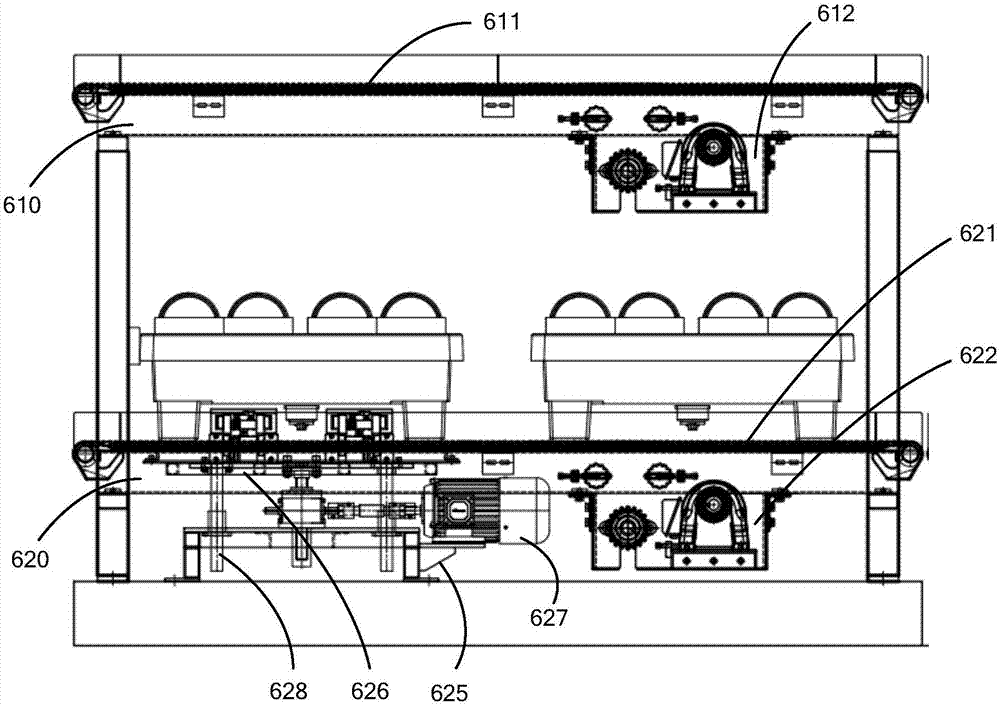

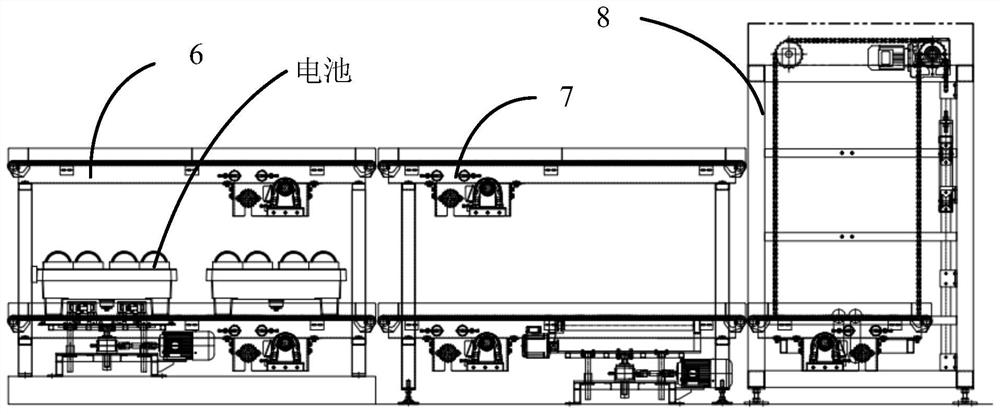

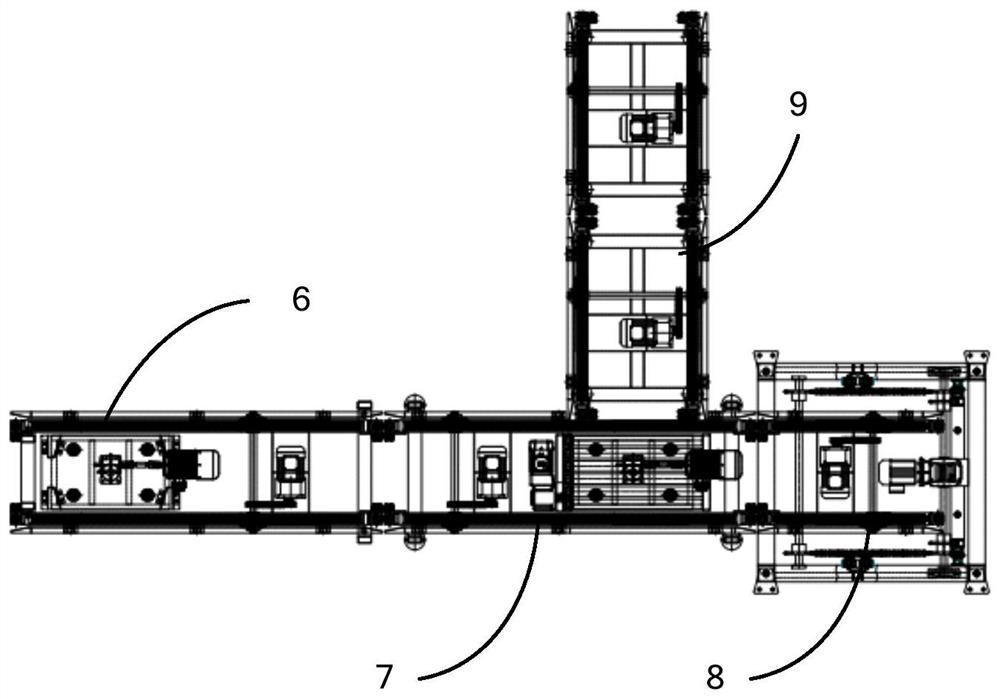

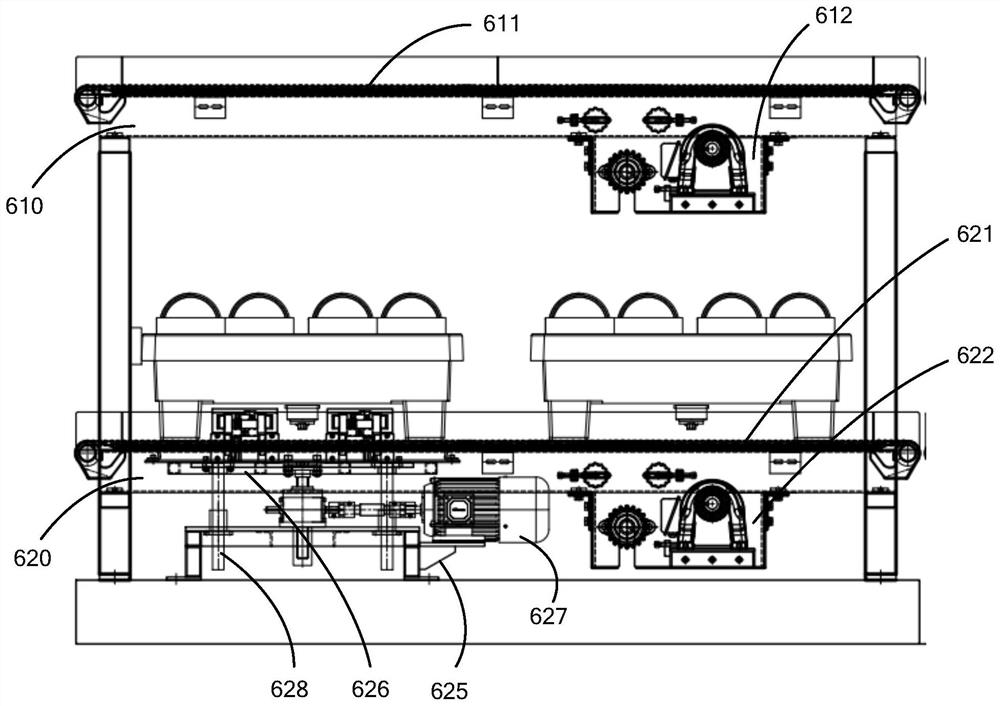

Battery delivery system for charging and battery swapping station

ActiveCN108001922ARealize fully automatic conveyingReduce transshipment costsStorage devicesConveyor partsElectrical batteryElectricity

The invention belongs to the technical field of battery swapping for electric cars and particularly relates to a battery delivery system for a charging and battery swapping station. The battery delivery system comprises a double-layer transporting chain machine, a double-layer transferring chain machine and a lifting chain machine which are arranged sequentially; and a single-layer chain machine is arranged on the side surface of the double-layer transferring chain machine. According to the system, full-automatic delivery of batteries between cars to be subjected to battery swapping and a charging frame can be realized through cooperation of the double-layer transporting chain machine, the double-layer transferring chain machine and the lifting chain machine, the battery transporting delivery cost is reduced, and the battery transporting delivery efficiency is improved.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

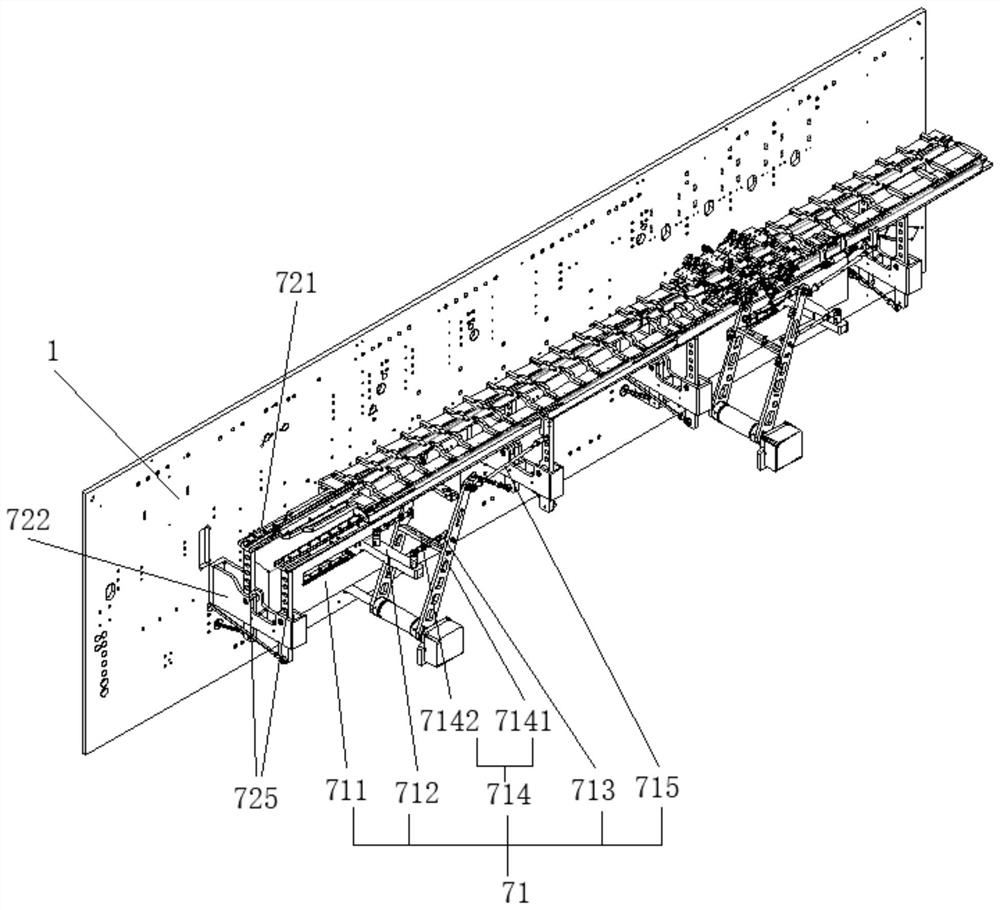

Bar material conveying system

PendingCN108016896ARealize fully automatic conveyingImprove feeding efficiencyConveyorsLoading/unloadingReciprocating motionAutomatic testing

The invention discloses a bar material conveying system which comprises a stock bin and a stepped lifting and feeding device arranged in the stock bin; the stepped lifting and feeding device comprisesfixed plates and movable plates; the movable plates back on the fixed plates, and are connected with a feeding driver; the feeding driver drives the movable plates to make reciprocating motion in thelength extension directions of the fixed plates; and the movable plates move to convey out bar materials located on the fixed plates in the stock bin. According to the bar material conveying system,the stepped lifting and feeding device adopts optimized structural design, the movable plates and the fixed plates are matched to realize automatic charging and automatic sorting, and the disorderly piled bar materials in the stock bin are conveyed to target positions one by one continuously and stably, so that full automatic conveying of the bar materials is realized, the feeding efficiency of the bar materials can be improved after the bar material conveying system is used, and the labor cost and the manual labor intensity are lowered.

