Patents

Literature

71results about How to "Reduced driving force requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

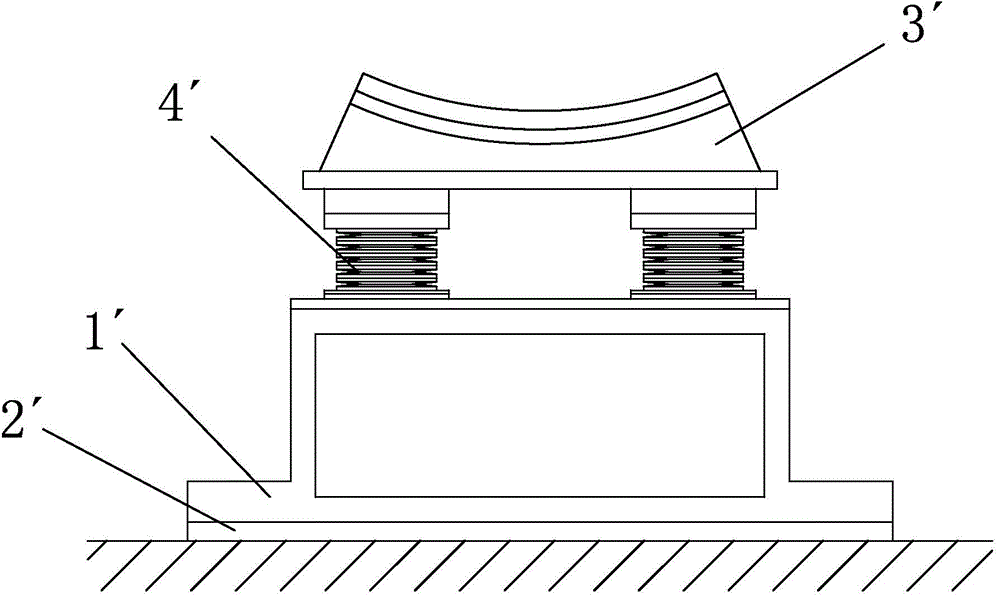

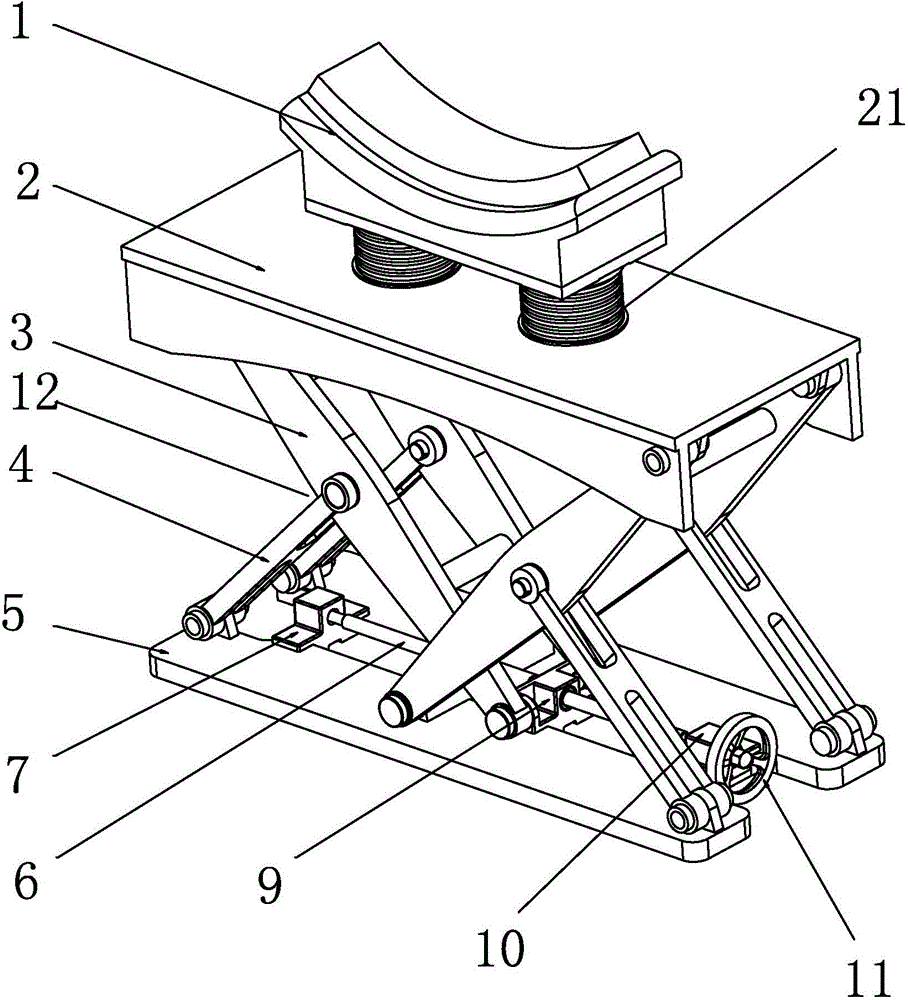

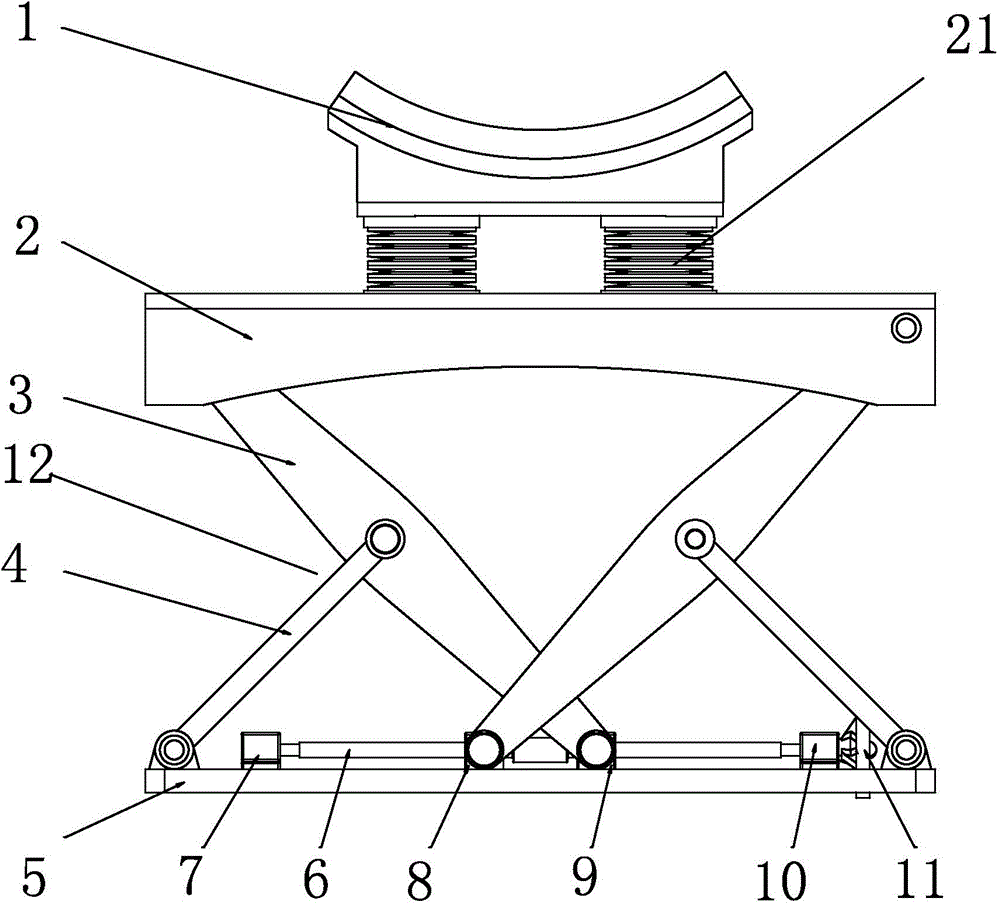

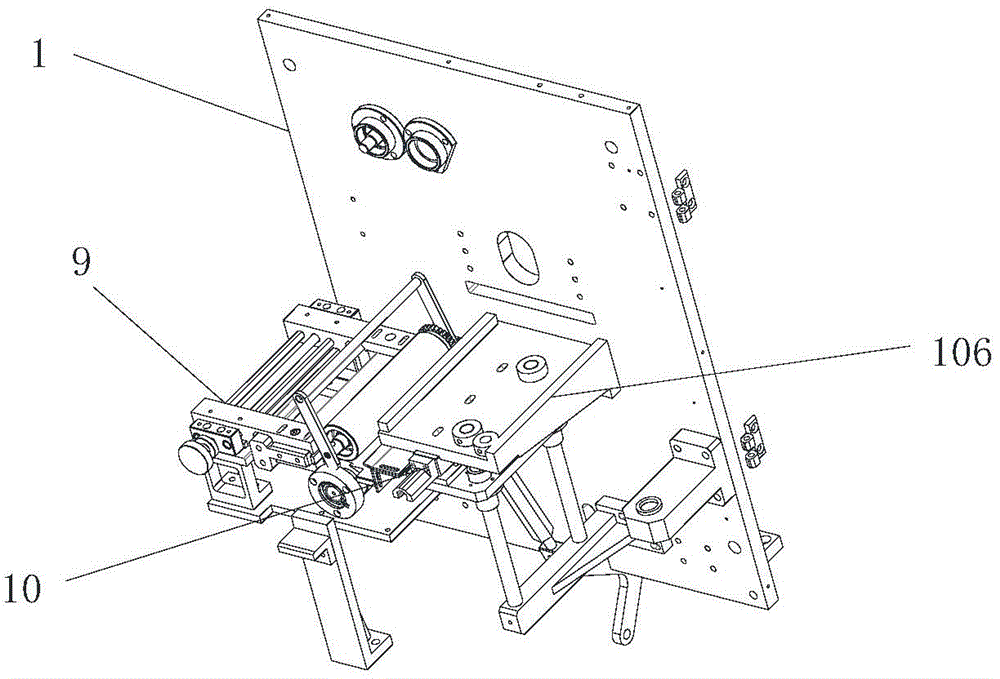

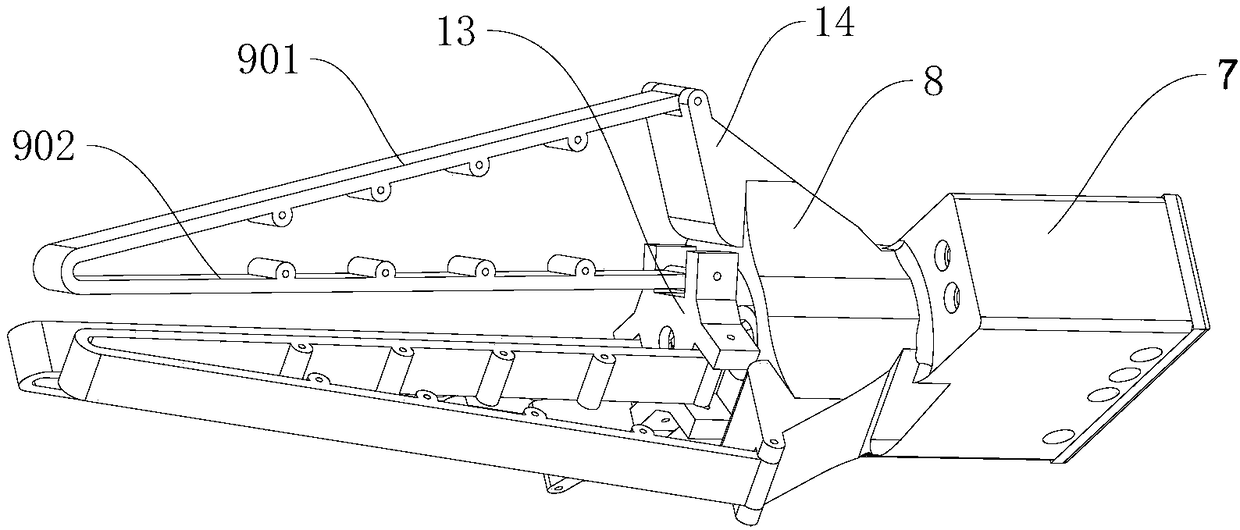

Scissors fork lifting type auxiliary supporting mechanism capable of being locked at random position

InactiveCN104944315AThe overall structure is simple and reliableSave spaceLifting framesEngineeringSpace requirements

The invention relates to a scissors fork lifting type auxiliary supporting mechanism capable of being locked at a random position. The scissors fork lifting type auxiliary supporting mechanism comprises a bracket and a top plate below the bracket. The bracket is fixedly connected with the top plate through two disc springs, a base plate is positioned below the top plate, a screw is horizontally arranged in the length direction of the base plate, a hand wheel is installed on the outer side of one end of the screw, and the middle of the screw is in threaded connection with a first sliding block and a second sliding block which are arranged at intervals. When the hand wheel is rotated, the first sliding block and the second sliding block can perform opposite-direction movements in the axial direction of the screw, four groups of linkage mechanisms are further arranged between the top plate and the base plate, the upper ends of the linkage mechanisms are hinged to the top plate, the lower ends of the linkage mechanisms are hinged to the first sliding block and the second sliding block respectively, and the first sliding block and the second sliding block can drive each group of linkage mechanisms to perform lifting movements when moving. The supporting mechanism can reliably support a product and have a large displacement lifting function, can perform fine adjustment of the vertical position, can be reliably locked at the random position, is small in vertical dimension and meets the installing space requirements.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

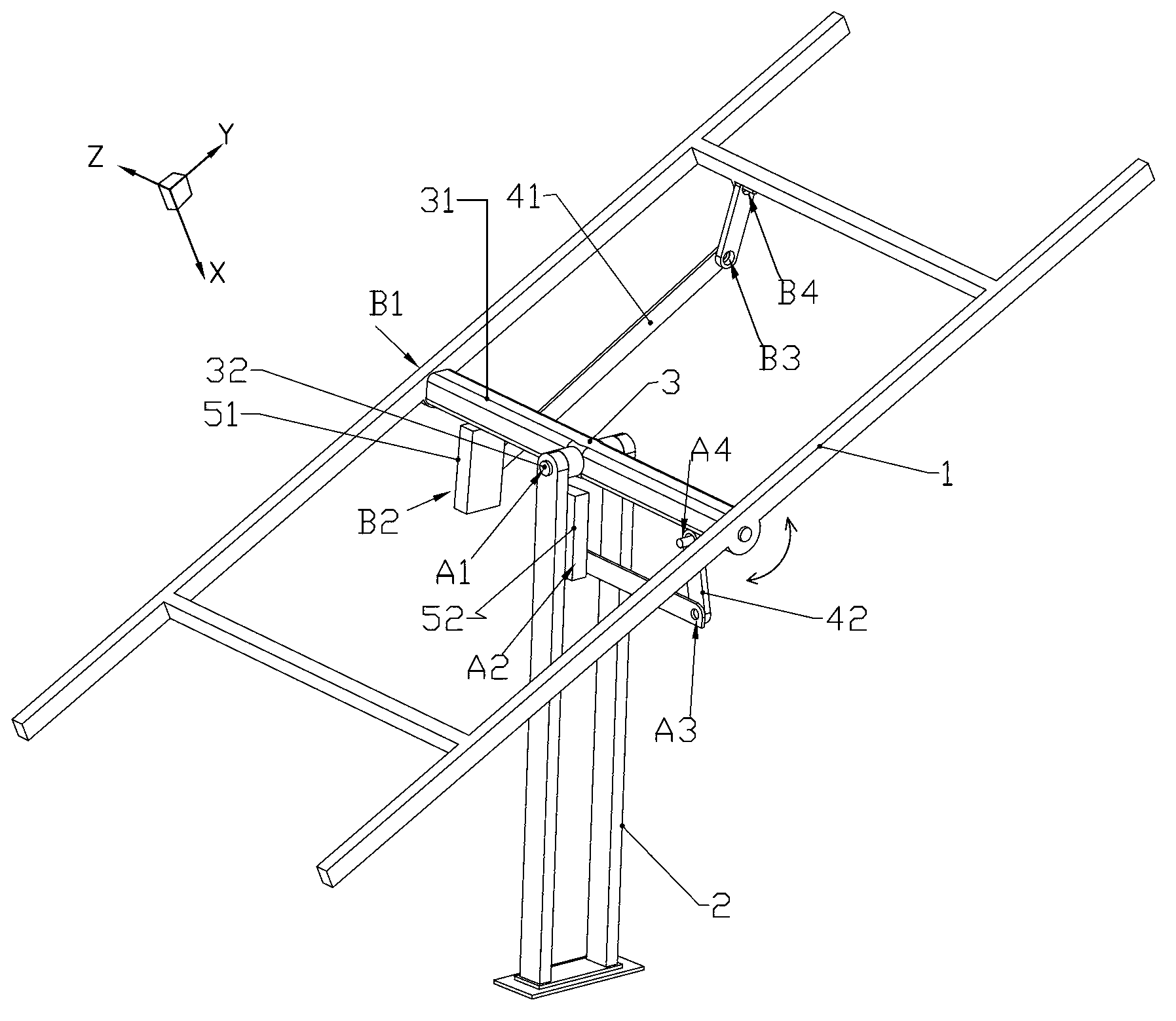

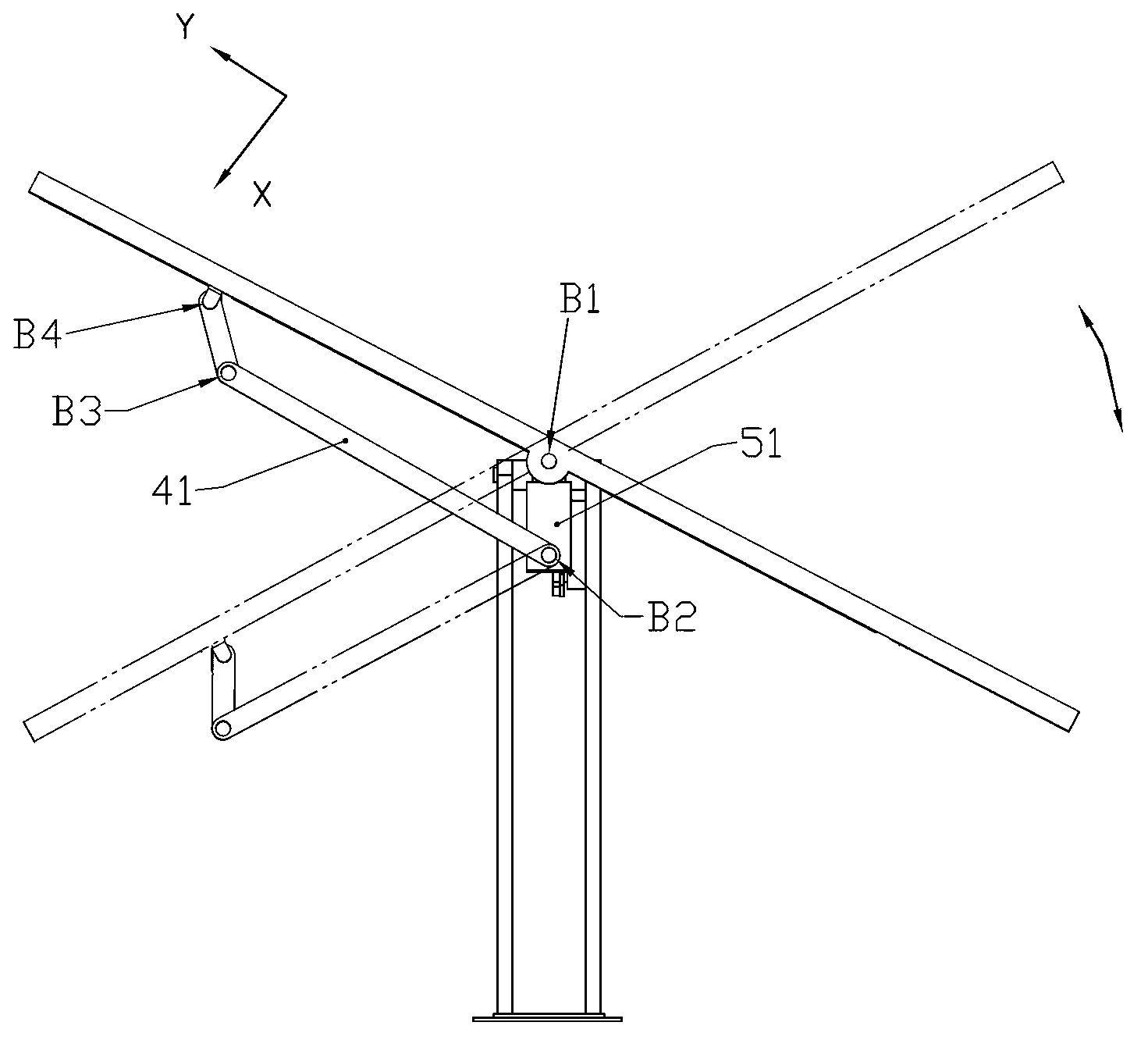

Double-shaft tracking support

ActiveCN103324204AReduce the burden onReal-time changePhotovoltaic supportsSolar heating energyTurn angleElevation angle

The invention discloses a double-shaft tracking support. The double-shaft tracking support comprises a bracket, a stand column, a center pivotal shaft, a turn angle adjusting device and an elevation angle adjusting device which are all used for bearing a solar component. The bracket is connected with the stand column through the center pivotal shaft, a turn angle pivotal shaft of the center pivotal shaft is hinged to the bracket so that the bracket can rotate in the turn angle direction, and an elevation angle pivotal shaft of the center pivotal shaft is hinged to the stand column so that the bracket can rotate in the elevation angle direction. The turn angle adjusting device comprises a first transmission part and a first driving part, wherein the first transmission part is connected to the bracket, and the first driving part is mounted on the turn angle pivotal shaft and is matched with the first transmission part. The elevation angle adjusting device comprises a second transmission part and a second driving part, wherein the second transmission part is connected to the elevation angle pivotal shaft or the bracket, and the second driving part is mounted on the stand column and is matched with the second transmission part. The double-shaft tracking support has the advantages of being firm in structure, low in cost, low in power consumption, stable in operation, convenient to install, transport and maintain daily and the like.

