Three-dimensional printer single-motor extrusion system capable of actively switching printing head

A three-dimensional printer, active switching technology, applied in the coating device, additive processing, etc., can solve the problems that the nozzle affects the surface quality of the model, the difficulty of leveling the print head, and the printed model that is easy to scratch, so as to prevent heat. Effects of uploading, improving printing accuracy and surface quality, and accelerating cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

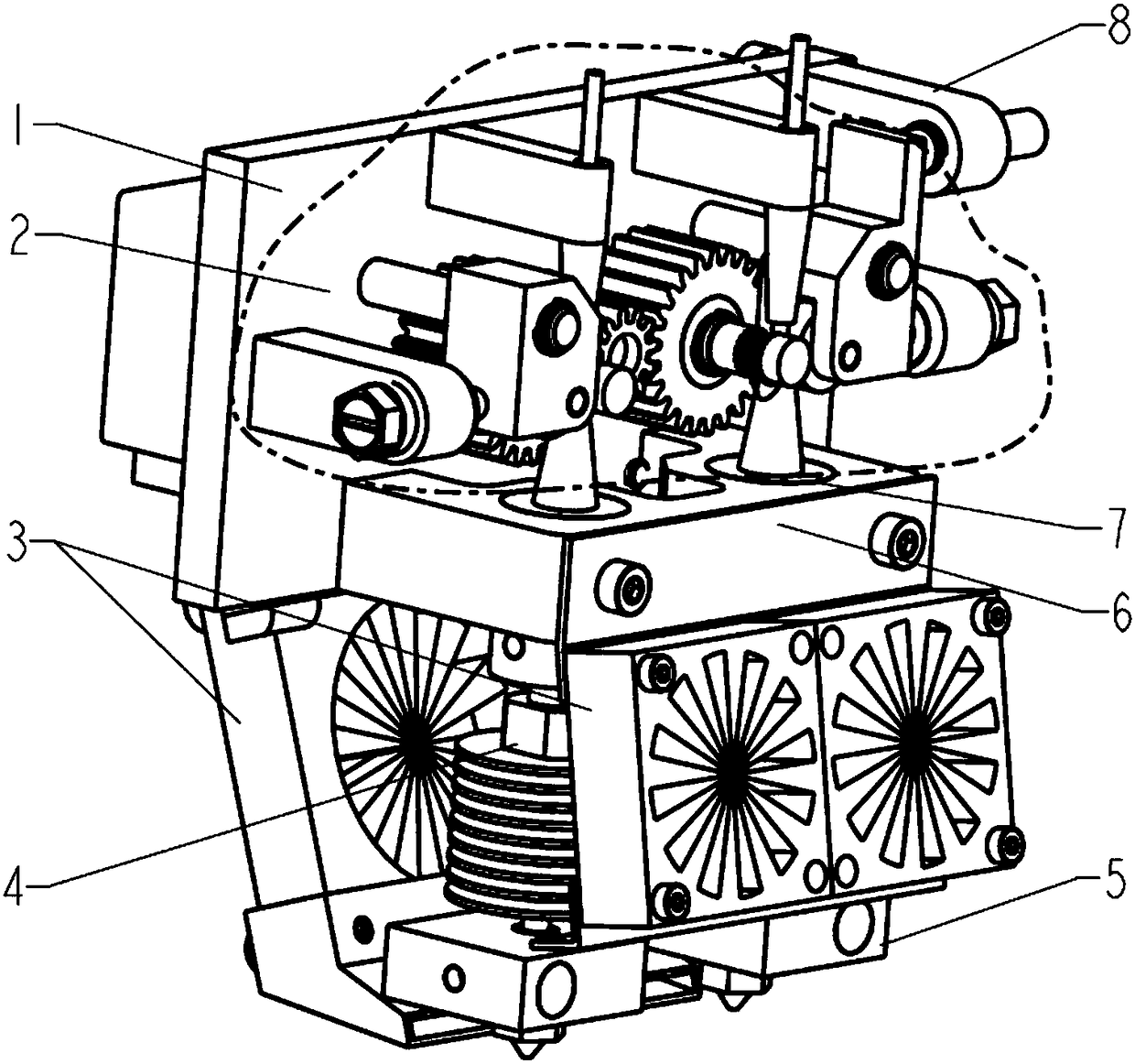

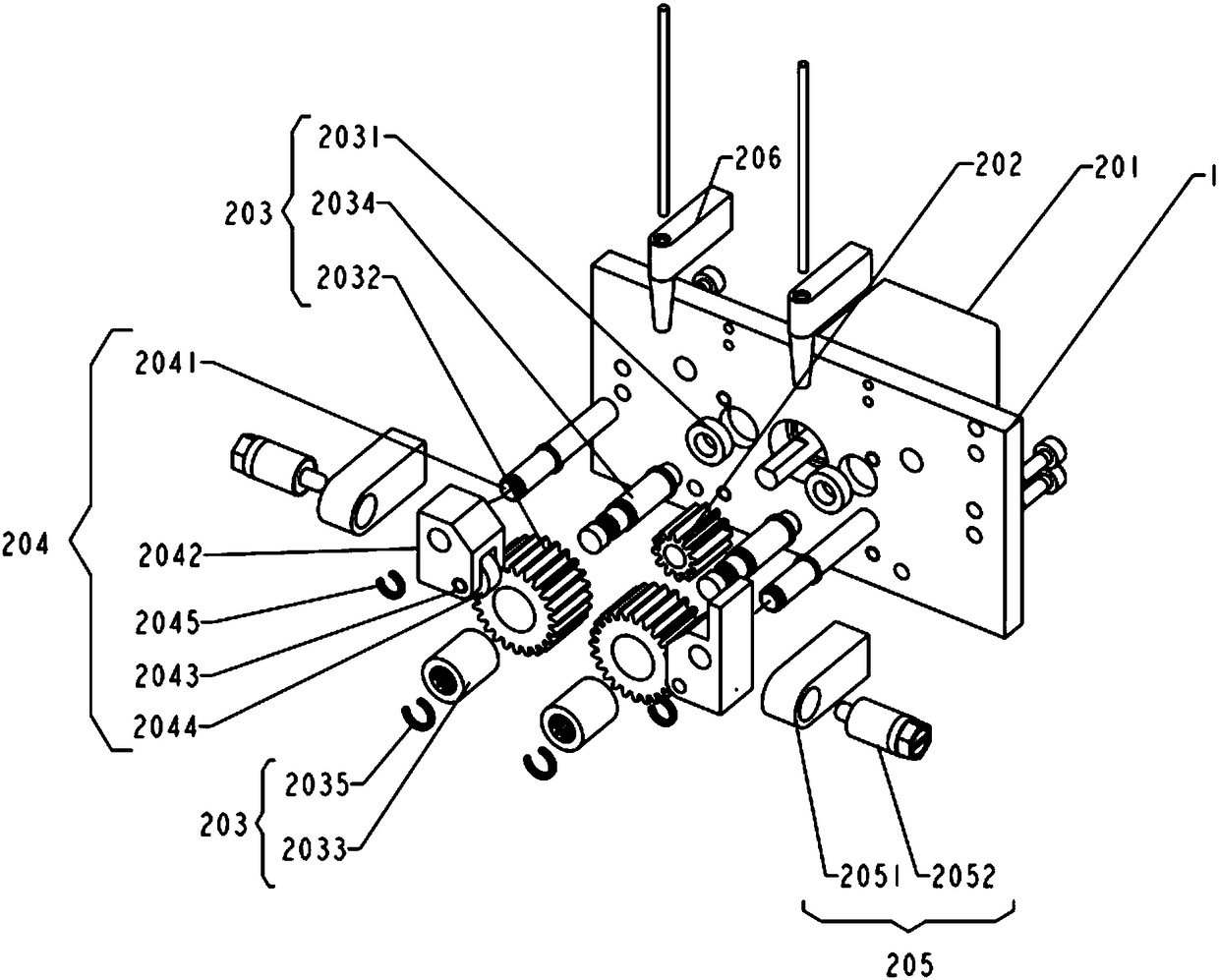

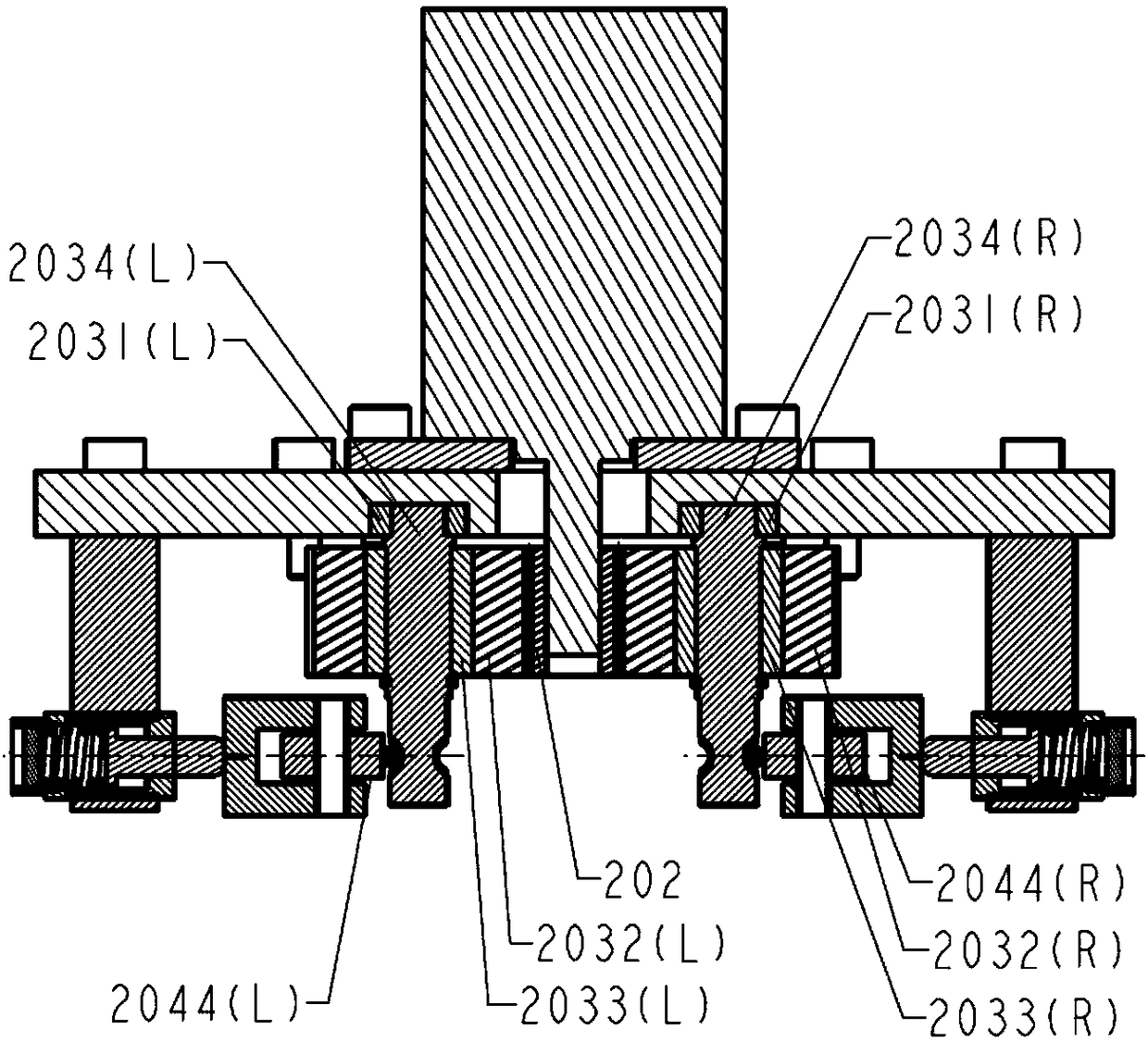

[0040] Such as figure 1 As shown, a 3D printer single-motor extrusion system that can actively switch print heads includes a substrate 1, a feeding assembly 2 installed on the substrate 1, an air cooling device 3, a print head fixing seat 6, and a switching auxiliary device 8. The fixed print head 4 and the movable print head 5 on the print head fixing seat 6 , and the switching mechanism 7 nested inside the movable print head 5 . The extrusion system continuously pushes the filament to the fixed print head 4 or the movable print head 5 through the feeding component 2 to melt and extrude, and the height of the movable print head 5 is switched through the switching mechanism 7 and the switching auxiliary device 8 to realize fixed p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com