Owner:江苏亨芯石英科技有限公司 +1

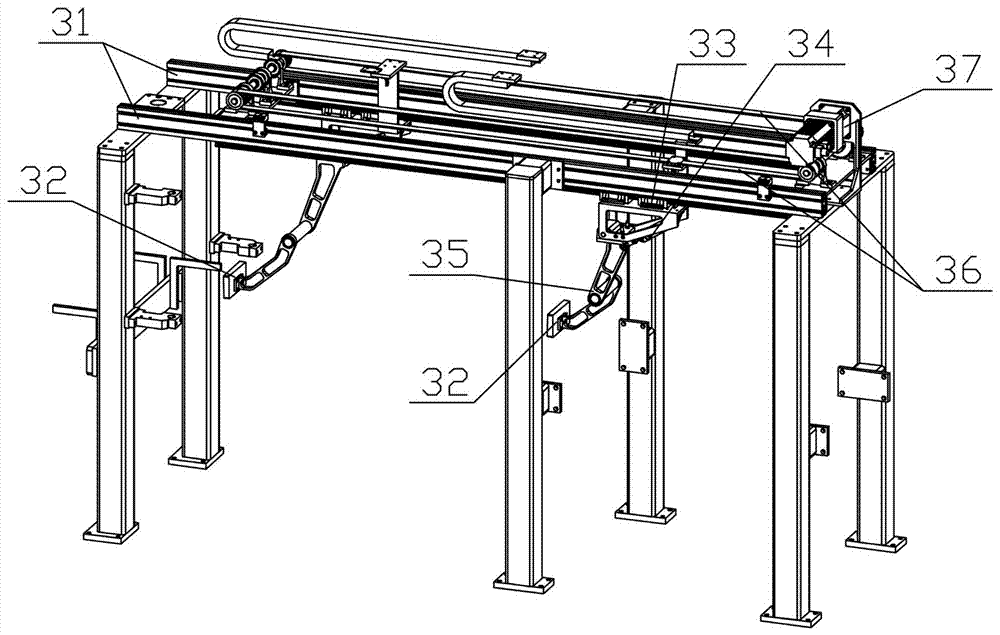

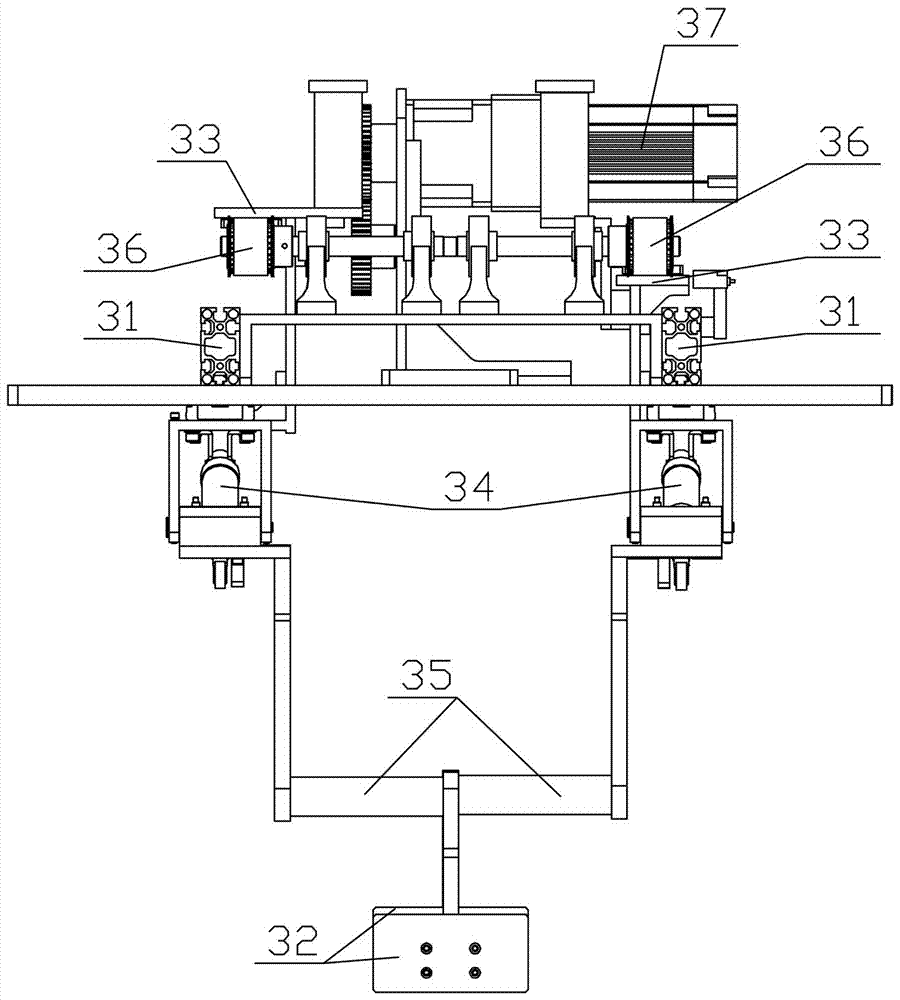

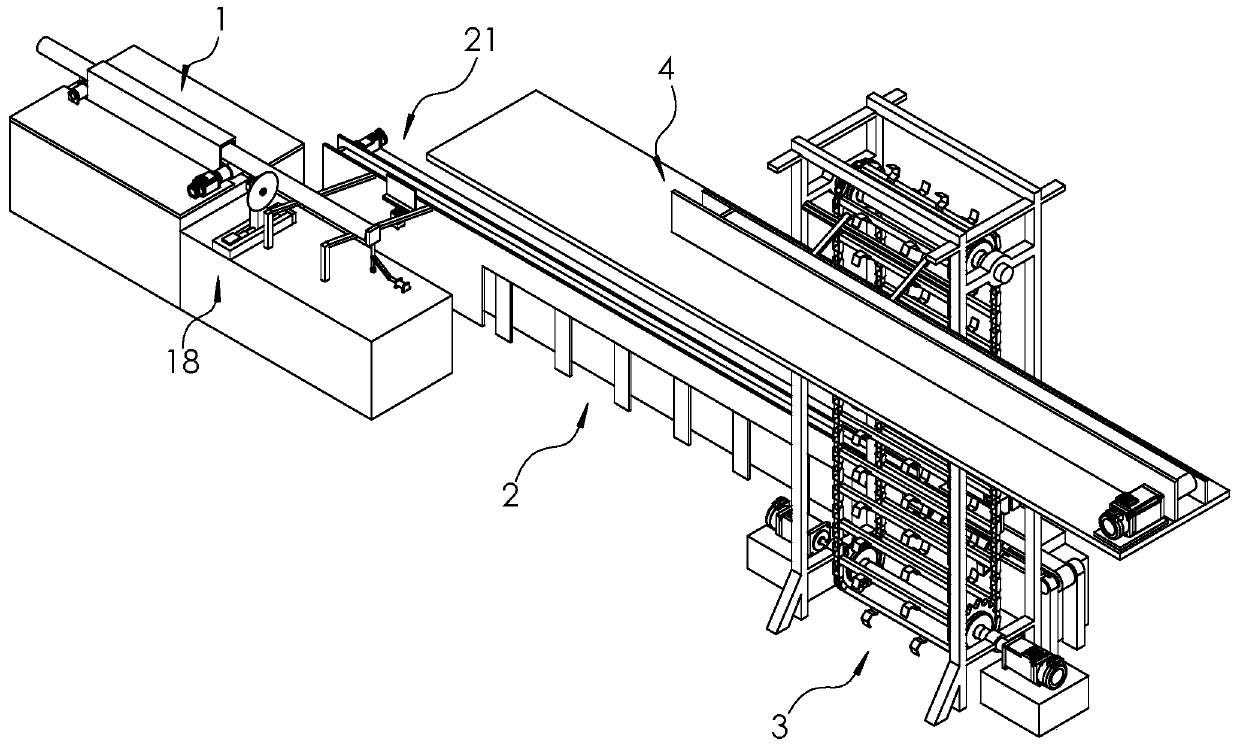

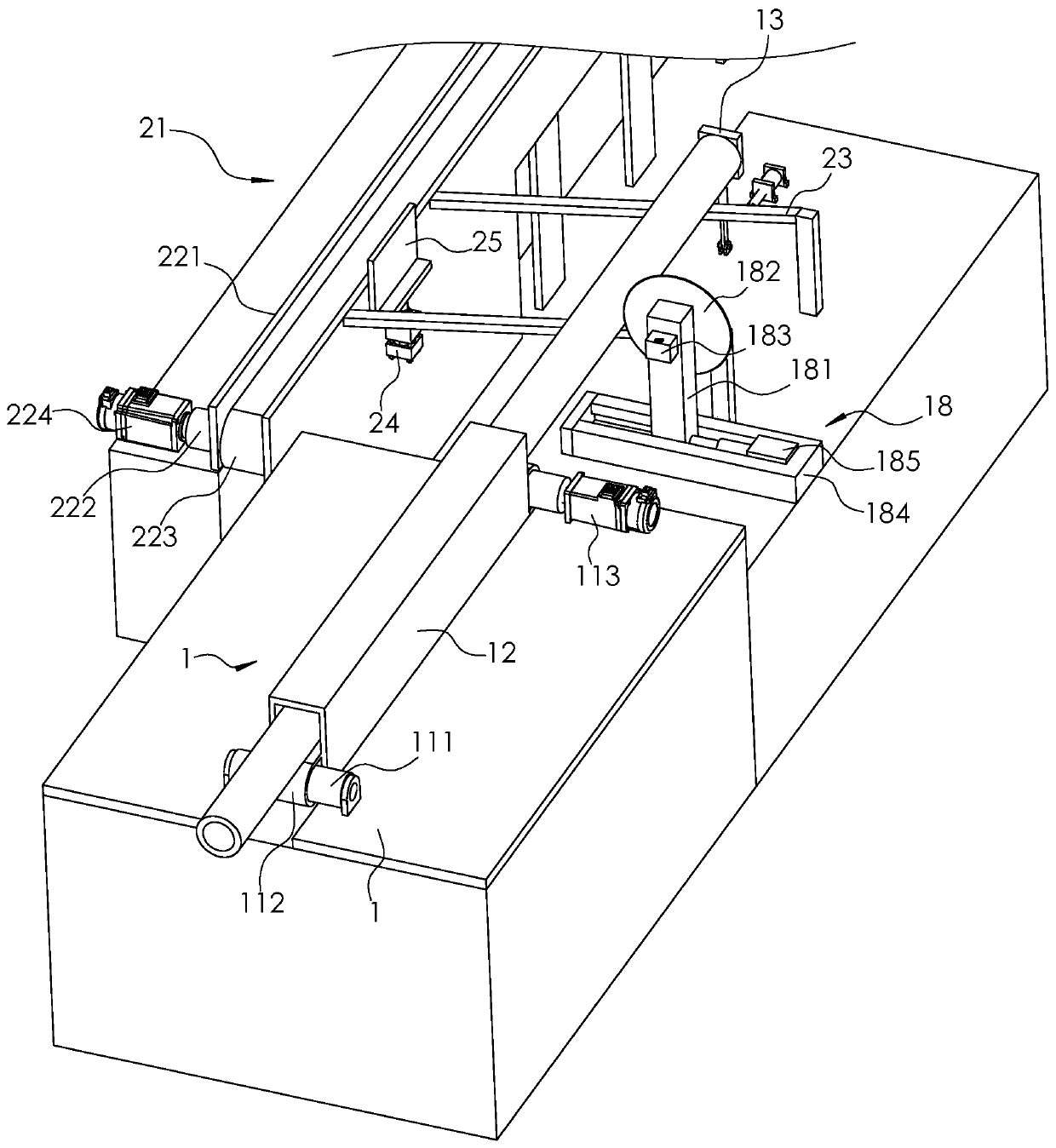

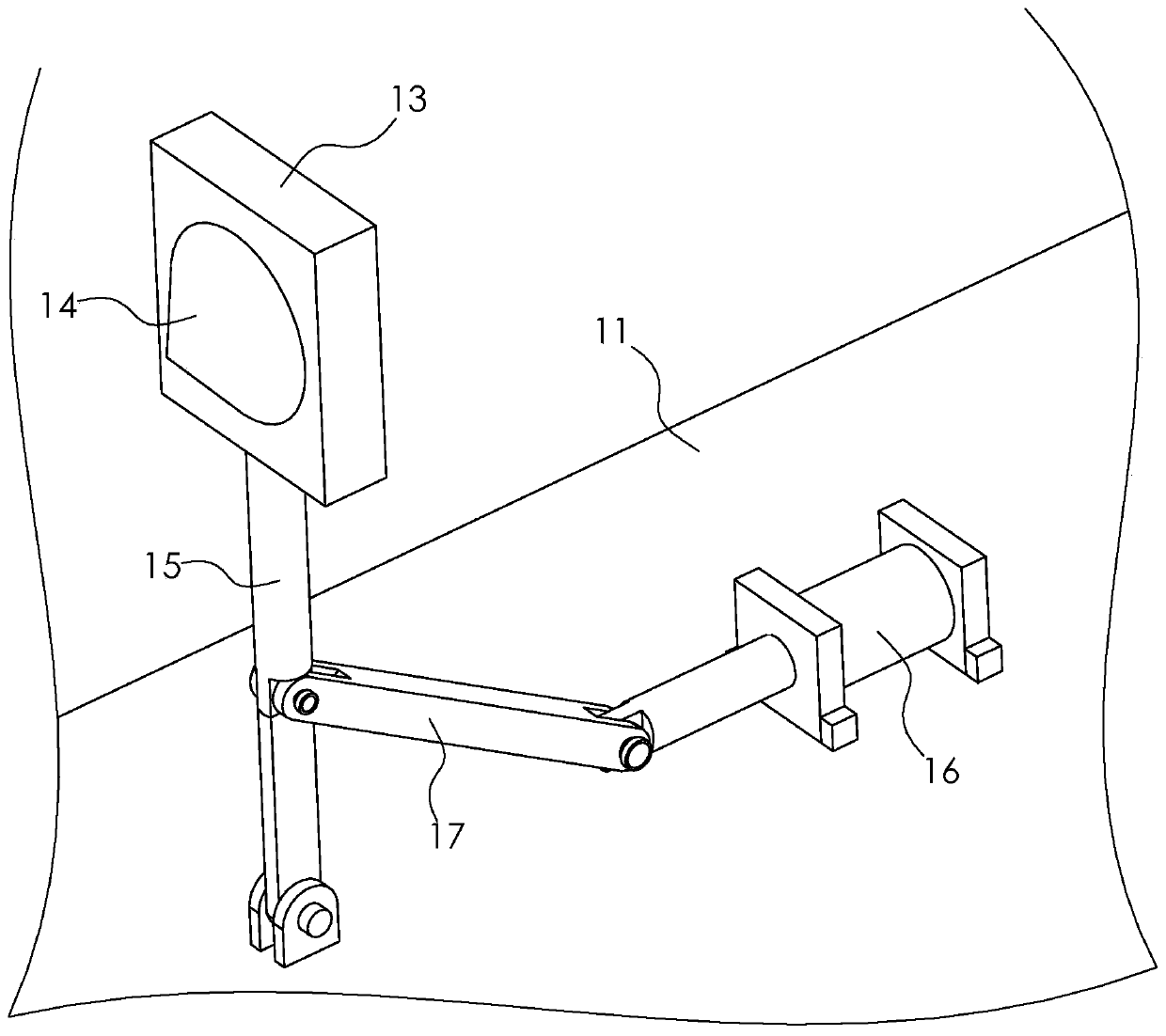

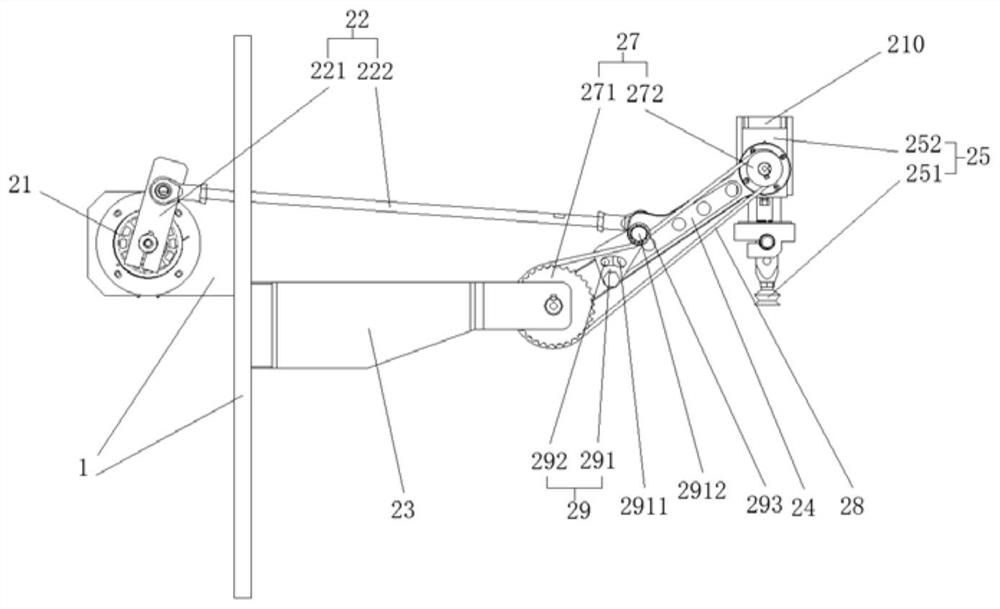

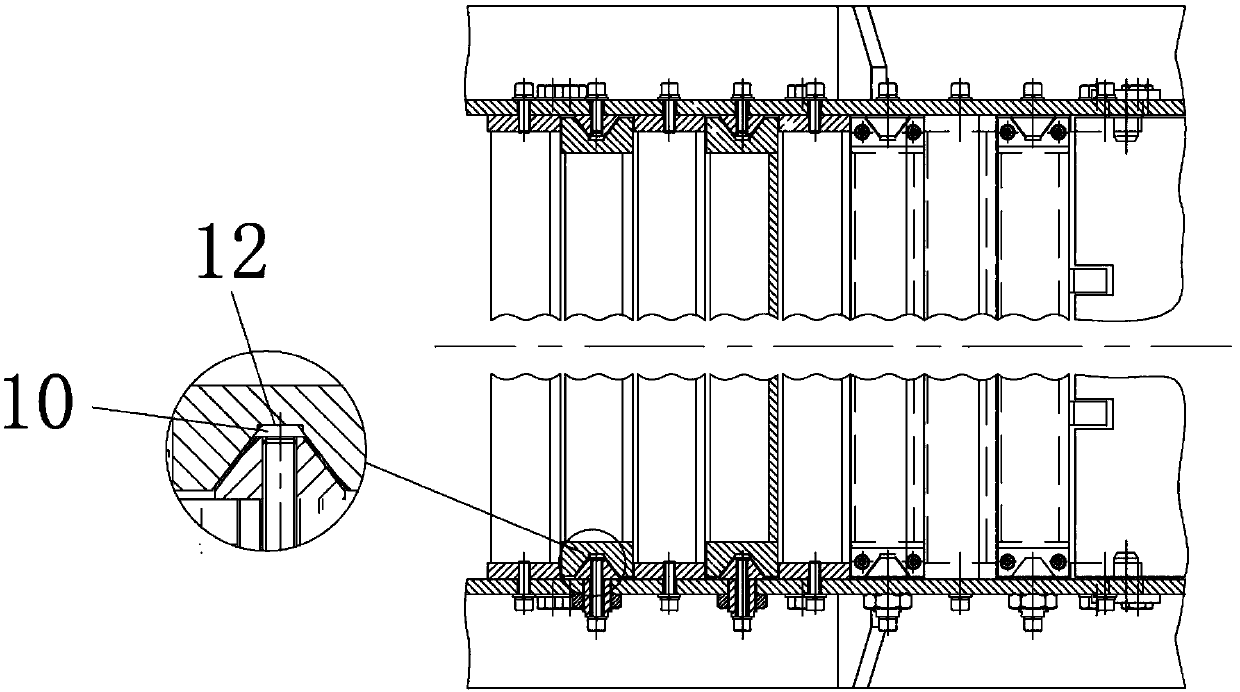

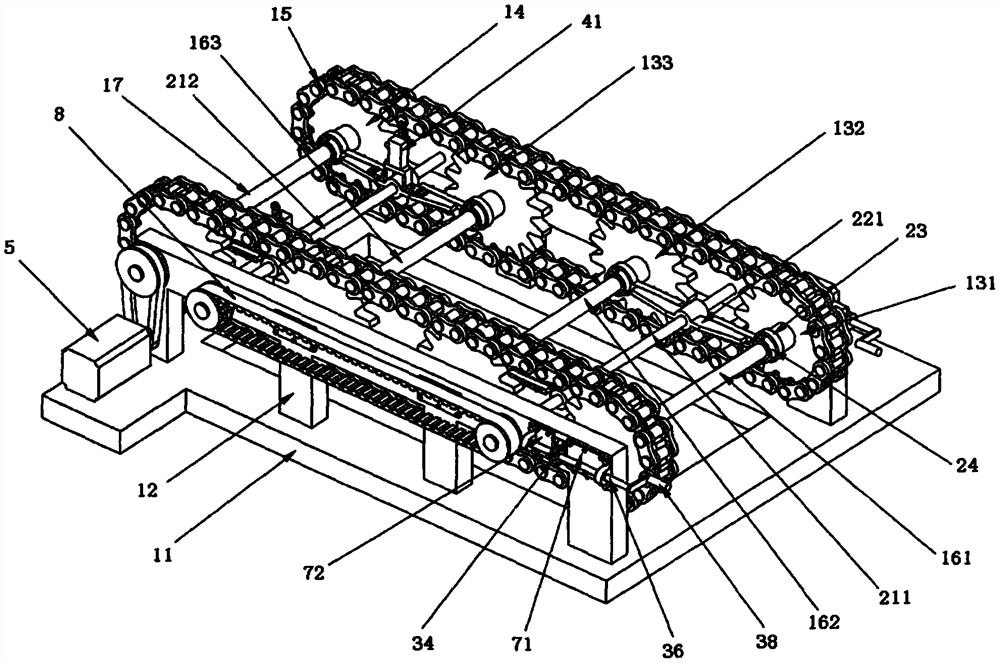

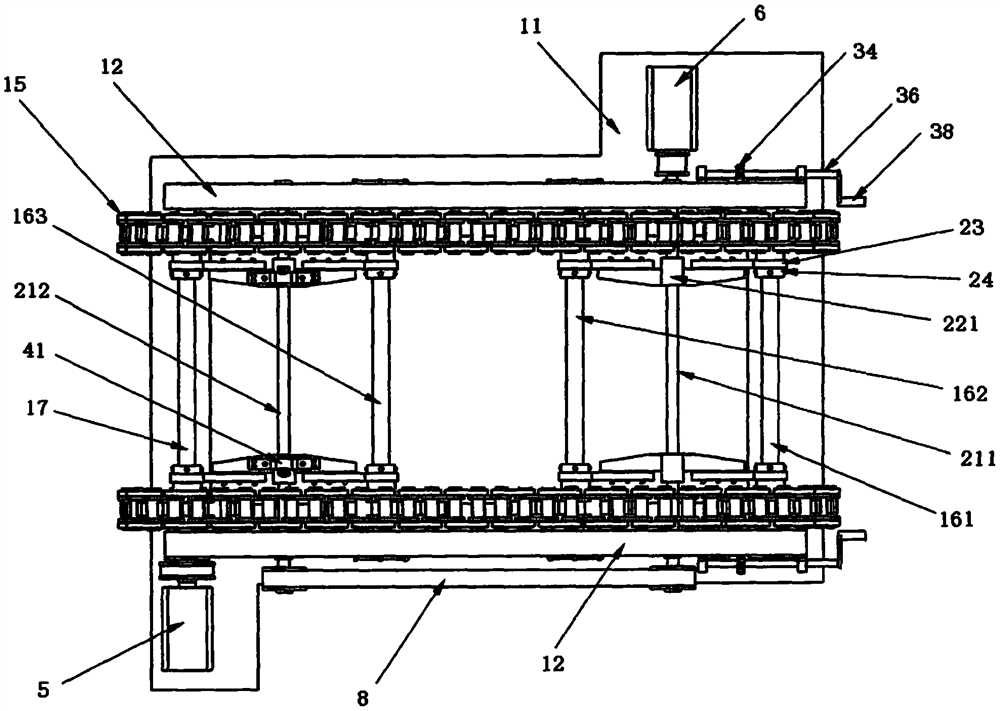

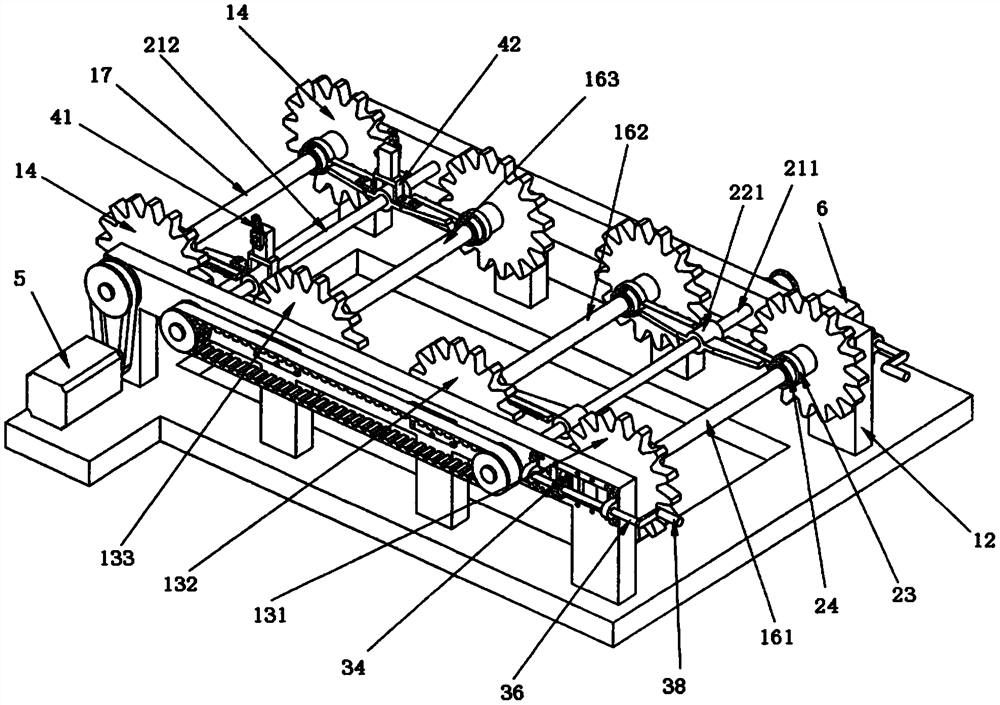

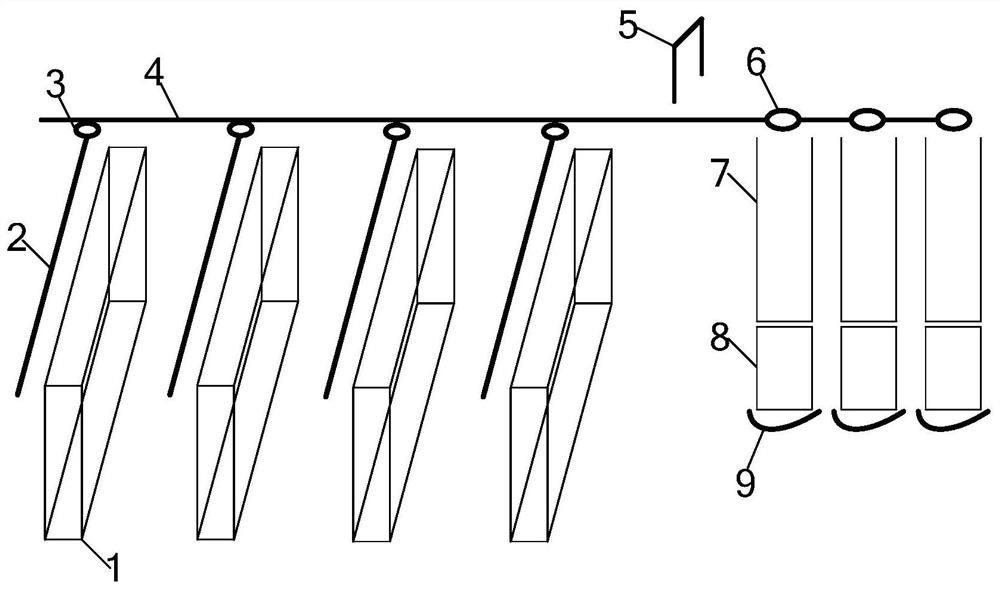

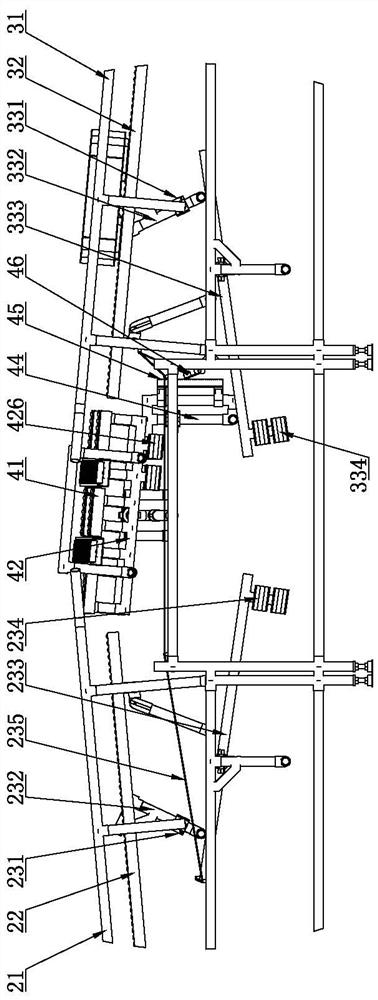

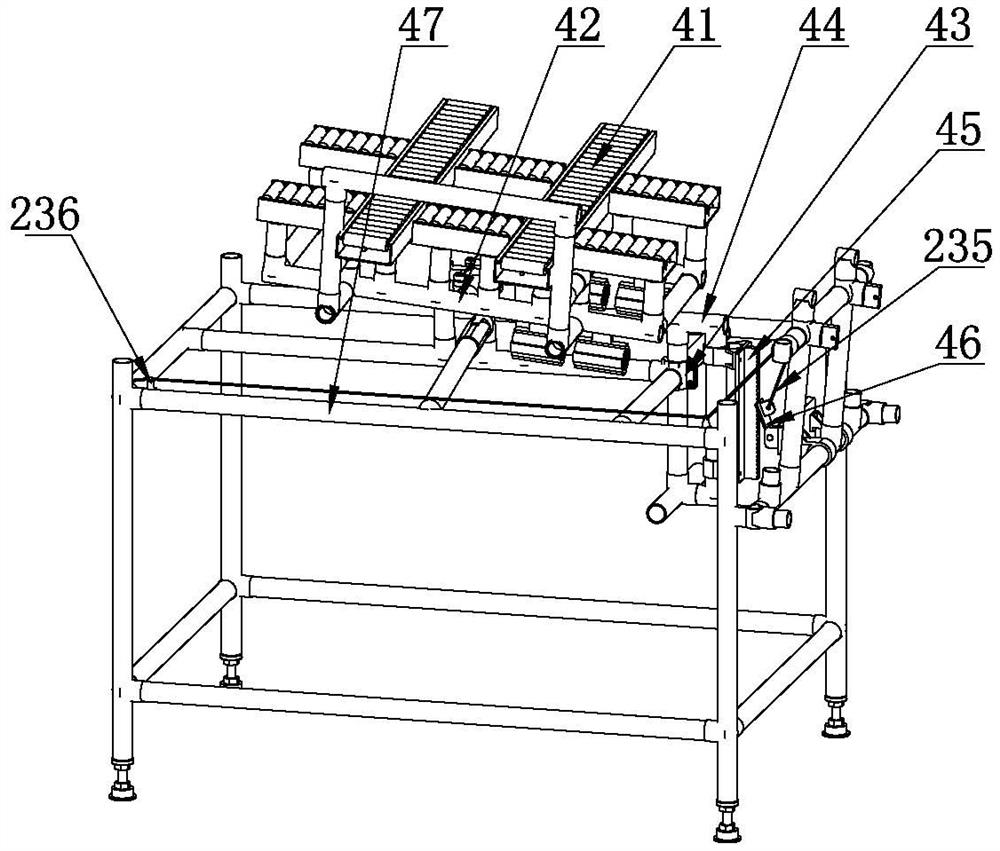

Chain type feeding and conveying device of net rack pipe end circular seam full-automatic welding machine

The invention discloses a chain type feeding and conveying device of a net rack pipe end circular seam full-automatic welding machine. The chain type feeding and conveying device of the net rack pipe end circular seam full-automatic welding machine comprises a chain conveying mechanism, a position adjusting mechanism, a tension adjusting mechanism and a to-be-welded pipe position detecting device, wherein the input end of the chain conveying mechanism is used for manual feeding, and the full-automatic welding machine is mounted at the output end of the chain conveying mechanism; the chain conveying mechanism comprises a machine base, machine frames, driven chain wheels, driving chain wheels, conveying chains, sliding shafts and rotating shafts, wherein the number of the machine frames is two, the sliding shafts are mounted in sliding grooves formed in the machine frames in a sliding mode, the rotating shafts and lead screws are rotationally mounted in cylindrical holes formed in the machine frames correspondingly, the two driven chain wheels are rotationally mounted on the two sides of each sliding shaft; the two sides of each rotating shaft are connected and provided with two driving chain wheels through sliding flat keys, the driven chain wheels and the driving chain wheels are provided with the conveying chains in a meshed mode, the number of the conveying chains is two, one end of each rotating shaft is in transmission connection with a motor through belt transmission. The chain type feeding and conveying device of the net rack pipe end circular seam full-automatic welding machine is simple and reasonable in structure and convenient to use; after a plurality of to-be-welded pipes are placed on the chain type feeding and conveying device at a time, full-automatic conveying of the whole welding process of the to-be-welded pipes can be achieved under driving of the motor, the conveying process is safe and reliable, the labor intensity of conveying is reduced, and the conveying efficiency is improved.

Owner:田国华

Automatic packaging system for winding cone yarns and method thereof

ActiveCN113602578APlace stableFully automatedWrapper twisting/gatheringPackaging automatic controlYarnWinding machine

The invention discloses an automatic packaging system for winding cone yarns and a method thereof. According to the automatic packaging system, winding automatic conveying systems are arranged on one sides of winding machines, a public cone yarn automatic conveying system is arranged on the front portions of the winding automatic conveying systems, an even number of cone yarn automatic packaging systems are arranged on one side of the cone yarn automatic conveying system, then winding cone yarn full automatic conveying and packaging is achieved, a cone yarn automatic detection and classification device is arranged above the front side of the cone yarn automatic conveying system, automatic classification of the cone yarns is achieved, and therefore full automation in the cone yarn packaging process of winding is achieved.