Owner:刘建中

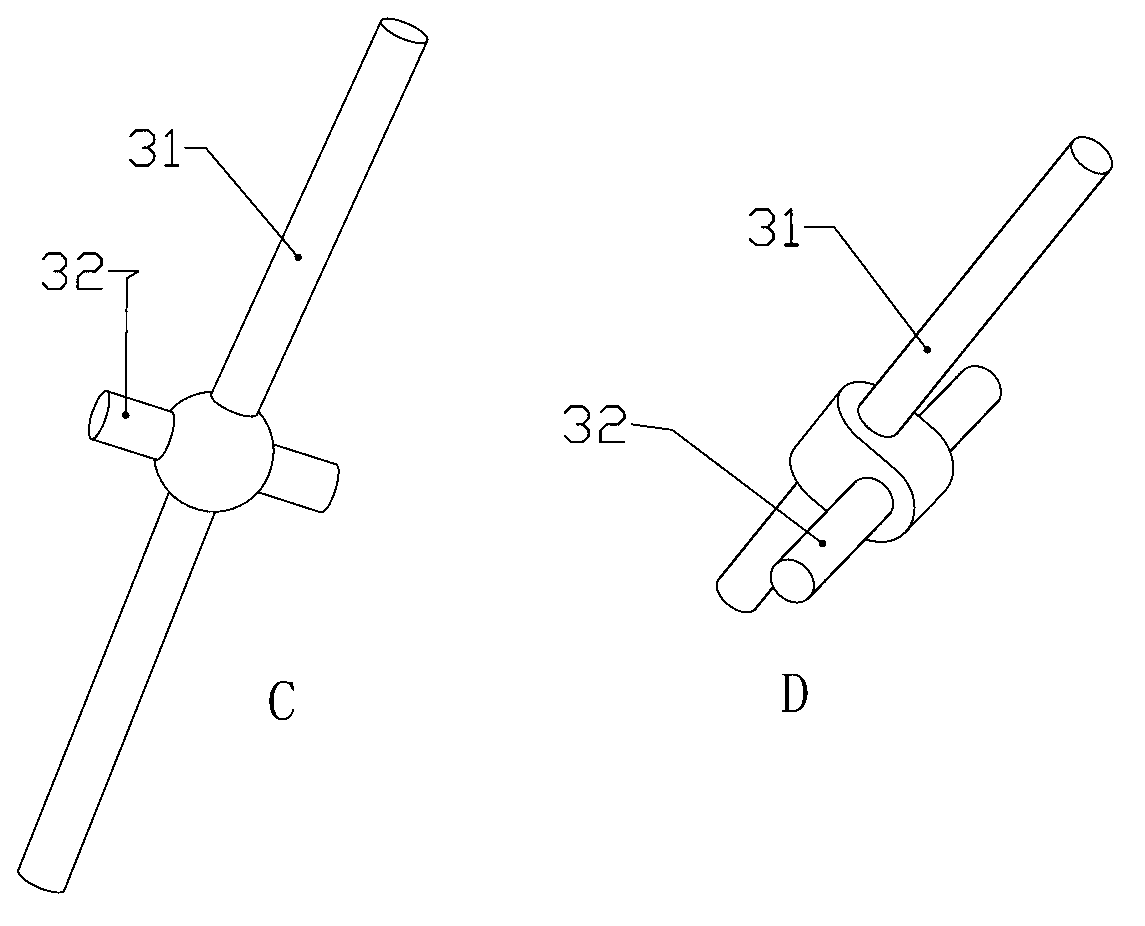

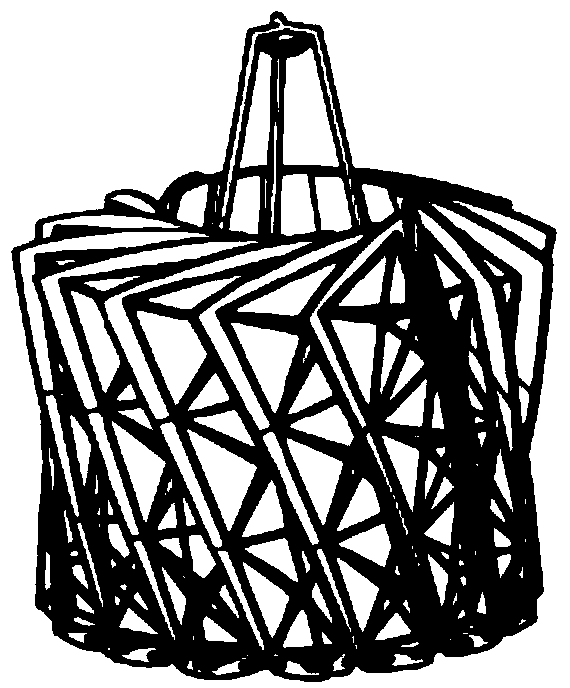

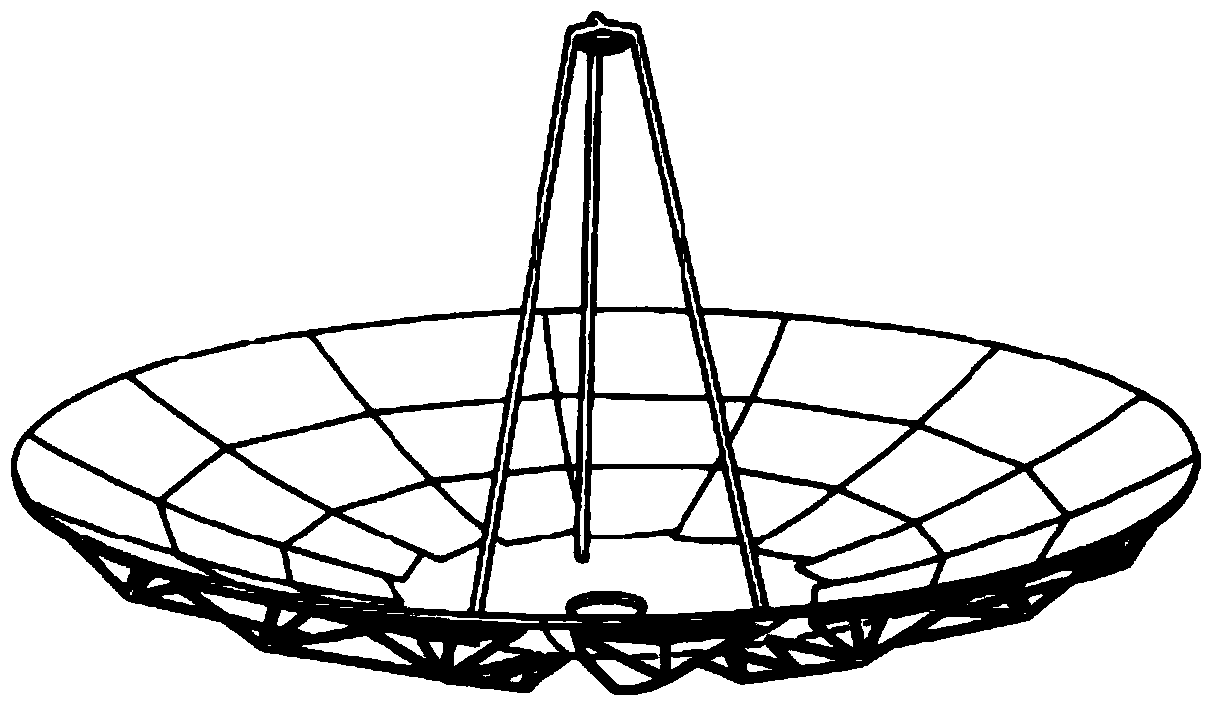

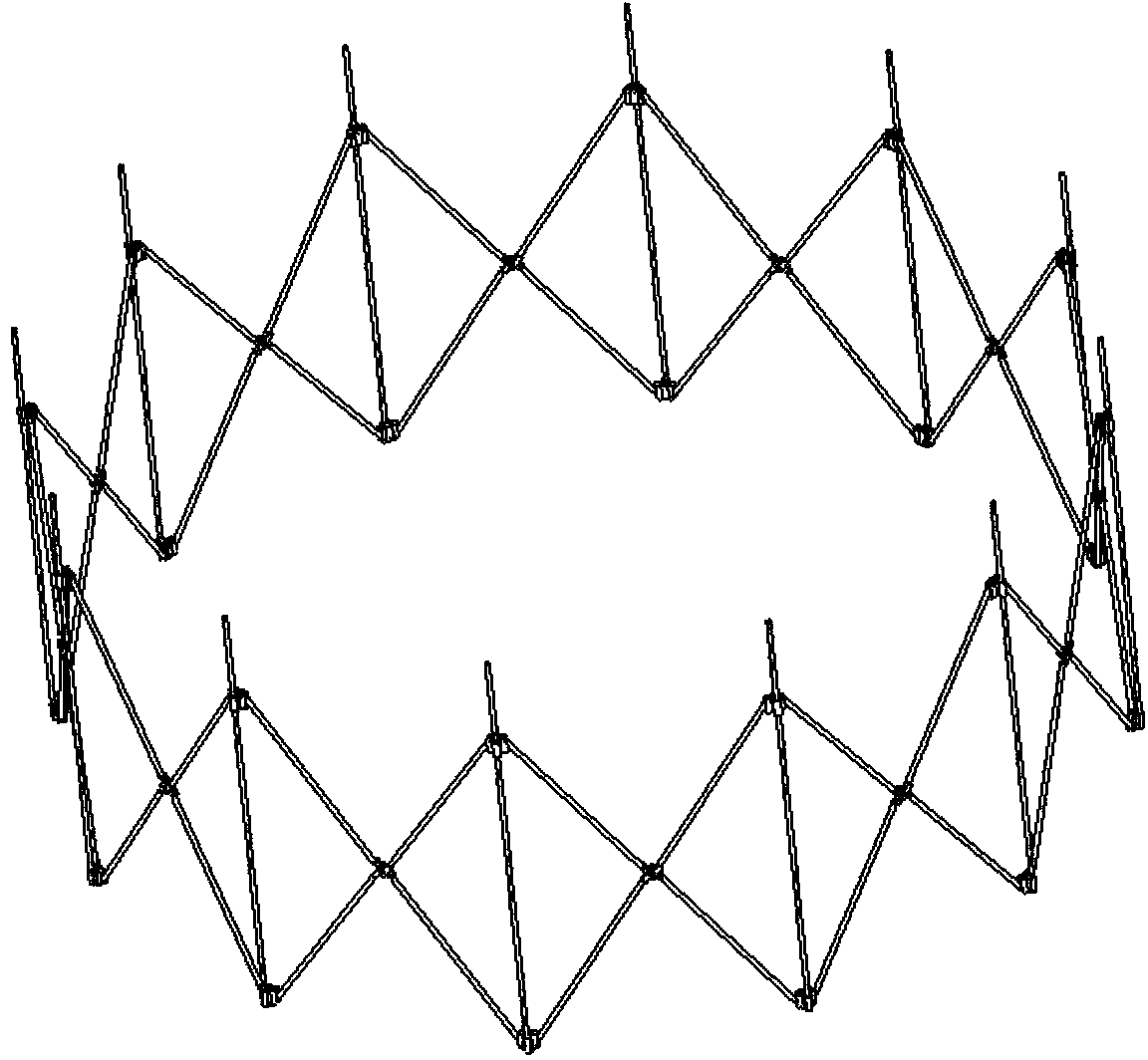

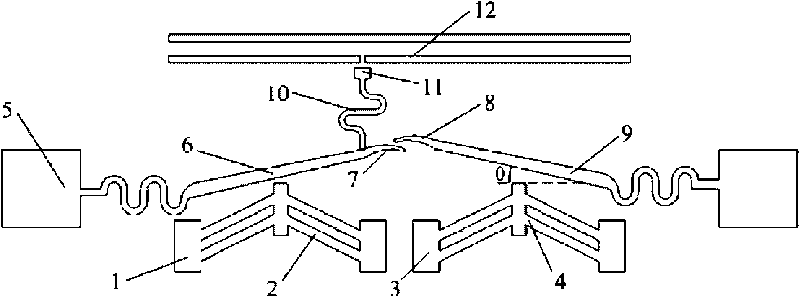

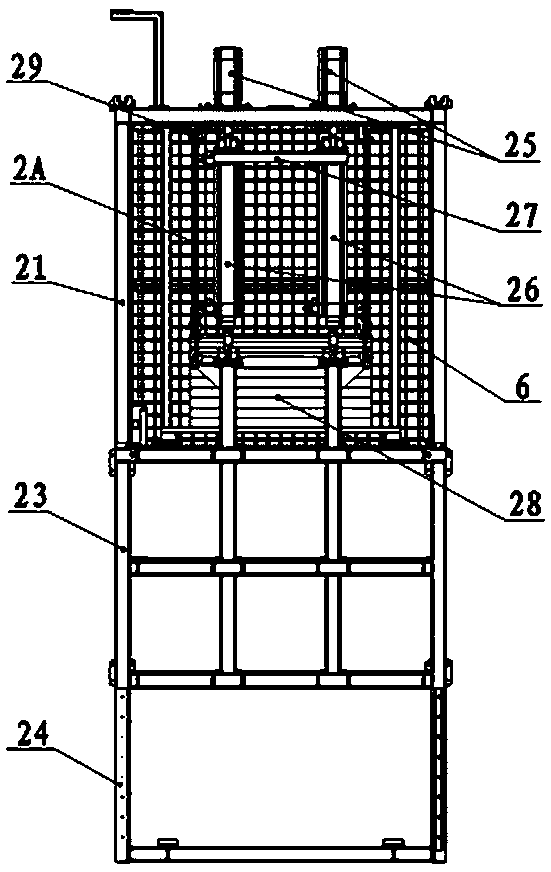

Novel scissor-based annular array extensible mechanism

InactiveCN104078741AUnfold control is simpleImprove Unwind SynchronizationCollapsable antennas meansAntenna supports/mountingsEngineeringAnnular array

The invention discloses a novel scissor-based annular array extensible mechanism. The mechanism comprises a plurality of scissor unit mechanisms of the same structure, the scissor unit mechanisms are connected and combined through shared mobile connector components, shared fixed connector components and vertical rods. Each scissor unit mechanism comprises a center rotating connector component, the mobile connector components, the fixed connector components, the vertical rods and inclined rods, the two mobile connector components and the two fixed connector components are fixedly connected with the two vertical rods respectively, one ends of the four inclined rods are hinged to one side ends of the two mobile connector components and one side ends of the two fixed connector components respectively, and the other ends of the four inclined rods are fixedly connected with the center rotating connector component respectively. Due to the fact that the scissor unit mechanisms are annularly arrayed, and the overall annular array extensible mechanism is formed. After the overall mechanism is arranged in an array, only one freedom degree exists, and the mechanism is simple in structure, and easy to machine and install. The novel scissor-base annular array extensible mechanism is large in extending caliber, small in shrinking caliber, small in overall weight and high in overall reliability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

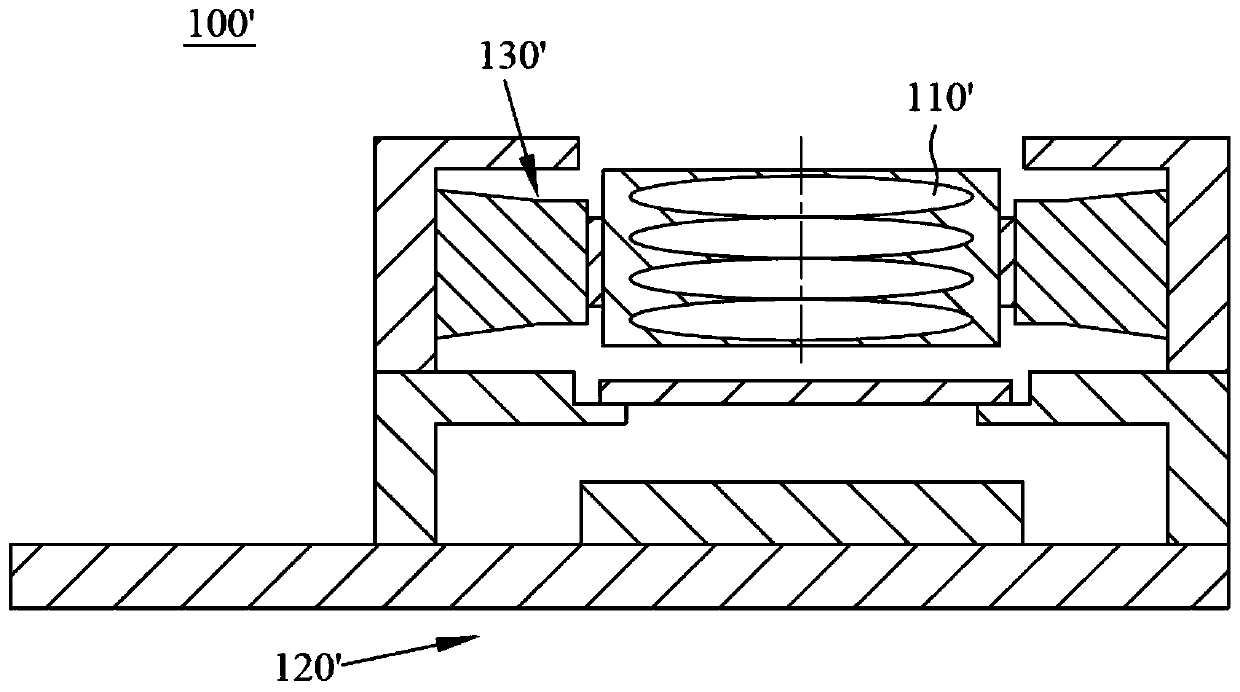

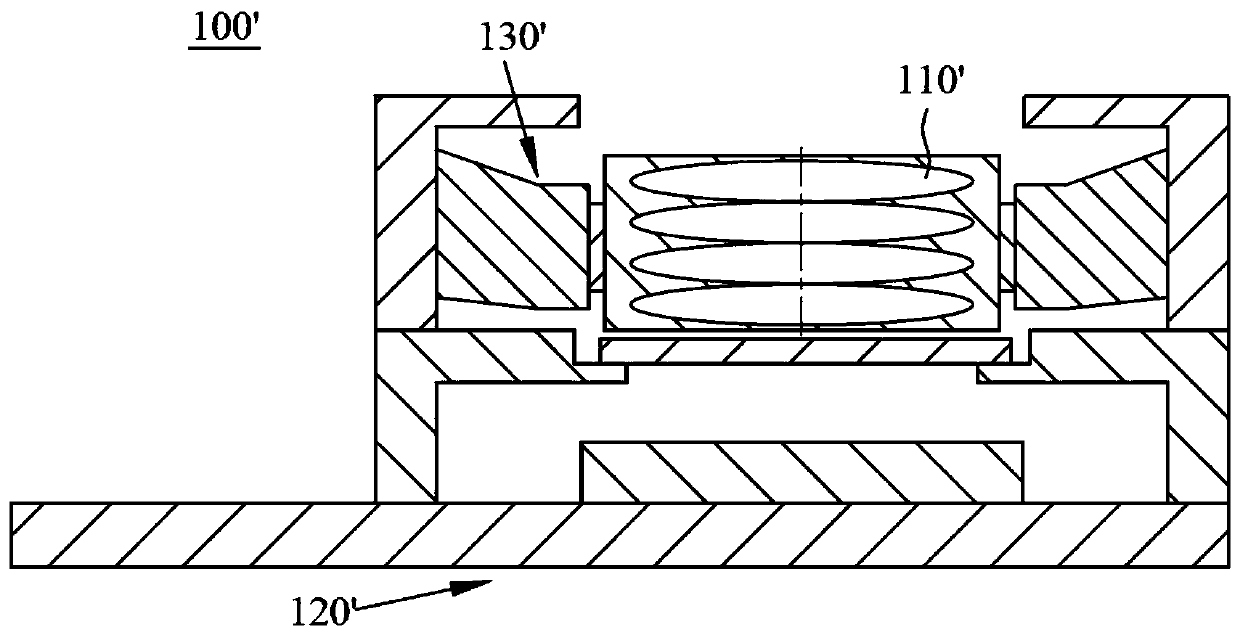

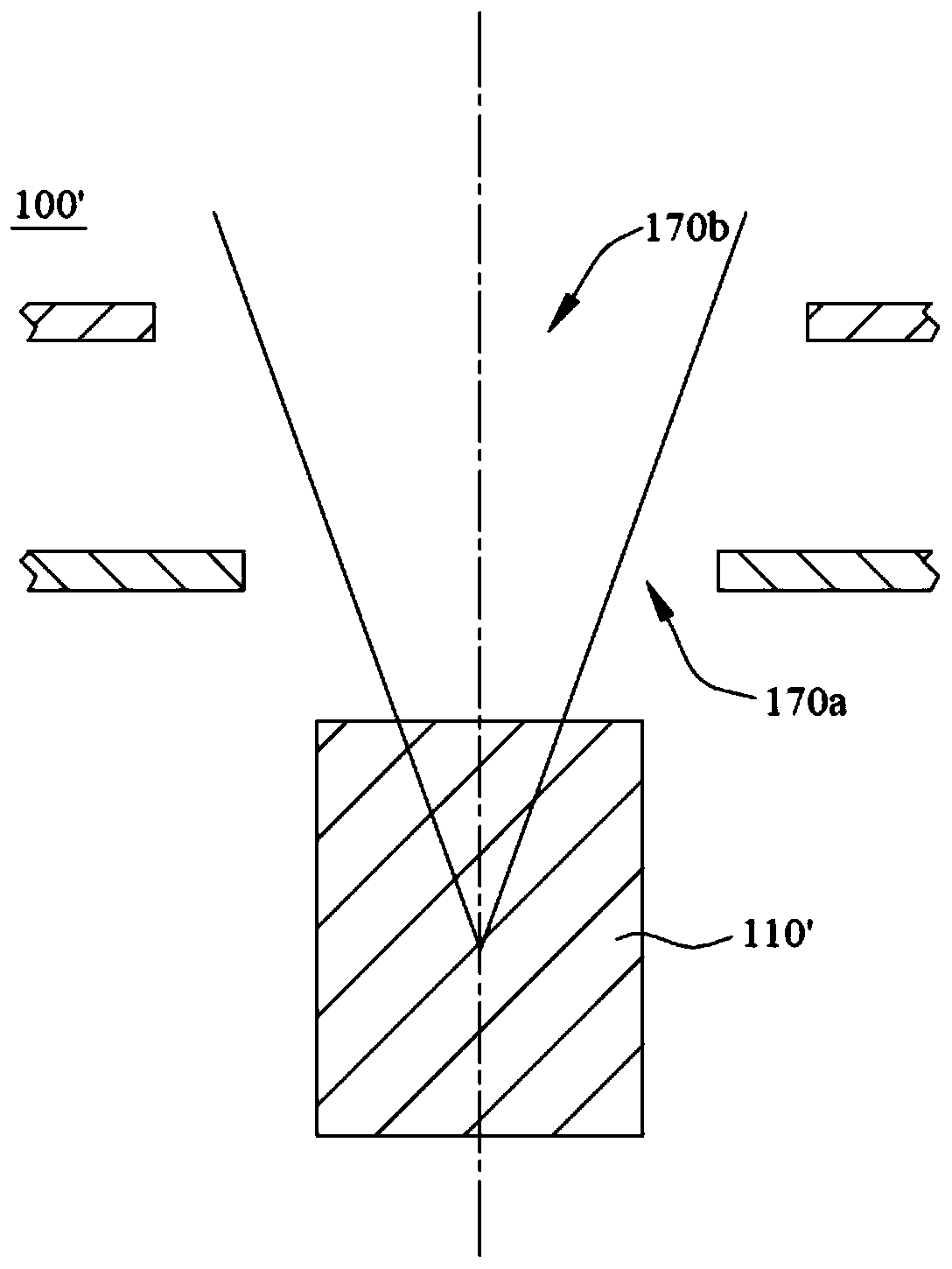

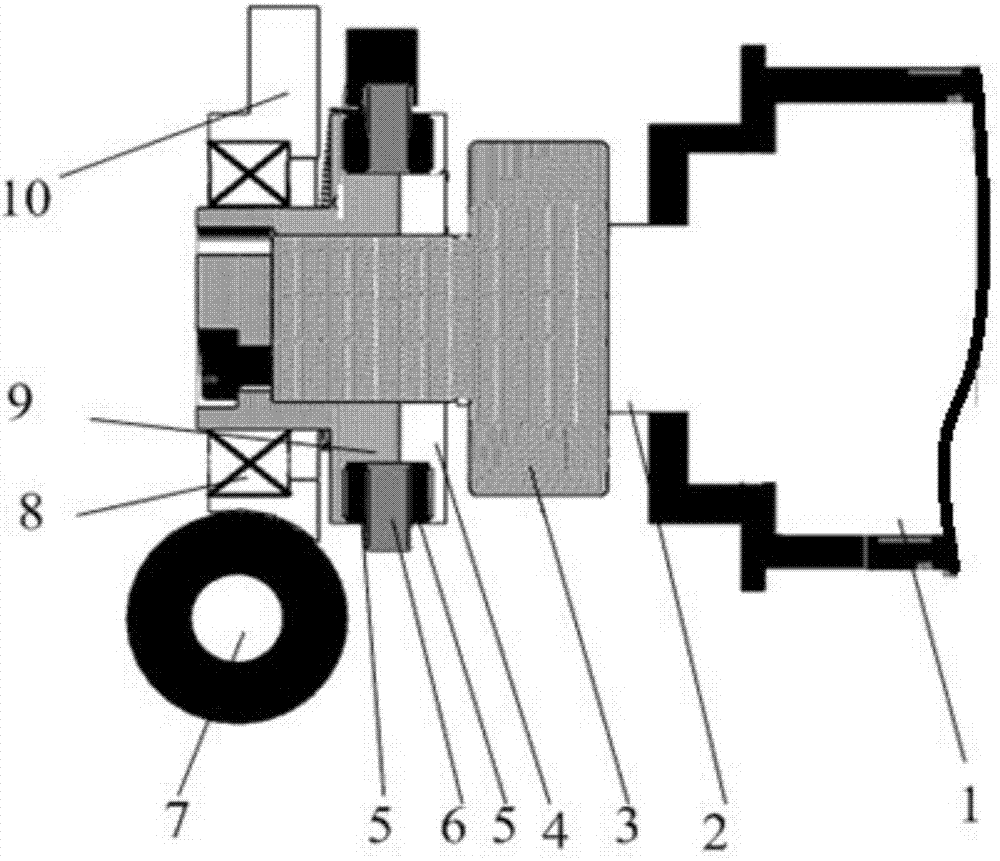

Camera module and electronic equipment

ActiveCN111405157ARealize the zoom functionReduce space consumptionTelevision system detailsColor television detailsLight sensingEngineering

The invention discloses a camera module and electronic equipment. The camera module comprises: at least one lens; a light sensing assembly used for sensing light passing through the lens; and a driving device which can drive the light sensing assembly to move in the direction close to or away from the lens so as to adjust the focal length of the camera module. The driving device capable of drivingthe light sensing assembly to move is arranged in the camera module, the distance between the light sensing assembly and the lens is changed through movement of the light sensing assembly, and the zooming function of the camera module can be achieved. Since the weight of the light sensing assembly is far less than that of the lens, the requirement on the driving force of the driving device is low. Under the same condition, the moving efficiency of the light sensing assembly is high, and rapid zooming is convenient to achieve. Furthermore, as the lens is immobile, the view field opening of thecamera module can be kept in a small size, the normal imaging requirement can be met, the occupied space in the electronic equipment is small, and the arrangement, design and installation cost of other parts or assemblies is low.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

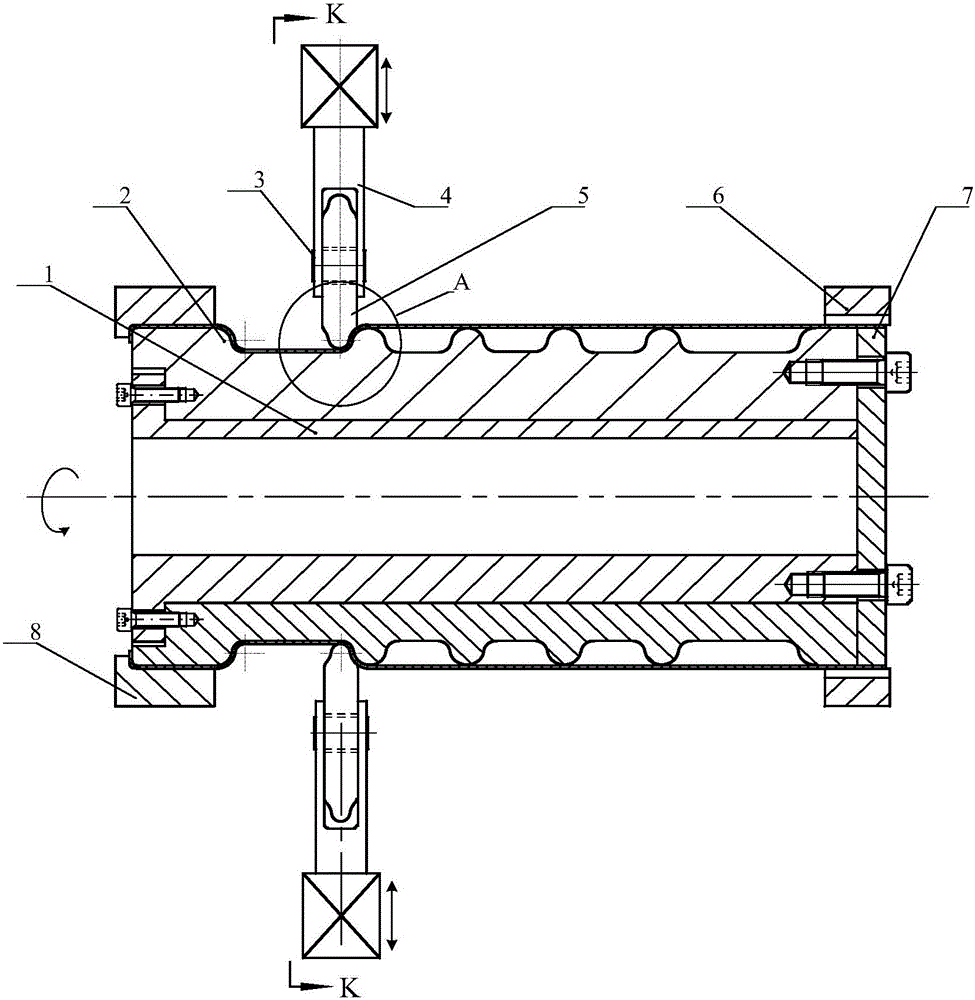

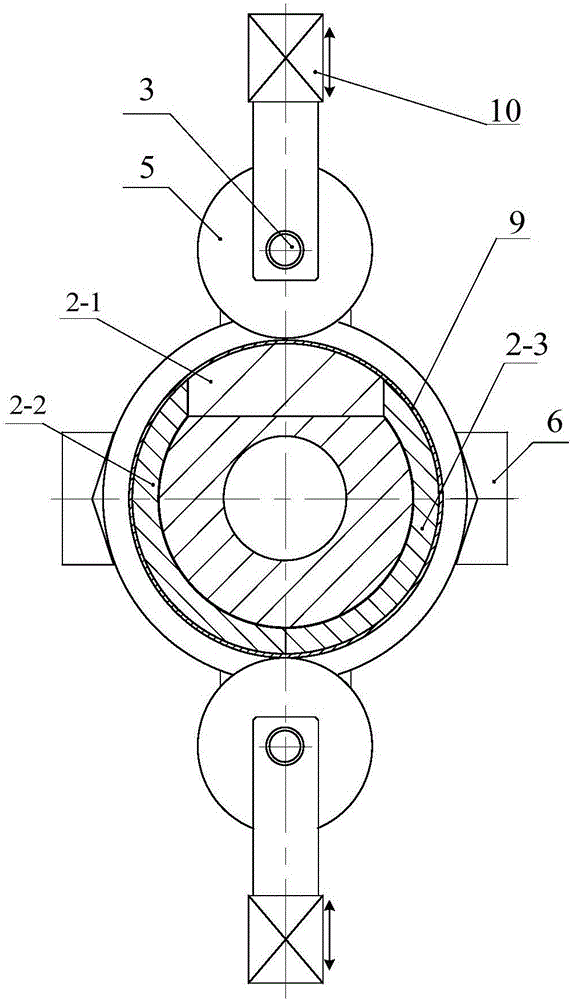

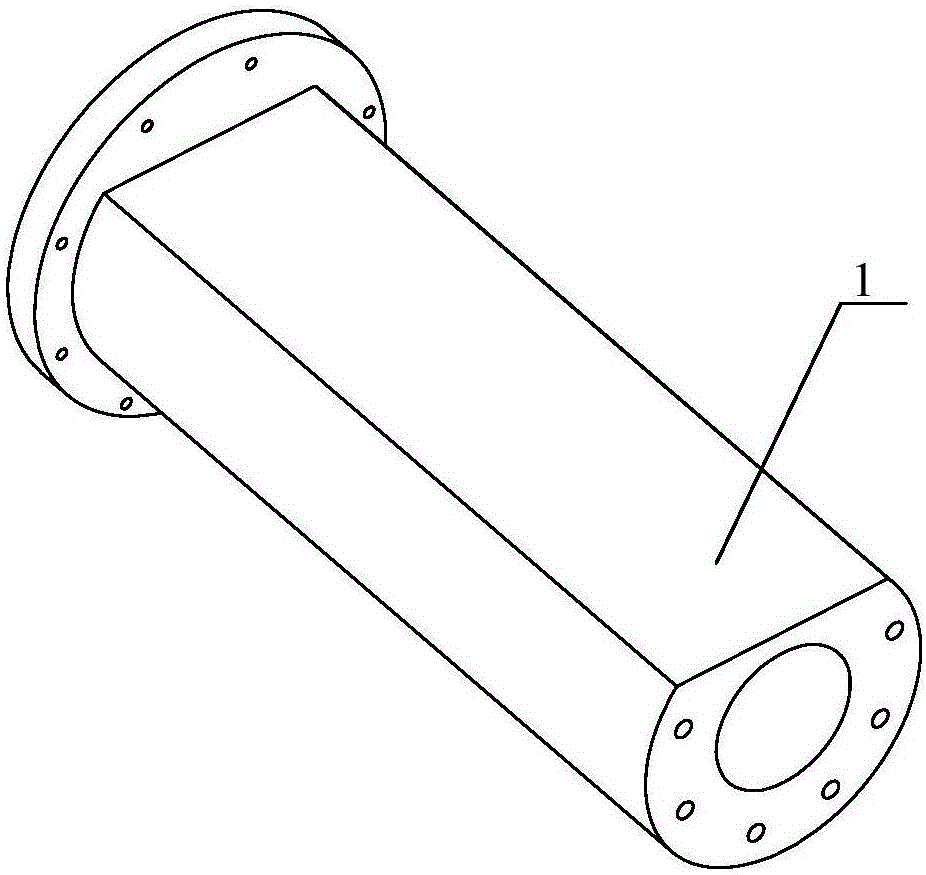

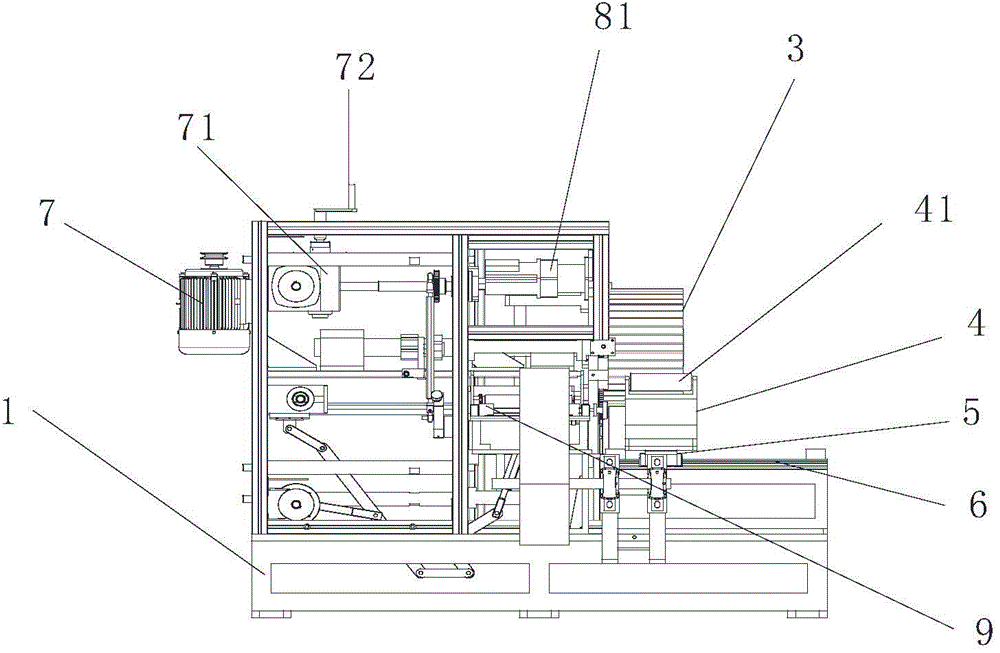

Large-diameter corrugated pipe vibration forming device and method

ActiveCN106040811AReduce deformation resistanceInhibits pipe wrinkling and crackingEngineeringHigh frequency vibration

