Alternate type material box conveying device

A conveying device, alternating technology, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient turning and transportation, reduce production efficiency, affect the automatic production level of the production line, etc., to achieve fully automatic Delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

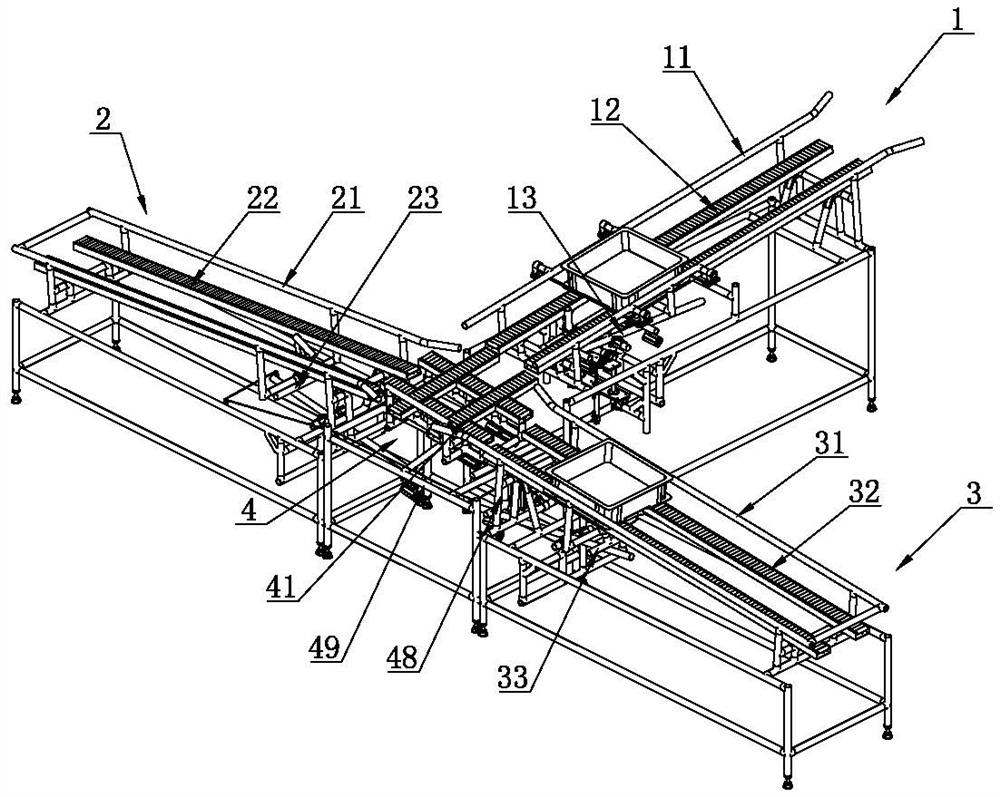

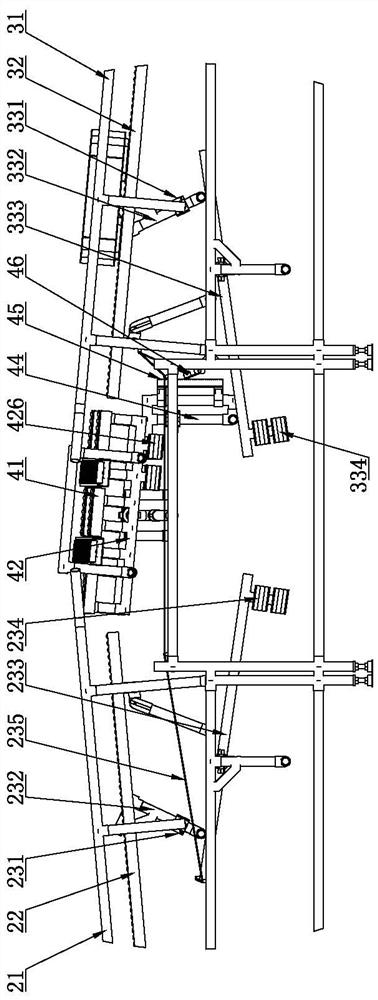

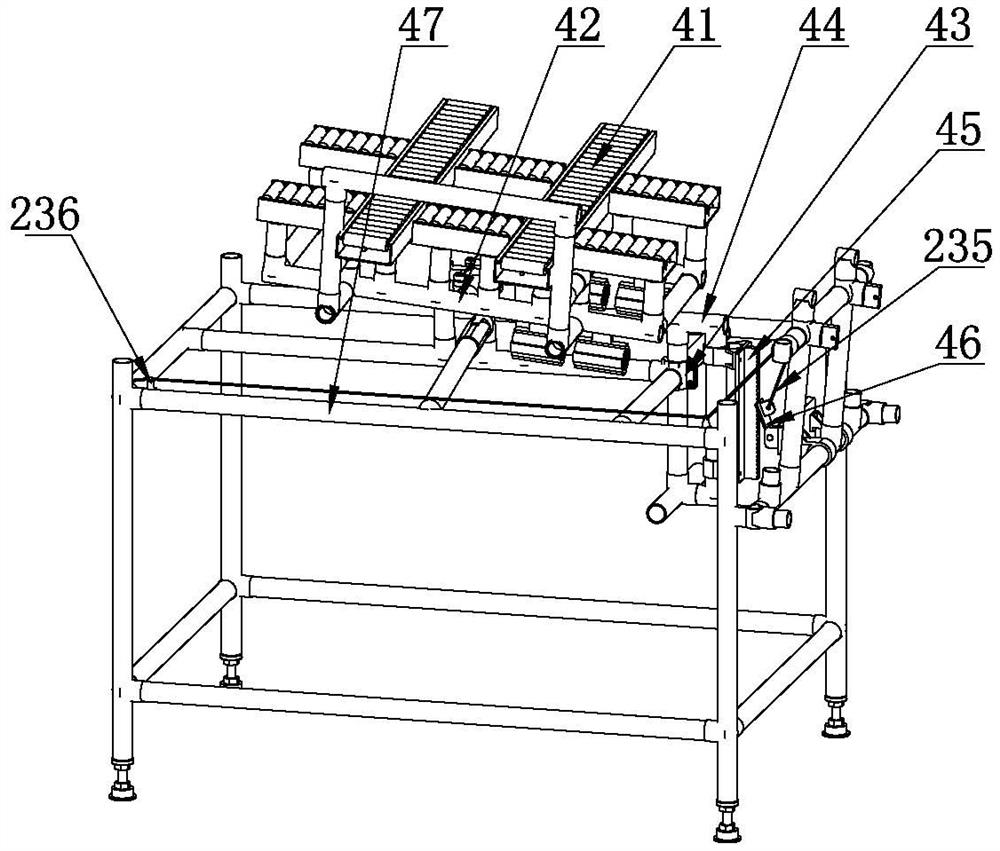

[0022] like Figure 1-6 A kind of alternate material box conveying device shown, comprises the first conveying mechanism 1, the second conveying mechanism 2 and the third conveying mechanism 3, the second conveying mechanism 2 and the third conveying mechanism 3 are arranged on the first conveying mechanism 1 At the end, and the phase of the second conveying mechanism 2 and the third conveying mechanism 3 is perpendicular to the first conveying mechanism 1, a transfer mechanism 4 is arranged at the exit of the first conveying mechanism 1, and the transfer mechanism 4 is used to send the first conveying mechanism 1 The material box of the material box is alternately sent into the second conveying mechanism 2 and the third conveying mechanism 3, the inlet of the transfer mechanism 4 is connected to the outlet of the first conveying mechanism 1, and the two outlets of the transfer mechanism 4 are respectively connected to the inlet of the second conveying mechanism 2 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com