Owner:NANTONG DOUBLE GREAT TEXTILE

Horn assembling, dispensing, feeding and discharging automatic machine

InactiveCN111054586ARealize fully automatic conveyingImprove efficiencyLiquid surface applicatorsSpraying apparatusAdhesive glueProcess engineering

The invention belongs to the technical field of a horn assembling, dispensing, feeding and discharging automatic machine, and discloses a horn assembling, dispensing, feeding and discharging automaticmachine. A horn automatic feeding and discharging module and a horn cover automatic feeding and discharging module are used for conveying products, horn covers and horns are grabbed by a grabbing module onto a carrier table module, a glue module and a carrier module do circular interpolation dispensing, finally, a discharging module achieves automatic traying and discharges defective products, different stations perform own functions and cooperate with one another closely, and therefore products are conveyed full automatically, the horns are automatically assembled into the horn covers, automatic glue dispensing is achieved, and automatic traying and tray collection are achieved; and efficiency is high, quality is stable, the automation degree is high, the effect is good, the production cost is low, and the machine is convenient, easy and rapid to use.

Owner:INNOVATION SOUND TECH

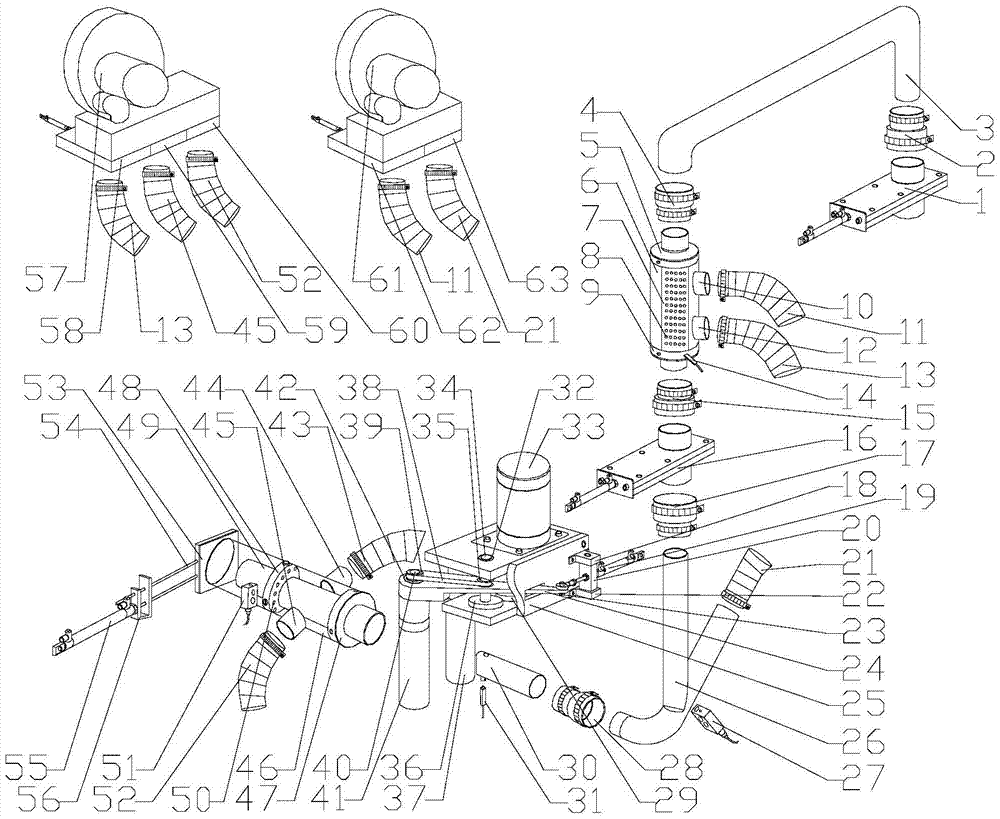

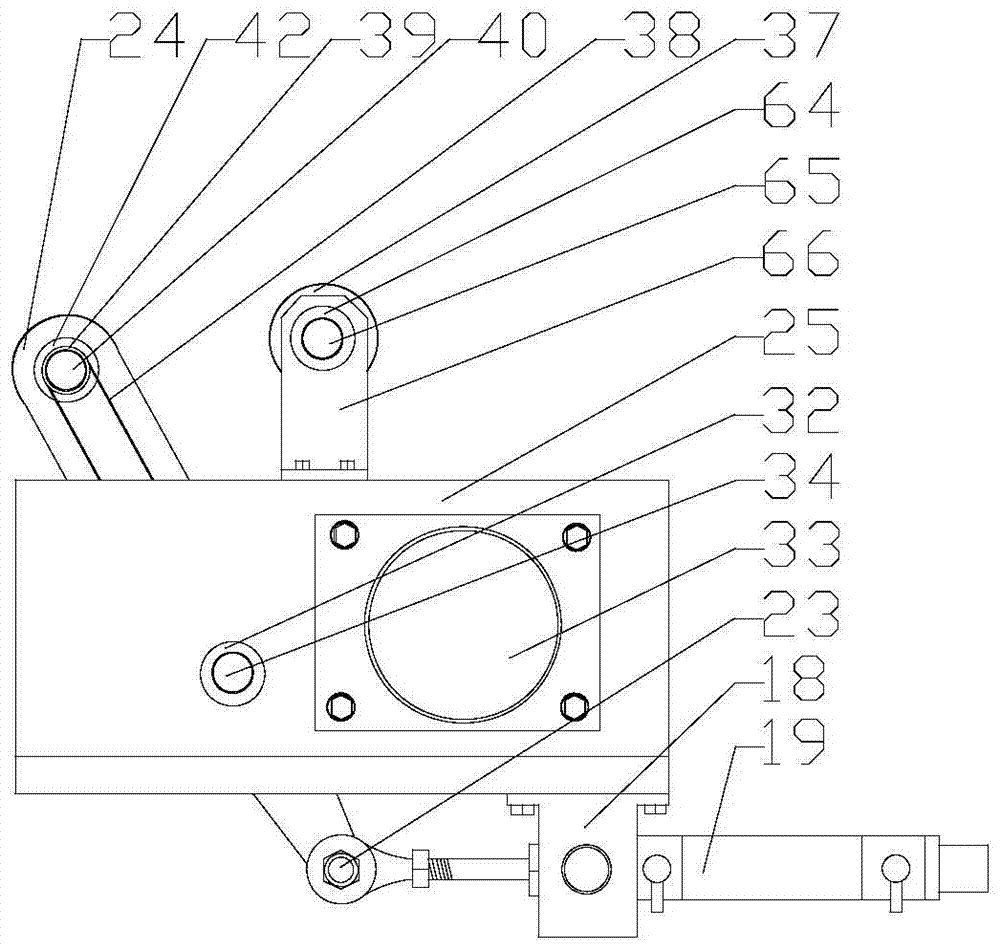

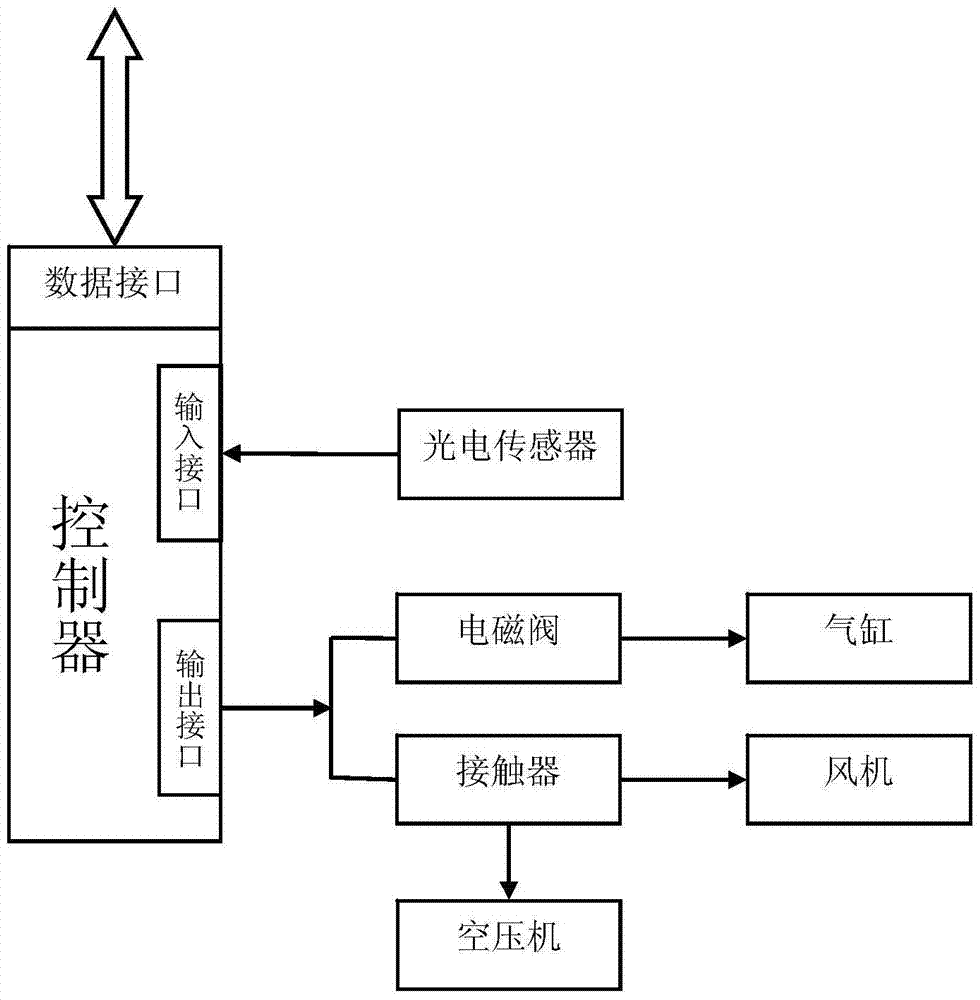

Full-automatic leakage checking and dust removing integrated equipment for serum transfer pipette

InactiveCN108655024ARealize fully automatic conveyingReduce manual labor intensityHollow article cleaningSortingPipetteEngineering

The invention relates to the technical field of biological medical instruments and particularly discloses a full-automatic leakage checking and dust removing integrated equipment for a serum transferpipette. The full-automatic leakage checking and dust removing integrated equipment for the serum transfer pipette comprises a conveying device, a leakage checking device, a removing device, a dust removing device, a charging device and a shifting device. The conveying device comprises a conveying chain and a positioning wheel disk, and the positioning wheel disk is provided with an arc positioning groove. The leakage checking device comprises a first lifting air cylinder, a first pushing air cylinder and a second pushing air cylinder. The removing device comprises a second lifting air cylinder and a third pushing air cylinder, the surface of the lower part of an L-shaped pushing block is of a wavy structure, and the side part of the L-shaped pushing block is provided with a semisphericalprotrusion. The dust removing device comprises a third lifting air cylinder and a fourth pushing air cylinder. The charging device comprises a feeding slide way and a discharging slide way. The shifting device comprises a saw tooth part and an adjusting block. The full-automatic leakage checking and dust removing integrated equipment for the serum transfer pipette has the beneficial effects that the detection consumed time is relatively short, unqualified products can be directly screened out, fine particular dust and impurities can be removed, the automation degree is relatively high, charging is tidy, a material opening cannot be blocked, and the adaptation is relatively good.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