The invention discloses a large-diameter corrugated pipe vibration forming device and a method. The forming device mainly consists of a mandrel, a corrugated core mold, a connecting disc, forming wheels, a support frame and a vibrating device. The corrugated core mold coats the mandrel, and is connected with a flange at the bottom of the mandrel and the connecting disc at the end part to form an integral mold. A pipe blank coats the outer surface of the corrugated core mold; left and right end clamping jaws are arranged at the two end parts of the pipe blank; and the forming wheels are distributed on the outer side of the pipe blank. After the clamping jaws clamp the pipe blank, the pipe blank rotates around the axis, the vibration excitation is applied to the forming wheels, and the forming wheels radially and axially feed the pipe blank. All traditional forming processes are synthesized; the friction force between the metal pipe blank and the forming mold is effectively reduced by a vibration exciting device; and when high-frequency vibration excitation is applied, the deformation resistance of the metal pipe blank can be reduced, the corrugation and breakage generation and development of the pipe blank are inhibited, the size precision of large-wave high corrugated pipes is guaranteed, and the surface smoothness of formed workpieces is increased.

Owner:YANSHAN UNIV

Electrothermal-driven in-plane bistable radio frequency microswitch

InactiveCN101719575AReduce power consumptionDesign impactTelevision system detailsImpedence networksStable stateIn plane

The invention relates to an electrothermal-driven in-plane bistable radio frequency microswitch belonging to the technical field of micro electromechanics. The electrothermal-driven in-plane bistable radio frequency microswitch comprises an electrothermal-driven mechanism, a mechanical locking mechanism and a signal conversion mechanism, wherein the electrothermal-driven mechanism is positioned under the mechanical locking mechanism; and the mechanical locking mechanism is connected with the signal conversion mechanism. The invention can realize the mechanical locking by using a pair of locking contacts, does not require continuous power consumption when keeping in a stable state, also fully develops the advantages of large driving force, high displacement power density and convenient integrated manufacture of an electrothermal driver and can be used as the actuation form of the mechanical locking structure of the switch. The switch has simple structure, foreseeable radio frequency (RF) characteristic, possibility of batch manufacture and practical application and suitability for integral manufacture.

Owner:SHANGHAI JIAO TONG UNIV

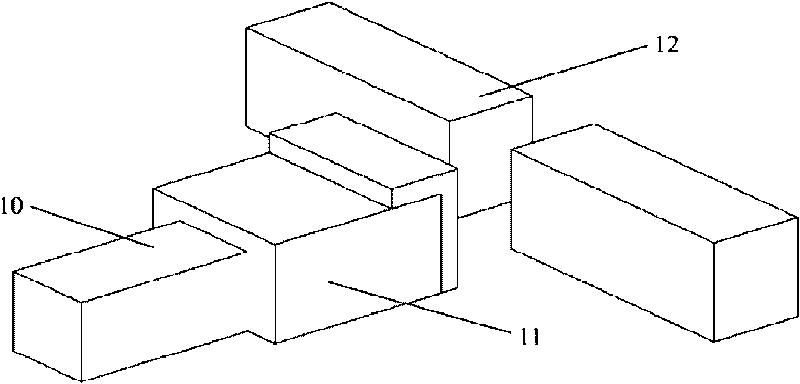

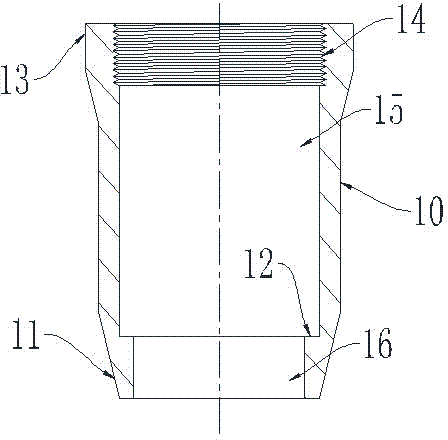

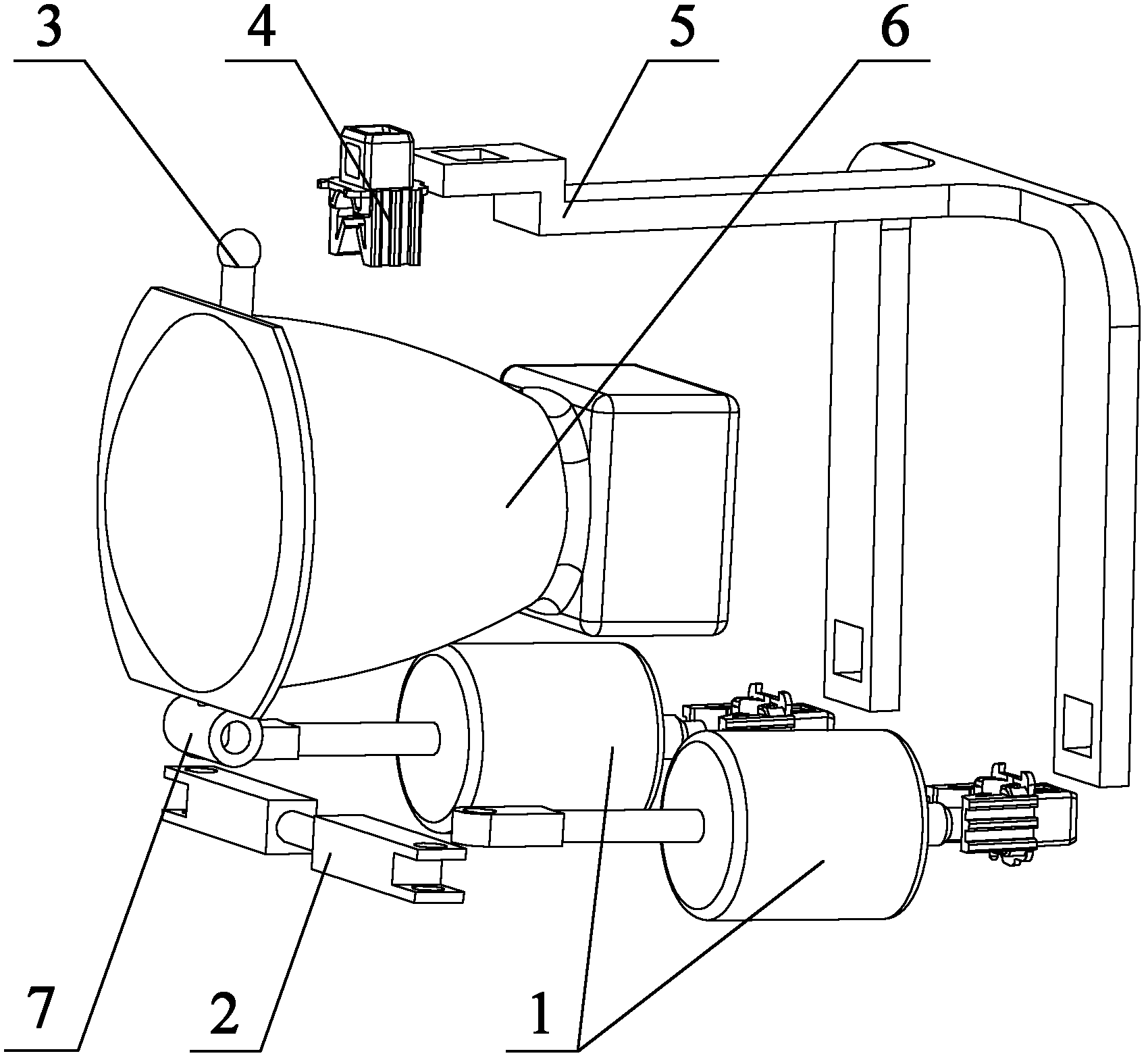

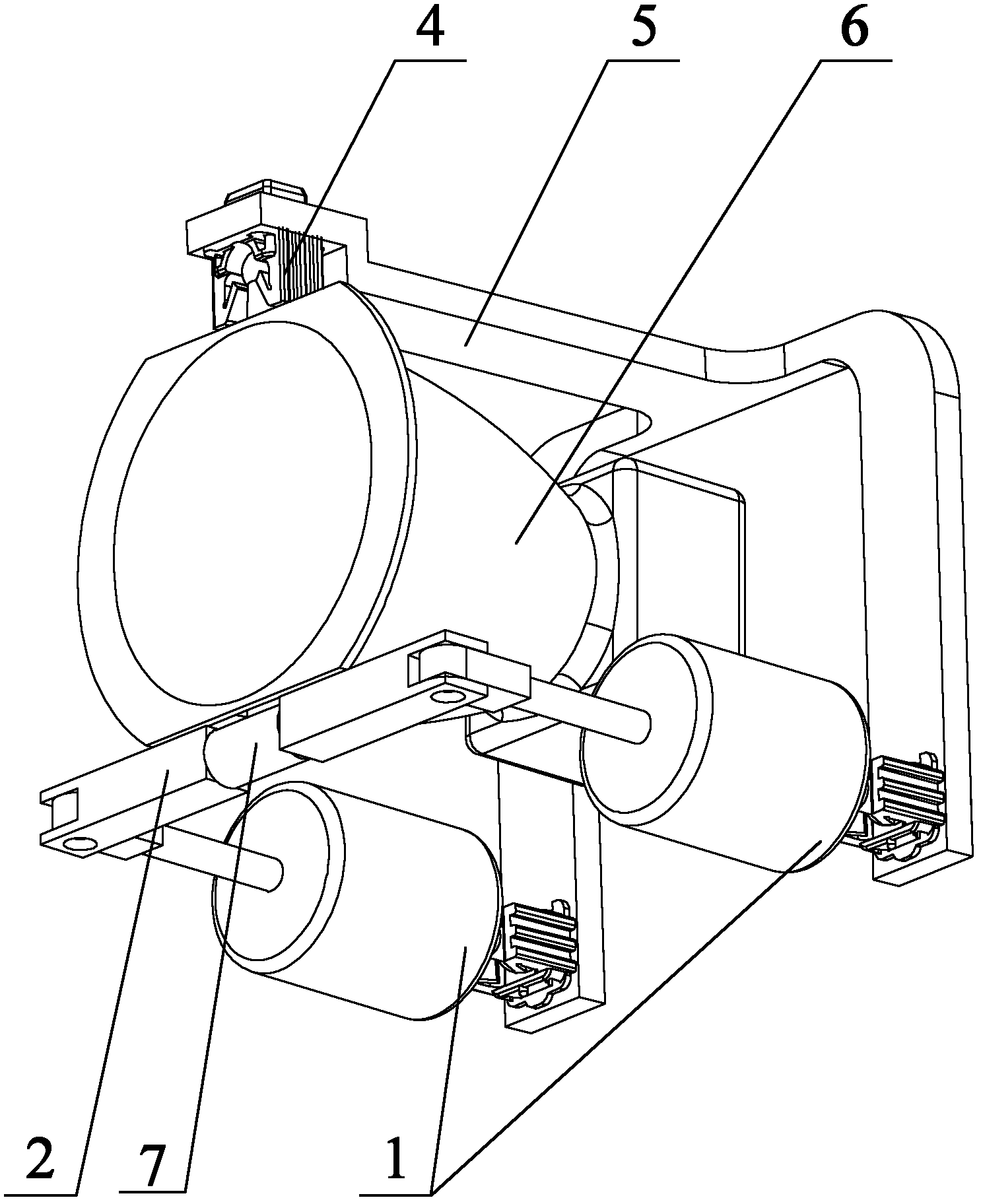

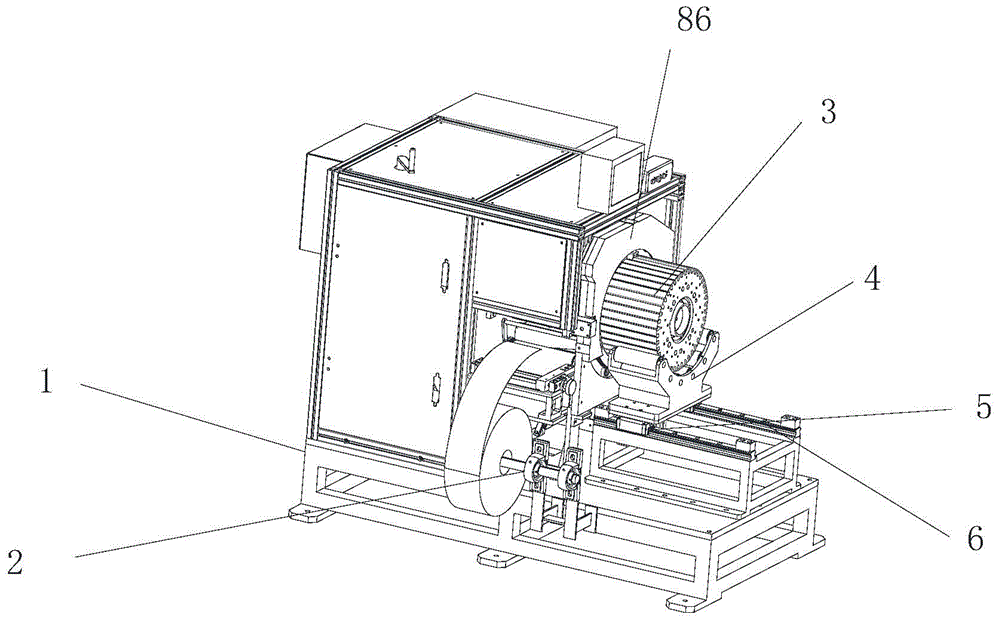

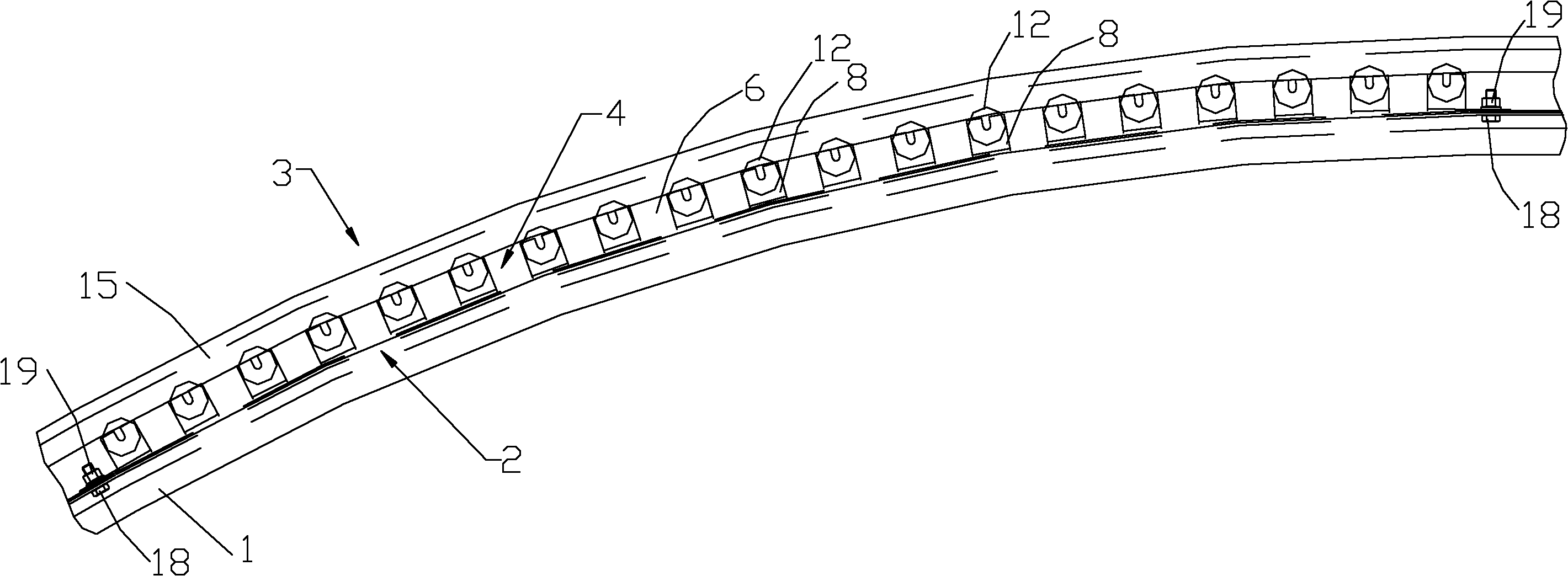

Fan stator paper inserting machine

InactiveCN104158360AReduce wearQuality assuranceApplying solid insulationPulp and paper industryStator

The invention belongs to the field of motor production equipment, specially relates to a paper inserting machine for a fan stator, and particularly relates to a paper inserting machine for a fan stator of which stator slots are arranged on the outer circumference of the stator. According to the paper inserting machine, a stator bearing mechanism is arranged on a frame on the right side of an indexing mechanism. According to the stator bearing mechanism, a guide rail is arranged on the frame, a sliding seat is arranged on the guide rail, the sliding seat is connected with a stator bearing seat, the upper part of the stator bearing seat is provided with an circular arc bearing concave cavity, and bearing rollers are evenly distributed in the bearing concave cavity along the axial direction. According to the invention, a fan stator paper inserting machine applicable to fan stator paper inserting is designed. The fan stator paper inserting machine has a stator bearing mechanism which can bear a fan stator without the need for hoisting or manual lifting operation, which, on one hand, offers protection to stator slots on the surface of the fan stator, and on the other hand, reduces the labor intensity of workers.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

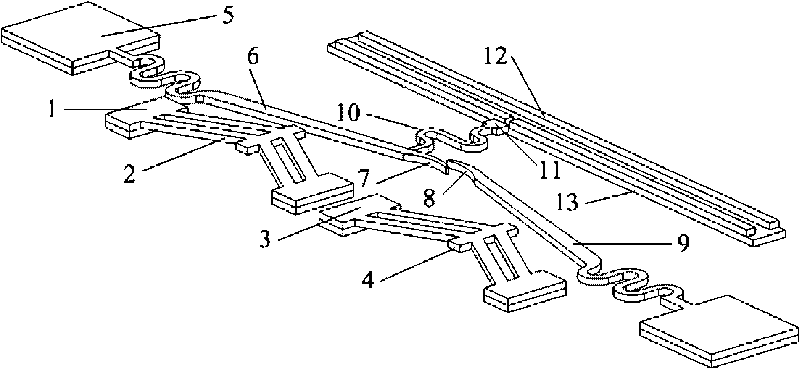

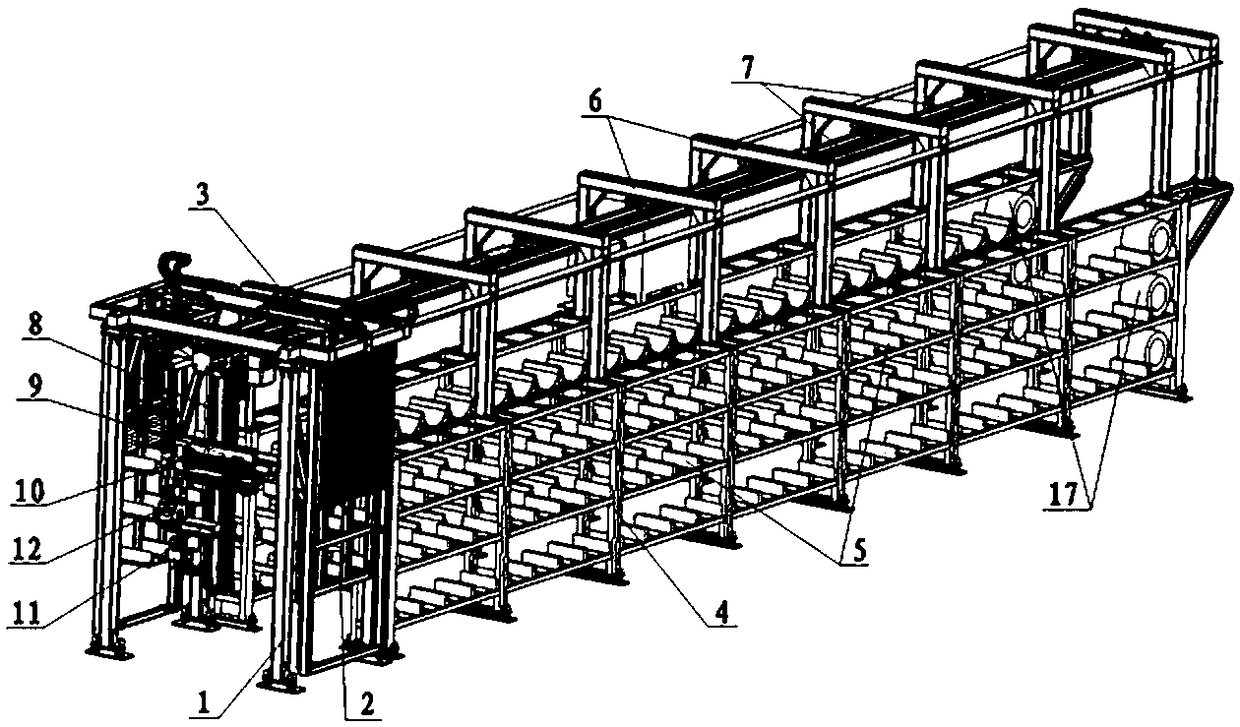

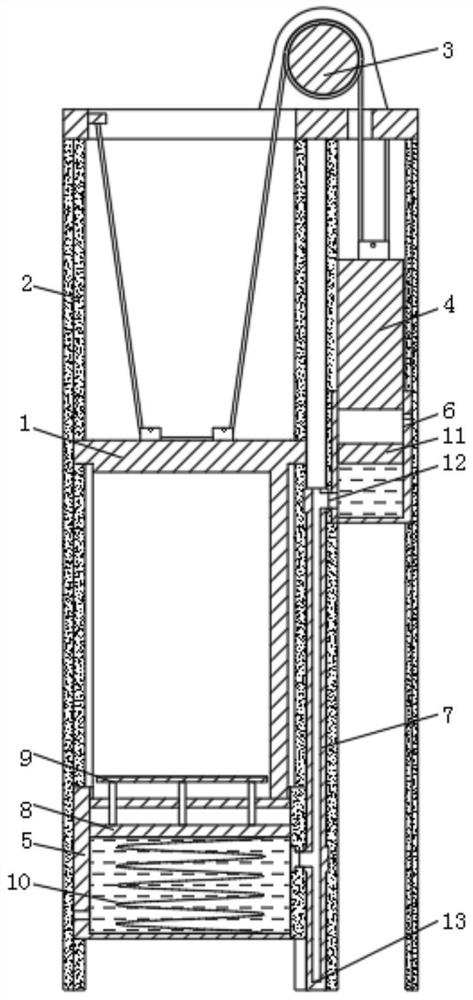

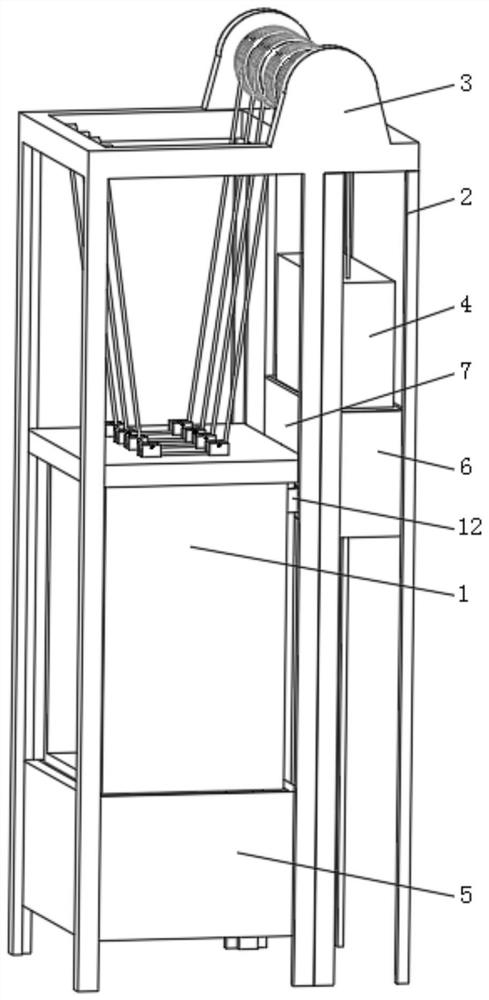

Intelligent yarn discharging and rectangular coordinate robot automatic yarn supplementing system

ActiveCN108190646AImprove efficiencyReduce labor intensityFilament handlingYarnRectangular coordinates

The invention discloses an intelligent yarn discharging and rectangular coordinate robot automatic yarn supplementing system. According to the system, yarn discharging mechanisms are perpendicularly arranged on one side or two sides of a yarn discharging support, the two ends of a yarn discharging horizontal-driving device are fixedly connected or are hinged to the yarn discharging support and theyarn discharging mechanisms so as to drive the yarn discharging mechanisms to horizontally move, each yarn discharging mechanism is provided with a plurality of yarn discharging brackets and a firstperpendicular linear driving device, wherein the yarn discharging brackets are perpendicular to the yarn discharging mechanism, and the first perpendicular linear driving device drives the yarn discharging brackets to vertically move; a yarn storage rack is fixedly provided with a plurality of yarn storage grooves in the direction perpendicular to the moving direction of the yarn discharging mechanisms; yarn supplementing supports are fixedly arranged on the ground or the yarn storage rack along the X axis; an X-axis cross beam is fixedly arranged on the yarn supplementing supports along the Xaxis; one end of a Z-axis vertical shaft is in perpendicular sliding driving connection with the X-axis cross beam; a Y-axis longitudinal beam is in sliding driving connection with a Z-axis guide rail; an A-axis mounting base is in perpendicular sliding driving connection with the Y-axis longitudinal beam; and a clamp rotating driving device is fixedly arranged on the A-axis mounting base and isperpendicularly and fixedly connected to the driving end of the clamp rotating driving device. The system has the advantages that the automation degree is high, the yarn discharging and supplementingefficiency is high, and a yarn roll is not liable to deform.

Owner:云南柔控科技有限公司 +1

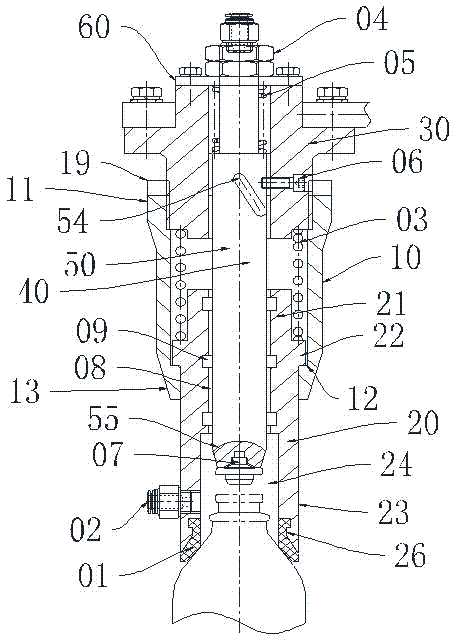

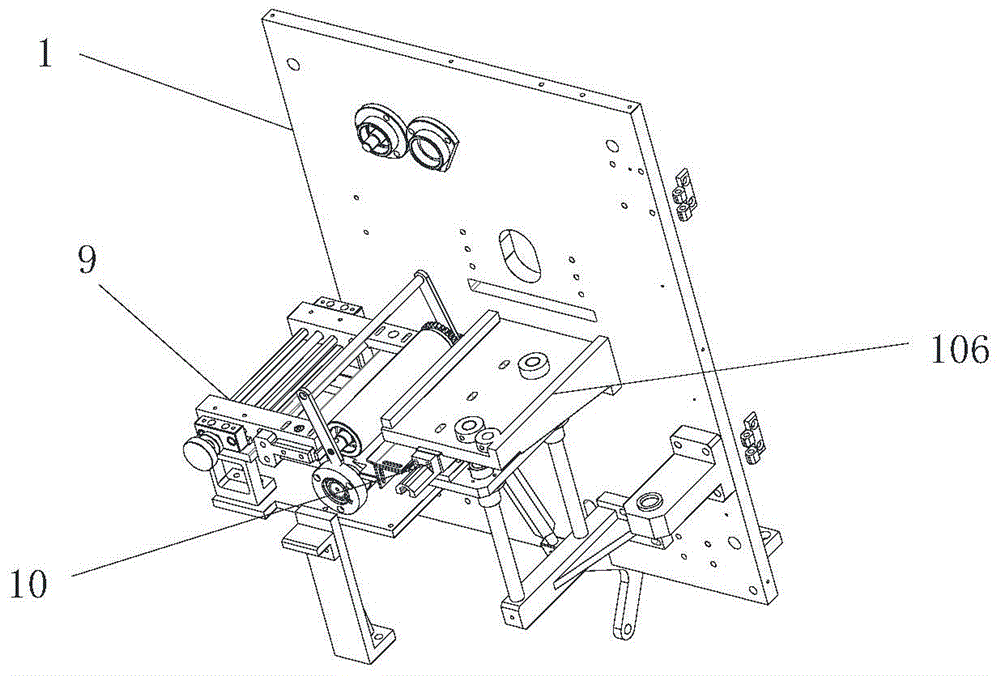

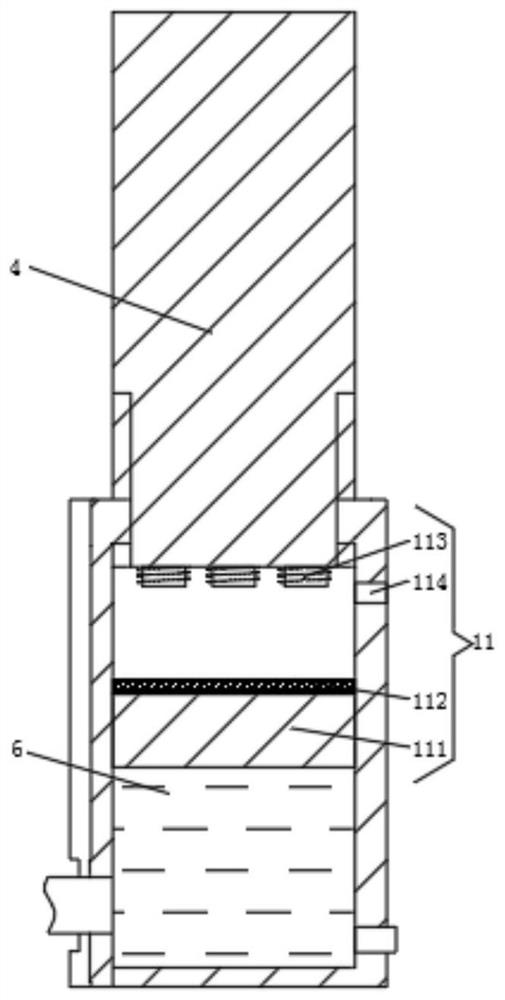

Integrated vacuum, air inflating and pressing device

ActiveCN104743480AReduced driving force requirementsAvoid destructionLiquid bottlingThreadless stopper insertionEngineeringAir exchange

The invention discloses an integrated vacuumizing, air inflating and pressing device for a medicine bottle. The integrated vacuumizing, air inflating and pressing device is used for overcoming the defect that a single device cannot achieve the operations of vacuumizing, air inflating and pressing in the prior art. The integrated vacuumizing, air inflating and pressing device comprises an air exchange sleeve, a mounting seat and a pressing mechanism. An air cavity chamber is arranged at the lower portion of the air exchange sleeve, and a sealing sleeve is arranged at the mouth portion arranged at the lower portion of the air cavity chamber. A connector is arranged at the lower portion of the air exchange sleeve, and the connector is communicated with the air cavity chamber. The air exchange sleeve is installed on the mounting seat, and the air exchange sleeve can move up and down. The lower portion of the pressing mechanism is arranged in the air exchange sleeve and is stretched into an air cavity, the upper portion of the pressing mechanism is installed on the mounting seat, and the upper portion of the pressing mechanism can move up and down. The integrated vacuumizing, air inflating and pressing device for the medicine bottle can complete the operation of vacuumizing, air inflating and pressing and has the advantage of being simple in structure.

Owner:湖南华尔特今朝科技有限公司

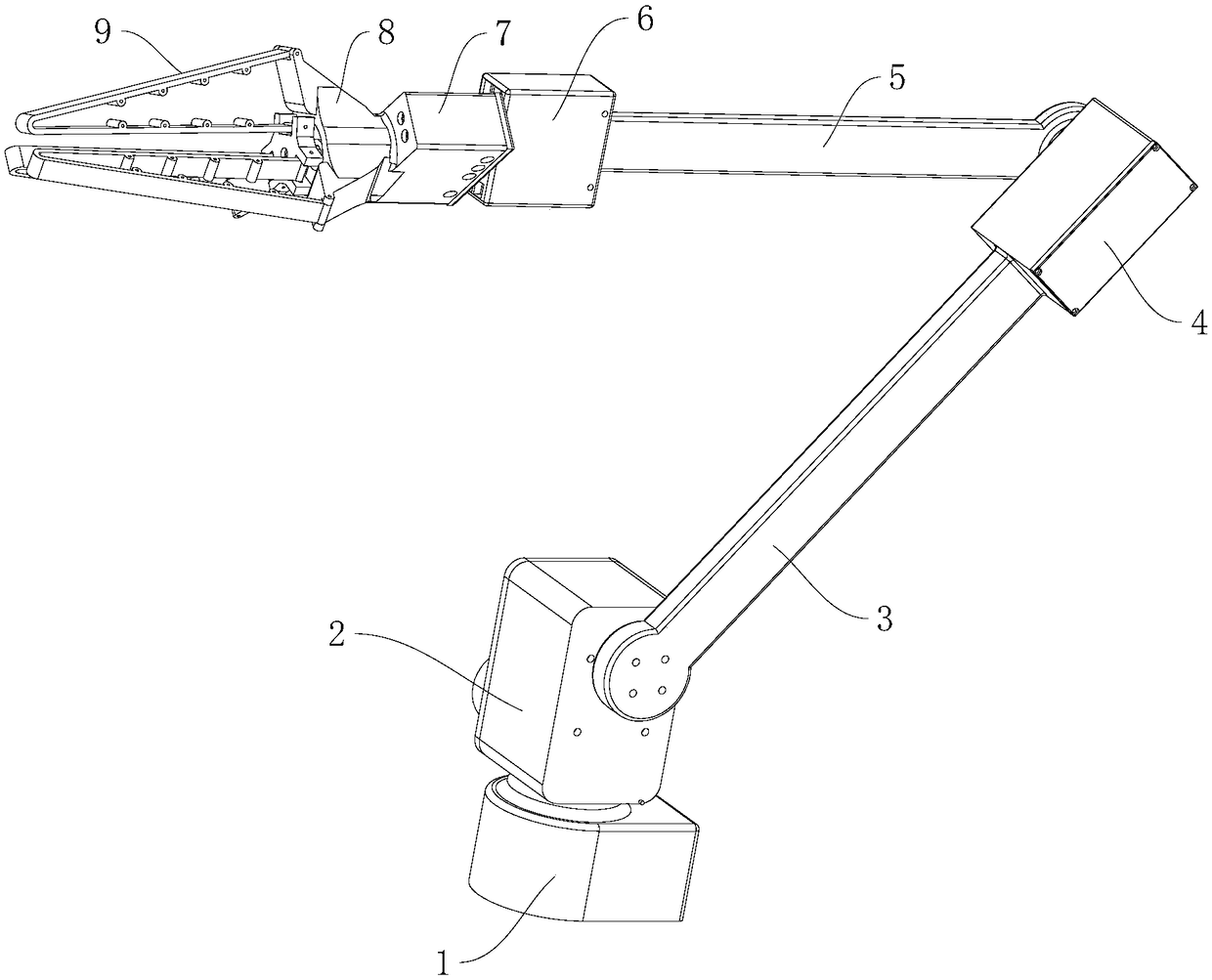

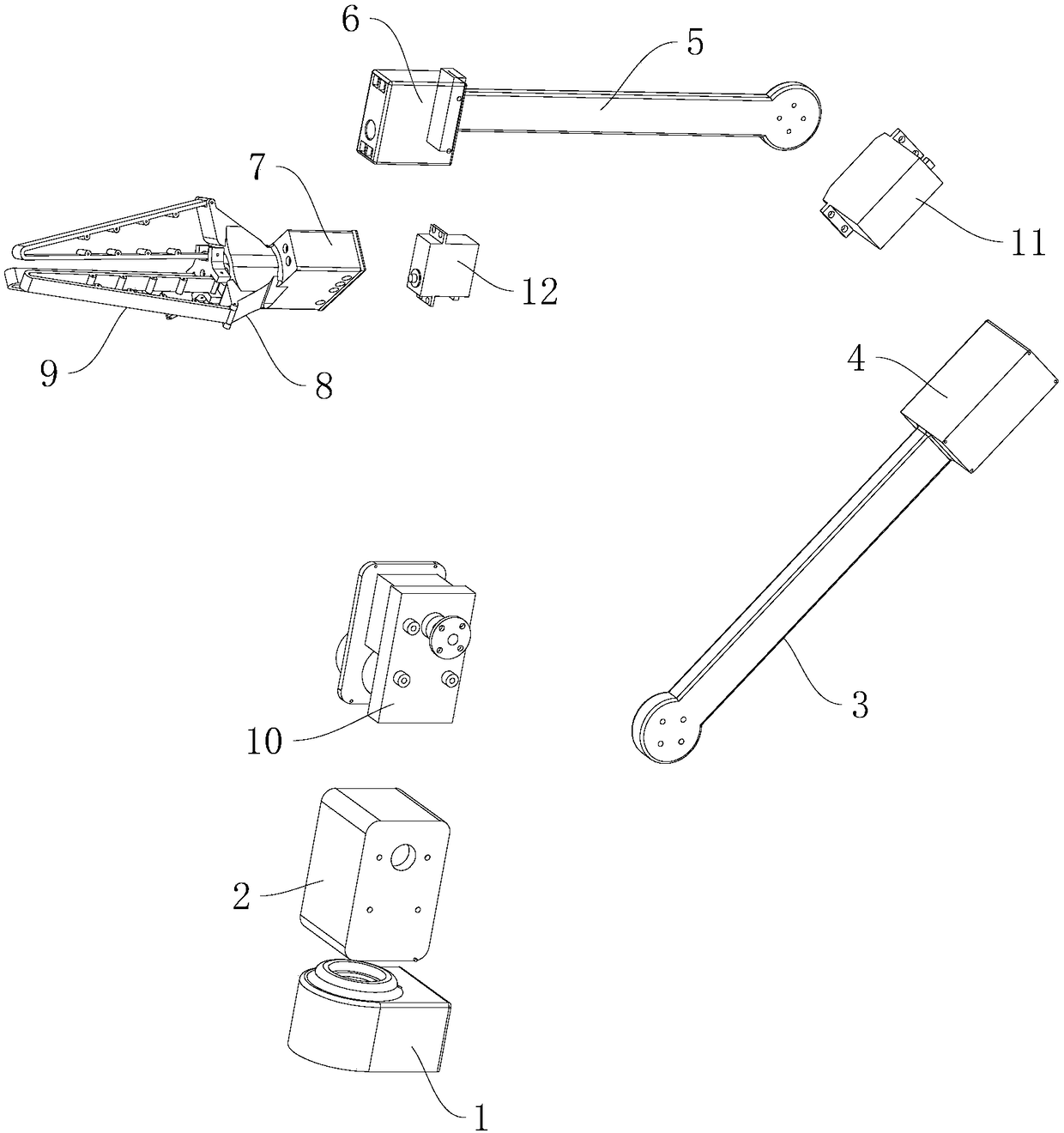

Flexible cooperative mechanical arm and control method thereof

InactiveCN109202873AAvoid damageReduce weightProgramme-controlled manipulatorGripping headsPower flowCollision detection

The invention belongs to the technical field of cooperative mechanical arms, and discloses a flexible cooperative mechanical arm and a control method thereof. The mechanical arm comprises a base, a mechanical arm main body and an execution clamping tool. The bottom end of the mechanical arm main body is rotatably connected with the base, and the execution clamping tool is arranged at the top of the mechanical arm main body. The interior of the base is provided with a control board and a bottom steering gear. The mechanical arm main body includes a first arm and a second arm, which are rotatably connected. The execution clamping tool includes a plurality of flexible clamping fingers, and the execution clamping tool is driven by an execution steering engine to perform clamping. The mechanical arm reduces the complex structure of a traditional cooperative robot arm, reduces the requirements for the driving force, adopts the flexible execution clamping tool, can perform the clamping from various angles, introduces the deformation reading to a position speed control loop, achieves a purpose that the steering engine actively cancels the arm vibration and improves the control precision ofthe mechanical arm. By means of the current detection of the steering engine, the mechanical arm achieves the collision detection and drag teaching at low cost. Therefore, the device is suitable forpromotion.

Owner:南京秘塔网络科技有限公司

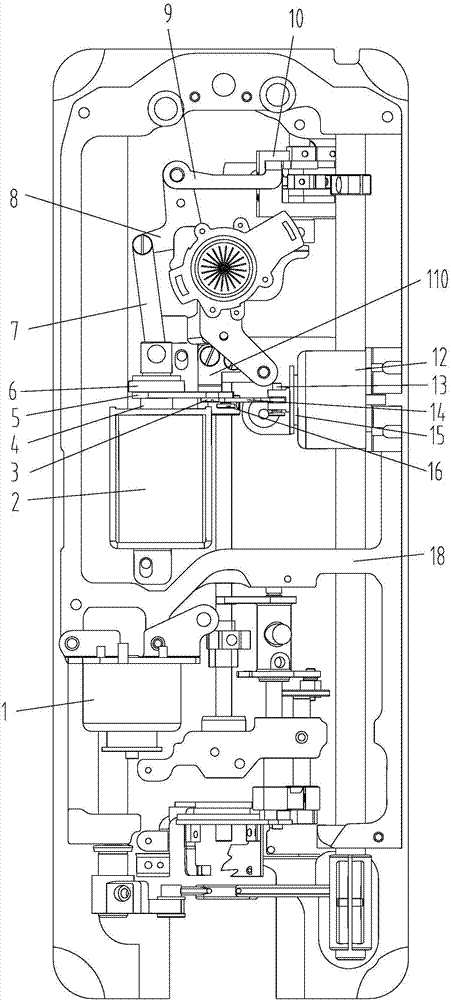

Sewing machine

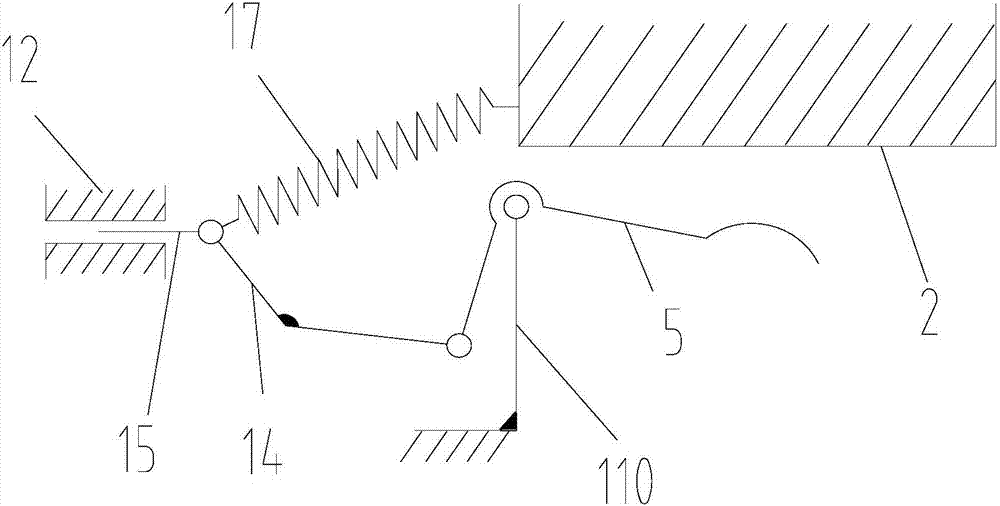

ActiveCN107326555AFunction as a tight seamSealed seam function realizationSewing-machine control devicesEngineeringSewing machine

The invention discloses a sewing machine. The sewing machine comprises a backstitch driving part and a backstitch executing mechanism connected with the backstitch driving part and used for realizing the backstitch sewing, and further comprises a tiny stitch executing mechanism connected with a tiny stitch driving part, elastically installed between the backstitch driving part and the backstitch executing mechanism and used for limiting the driving distance of the backstitch driving part. The sewing machine is capable of realizing the tiny stitch function by inserting and embedding the tiny stitch driving part between the backstitch driving part and the backstitch executing mechanism.

Owner:JACK SEWING MASCH CO LTD

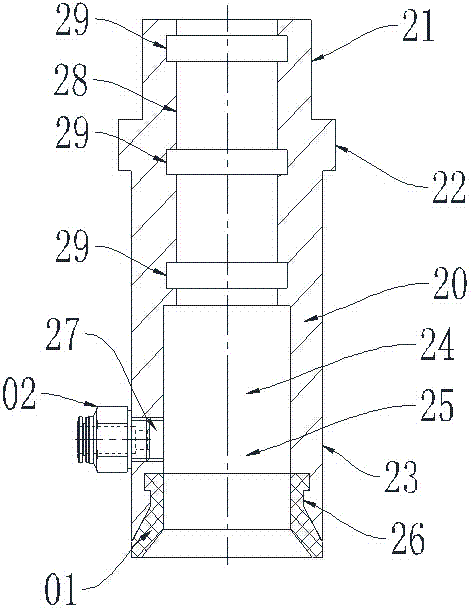

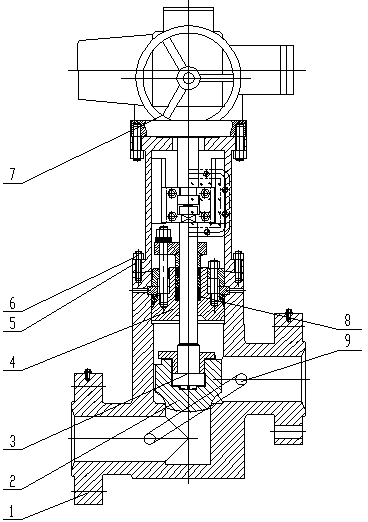

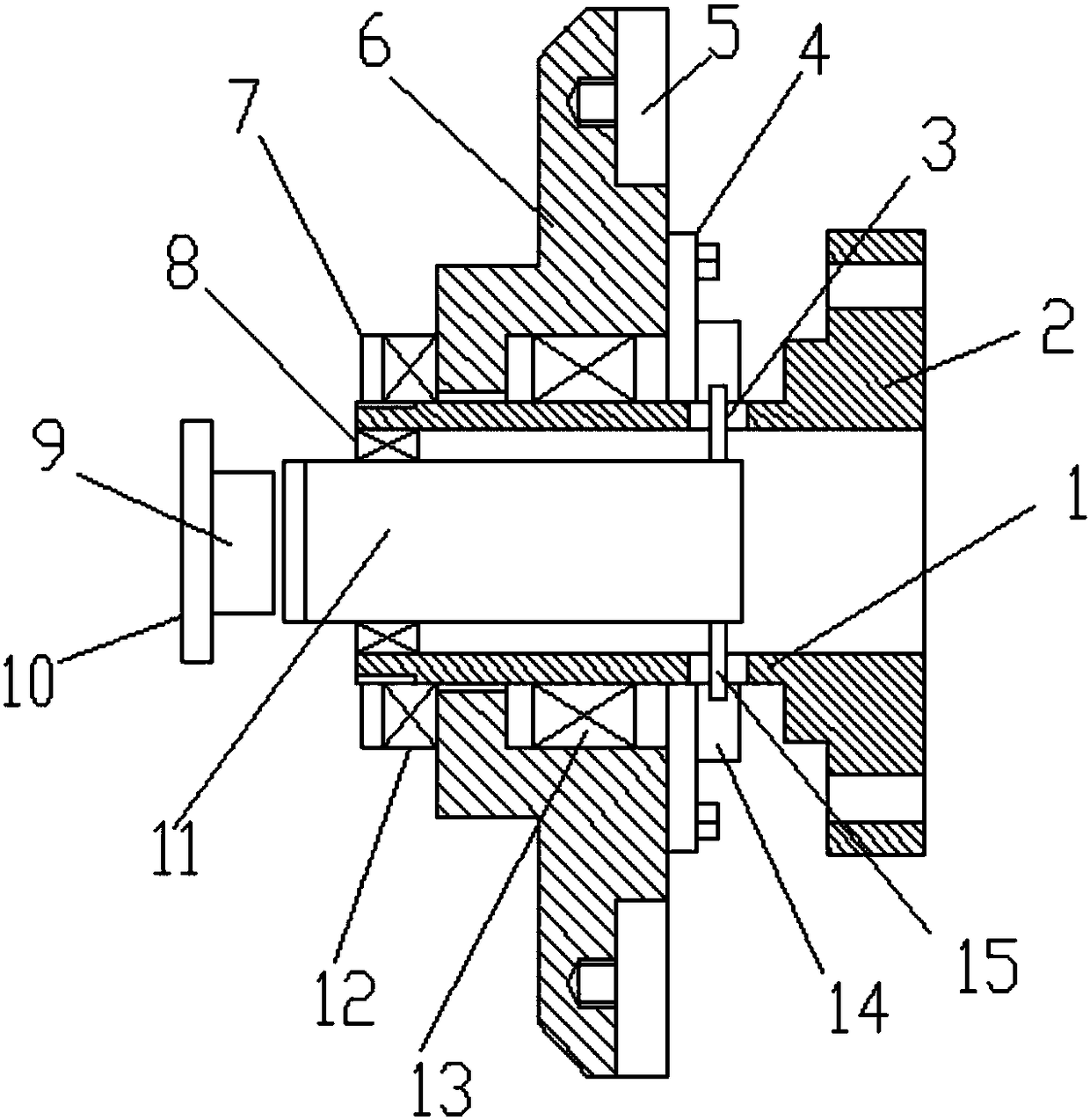

Military extra-high-pressure oxygen valve

ActiveCN103410988AImprove sealingReduced driving force requirementsLift valveValve housingsHigh pressure oxygenHigh pressure

The invention discloses a military extra-high-pressure oxygen valve which comprises a sealing structure between a valve seat of a valve body and a valve clack. The sealing structure between the valve seat of the valve body and the valve clack is an angle-difference sealing pair with the angle difference ranging from 2 degrees to 5 degrees, and a valve stem is sealed to form a composite packing sealing structure. The military extra-high-pressure oxygen valve has the advantages that owing to the angle-difference sealing pair, an extremely narrow linear sealing belt is formed when two matched sealing surfaces are in contact with each other, high sealing specific pressure can be generated by means of applying extremely low sealing force, the military extra-high-pressure oxygen valve is excellent in sealing performance and low in driving force requirement, accordingly, requirements of extra-high-pressure industrial-grade pure oxygen under harsh and complicated working conditions in the aerospace field can be met completely, and the purpose of safety usage is achieved.