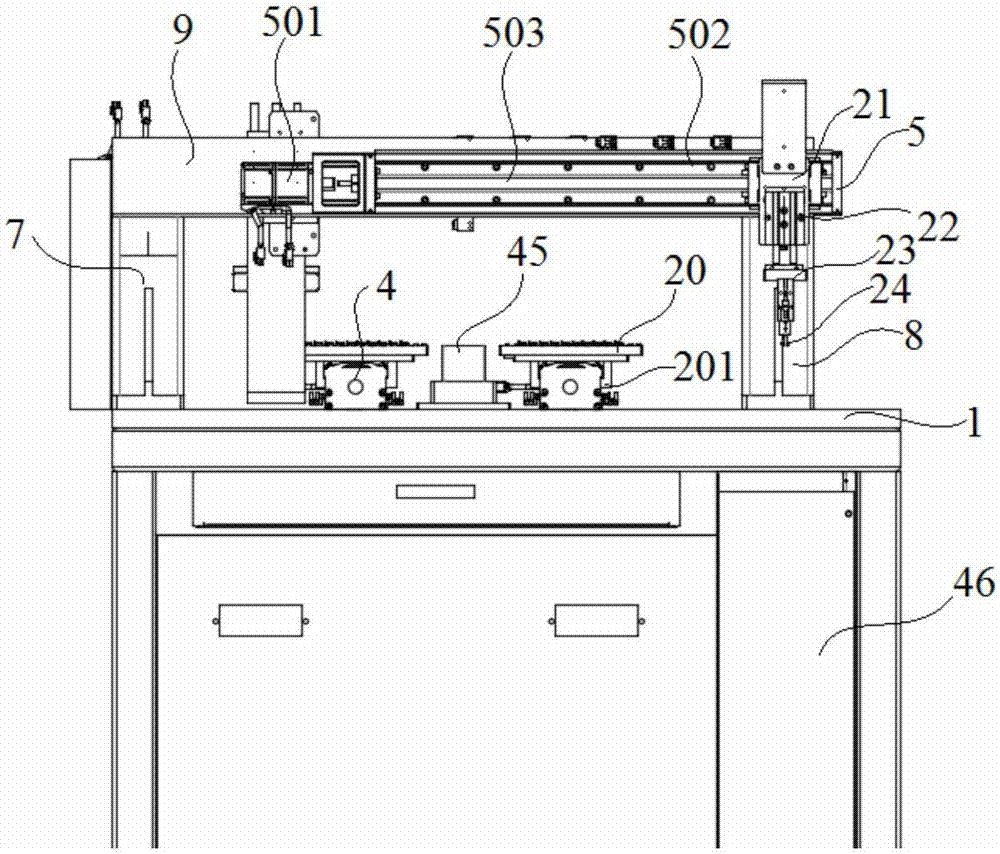

Automatic chamfer detection machine

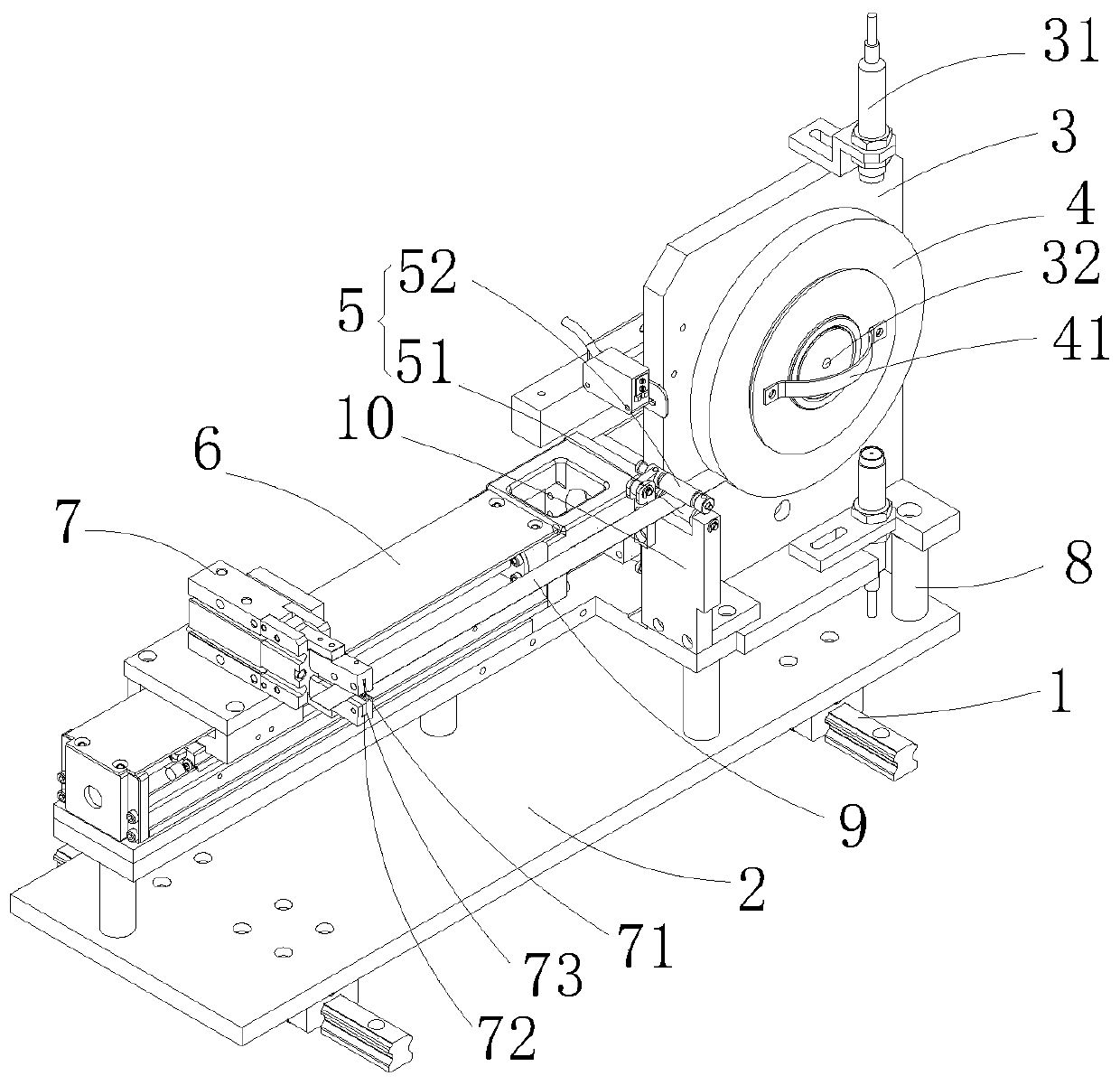

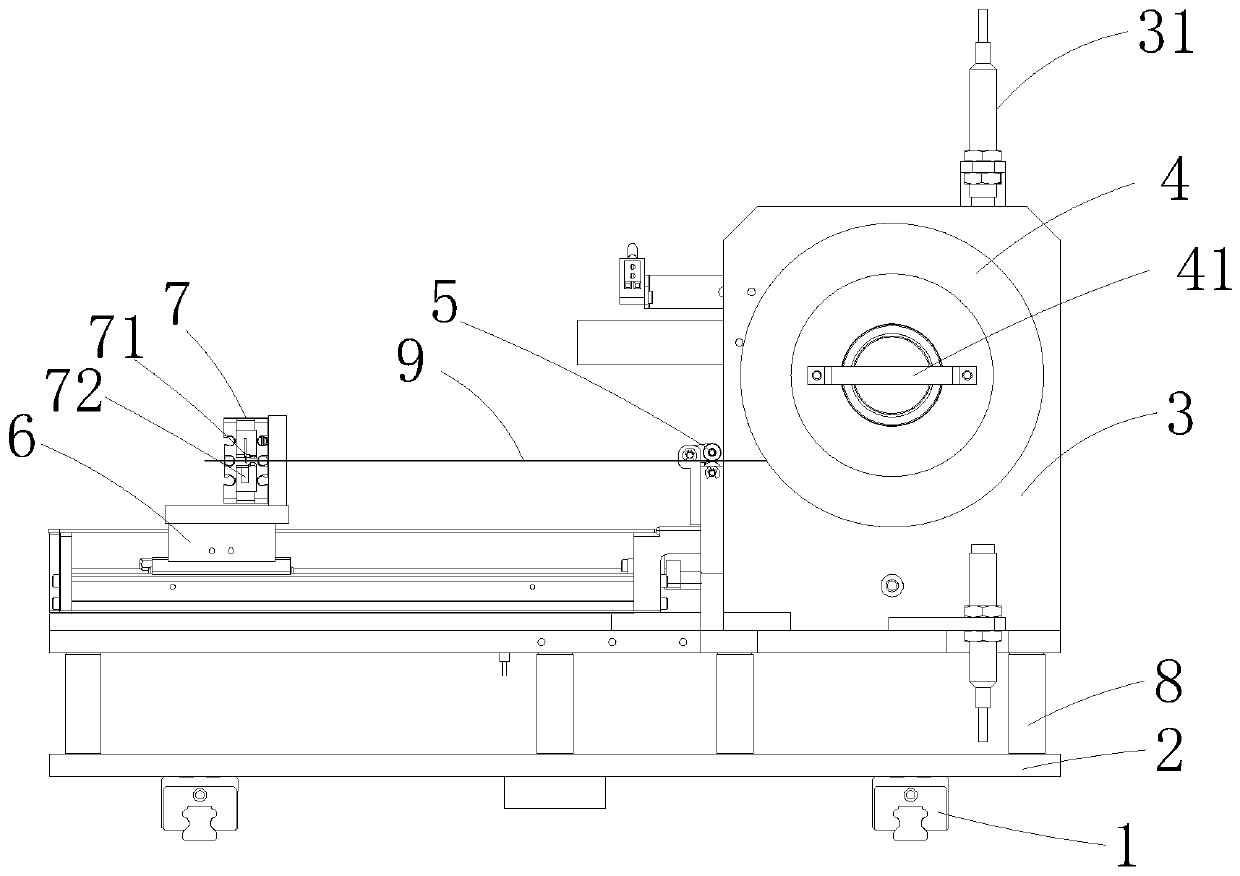

ActiveCN107167108ARealize fully automatic conveyingHigh degree of automationMeasurement devicesSortingElectric machineryStructural engineering

The invention discloses an automatic chamfer detection machine. The detection machine comprises a base, a support rack installed on the base, an X-direction transmission device, a front-end Y-direction transmission device and a back-end Y-direction transmission device. The support rack consists of a left column, a right column and a cross beam. The left column and the right column are respectively fixed on two sides of the upper surface of the base. The cross beam is connected to the top ends of the left column and the right column in a crossing manner. The front-end Y-direction transmission device further comprises a front-end Y-direction motor, two front-end Y-direction guide rails, a front-end Y-direction screw rod and a front-end Y-direction nut. The front-end Y-direction motor is installed on one end of a charging side of the support rack. Multiple guidance column through-holes for threading-in of guidance columns are arranged in an adjustment rack. The guidance columns penetrate through the guidance column through holes and are fixedly connected with the upper surface of a light source. A material collecting box used for collecting defective products is arranged in the center of the base. A case where the power supply and the electric control equipment are arranged is arranged under the base. According to the invention, the detection machine is capable of replacing workers to achieve chamfer detection, so all kinds of problems in eye detection are solved; manpower is saved; detection processes are precise and reliable; detection efficiency is high; and cost is greatly reduced.

Owner:KESEN SCI & TECH DONGTAI CO LTD

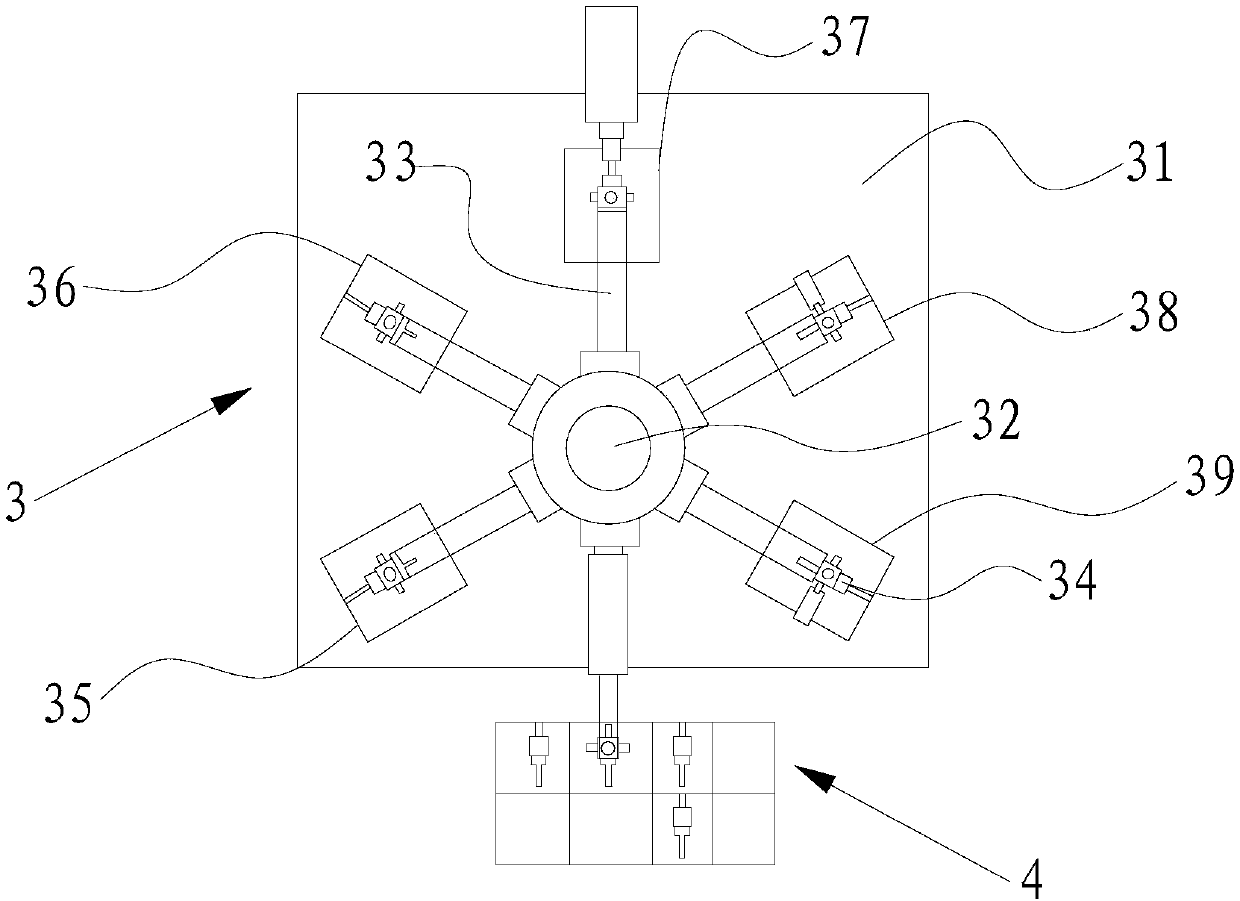

Fully-automatic multi-station balancing machine assembly line

PendingCN107607260ARealize fully automatic conveyingEasy to detectStatic/dynamic balance measurementSortingBalancing machineEngineering

The invention relates to a fully-automatic multi-station balancing machine assembly line. The assembly line comprises a material feeding assembly, a manipulator assembly, a rotor transferring assemblyand a classification material collection box. The manipulator assembly is installed under the material feeding assembly. The rotor transferring assembly is installed under the manipulator assembly, and comprises a substrate, a rotation shaft, six rotation arms, clamping mechanisms, a first detection station, a first reduplication removing station, a rotor rotation direction station, a second reduplication station and a second detection station, wherein the rotation shaft is vertically arranged on the substrate; the rotation arms are fixed on the peripheral surface of the rotation shaft at equal intervals; the clamping mechanisms are installed on free ends of the rotation arms respectively; and the first reduplication removing station, the rotor rotation direction station, the second reduplication station and the second detection station are successively installed on the upper surface of the substrate and match the clamping mechanisms. The classification material collection box is installed on one side of the rotor transferring assembly and matches the clamping mechanisms. According to the invention, fully-automatic transmission, detection and downloading of rotors can be achieved;and improving of production efficiency is facilitated.