Owner:LANZHOU HIGH PRESSURE VALVE

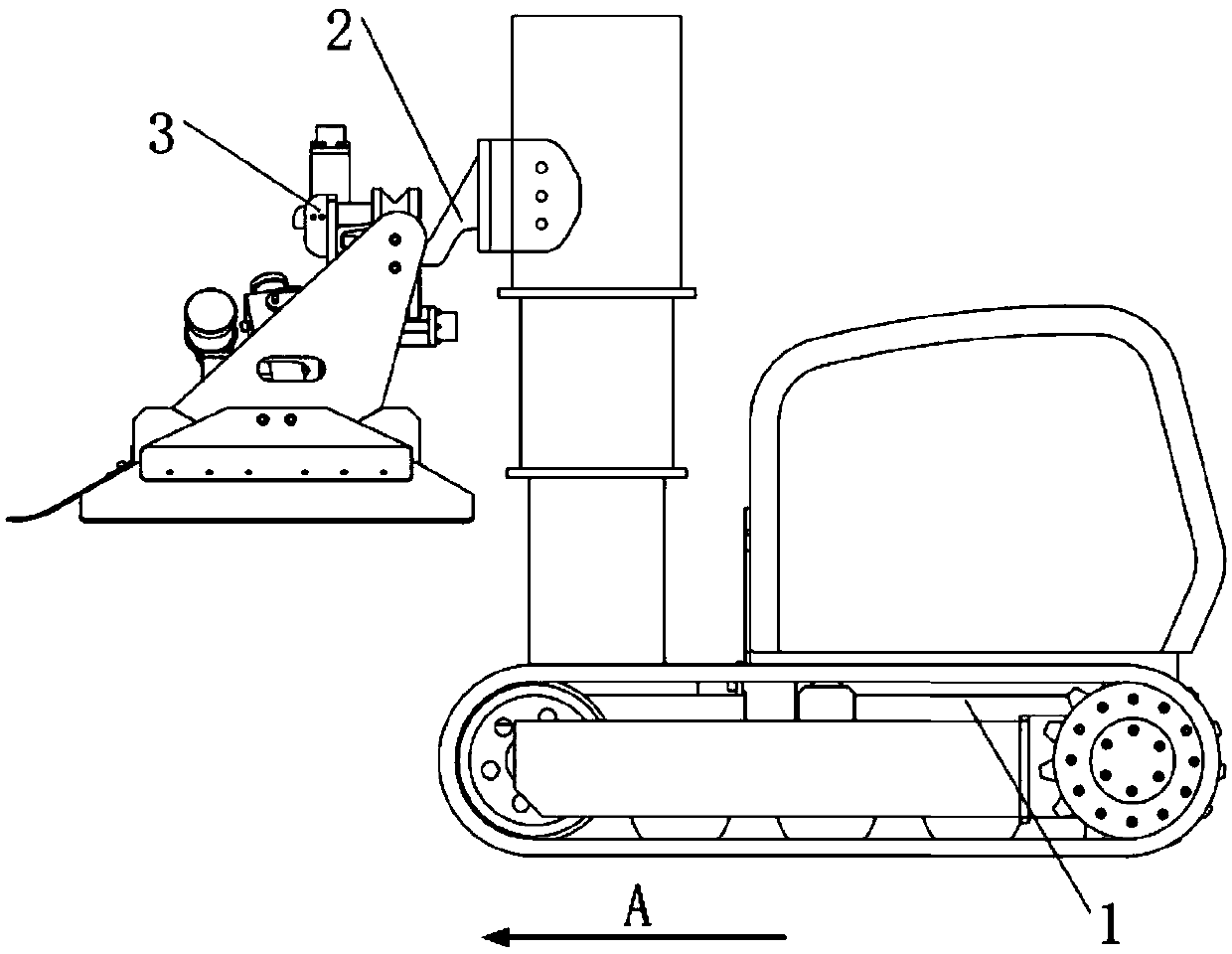

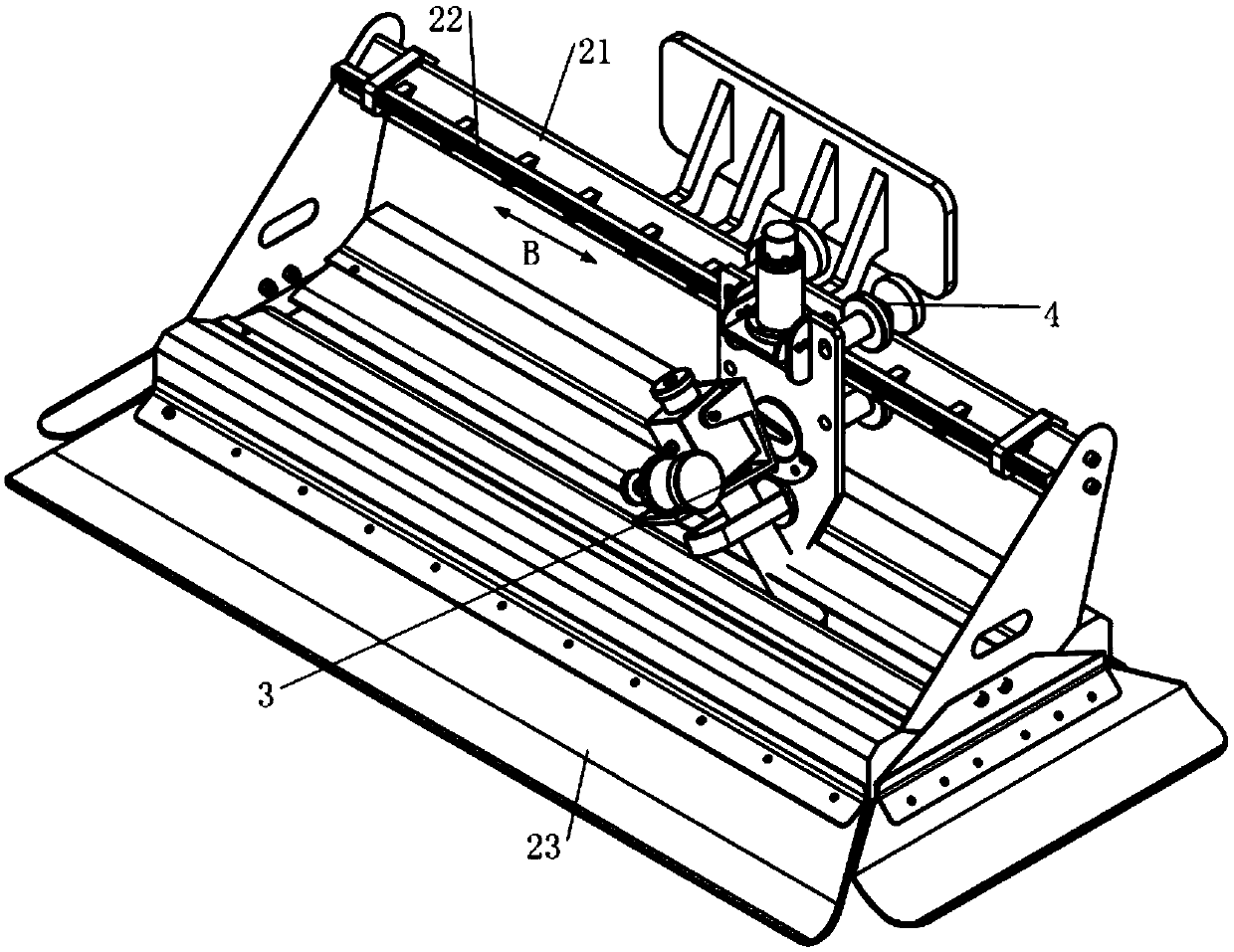

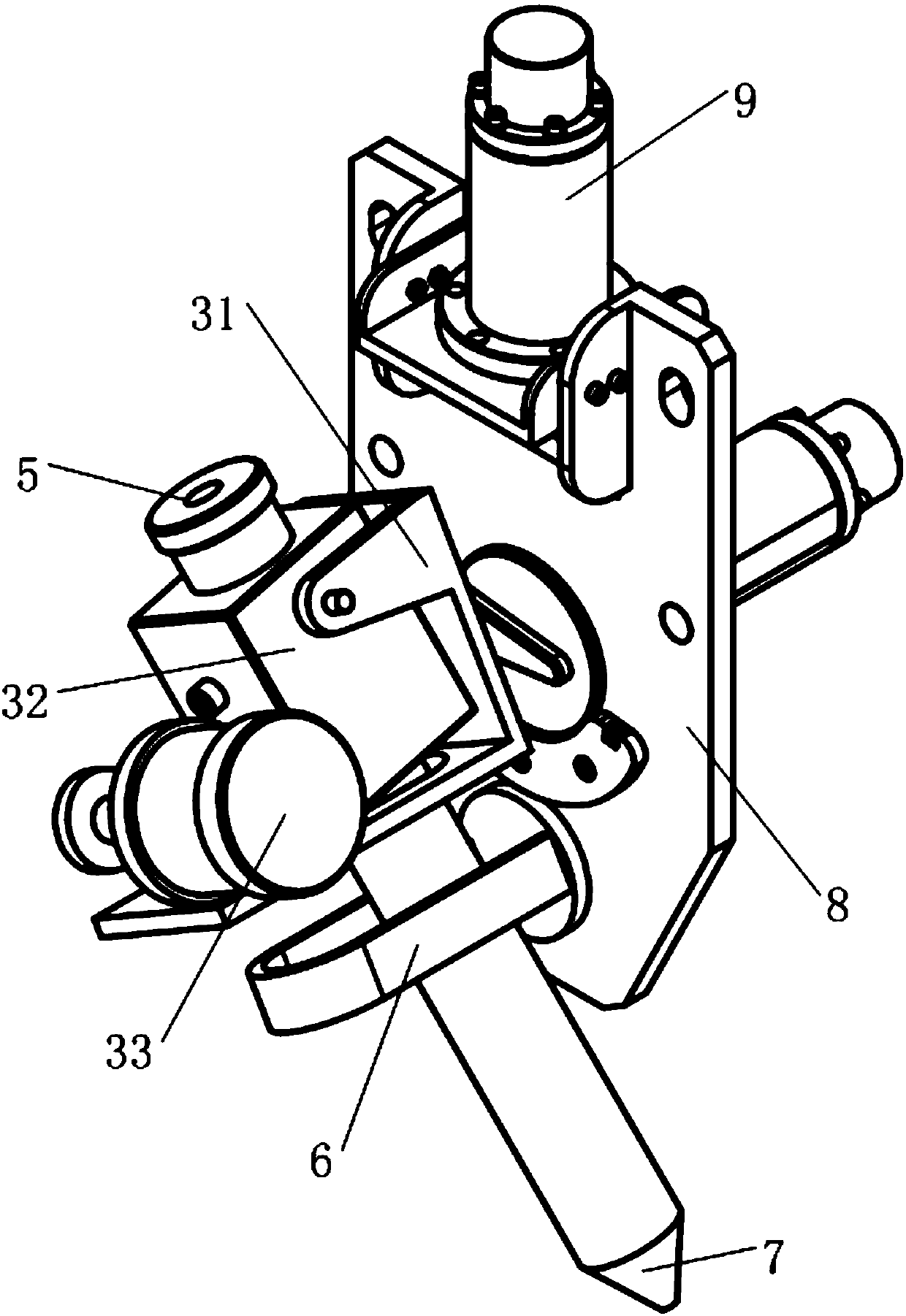

Swing spray gun and water jet equipment

ActiveCN108677672AExtended service lifeImprove work efficiencyRoads maintainenceHigh pressure waterHigh pressure

The invention provides a swing spray gun and water jet equipment. The swing spray gun comprises a base, a bearing seat, a jet pipe and a third driving device, wherein the bearing seat is driven by a second driving device to rotate around a first axis relative to the base; the jet pipe is rotatably mounted on the bearing seat around a second axis, the top end of the jet pipe is connected with a high-pressure water source, and a nozzle located at the bottom of the jet pipe faces the layer to be treated; and third driving device is installed on the bearing seat, an eccentric structure is arrangedon an output shaft parallel to the second axis, an eccentric protrusion of the eccentric structure is hinged to a connecting rod, the other end of the connecting rod is hinged to the jet pipe, and the hinged position and the second axis position are arranged at intervals by a set distance to form a crank-rocker mechanism. According to the design, swing amplitude of the nozzle can be increased firstly, and then the working efficiency of the jet pipe during a single stroke can be increased; secondly, the same swing amplitude requires less driving force and prolongs the service life of the thirddriving device; and in addition, an injection pipe returns to the initial position in the non-working state without shaking, and the performance and reliability of the device are ensured.

Owner:CITIC HEAVY INDUSTRIES CO LTD

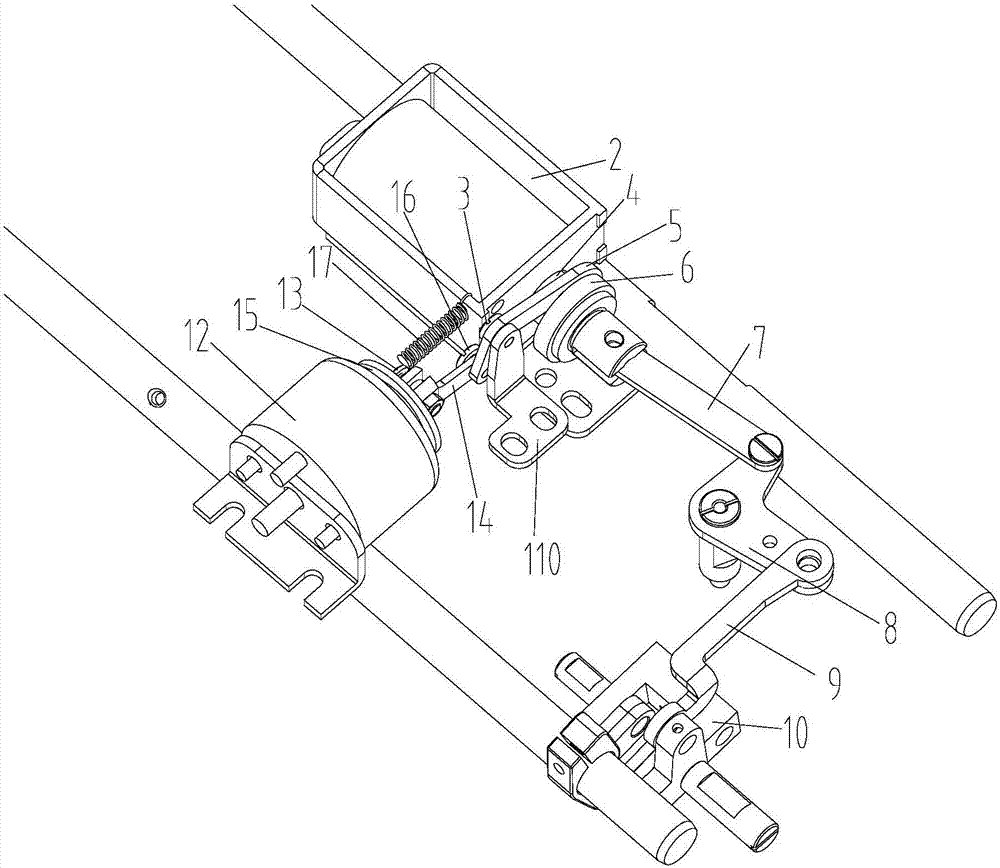

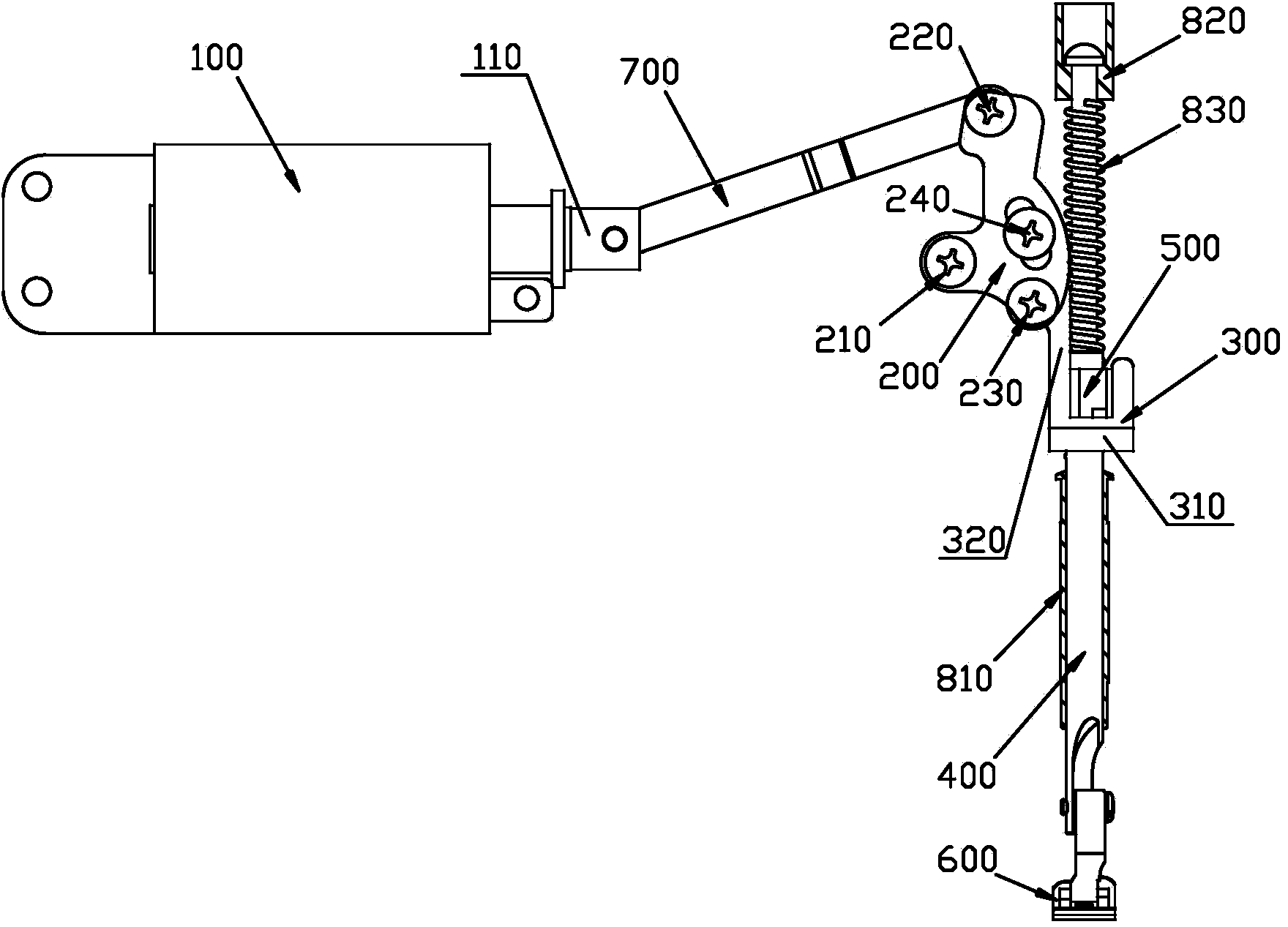

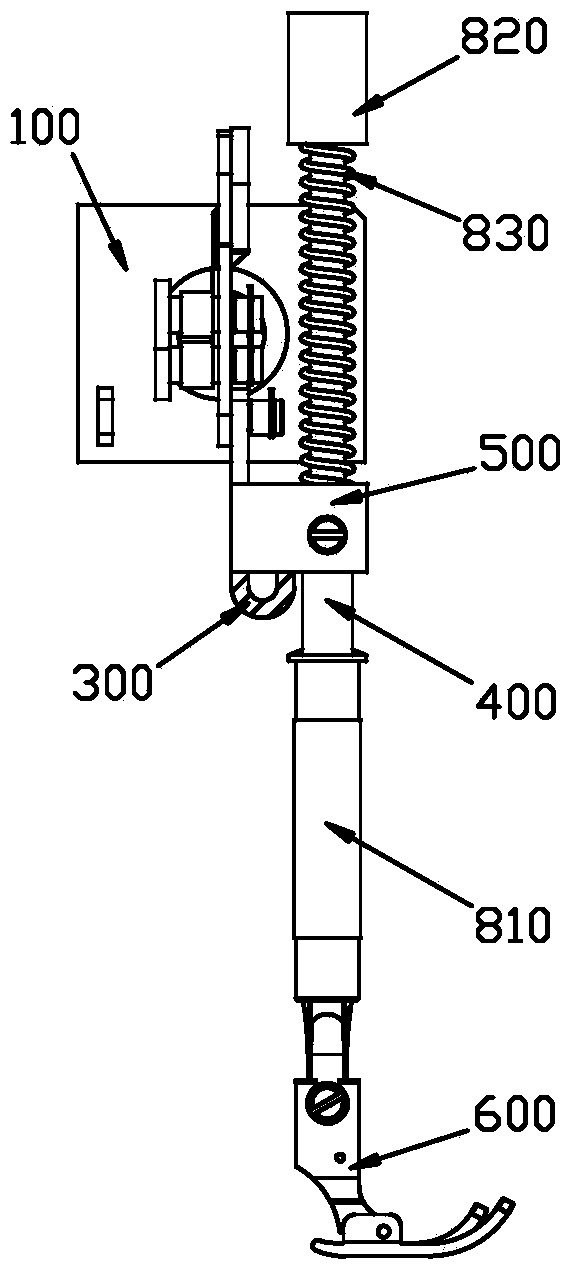

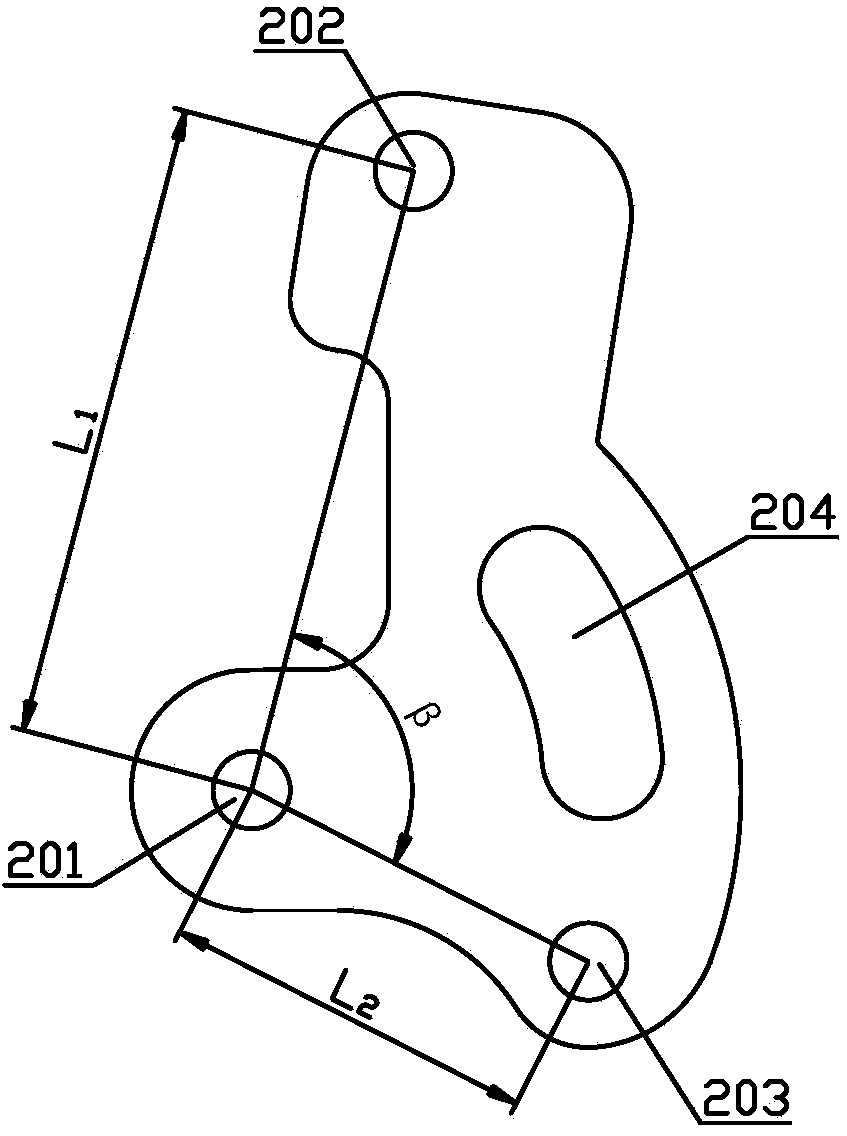

Automatic presser foot lifting device of sewing machine

The invention provides an automatic presser foot lifting device of a sewing machine. The automatic presser foot lifting device of the sewing machine comprises a drive source, a transmission lever, a lifting frame, a pressing rod, a pressing rod guide frame and a presser foot. The drive source is fixed to a shell of the sewing machine. The drive source comprises a telescopic shaft. The transmission lever comprises a pivot, a long arm of force and a short arm of force, wherein the pivot is hinged to the shell of the sewing machine, and the long arm of force and the telescopic shaft of the drive source are hinged to the two ends of a connecting rod respectively. The lifting frame comprises a bottom frame and a side frame, wherein the upper end of the side frame is hinged to the short arm of force. The pressing rod guide frame and the presser foot are fixed to a pressing rod body. The portion, below the pressing rod guide frame, of the pressing rod body is matched with a first guide sleeve fixed to the shell. The upper end of the pressing rod is matched with a second guide sleeve fixed to the shell. The lower end face of the pressing rod guide frame is attached to the upper end face of the bottom frame of the lifting frame. According to the automatic presser foot lifting device of the sewing machine, automatic pressure foot lifting motion of the sewing machine can be achieved through the drive source under the action of a small drive force, so that the drive source is small in size and low in manufacturing cost, the sewing machine is more attractive, and packaging and transportation of the sewing machine are facilitated.

Owner:JACK SEWING MASCH CO LTD

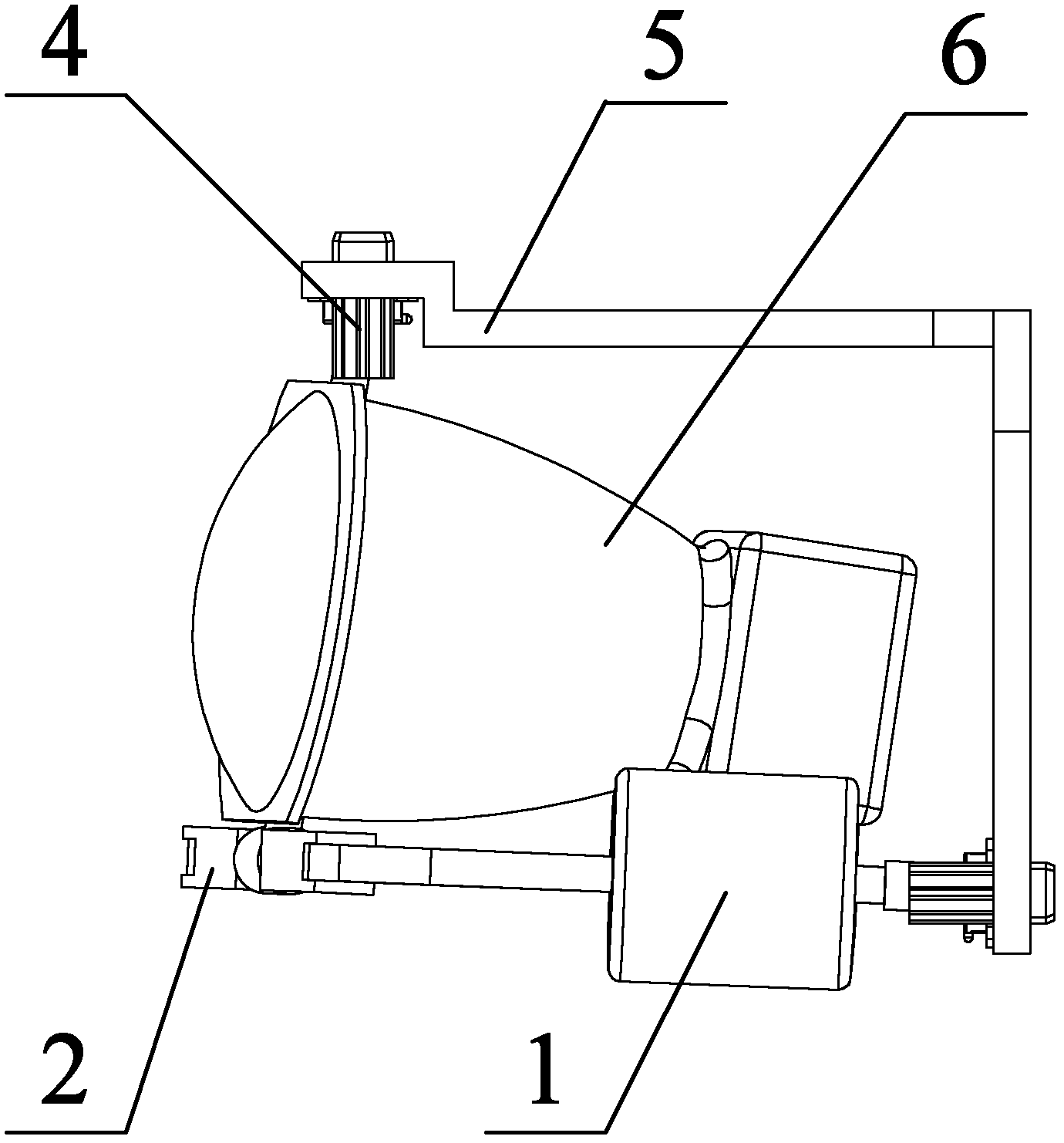

Self-adaptive automobile lamp steering system and automobile

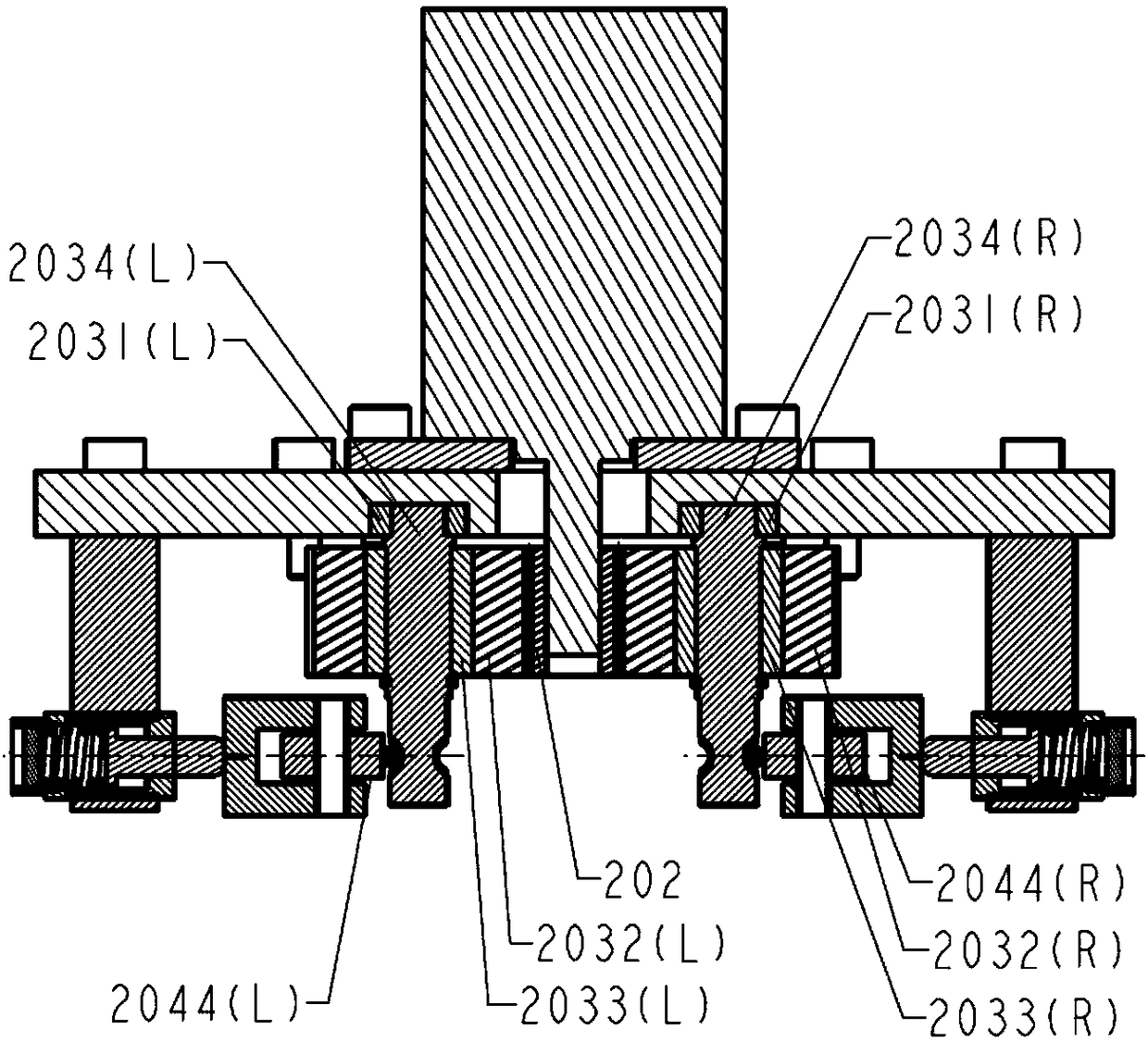

ActiveCN102582507AReduced driving force requirementsCompact layoutOptical signallingEngineeringSelf adaptive

The invention provides a self-adaptive automobile lamp steering system and an automobile. The self-adaptive automobile lamp steering system comprises a lamp holder, a support, two retractable parts, a crossbeam, a bulb and a spherical hinge seat. Existing horizontal movement and pitching movement which are independent are coupled into movement of the two retractable parts by the self-adaptive automobile lamp steering system. Spatial output angle of the self-adaptive automobile lamp steering system is fixed after positions of the two linear retractable parts are determined. When the two linear retractable parts move oppositely, the lamp holder connected with the crossbeam is driven to swing horizontally, and when the two linear retractable parts move in the same direction, the lamp holder connected with the crossbeam is driven to pitch. The two linear retractable parts retract simultaneously at a specific speed to drive the lamp holder to swing horizontally and pitch simultaneously, and the requirements of each linear retractable part are lowered. The two linear retractable parts are compactly arranged so that operating space is saved, and since the two linear retractable parts are identical in structure, complexity in production and assembly of parts is lowered, and production cost is effectively reduced.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

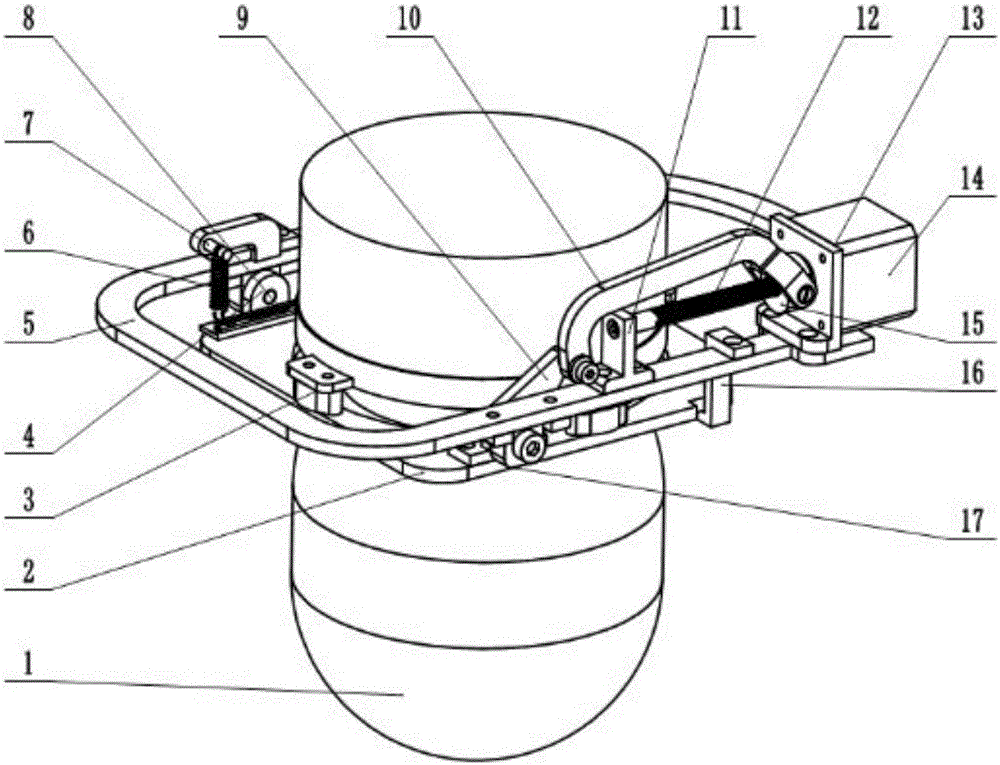

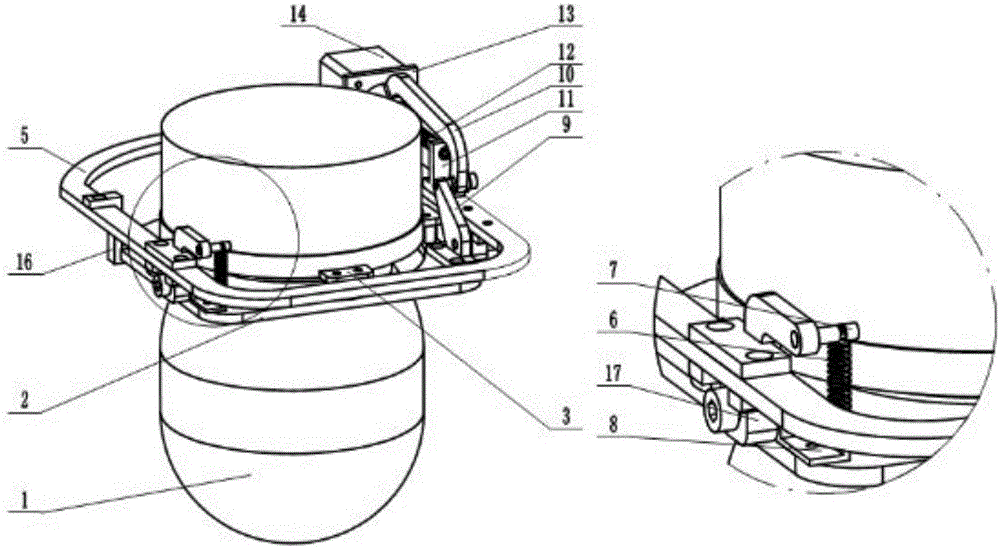

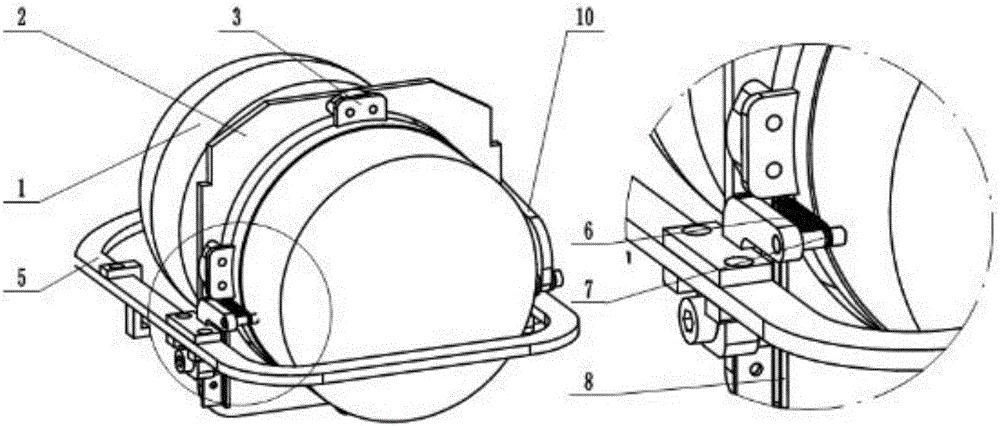

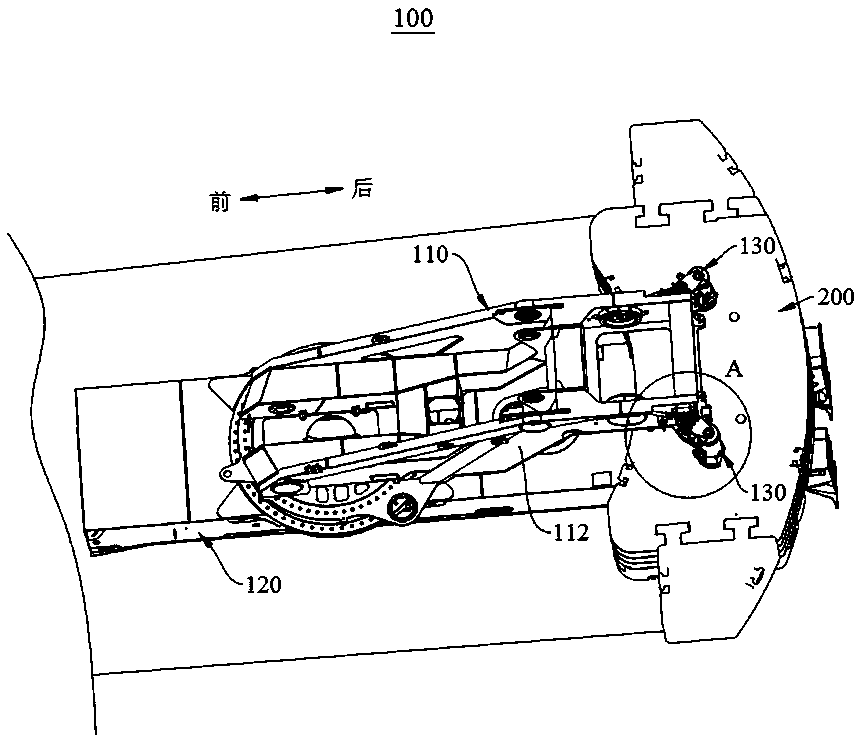

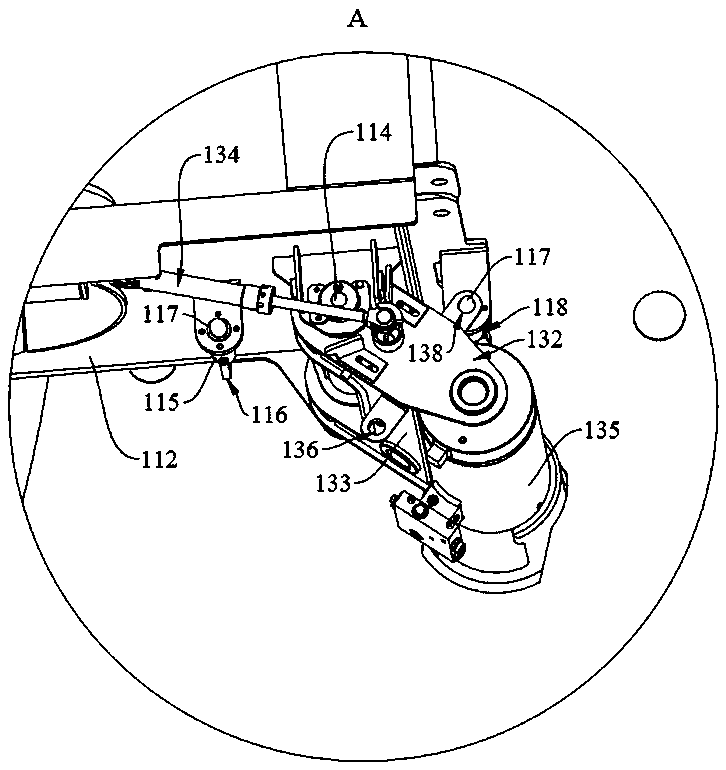

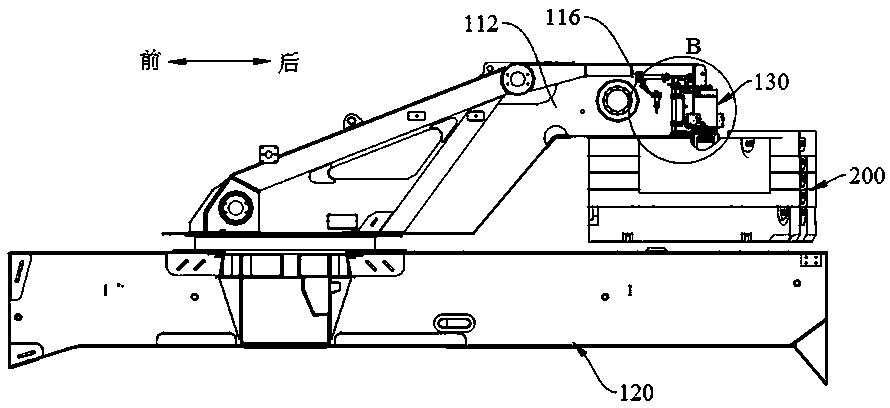

Unmanned aerial vehicle nacelle retracting mechanism and assembly method

ActiveCN106005453ALock firmlyEasy to install and maintainAircraft componentsNacelleLocking mechanism

The invention discloses an unmanned aerial vehicle nacelle retracting mechanism and an assembly method and relates to the technical field of unmanned aerial vehicle nacelle retracting. The problems of reliable retracting and releasing of an unmanned aerial vehicle nacelle and the stability of a nacelle body in a working state are solved. The unmanned aerial vehicle nacelle retracting mechanism is mainly composed of a fixed assembly, a rotating assembly, a slide block crank mechanism and an auxiliary locking mechanism. The nacelle is fixed to a vibration isolation plate through a vibration absorber, so that the rotating assembly is composed. The fixed assembly is in pin shaft connection with the rotating assembly. A slide block of the slide block crank mechanism pushes a crank and the rotating assembly to rotate through a connection rod. Reversing of the locking torque of the auxiliary locking mechanism is achieved by changing the hanging point position of a locking tension spring in the rotating process of the rotating assembly, the rotating assembly is locked to the fixed assembly under the releasing and retracting states, and the stabilization of the nacelle body is achieved. According to the unmanned aerial vehicle nacelle retracting mechanism and the assembly method, the structure is compact, retracting, releasing and supporting of the nacelle are achieved in a modularized mode, and the nacelle is pushed to be rotationally retracted and released through the slide block crank mechanism subjected to size optimization; and the driving force requirement for a power source is reduced as far as possible, and the driving mechanism size is decreased.

Owner:CHANGGUANG SATELLITE TECH CO LTD

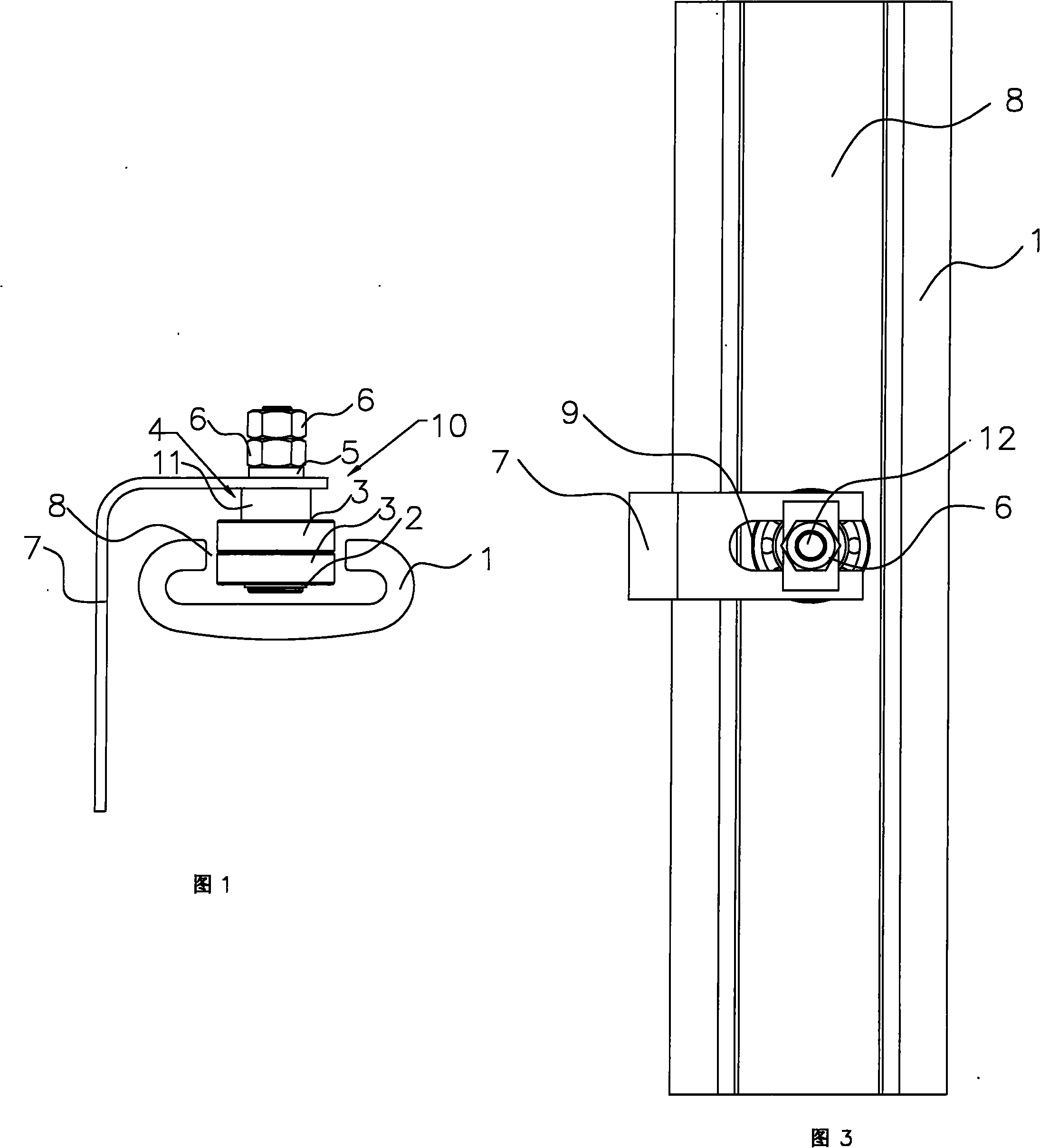

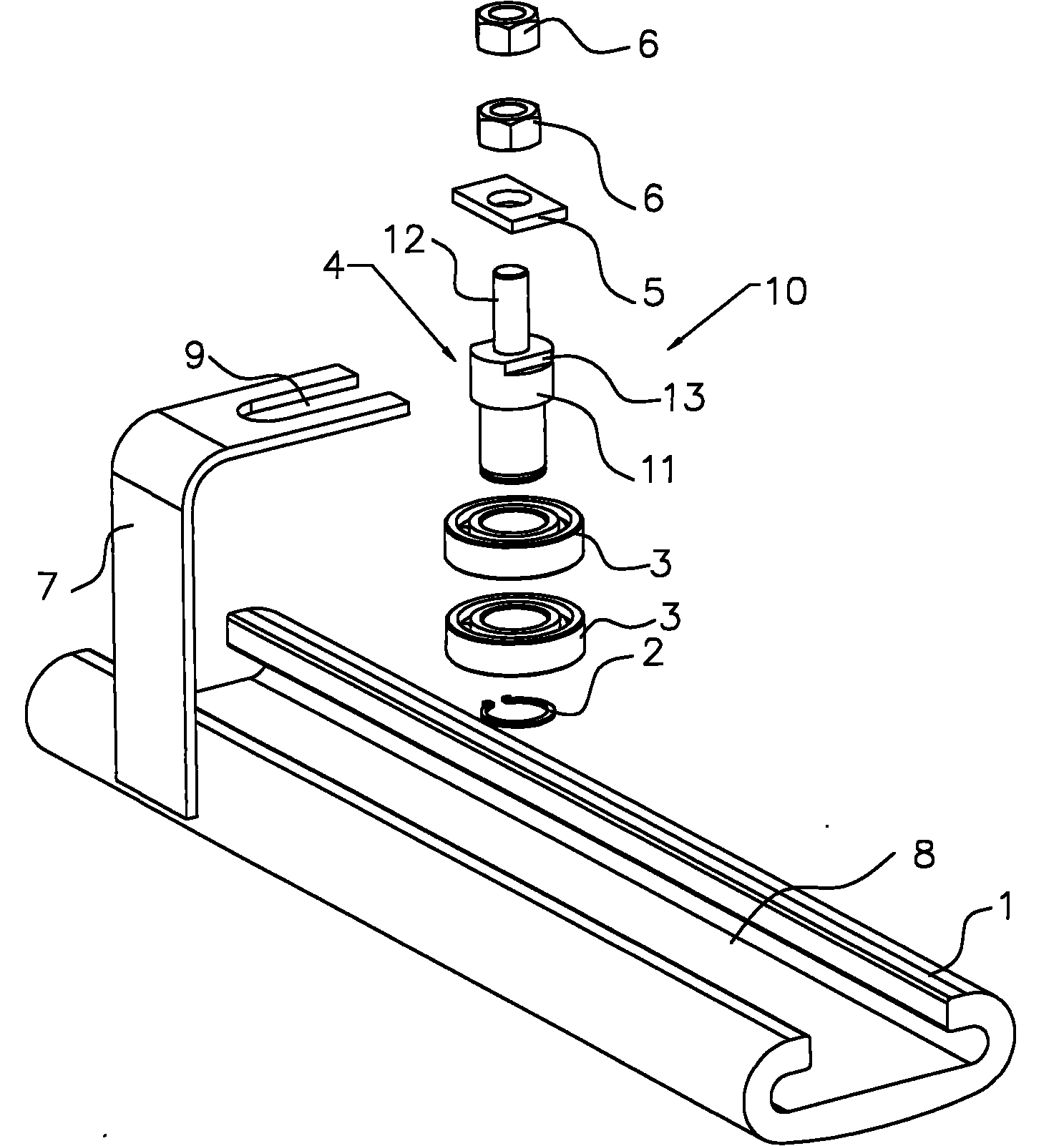

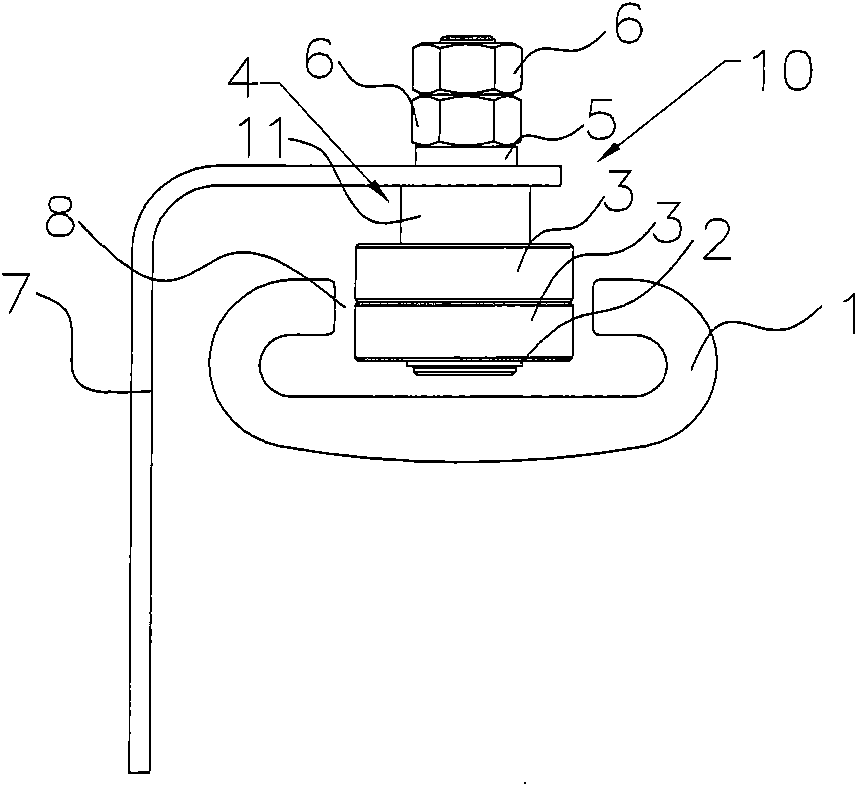

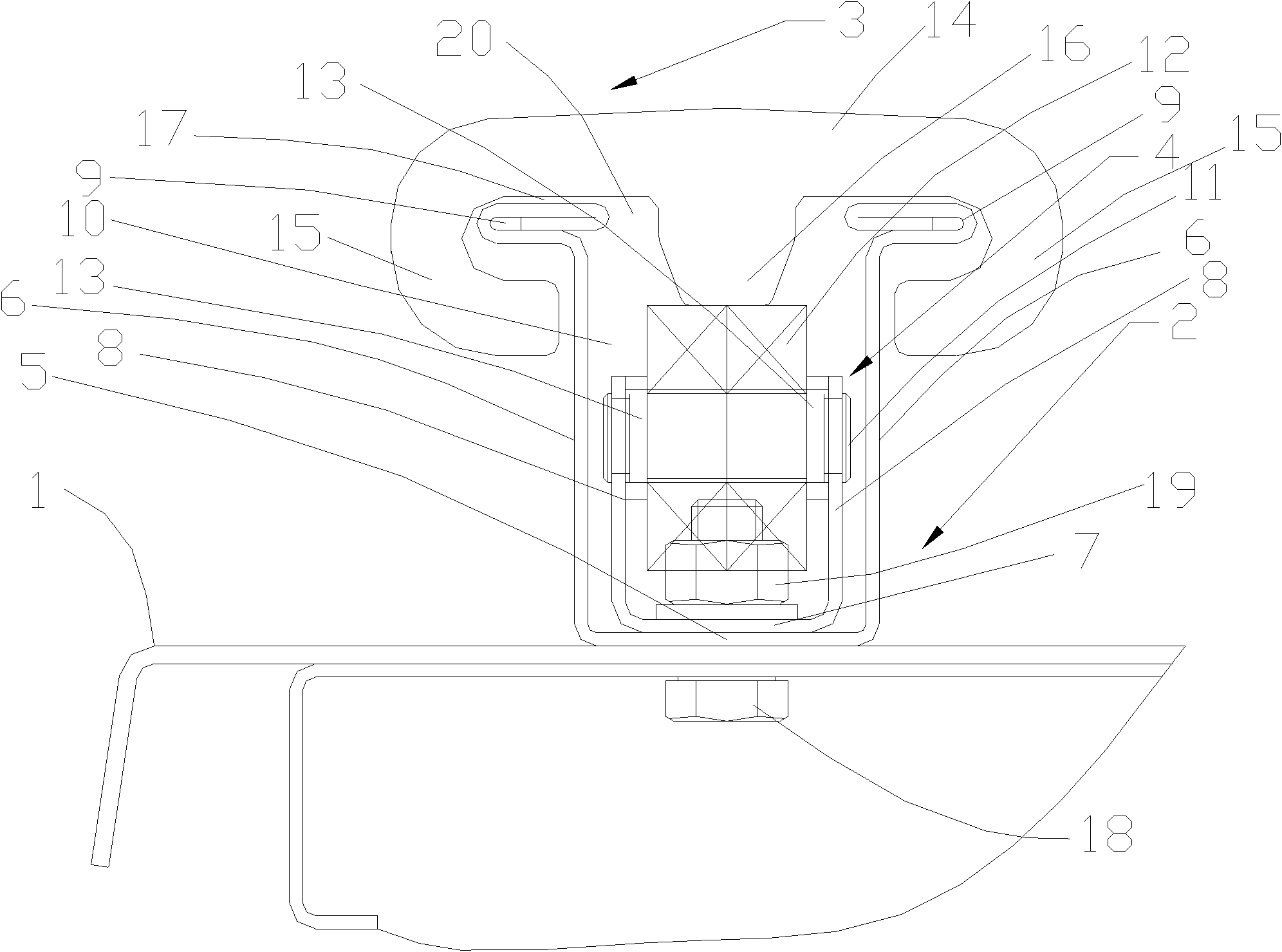

Hand strap guide device on escalator or travolater

InactiveCN101804941AMoving doesn't affectPrevent slippingEscalatorsRolling resistanceResistance force

The invention discloses a hand strap guide device on an escalator or a travolater, which comprises a movable hand strap, wherein the cross section of the hand strap is in a C shape, an opening of the C shape of the hand strap is upward, and the guide device also comprises a support frame, a guide shaft and a bearing, wherein the guide shaft is arranged on the support frame, the bearing is sheathed on the end part of the guide shaft, and the axial line of the bearing is in up-down arrangement and is vertical to the moving direction of the hand strap, at least a part of the bearing extends into the opening of the C shape, the bearing is separated from the hand strap when the hand strap is moved normally, the bearing can not influence the normal movement of the hand strap, the outer ring of the bearing is in rolling contact with the tail end of the C shape of the hand strap when the hand strap deviates in the transverse direction, the bearing can guide and correct the hand strap, and in addition, the outer ring of the bearing is in rolling contact of the hand strap, so the hand strap has small friction resistance, and the slippage phenomenon of the hand strap can be avoided. Thereby, possibly occurring safety accidents can be avoided. The resistance of the hand strap is reduced through the rolling friction, the driving force requirement of the hand strap can also be reduced, the noise caused by friction can be reduced, and the service life of the hand strap can be improved.