Owner:宿迁聚博科技有限公司

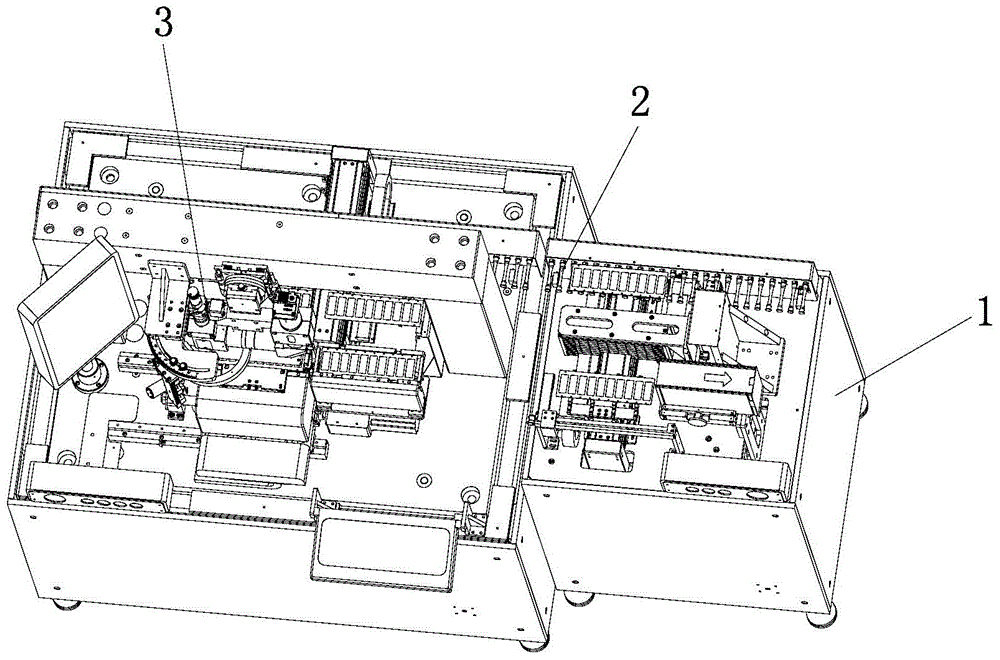

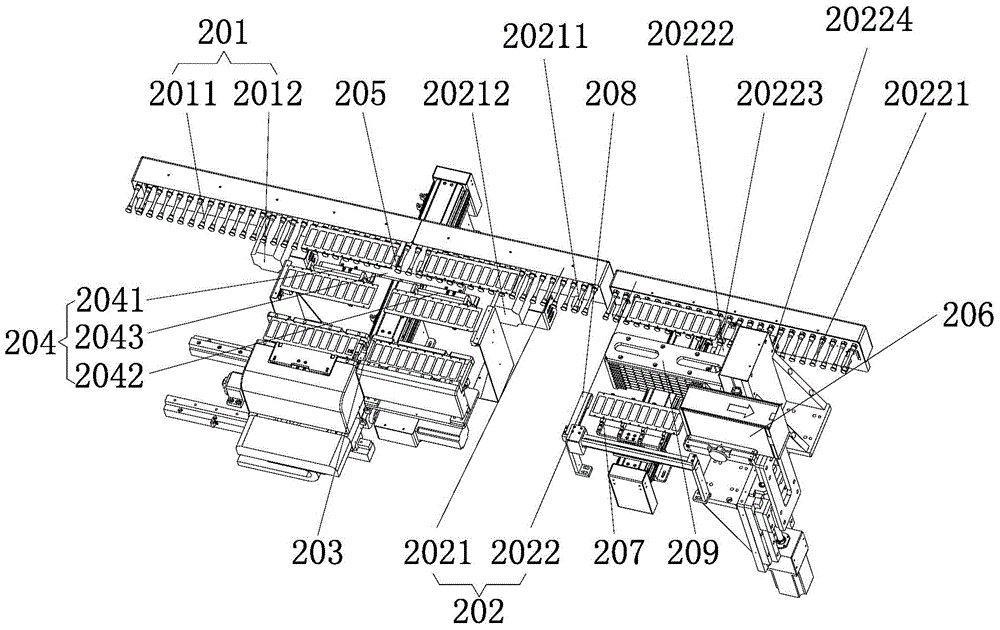

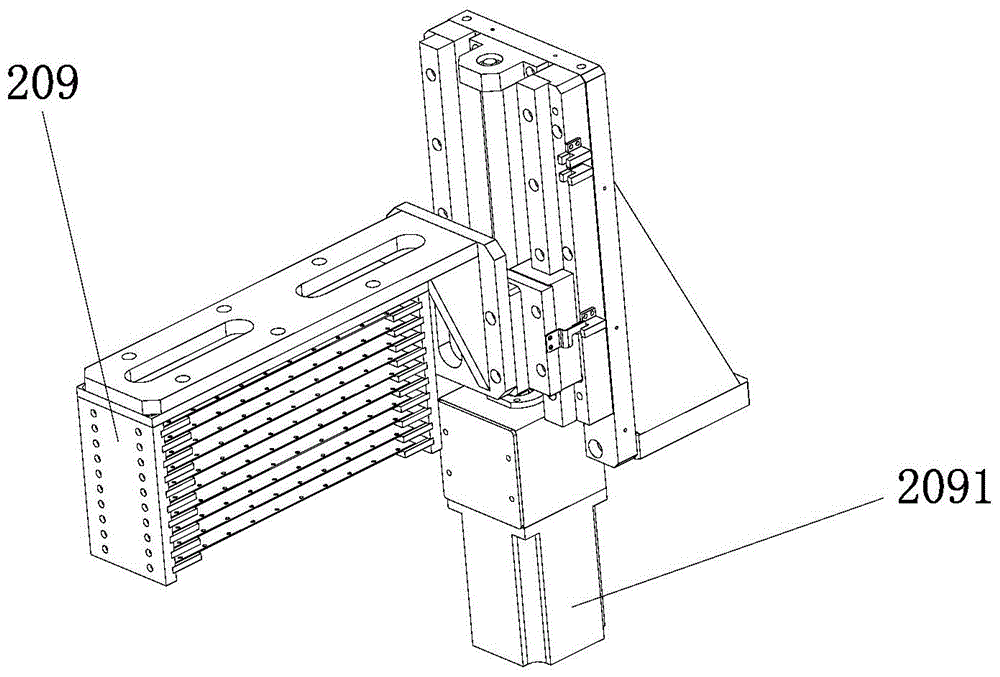

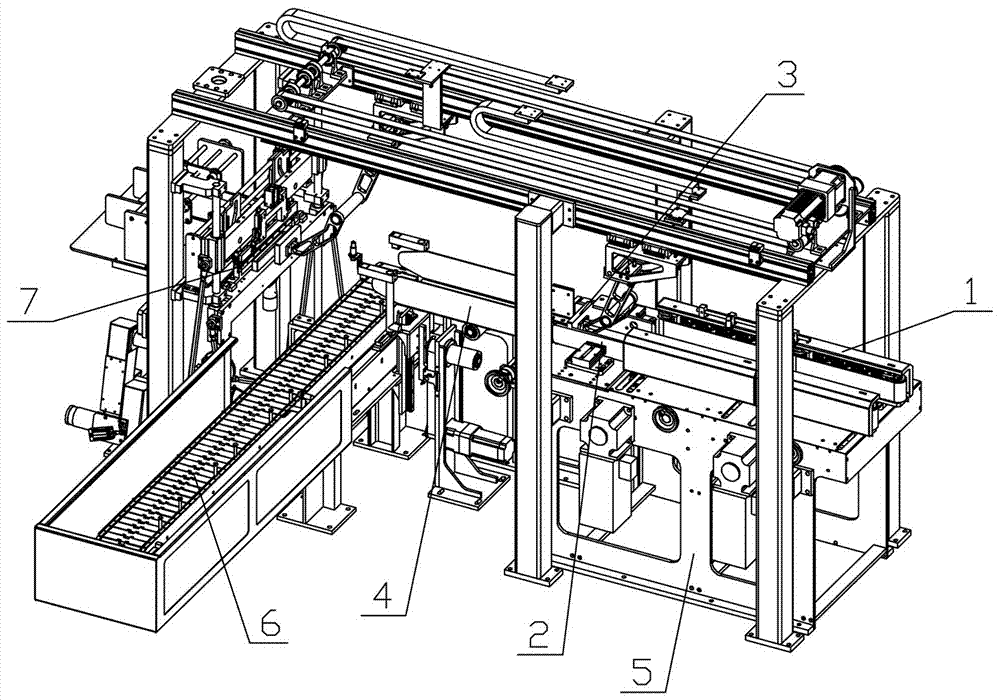

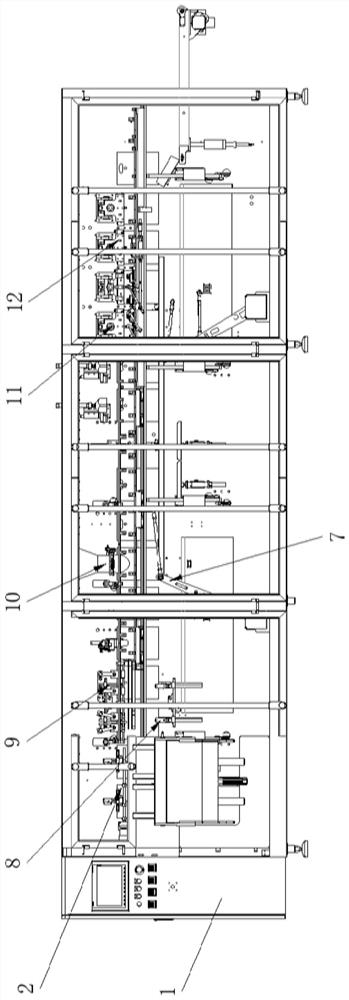

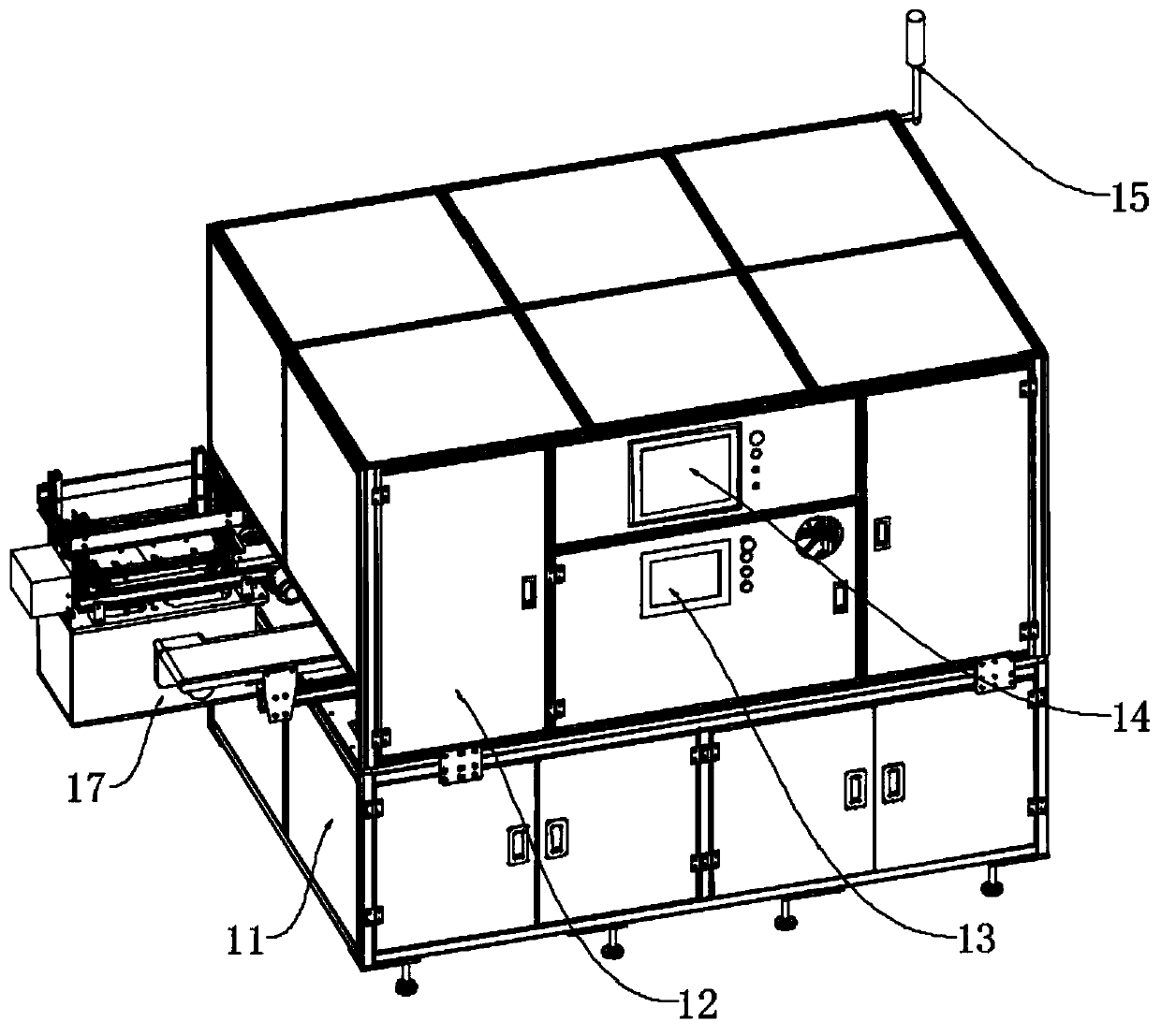

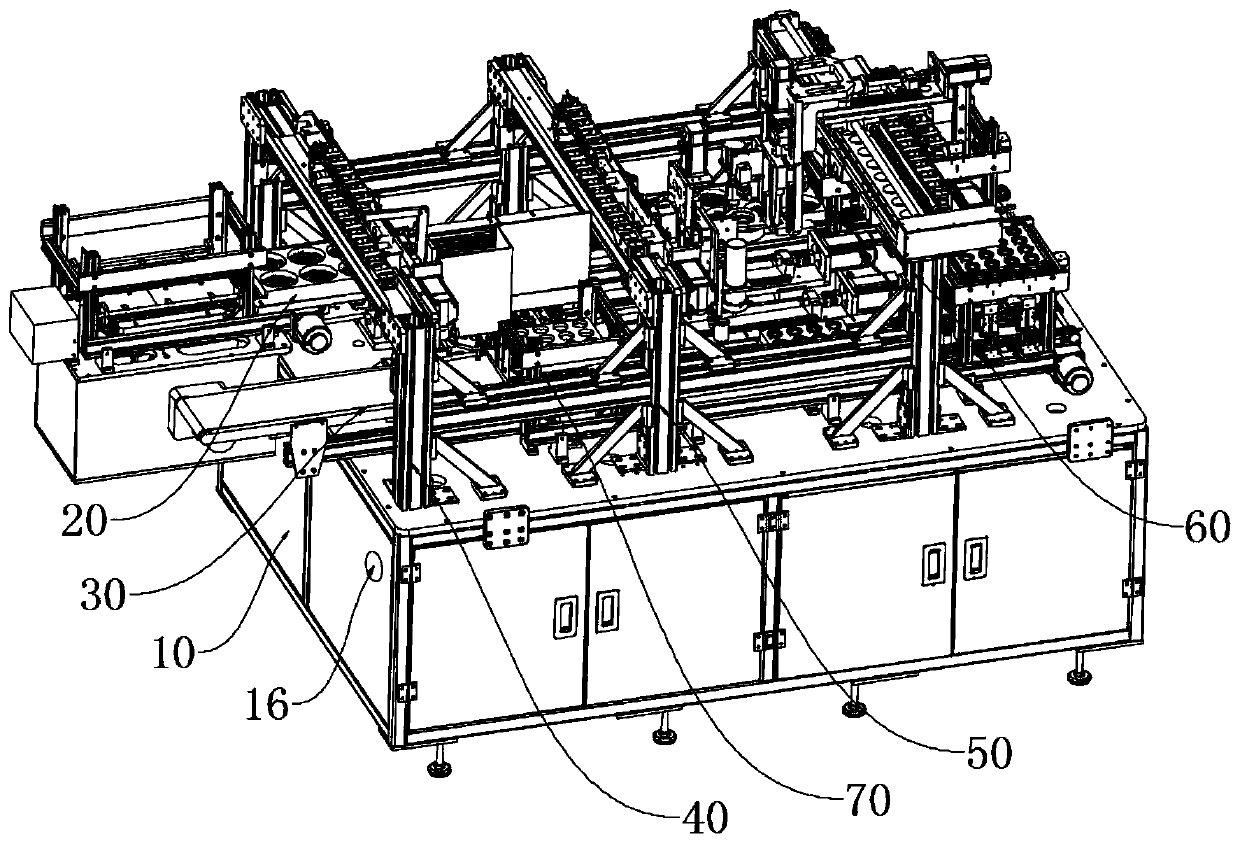

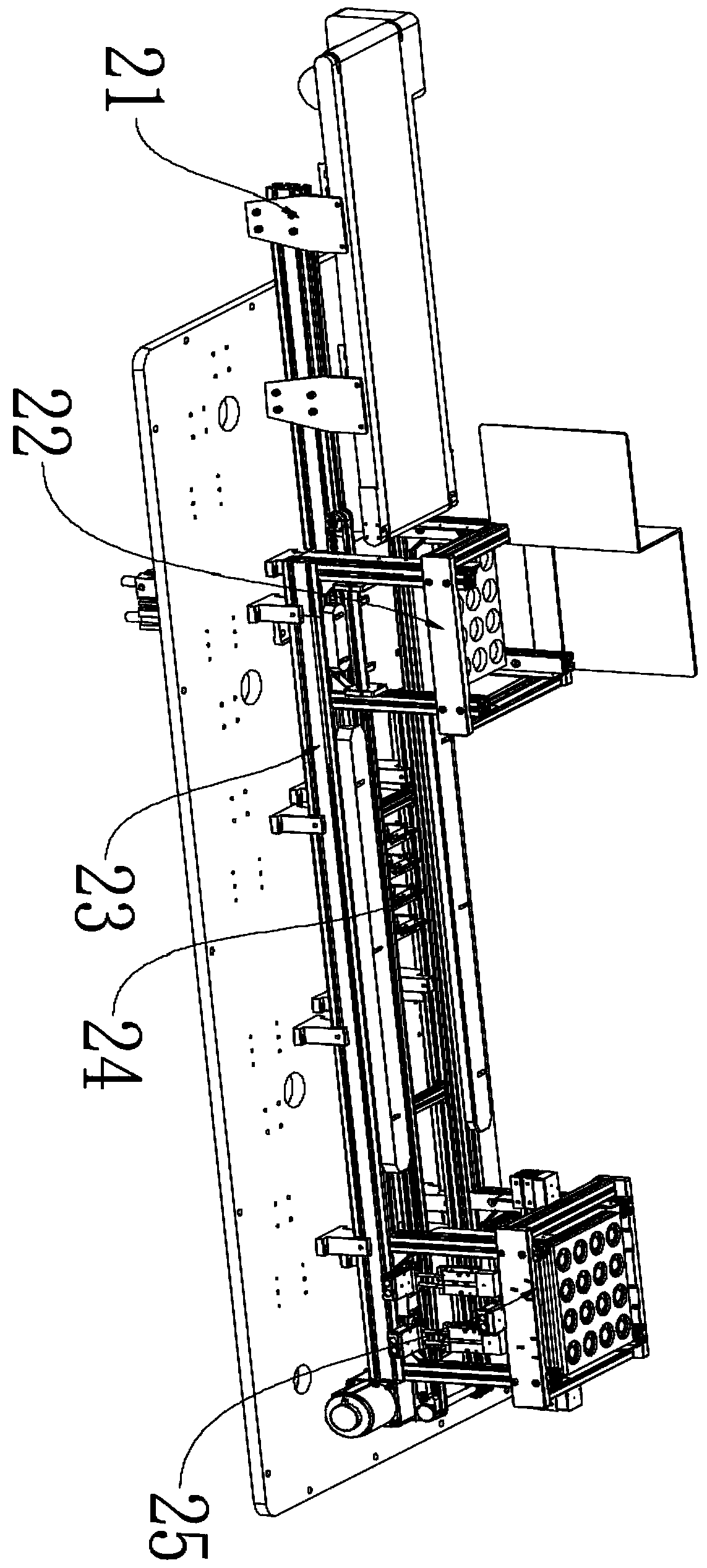

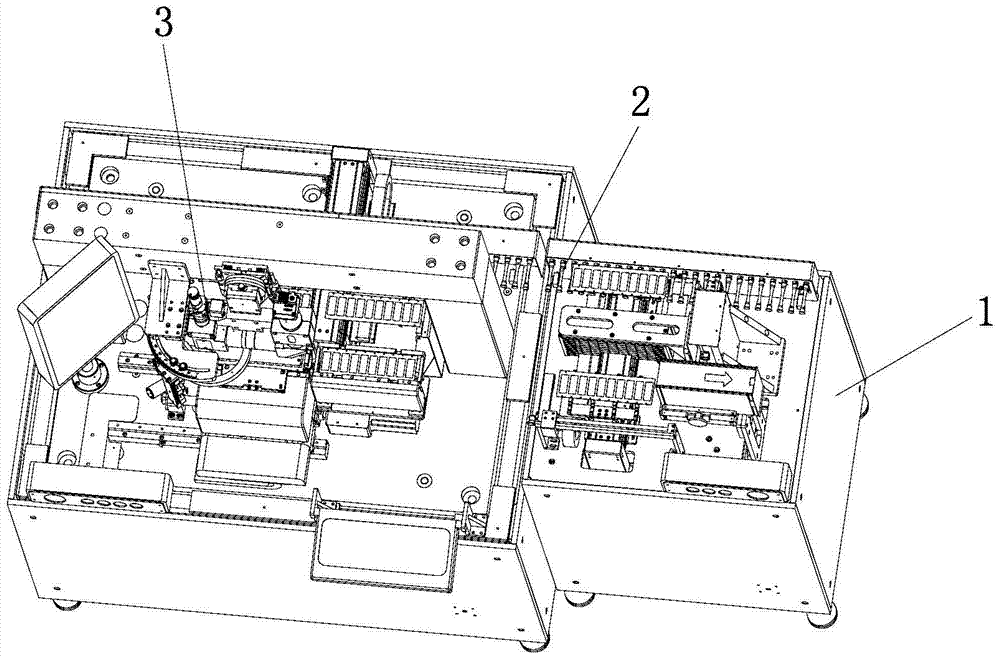

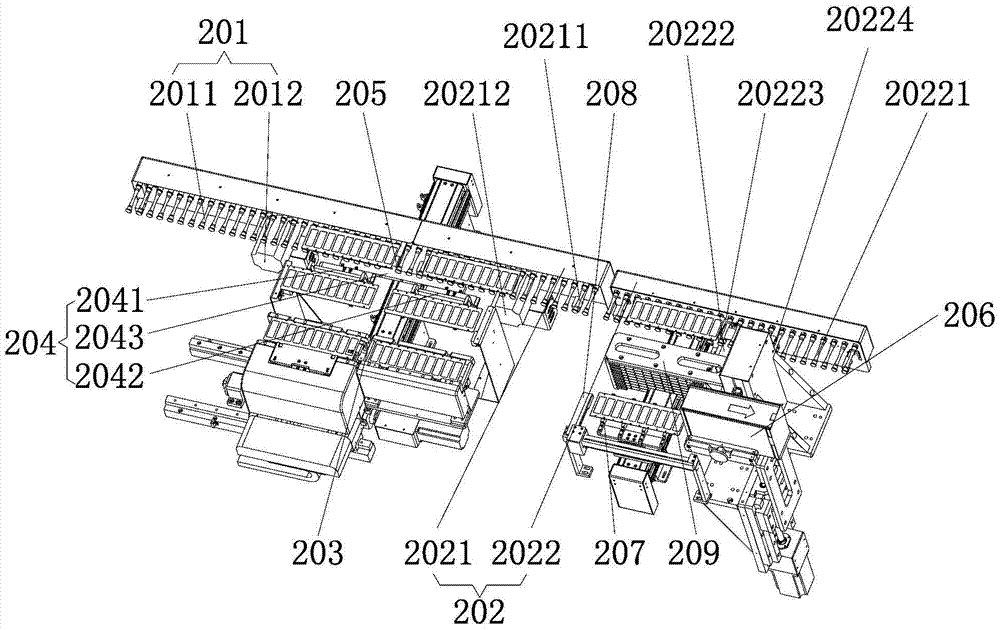

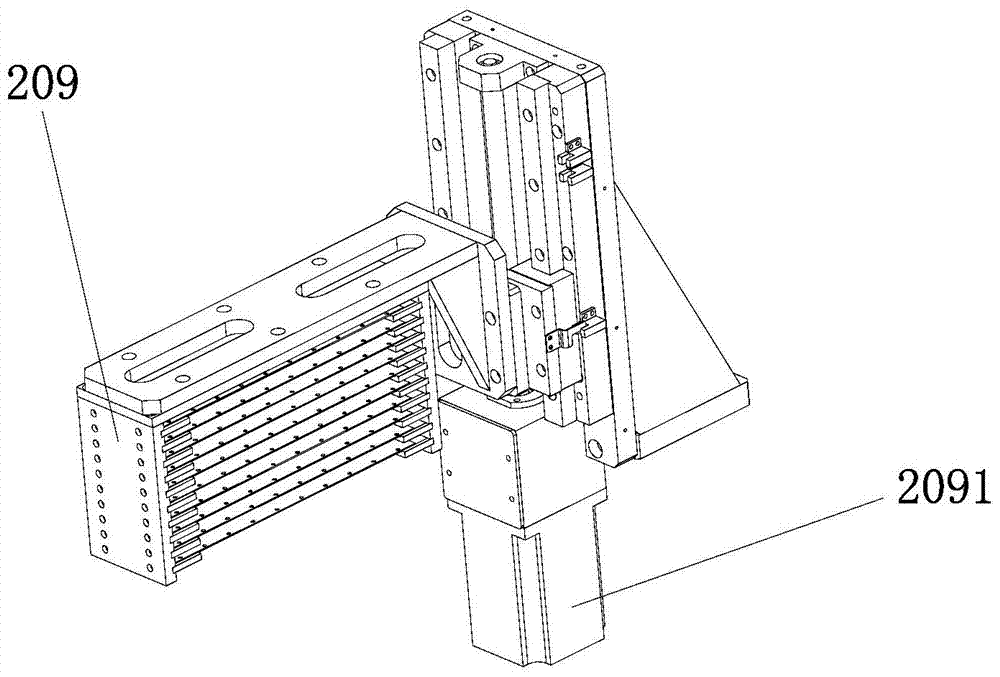

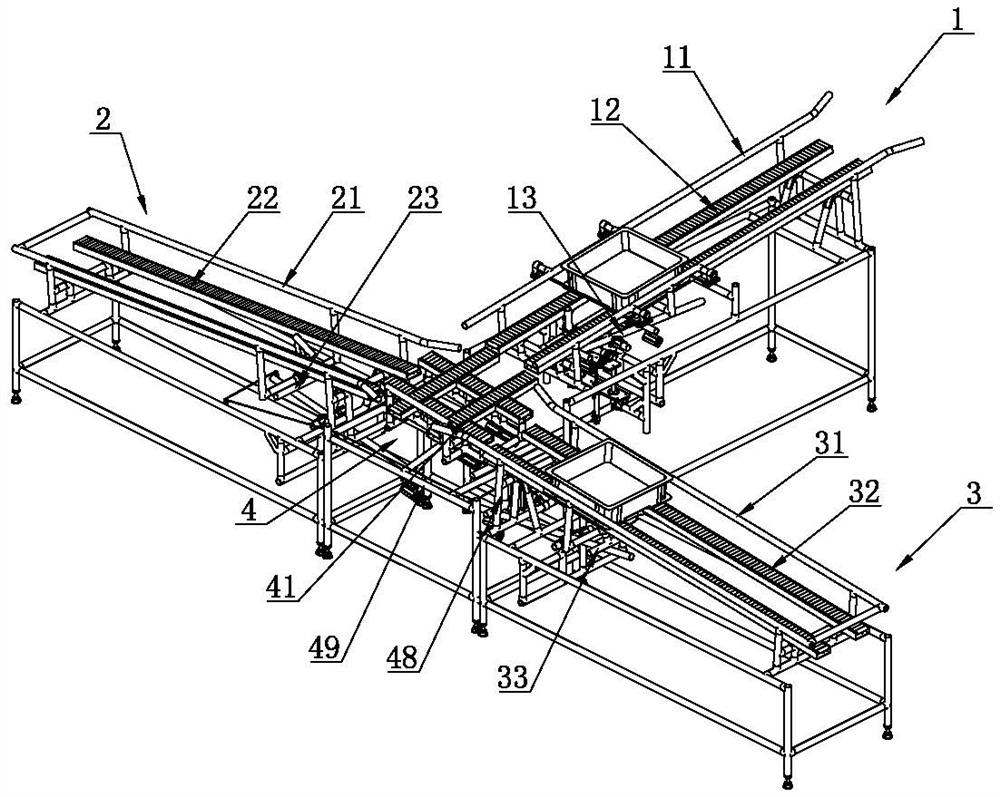

Camera module testing equipment

ActiveCN104967841BRealize fully automatic conveyingHigh degree of automationTelevision systemsTransmission beltEngineering

The invention relates to the technical field of mobile phone camera module detection equipment, and particularly relates to camera module detection equipment, which comprises a rack, a transmission device and an optical system. Transmission of a material plate among an input transmission belt, a detection transmission belt and an output transmission belt is realized via a lateral transport mechanism, and output via the output transmission belt is finally carried out. After a camera module is transported on the detection transmission belt, with the help of a first light source group, a second light source group and a third light source group, a first camera and a second camera of the optical system realize detection on a gold wire on a circuit connection substrate on an image sensor group and detection on dust and scratches of the image sensor respectively, and after detection, output via the output transmission belt is carried out. Full-automatic transport of the material plate is realized, the automatic degree of the camera module detection equipment is improved, the working efficiency is improved, automatic detection of the camera module is realized, the detection efficiency is high, the precision is high, and the detection mission rate is low.

Owner:东莞市升宏智能科技有限公司

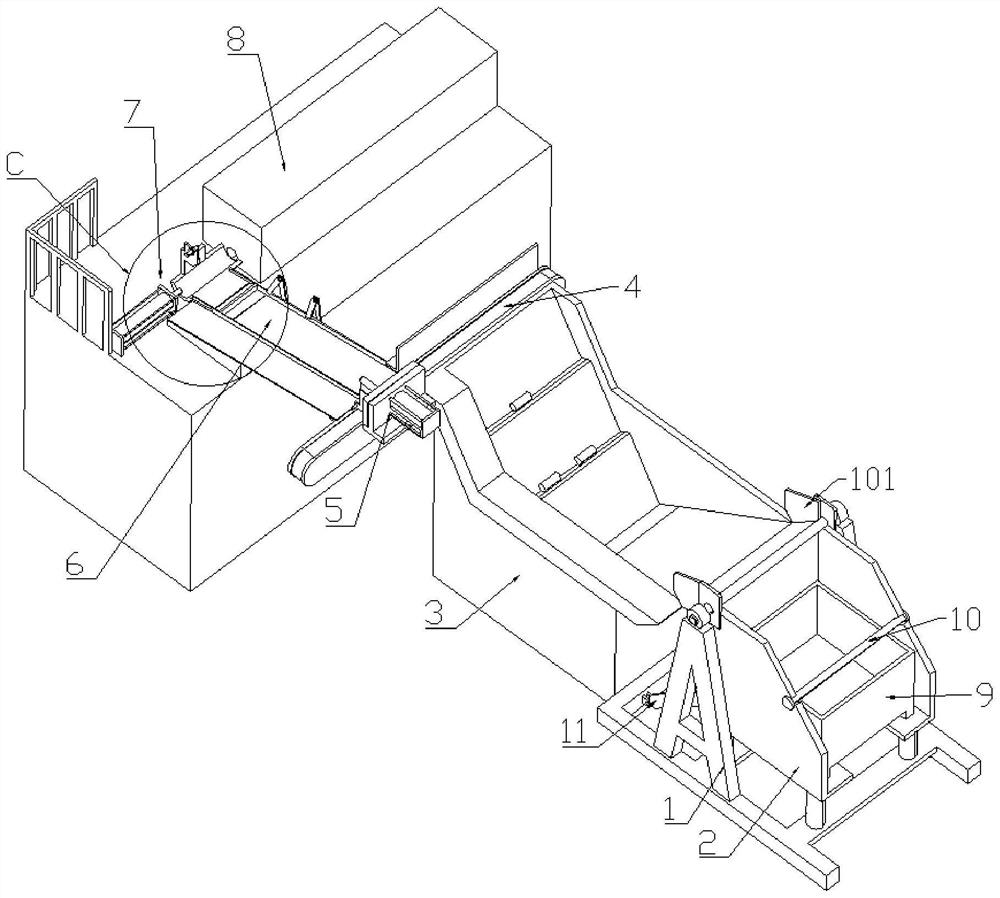

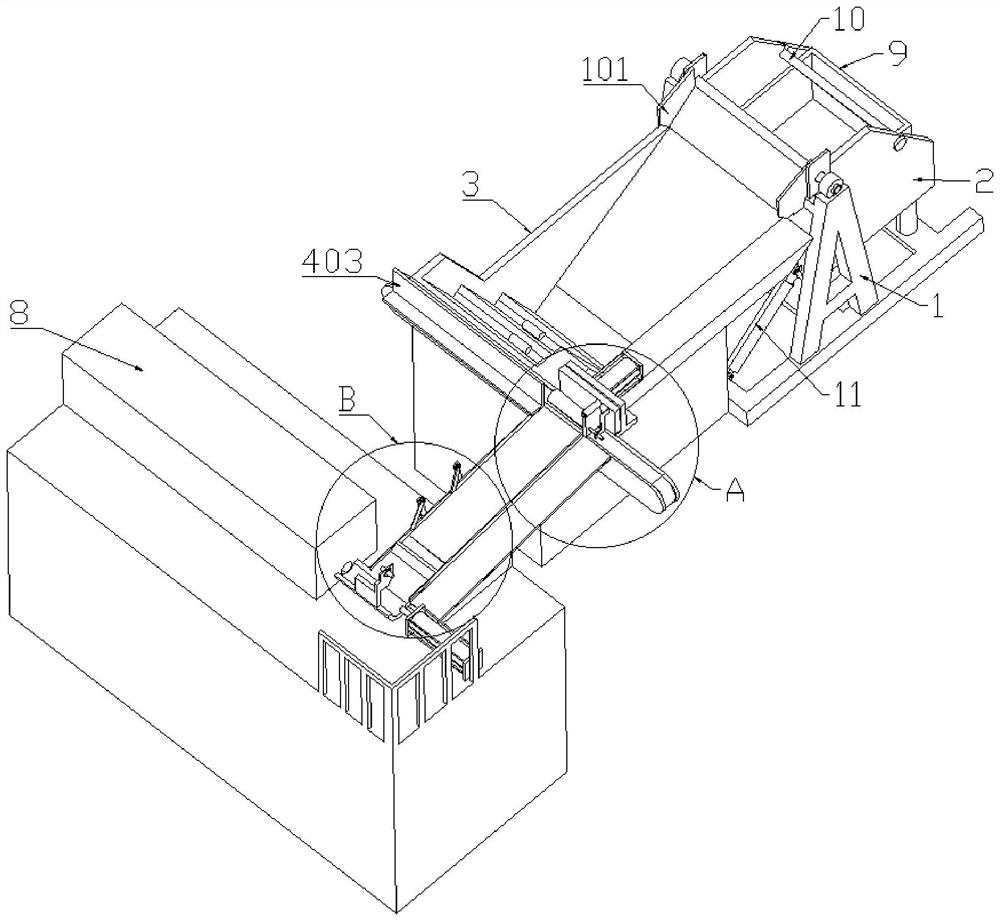

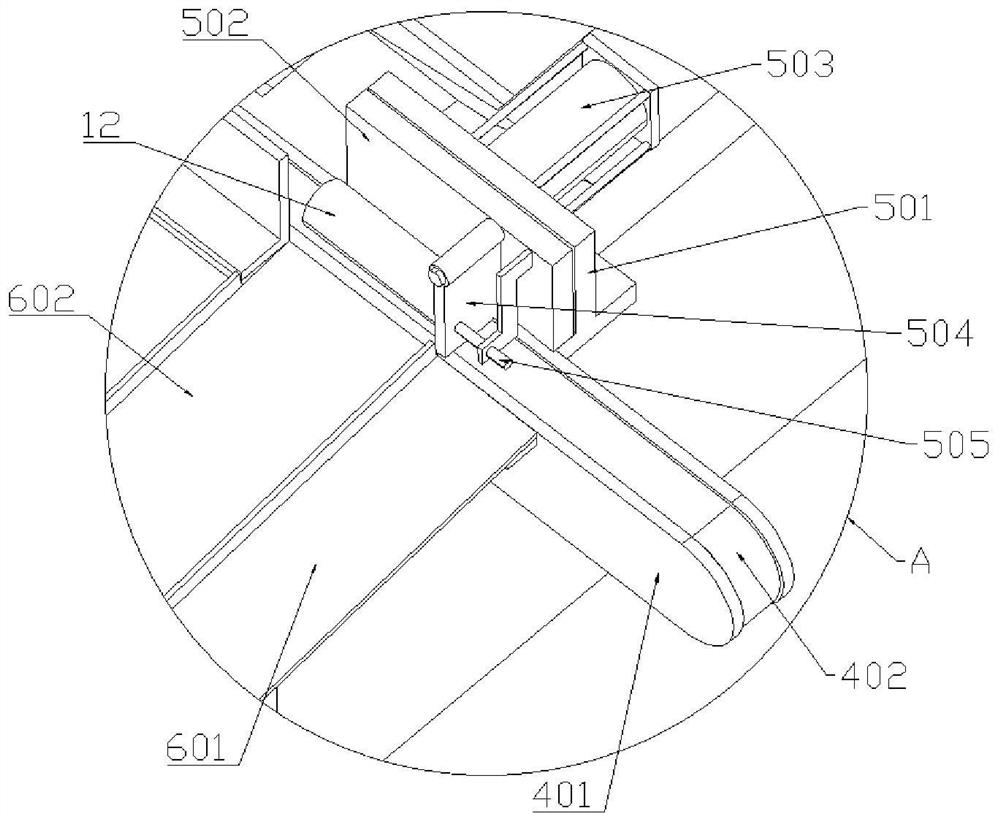

Full-automatic feeding device of heating furnace

PendingCN114739186AAvoid accumulationRealize fully automatic conveyingCharge manipulationIncreasing energy efficiencyIntermediate frequencyHeating furnace

The invention provides a heating furnace full-automatic feeding device which comprises an overturning hopper, a feeding bin and an intermediate frequency heating furnace, a supporting frame is arranged on one side of the feeding bin, the top end of the overturning hopper is rotationally connected with the top end of the supporting frame, and an overturning driving device is arranged between the overturning hopper and the supporting frame; a conveying device is arranged at the top end of the side, away from the overturning hopper, of the feeding bin, a plurality of jacking plates arranged in a stepped mode are arranged on the side, close to the conveying device, in the feeding bin, the bottom ends of the jacking plates are connected with a first jacking device, and a first pushing mechanism is installed at the top end of the conveying tail end of the conveying device. A blanking control table is arranged between the conveying device and a feeding port of the intermediate frequency heating furnace, the position of the blanking control table corresponds to the position of the first pushing mechanism, and a second pushing mechanism is arranged at the feeding port of the intermediate frequency heating furnace. Full-automatic conveying of the bars is achieved in the whole process, manpower is liberated, stability and safety of bar conveying are improved, orderly feeding of the bars is achieved, and production efficiency can be improved.