Owner:SJEC CORP

Telescopic comb tooth type three-dimensional parking system

The invention relates to the technical field of three-dimensional garages, and particularly discloses a telescopic comb tooth type three-dimensional parking system. The telescopic comb tooth type three-dimensional parking system comprises a mechanical three-dimensional garage; a plurality of movable parking plates used for parking automobiles are arranged inside the mechanical three-dimensional garage; the system also comprises a vehicle carrying platform and a transfer vehicle; the vehicle carrying platform is provided with a groove; the tops of the groove are symmetrically fixed with fixed comb tooth racks; the transfer vehicle comprises an upper chassis, a lower chassis, a lifting mechanism and a plurality of telescopic comb tooth groups; the telescopic comb tooth groups are positionedin the upper chassis; each telescopic comb tooth group comprises two push-pull rods and two centrosymmetric telescopic comb teeth; the telescopic comb teeth are arranged in the width direction of theupper chassis; telescopic comb teeth comprise long rods and short rods which are fixedly connected horizontally; the axes of the long rods and the short rods are parallel; the outer ends of the long rods and the short rods are flush; the push-pull rods comprise telescopic ends and fixed ends; the fixed ends of the push-pull rods are fixedly connected with the upper chassis; and the telescopic endsof the push-pull rods are fixedly connected with the inner ends of the long rods. By adopting the technical scheme, the stability of the automobile during transportation can be improved.