Owner:山东鲁联机械制造有限公司

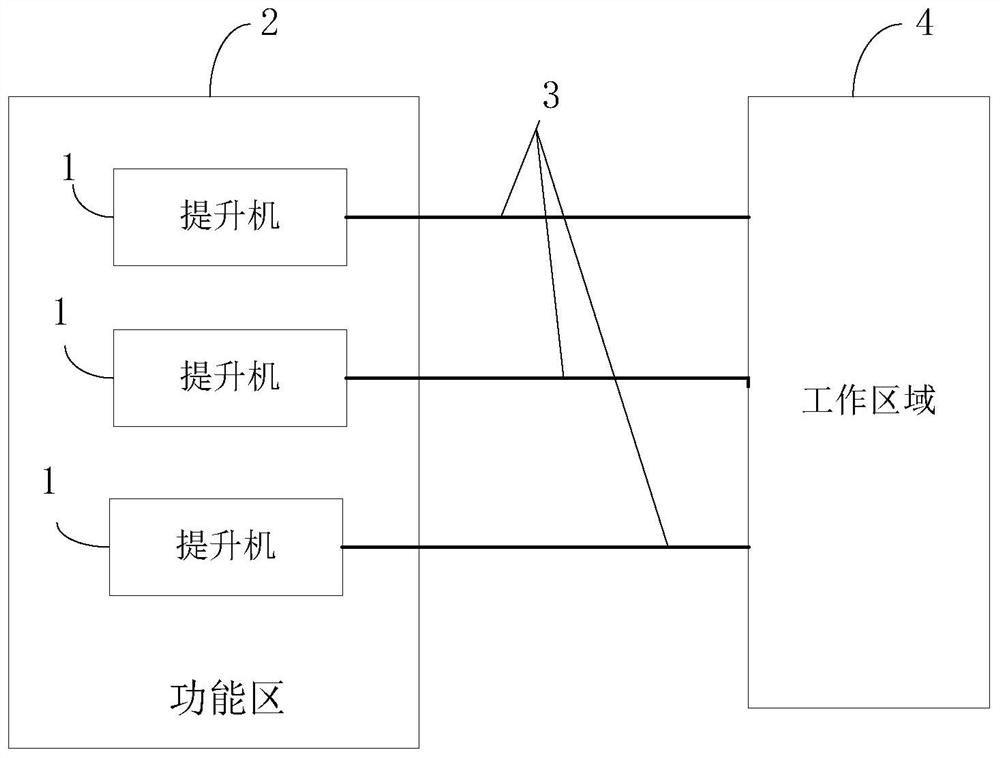

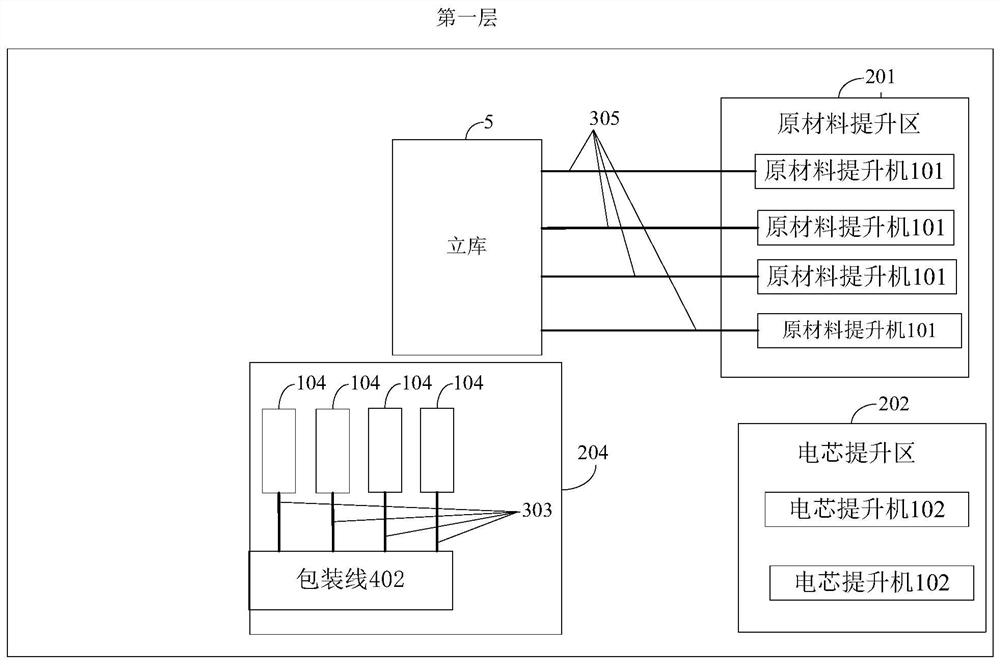

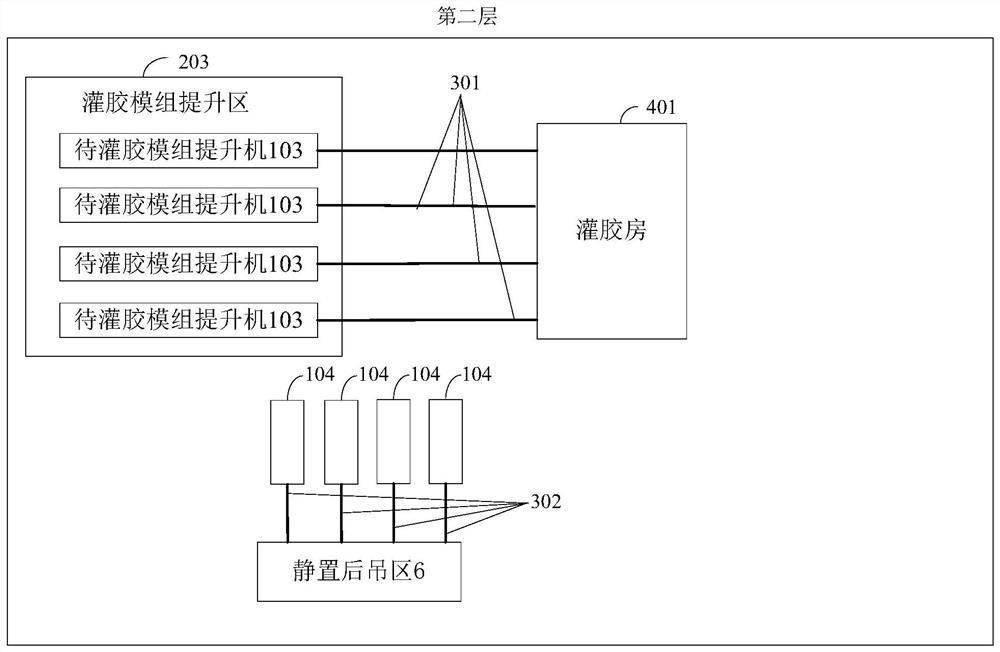

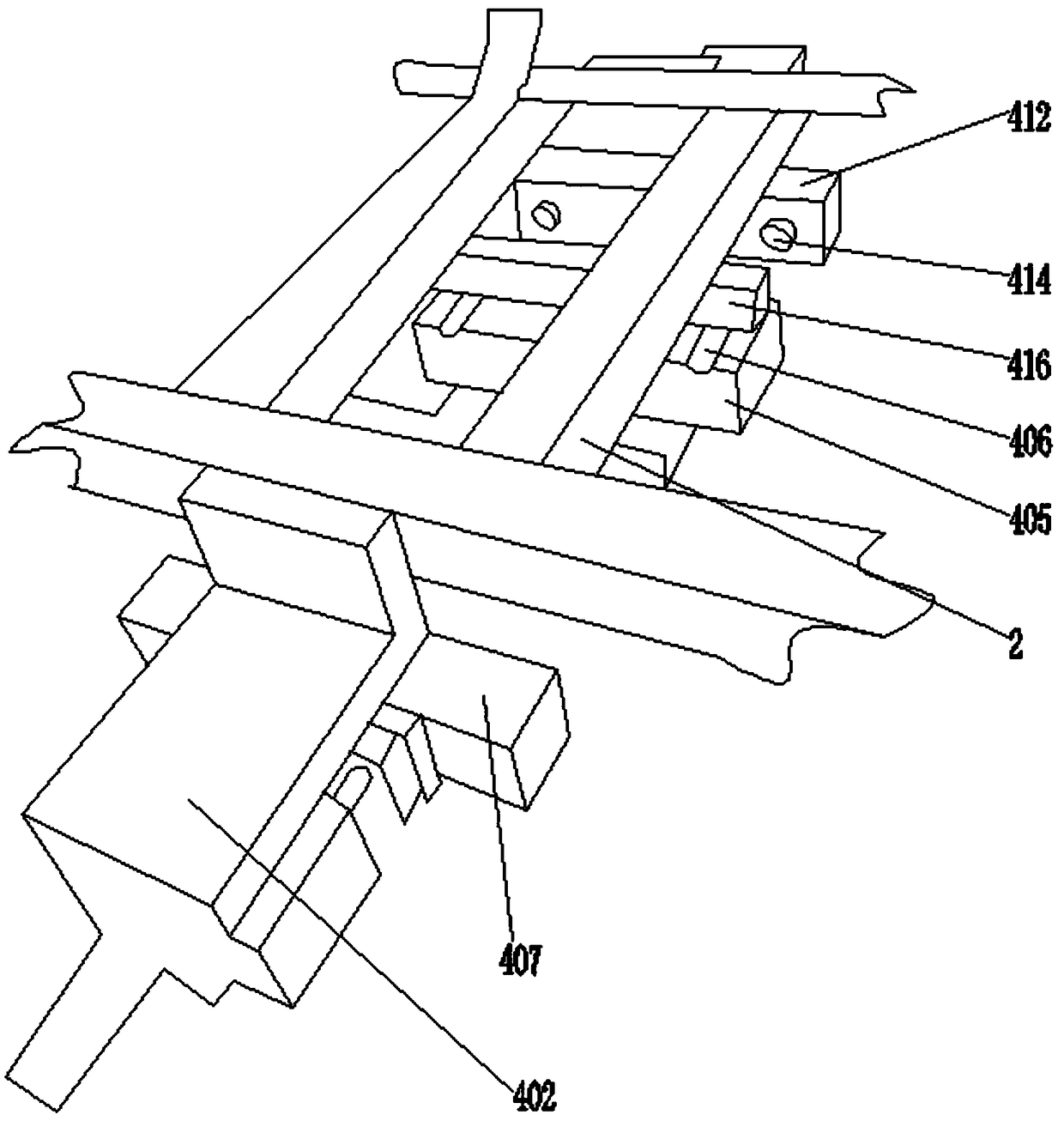

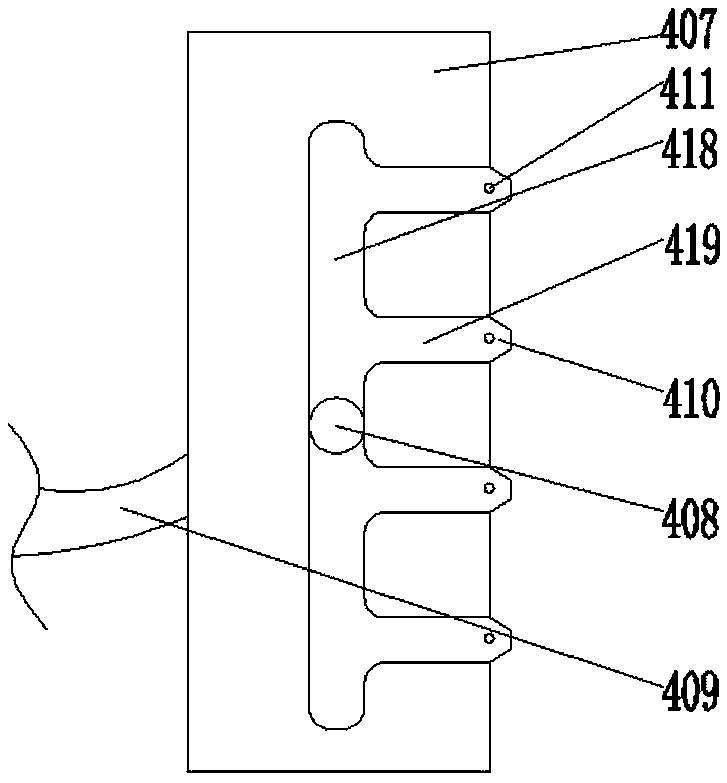

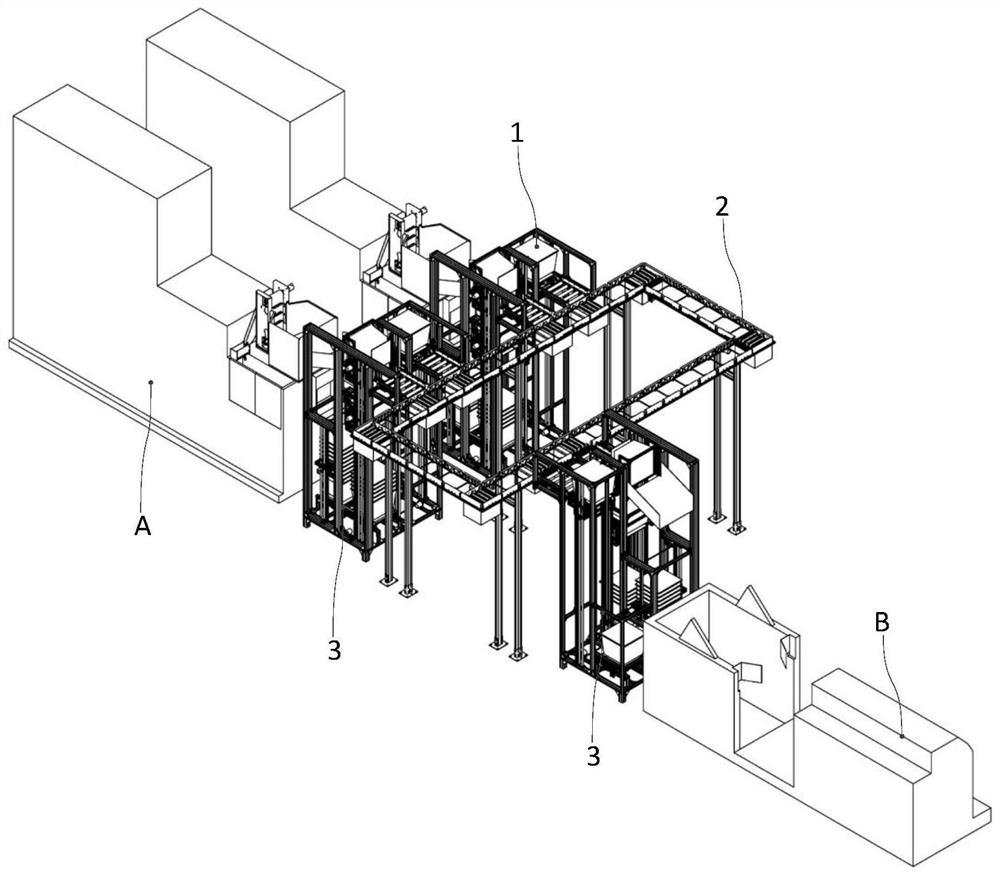

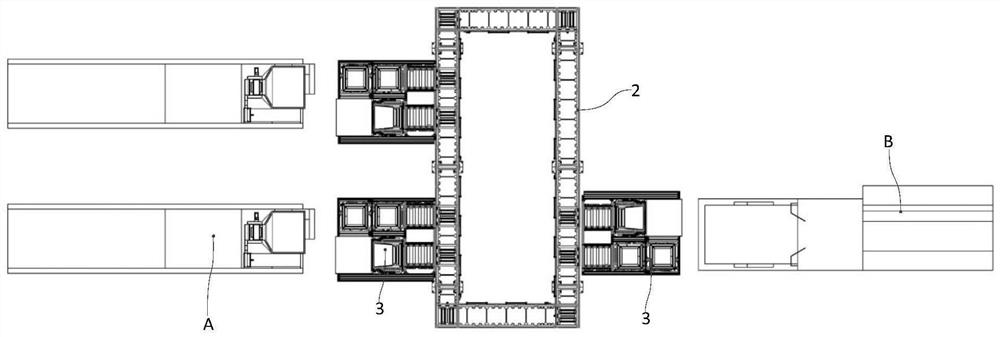

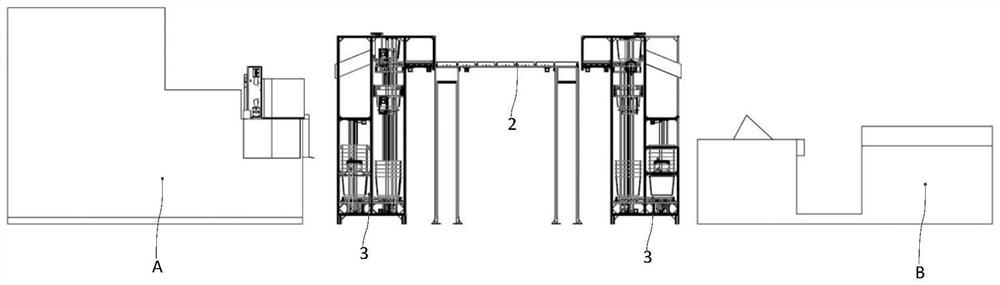

Air Logistics Transportation System

ActiveCN111703911BRealize fully automatic conveyingImprove space utilizationStorage devicesLogistics managementTransit system

The present invention provides an air logistics transportation system, comprising: a plurality of elevators; a plurality of functional areas, wherein each functional area is provided with a plurality of elevators, and the elevators are used to transport materials in the functional areas to a preset height ;Aerial logistics line, the air logistics line is set between the elevator and the working area to transport the materials output by the elevator to the corresponding work area; the controller is used to carry out the elevator and the air logistics line according to the material conveying instructions. control. The system adopts the air logistics line to transport materials, which can not only improve the space utilization rate, but also realize the automatic transportation of materials.

Owner:常州华数锦明智能装备技术研究院有限公司

Full-automatic serological pipette leakage detection equipment

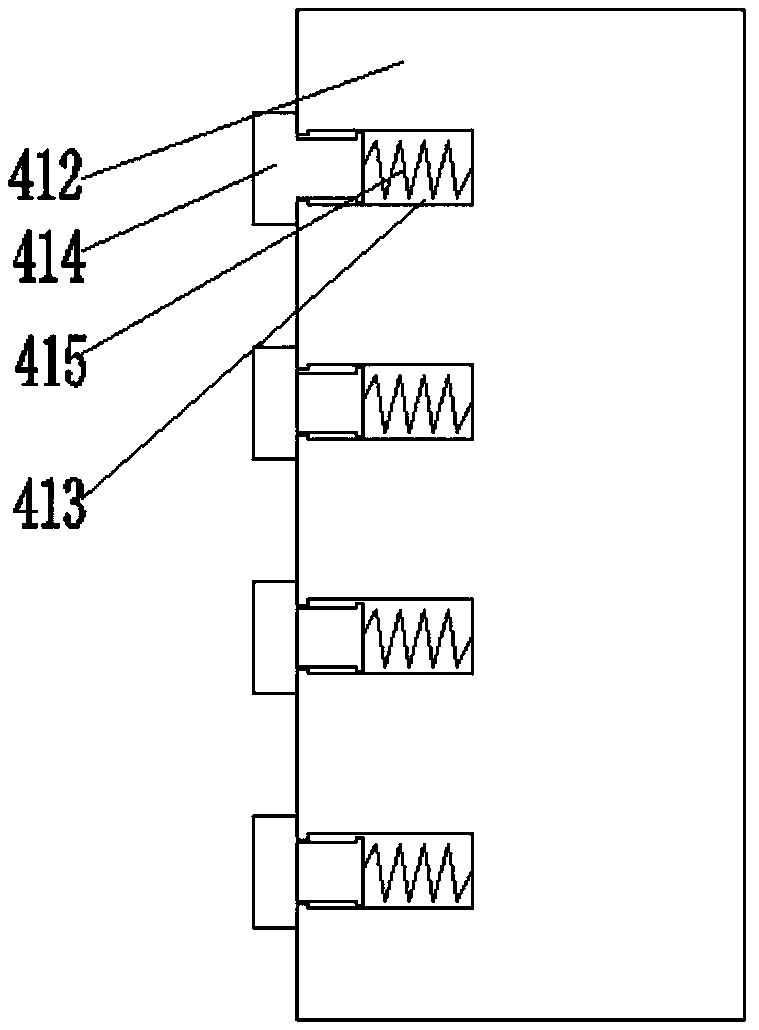

InactiveCN108855983ARealize fully automatic conveyingReduce manual labor intensitySortingPipetteBaseboard

The invention relates to the technical field of biomedical instruments, and particularly discloses full-automatic serological pipette leakage detection equipment. A wheel disc assembly comprises a gear disc and a positioning wheel disc, arc positioning grooves are formed in the positioning wheel disc, and positioning parts matched with the arc positioning grooves are arranged on a conveying chain;first adjustment springs are arranged in spaces among end caps and the bottoms of installation grooves; a feeding slide is defined by each two of a first vertical baffle and a plurality of second vertical baffles, a discharging slide is defined by a third vertical baffle and a fourth vertical baffle, and a baseboard which tilts to a discharging side from a feeding side is arranged between two side boards; sawtooth parts are arranged at positions, away from handle parts, on adjustment rods, sawteeth on the sawtooth parts are of stepwise rising structures, and one end of each adjustment block is of a conical structure matched with the corresponding sawteeth on the corresponding sawtooth part. The full-automatic serological pipette leakage detection equipment has the characters that detection consumption time is little, the automatic degree is high, the detection cost is low, loading is tidy, a material opening is not blocked, and the adaptability is good.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

Battery delivery system for charging and swapping stations

ActiveCN108001922BRealize fully automatic conveyingReduce transshipment costsStorage devicesConveyor partsElectrical batteryElectric cars

The invention belongs to the technical field of battery swapping for electric cars and particularly relates to a battery delivery system for a charging and battery swapping station. The battery delivery system comprises a double-layer transporting chain machine, a double-layer transferring chain machine and a lifting chain machine which are arranged sequentially; and a single-layer chain machine is arranged on the side surface of the double-layer transferring chain machine. According to the system, full-automatic delivery of batteries between cars to be subjected to battery swapping and a charging frame can be realized through cooperation of the double-layer transporting chain machine, the double-layer transferring chain machine and the lifting chain machine, the battery transporting delivery cost is reduced, and the battery transporting delivery efficiency is improved.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

An automatic stretching device and control method for silk stocking cuffs

ActiveCN104988665BRealize fully automatic conveyingRealize the clamping effectWork-feeding meansLinking machinesGear driveElectric machinery

Owner:ZHEJIANG SCI-TECH UNIV

Automatic seal device for Internet commodity packaging box

InactiveCN112428708ARealize fully automatic conveyingAvoid damageStampingElectric machineryThe Internet

The invention relates to the technical field of Internet commodity sales, and discloses an automatic seal device for an Internet commodity packaging box, which comprises a base, the upper end of the base is fixedly connected with a first support column, a second support column and a third support column separately, the upper end of the third support column is provided with a motor, the output endof the motor is provided with a driving lever, and a grooved wheel is arranged above the driving lever. According to the automatic seal device for the Internet commodity packaging box, a third connecting rod drives a sliding rod to overturn by 90 degrees in a reciprocating mode, a sliding block moves in a sliding groove of the sliding rod in a reciprocating mode and limits the sliding rod, and when the packaging box intermittently rotates to the left end of a roller along with the roller in a clamping groove, the packaging box is in a vertical state, at the moment, the sliding rod moves to a horizontal state and drives seal equipment to penetrate through a seal through hole to be pressed on the packaging box, so that seal is completed, and a spring in the seal equipment is compressed to prevent packaging box damage caused by excessive pressing.

Owner:广州威纵电子商务有限公司

Masking tape conveying mechanism for optical fibre and cable automatic cutting machine

PendingCN110254824ARealize fully automatic conveyingHigh speedWrapping material feeding apparatusMasking tapeEngineering

The invention provides a masking tape conveying mechanism for an optical fibre and cable automatic cutting machine. The masking tape conveying mechanism is used for masking tape conveying of the automatic cutting machine and comprises a sliding rail, a movable panel, a masking tape bracket, a masking tape disc, a rubber pressing roller, a screw rod module and an air gripper; the movable panel is arranged on the sliding rail, and the masking tape bracket and the screw rod module are fixed on the surface of the movable panel; the masking tape bracket is vertically arranged on the movable panel, the masking tape disc is clamped on one side of the masking tape bracket, the rubber pressing roller is arranged between the masking tape bracket and the screw rod module, masking tape can pass through the middle of the rubber pressing roller, the air gripper is arranged on a sliding block of the screw rod module, the bottom of an upper finger of the air gripper is provided with a cutter, the middle portion of a lower finger is provided with a groove, and the masking tape passes through the position between the fingers of the air gripper and is cut off. The masking tape conveying mechanism realizes the technical effect of automatically conveying the masking tape, reduces the processing cost, enables the masking tape transfer speed to be fast, enables the efficiency to be high, ensures automatic cutting of the masking tape in the conveying process, and is low in machining cost.

Owner:江苏光谷通信设备有限公司

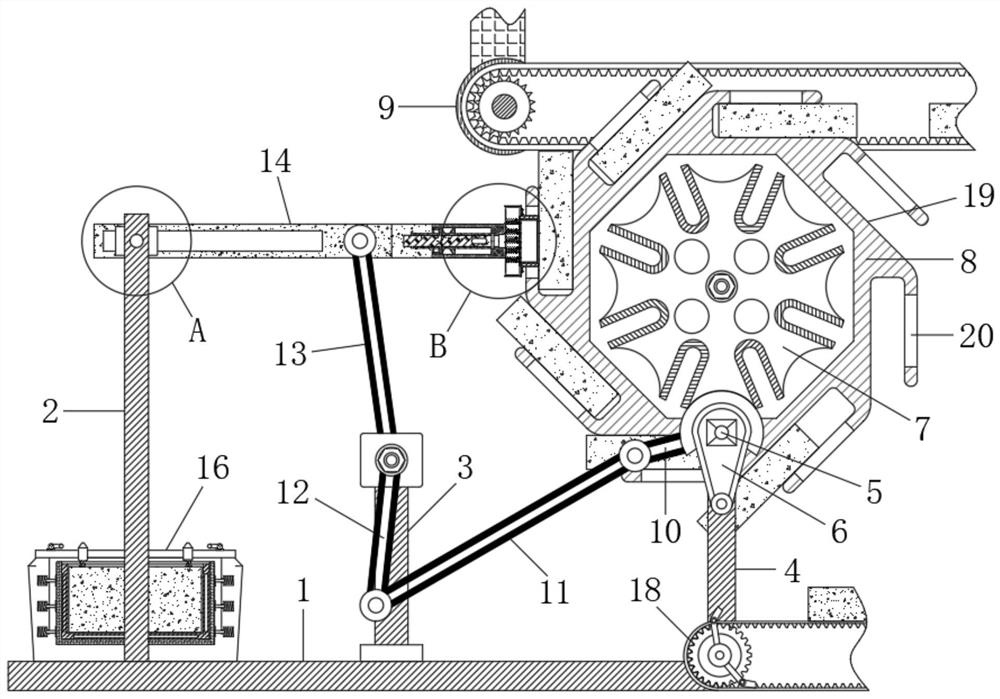

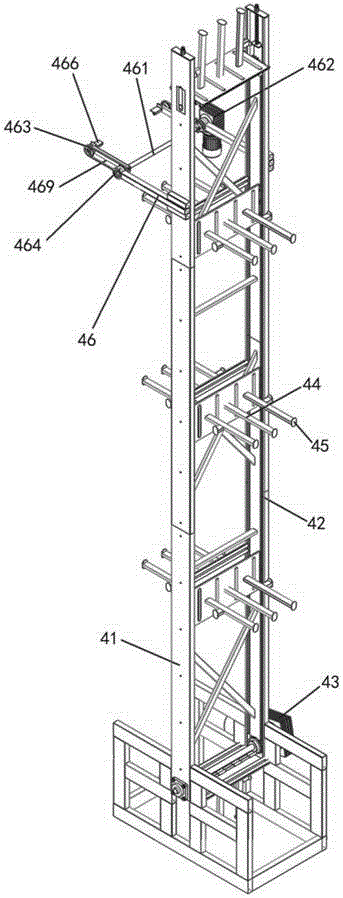

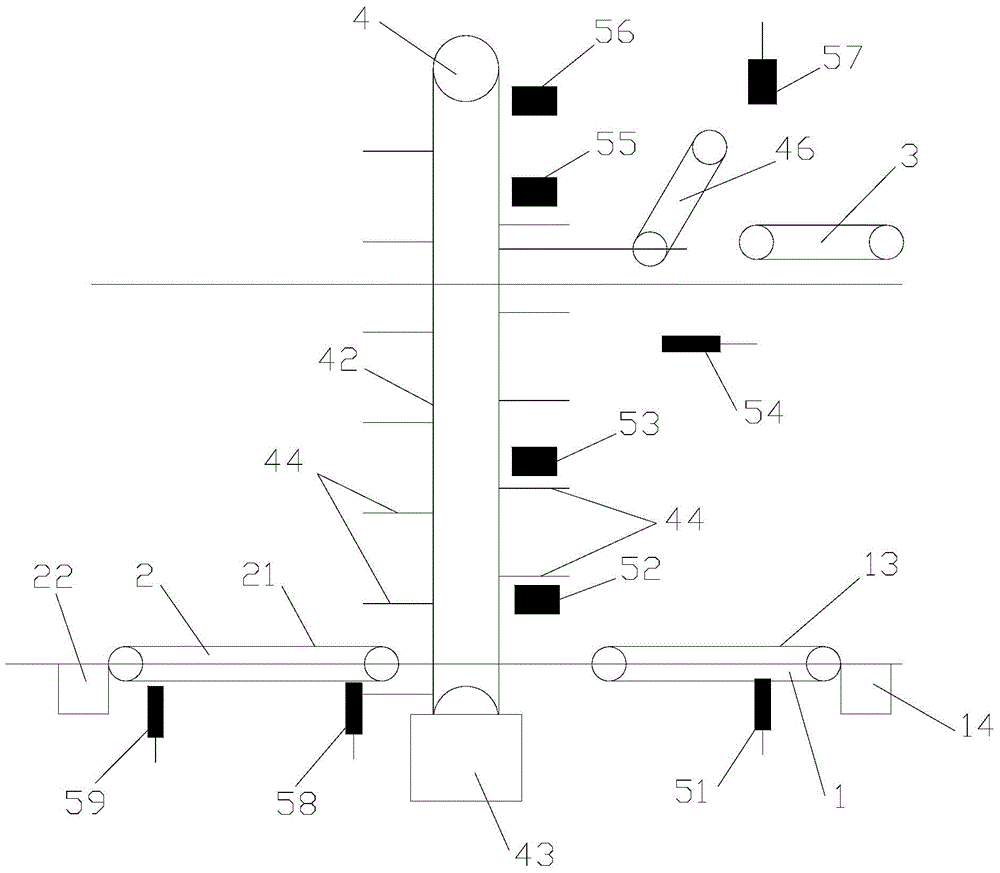

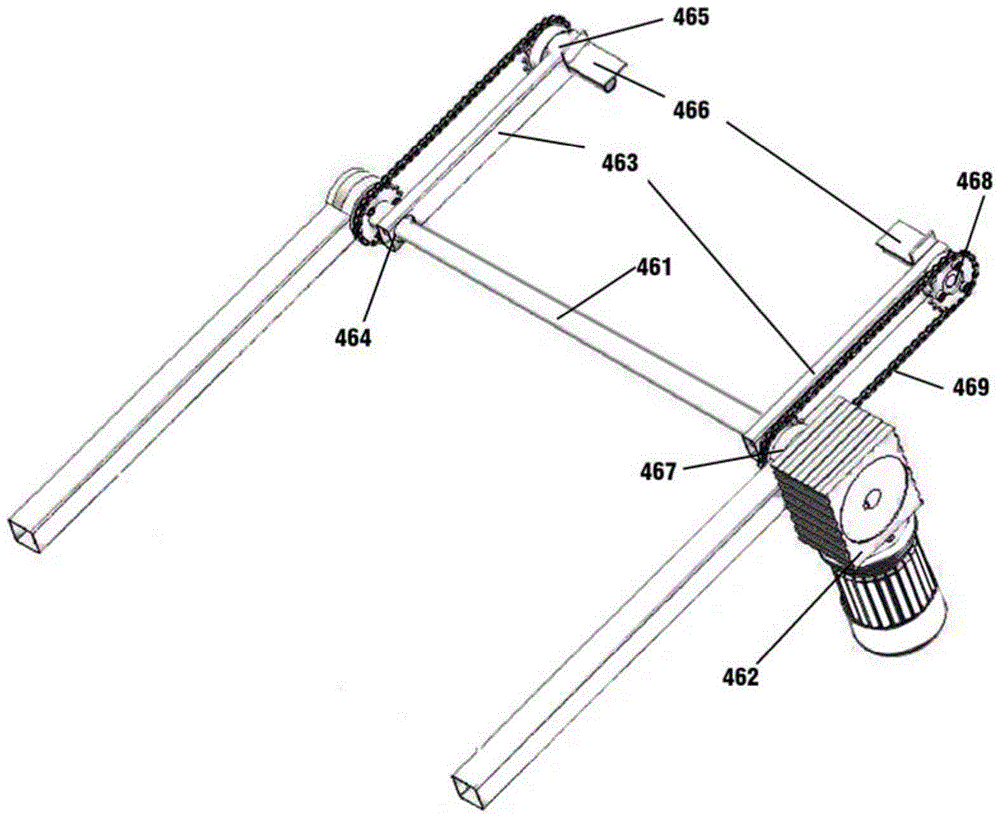

A fully automatic three-dimensional conveyor

ActiveCN104925483BRealize fully automatic conveyingSolve the problem that it is difficult to realize multi-floor dish deliveryControl devices for conveyorsMechanical conveyorsElectricityElectric machinery

The invention discloses a full-automatic stereoscopic conveyor which comprises a first transverse conveying mechanism, a longitudinal lifting mechanism and a sensing system. The first transverse conveying mechanism is used for horizontally conveying articles. The longitudinal lifting mechanism is used for lifting the articles to needed height. The sensing system is used for achieving full-automatic forwarding of the articles, and comprises a first sensor on a first synchronous belt, a second sensor and a third sensor. The second sensor is arranged on a rack, and is electrically connected with the first sensor and used for controlling a first motor to be started. The third sensor is arranged above the second sensor and used for controlling the first motor to be stopped. The mode that the sensors are adopted to control multiple sets of driving motors is adopted, and the automation degree is high. Meanwhile, the full-automatic stereoscopic conveyor is quite good in stability, service plates are always kept horizontal in the whole process from a kitchen to a dining room, and even though the service plates bear soup dishes, splashing can be avoided. The full-automatic stereoscopic conveyor is simple in structure, safe, practical and high in reliability.

Owner:黄山鼎奇链传动股份有限公司

Alternate type material box conveying device

InactiveCN112660776ARealize alternate conveyingRealize fully automatic conveyingControl devices for conveyorsStructural engineeringTransfer mechanism

The invention discloses an alternate type material box conveying device. The device comprises a first conveying mechanism, a second conveying mechanism and a third conveying mechanism, the second conveying mechanism and the third conveying mechanism are arranged at the tail end of the first conveying mechanism, a transfer mechanism is arranged at an outlet of the first conveying mechanism, the first conveying mechanism comprises a first conveying rail mounted on a first conveying pipe frame, the second conveying mechanism comprises a second conveying rail mounted on a second conveying pipe frame, and a second triggering assembly is arranged in the second conveying pipe frame; the third conveying mechanism comprises a third conveying rail mounted on a third conveying pipe frame, and a third triggering assembly is arranged in the third conveying pipe frame; the transfer mechanism comprises a transfer rail mounted on a transfer pipe frame, a transfer triggering assembly is arranged in the transfer pipe frame, and the second triggering assembly and the third triggering assembly are both in linkage with the transfer triggering assembly. A mechanical linkage structure is adopted, alternate transfer of material boxes is achieved, and full-automatic conveying is achieved.

Owner:YANGZHOU POLYTECHNIC INST

Engine cylinder liner pressing machine

ActiveCN103481053BRealize fully automatic feedingRealize fully automatic conveyingMetal working apparatusCarrying capacityEngineering

The invention discloses an engine cylinder liner press and belongs to the field of machinery. The engine cylinder liner press comprises a base, a top seat, a rear pillar, a front pillar, a cylinder liner feeding mechanism, a cylinder feeding mechanism, a cylinder liner head pressing device and a positioning and carrying device. The front of the base is connected with the front of the top seat through the front pillar. The rear portion of the base is connected with the rear portion of the top seat through the rear pillar, the cylinder liner head pressing device is arranged below the top seat and fixedly connected with the same. The cylinder liner feeding mechanism is mounted on the inner side of the rear pillar. The feeding portion of a cylinder liner feeder in the cylinder liner feeding mechanism is arranged right below the cylinder liner head pressing device. The cylinder feeding mechanism and the positioning and carrying device are arranged on the base. Full-automatic feeding of cylinder liners and cylinders is realized, and high-precision automatic positioning and high carrying capacity of the cylinders can be achieved.

Owner:金湖县项目服务中心

contact system

ActiveCN112340411BHigh degree of automationSave spaceMetal working apparatusConveyor partsYarnWinding machine

The invention relates to a spinning system, which includes a track conveying system, a lifting system, and a yarn basket; the track conveying system includes a linear conveying track, and an orthogonal steering mechanism; several of the linear conveying tracks are cross-connected to form a ring spinning machine group and a spinning frame. The track conveying channel between the bobbin machine groups; the lifting system is installed on the spinning frame or winding machine station, and a docking platform is arranged above the lifting system, and the docking platform is connected with the track conveying channel; The yarn basket is provided with an identity identification device; the bottom of the yarn basket is provided with a roller driving plane, and the top of the yarn basket is provided with a holding basket top; the track conveying system and the lifting system are provided with a number of yarn basket identity reading devices. The device also includes a control system, the control system reads the yarn basket through the yarn basket identity reading device, and transports the yarn basket to a designated lifting system segment by segment. The present invention reforms the existing spinning workshop, and the overall automation degree of the equipment is high.

Owner:LUTAI TEXTILE +1

Serum pipette full-automatic leakage measuring and dust removing integration mechanism

InactiveCN108787492ARealize fully automatic conveyingReduce manual labor intensityMeasurement of fluid loss/gain rateHollow article cleaningPipetteEngineering

The invention relates to the technical field of biomedical equipment, and in particular, discloses a serum pipette full-automatic leakage measuring and dust removing integration mechanism. The mechanism comprises a conveying device, a leakage measuring device, an eliminating device and a dust removing device; the conveying device comprises a conveying chain, a gear disc and a positioning wheel disc; the positioning wheel disc is provided with an arc positioning groove; the conveying chain is provided with a positioning part; the leakage measuring device comprises a first lifting cylinder, a first pushing cylinder and a second pushing block; the eliminating device comprises a second lifting cylinder, a third pushing cylinder and an L-shaped pushing block; the surface of the lower part of the L-shaped pushing block is of a waveform structure; a semispherical projection is arranged at the side part of the L-shaped pushing block; the dust removing device comprises a third lifting cylinder,a fourth pushing cylinder and a third support groove; the bottom of the third support groove is of an arc structure; and two side walls of the third support groove are of flaring structures. The mechanism has the characteristics of shorter detecting time, capability of directly screening out unqualified products, capability of removing fine-particle dust and impurities and lower detecting cost.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

Serum transfer pipette side leakage and removal integrated device

ActiveCN108745948ARealize fully automatic conveyingReduce manual labor intensityHollow article cleaningSortingPipetteEngineering

The invention relates to the technical field of biomedical instruments, and particularly discloses a serum transfer pipette side leakage and removal integrated device. The serum transfer pipette sideleakage and removal integrated device comprises a conveying device, a side leakage device and a removal device. The conveying device comprises a conveying chain, a gear disc and a positioning wheel disc. The positioning wheel disc is provided with an arc positioning groove, and the conveying chain is provided with a positioning part. The side leakage device comprises a first lifting air cylinder,a first pushing air cylinder, a second pushing air cylinder and a first supporting block. A second pushing block is provided with plugs. The removal device comprises a second lifting air cylinder, a third pushing air cylinder and a second supporting block, the second supporting block is provided with a second supporting groove, and a plurality of pin rollers are arranged in the second supporting groove. The third pushing air cylinder is provided with an L-shaped push block, the surface of the lower portion of the L-shaped push block is of a wavy structure, and hemispherical protrusions are arranged at the side portion of the L-shaped push block. The serum transfer pipette side leakage and removal integrated device has the beneficial effects that the detection consumed time is short, disqualified products can be directly screened, the automation degree is high, and the detection cost is low.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com