Owner:重庆莫微恒石智慧停车服务有限公司

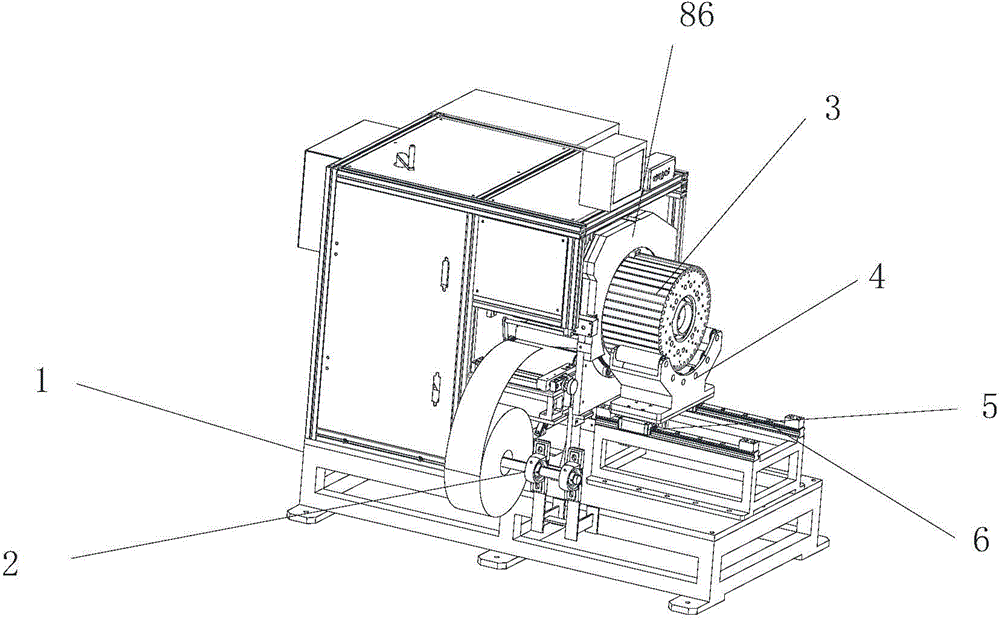

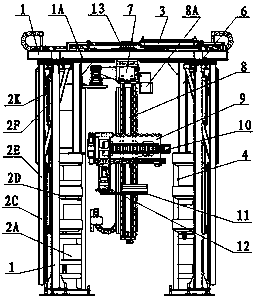

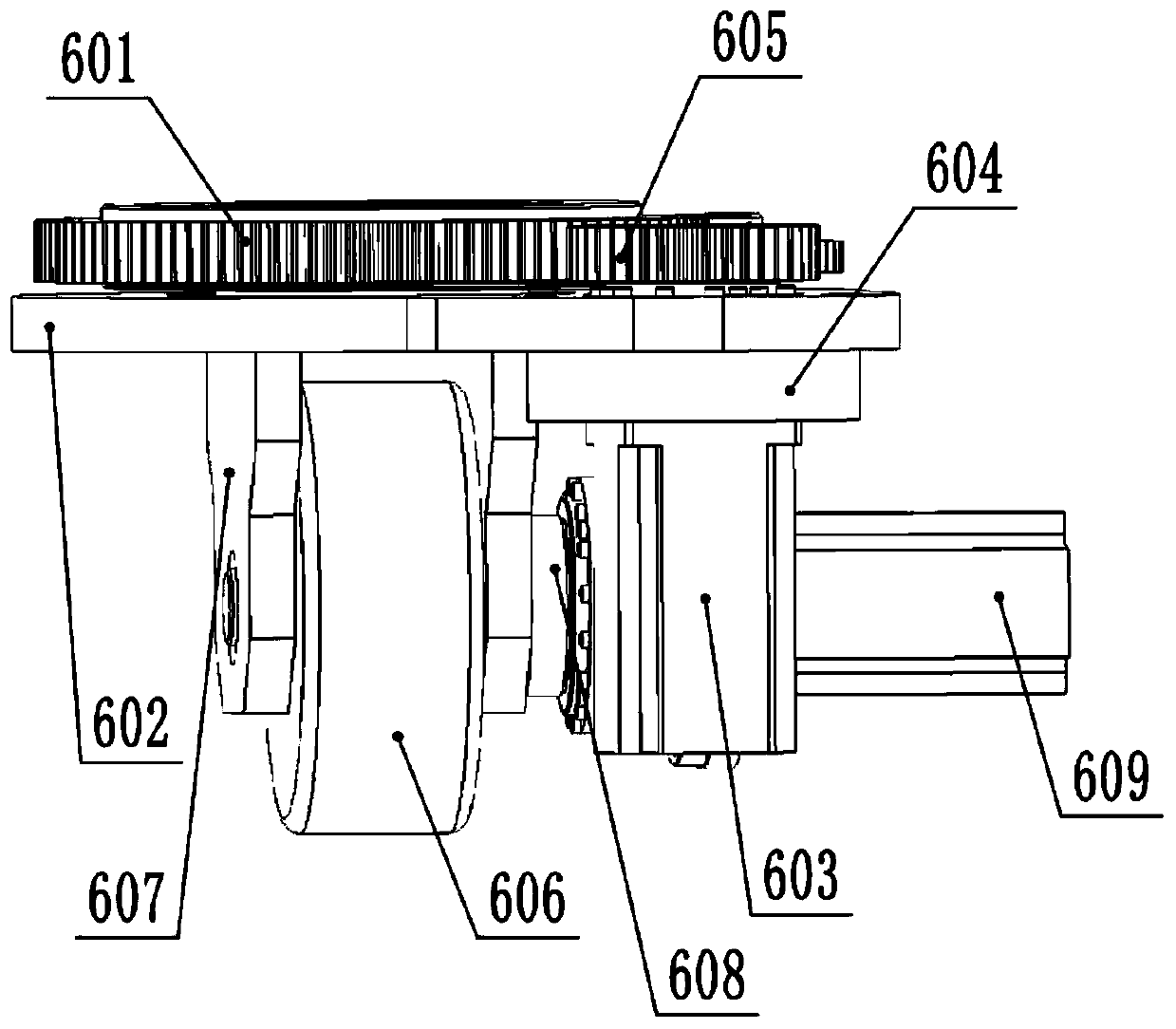

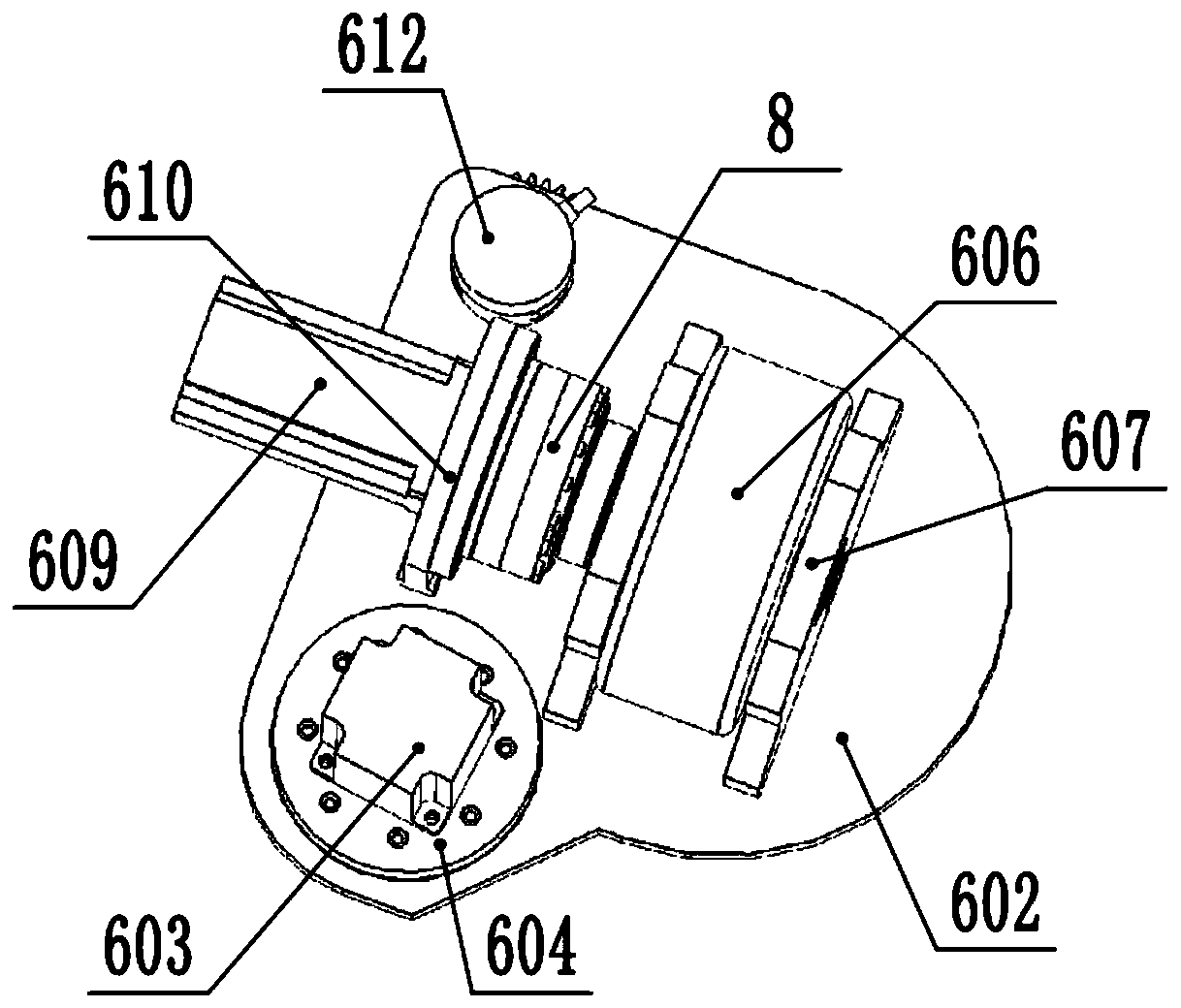

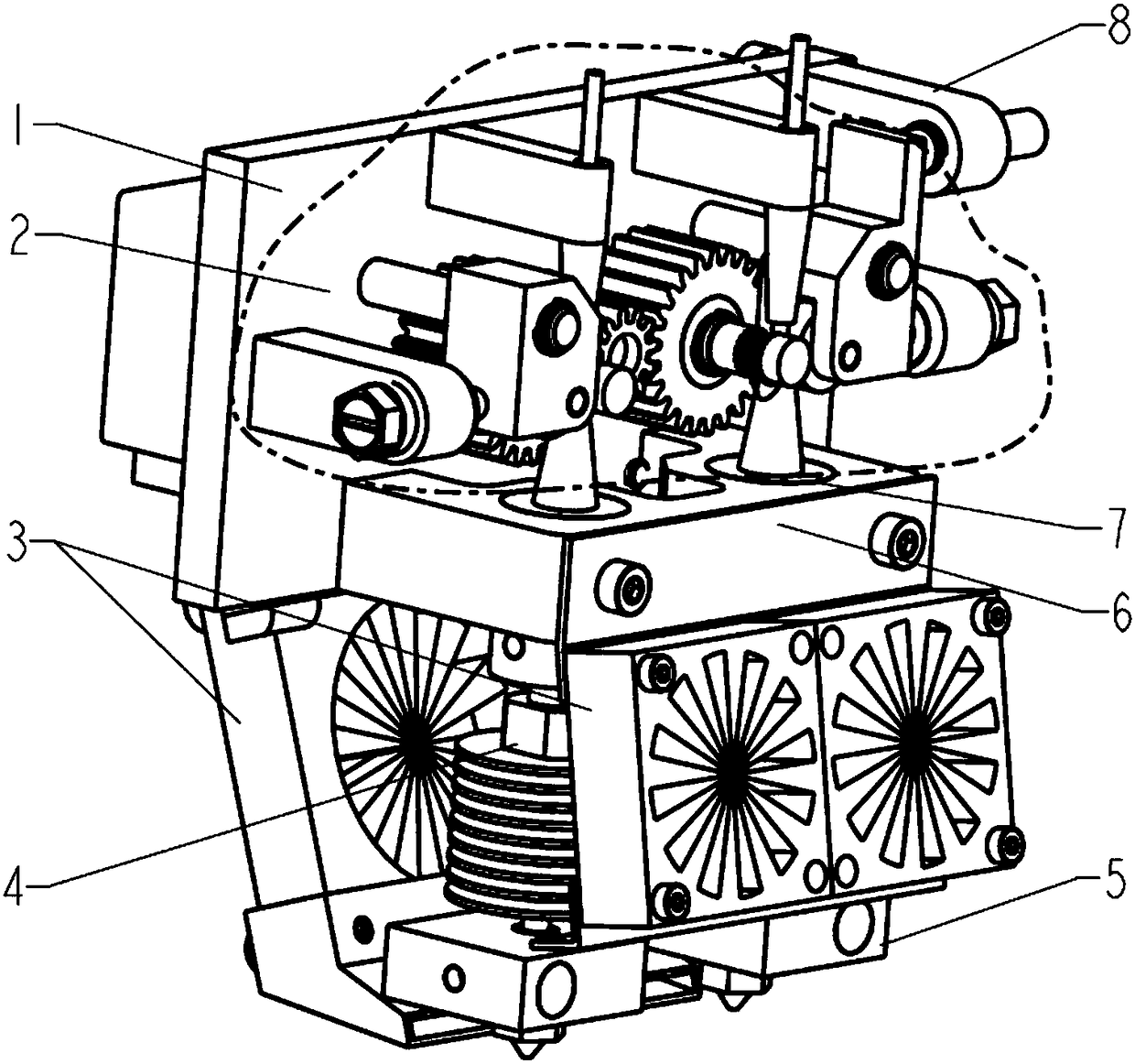

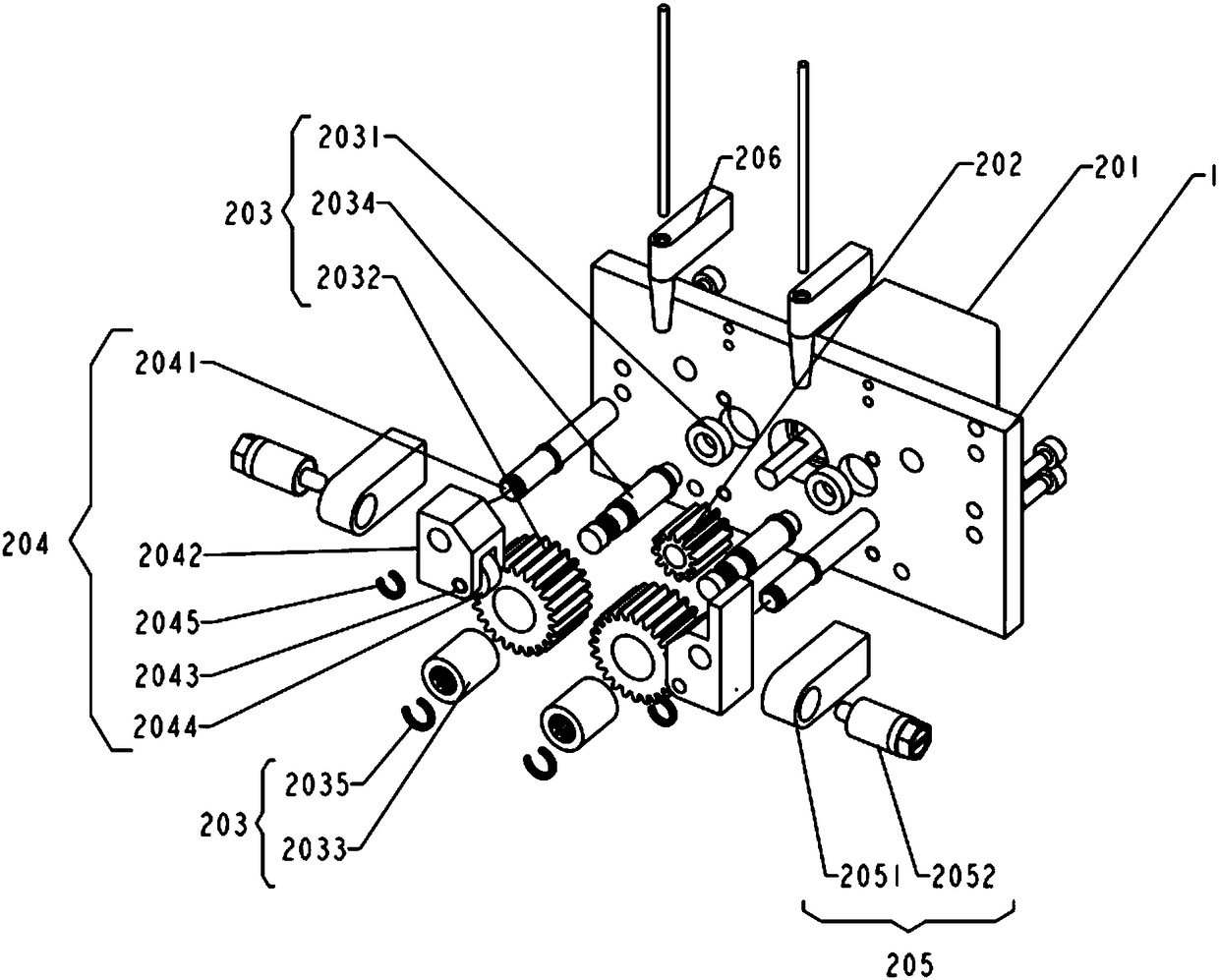

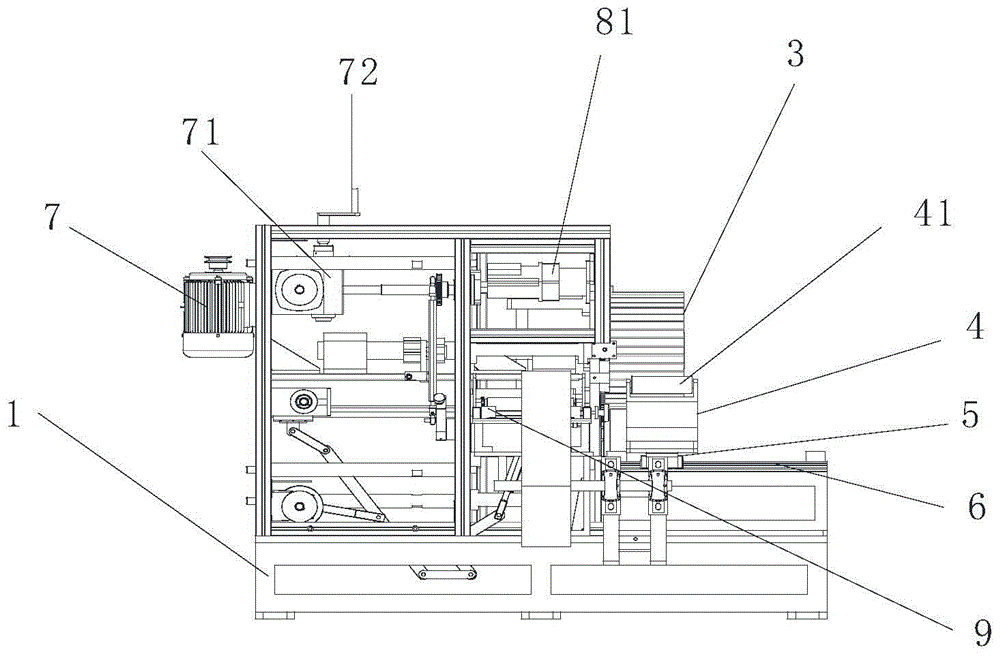

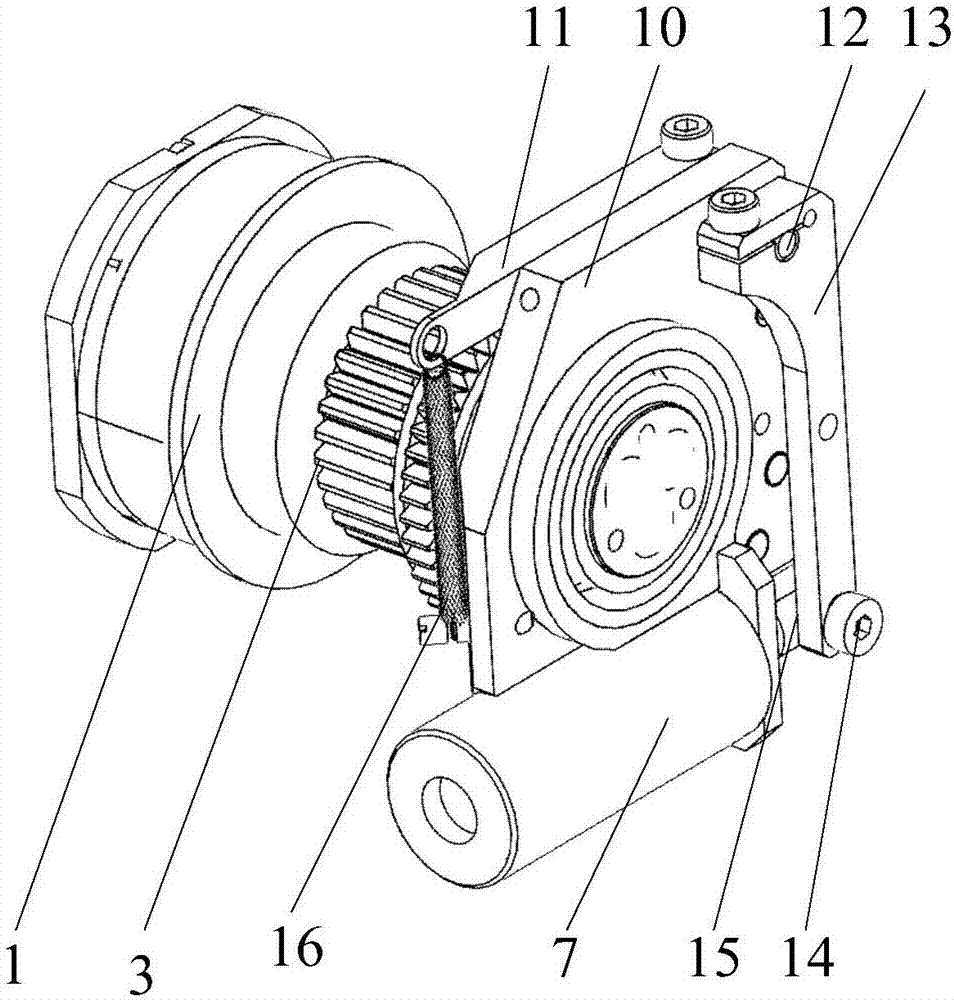

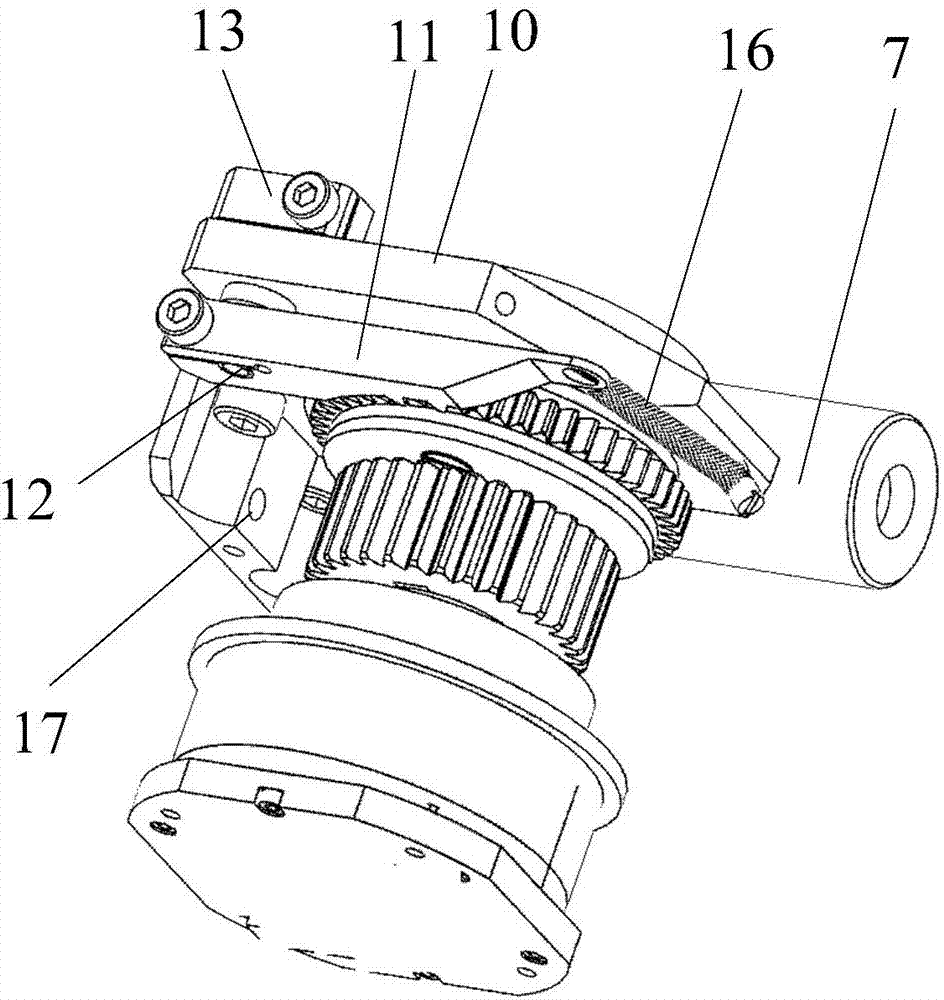

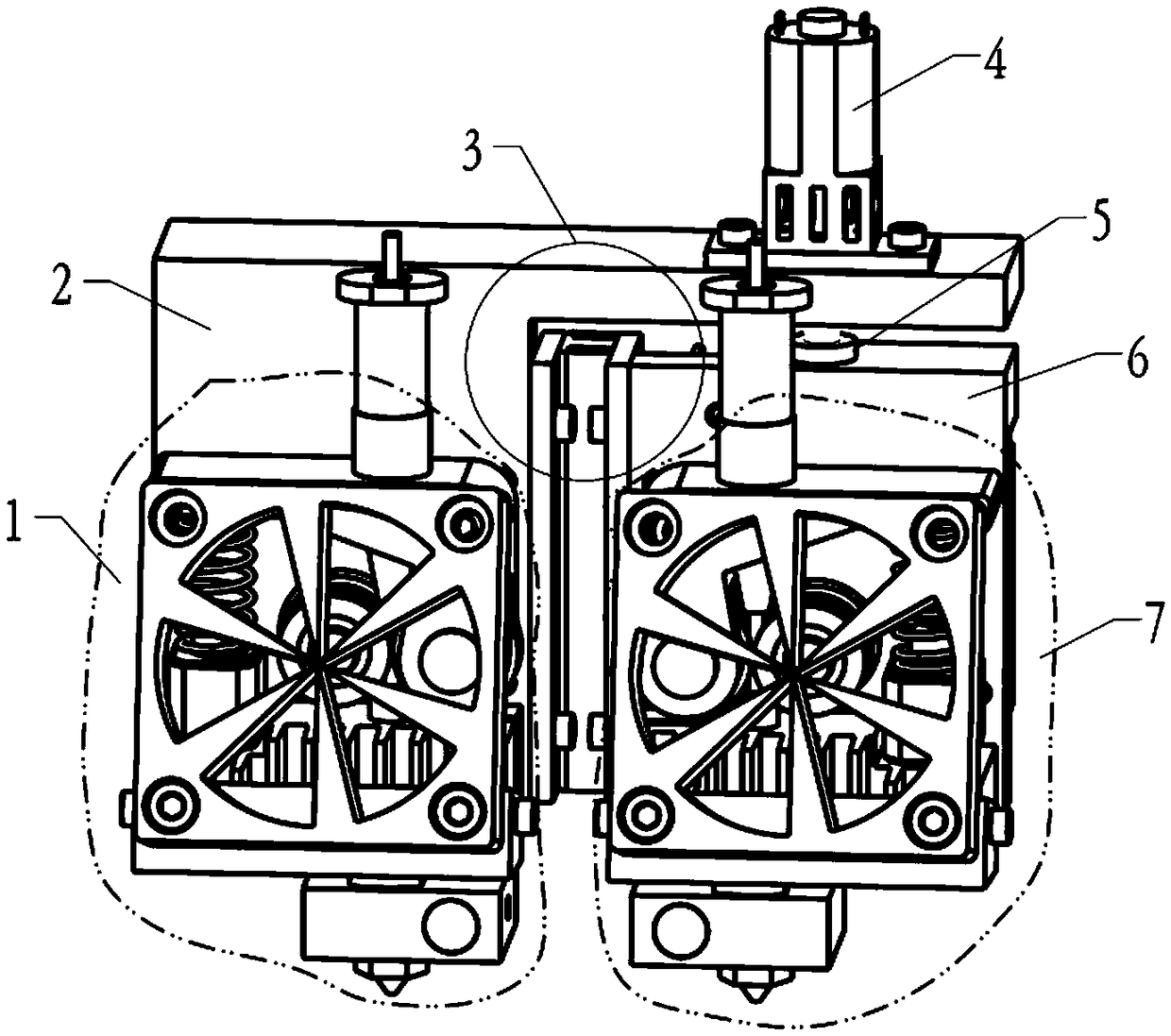

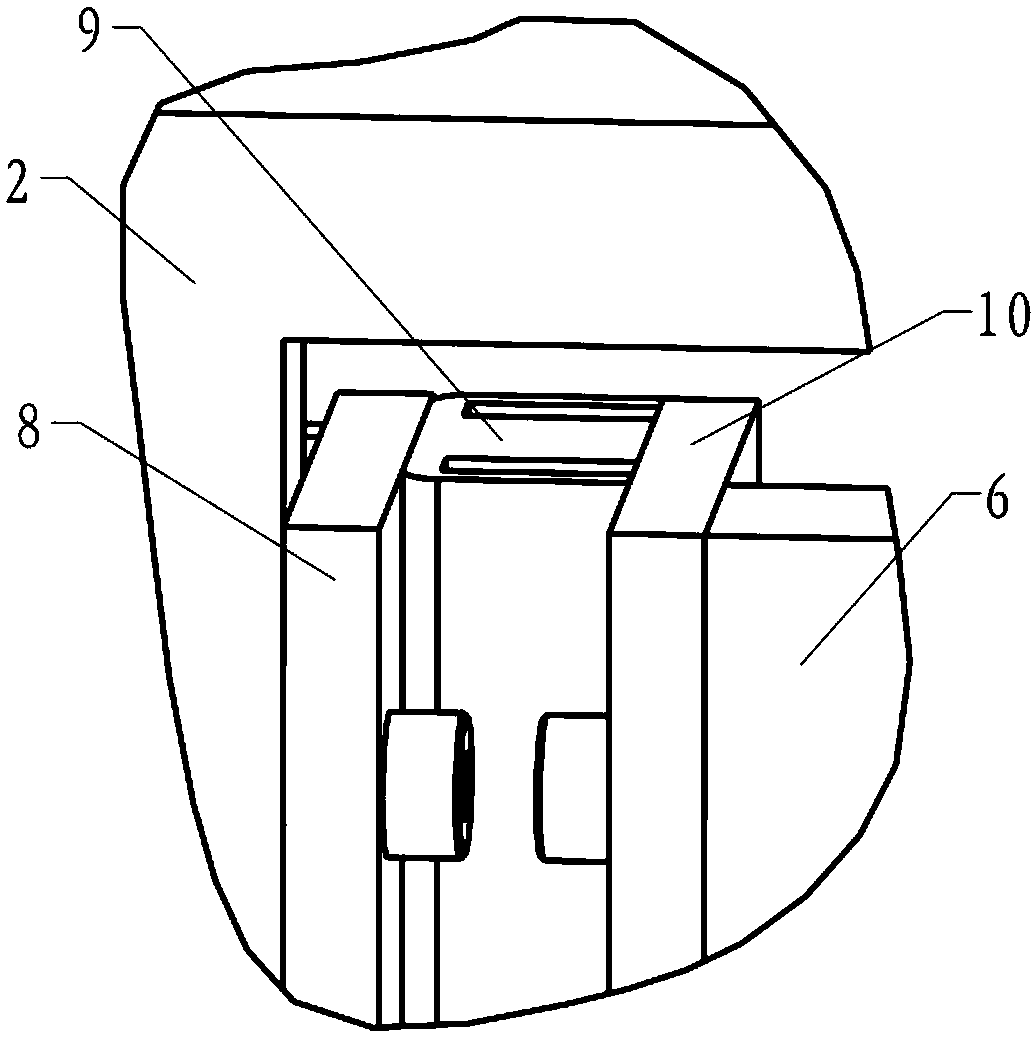

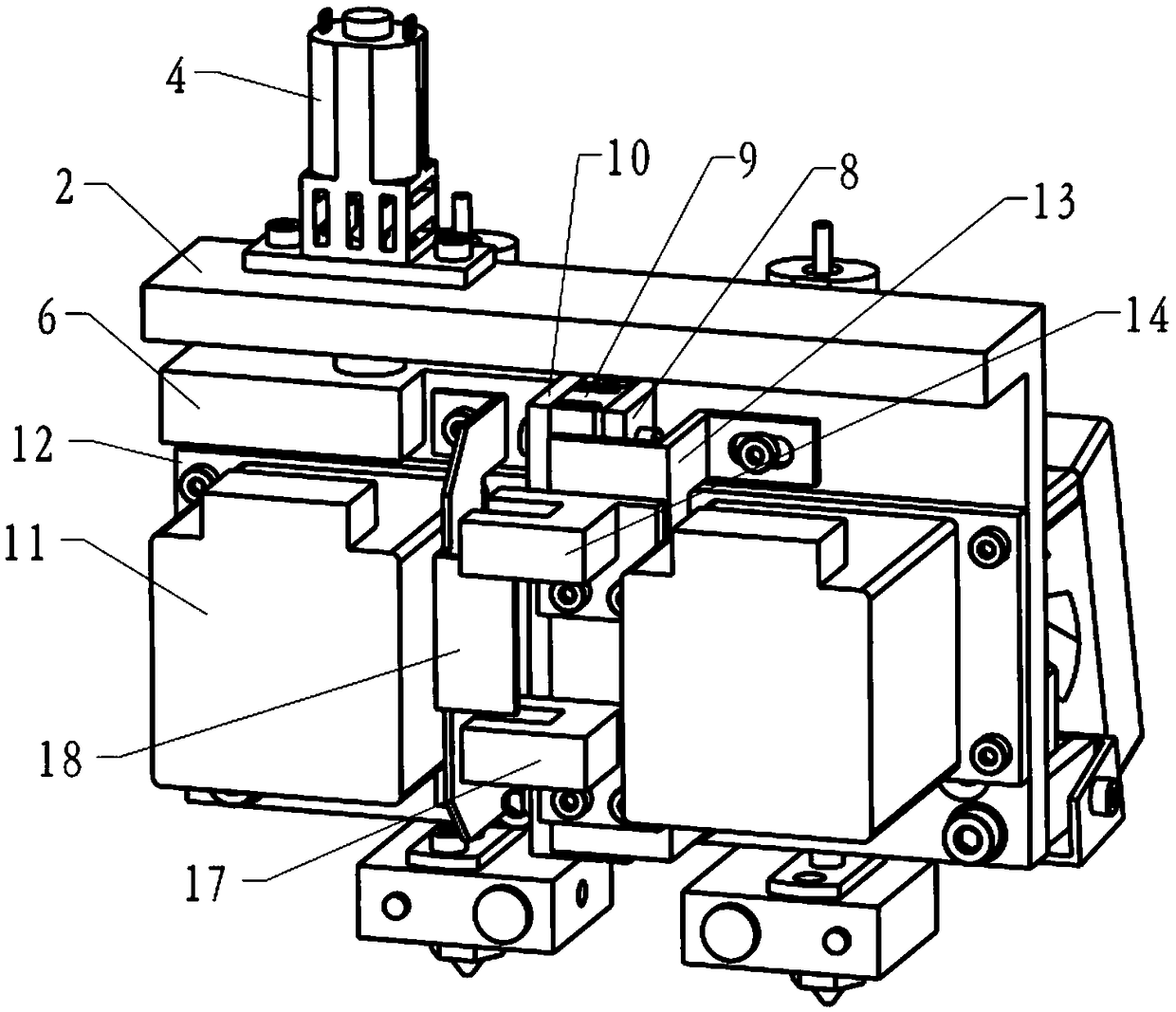

Three-dimensional printer single-motor extrusion system capable of actively switching printing head

ActiveCN108582781AHigh positioning accuracyHigh dimensional accuracyApplying layer meansEngineeringDrive motor

The invention discloses a three-dimensional printer single-motor extrusion system capable of actively switching a printing head. The three-dimensional printer single-motor extrusion system capable ofactively switching the printing head comprises a base plate, a feeding assembly, a printing head fixing base, a switching auxiliary device, a fixed printing head and a movable printing head arranged on the printing head fixing base, and a switching mechanism nested into the movable printing head, wherein the feeding assembly, the printing head fixing base and a switching auxiliary device are arranged on the base plate; the feeding assembly is used for continuously pushing a filament material into the fixed printing head and the movable printing head for melting and extruding; and the switchingmechanism and the switching auxiliary device are used for up-and-down moving the movable printing head. According to the three-dimensional printer single-motor extrusion system capable of actively switching the printing head provided by the invention, through designing the movable printing head assembly and the fixed printing head assembly, the automatic switching of the two printing heads can berealized through switching the movable printing head; the movable printing head and the fixed printing head are independent so as to be free of being interacted; and the system is simple in structure, the printing accuracy is ensured, two filament materials can be printed alternately by only using one drive motor without the need for using any other external force except for the extrusion system,and the height difference of the two printing heads can be switched, so that the weight and the cost of the extrusion system are reduced.

Owner:GUANGZHOU ELECTRONICS TECH

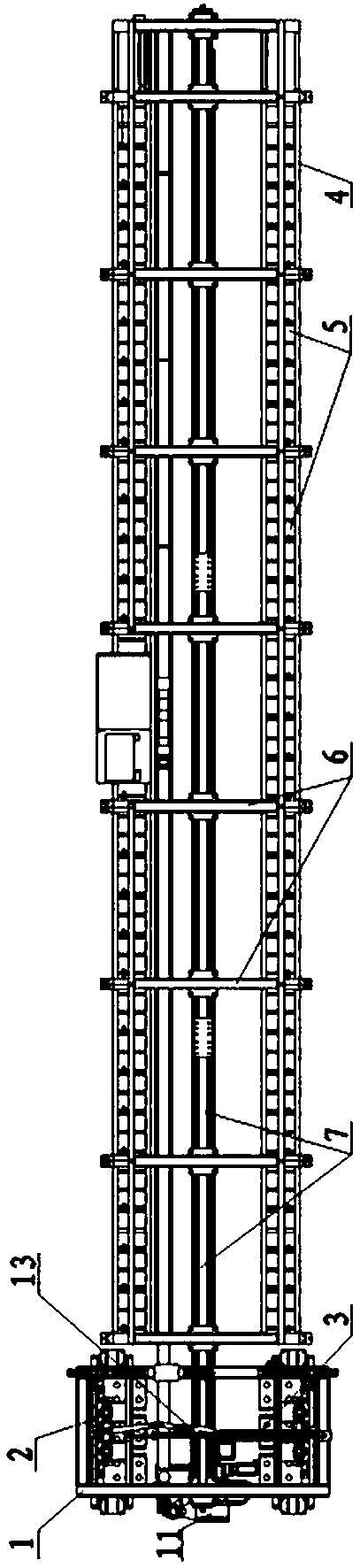

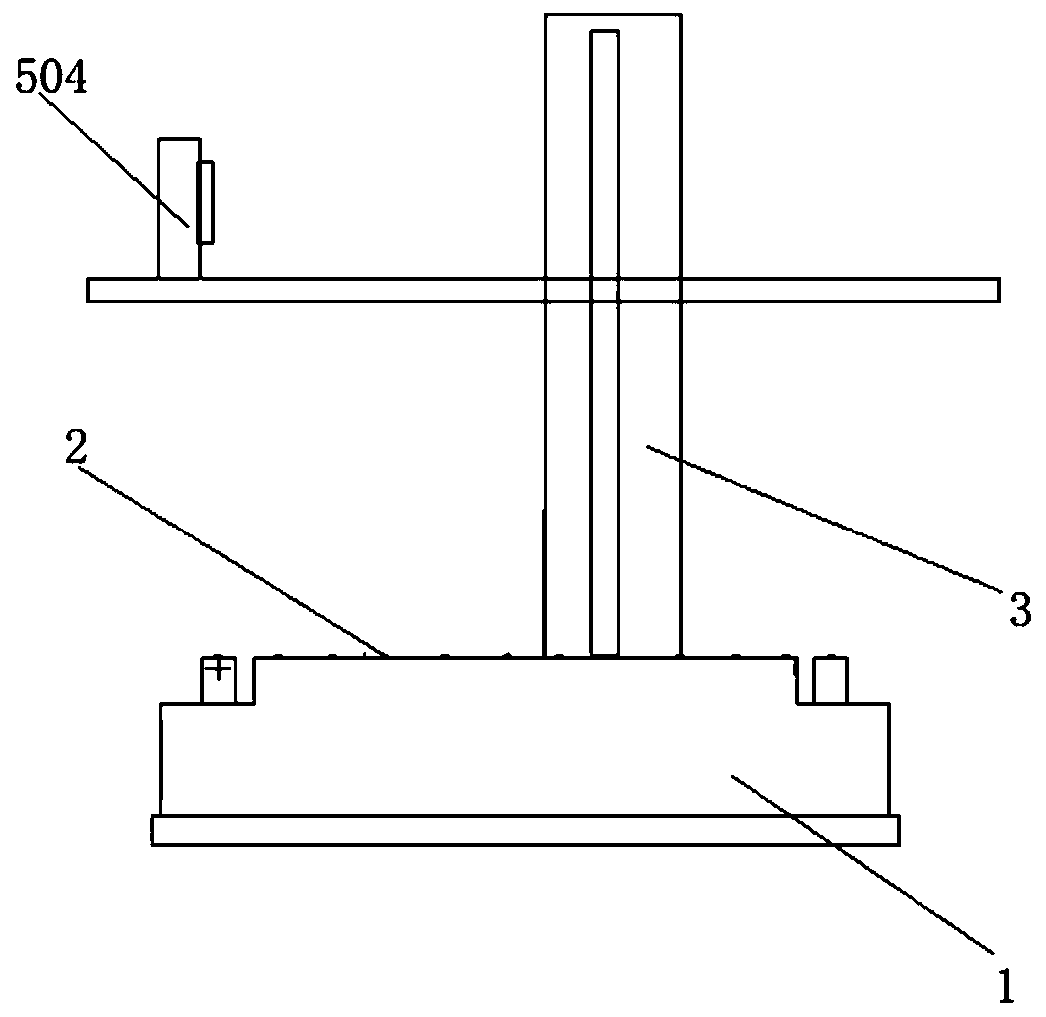

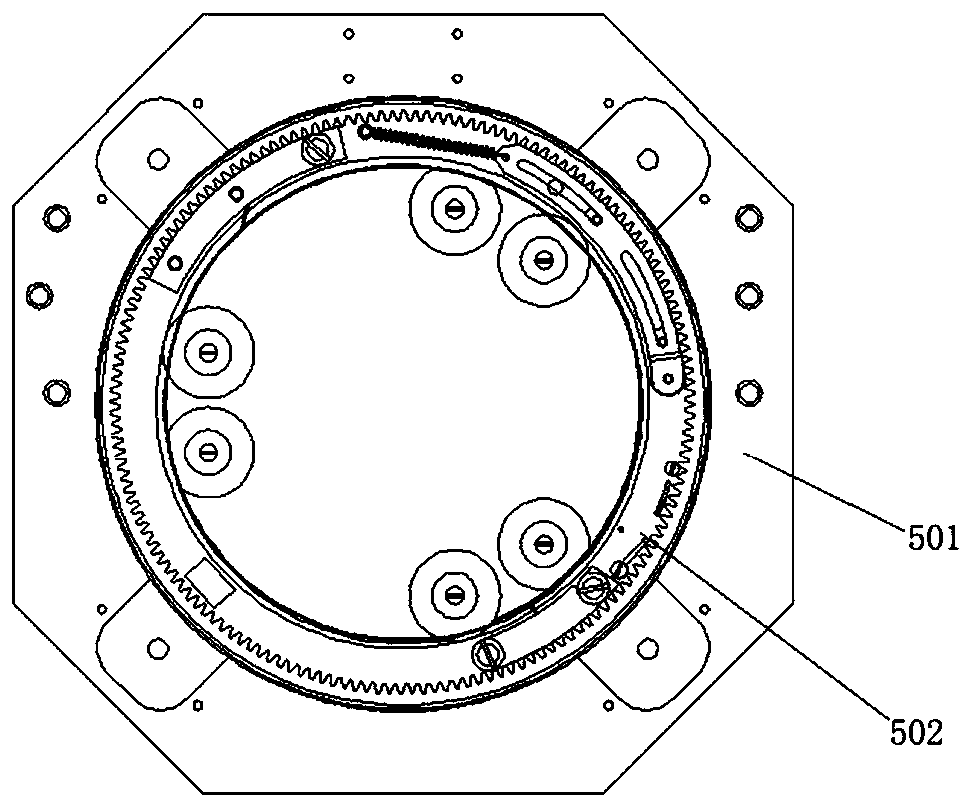

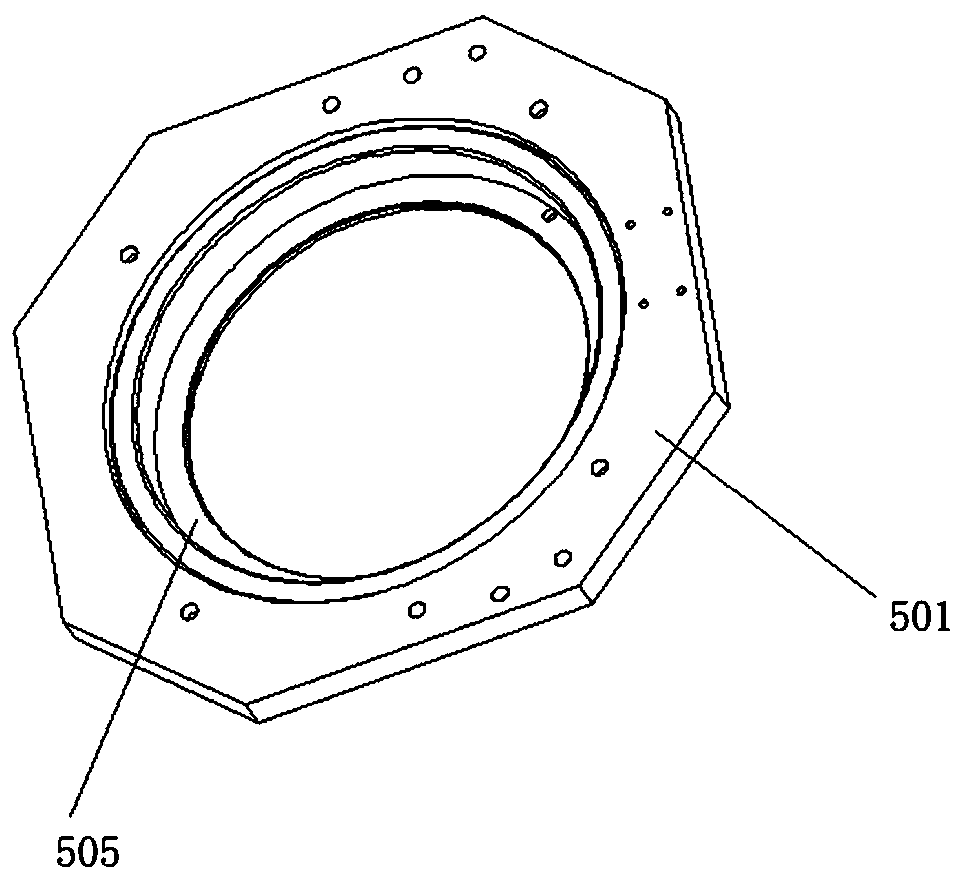

Tray type online winding machine and winding method thereof

ActiveCN110422374ASolve the problem of large space requirementsReduce high failure rateWrapping material feeding apparatusWeb rotation wrappingWinding machineEngineering

The invention discloses a tray type online winding machine capable of preventing products from scattering and a winding method of the tray type online winding machine, and belongs to the technical field of winding machines. The winding machine comprises an upright column, a lifting assembly mounted in the upright column, an elevating assembly in transmission connection with the lifting assembly, atray in transmission connection with the elevating assembly and a winding assembly mounted on the tray, wherein the winding assembly comprises a supporting plate which is hollow inside and arranged in the tray, an outer gear ring arranged on the inner side wall of the supporting plate, an inner gear ring in transmission connection with the outer gear ring, an annular ring fixedly connected to thelower surface of the inner gear ring, a driving assembly for driving the annular ring and a film fixing shaft fixed on the upper surface of the inner gear ring. The tray type online winding machine and the winding method thereof have the advantages that rotation of a base plate loaded with large objects is not required; product scattering caused by rotation of the base plate can be avoided, safety factors are increased, and energy can be effectively saved.

Owner:南京斯杩克机器人技术有限公司

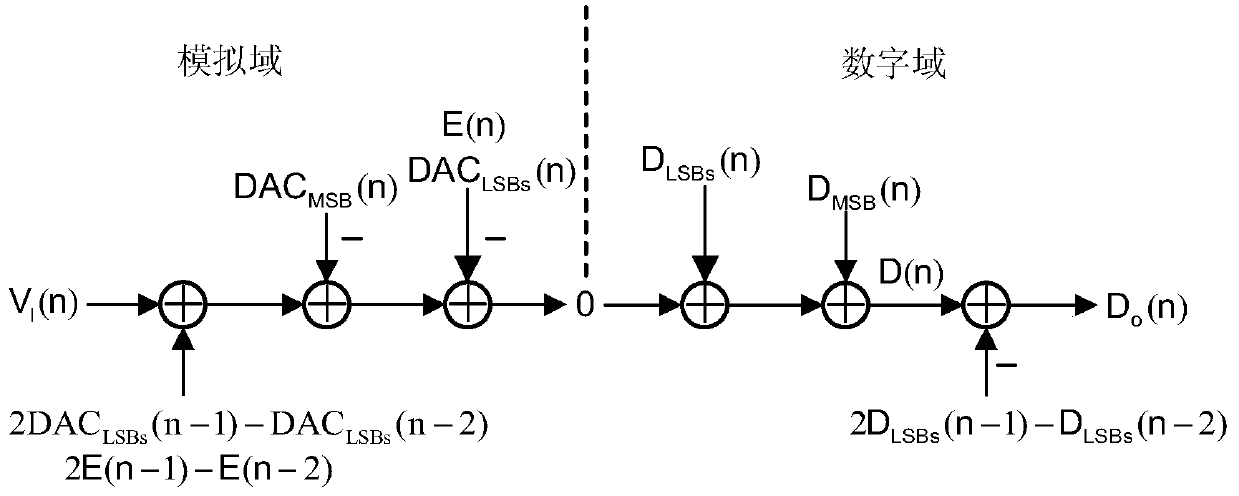

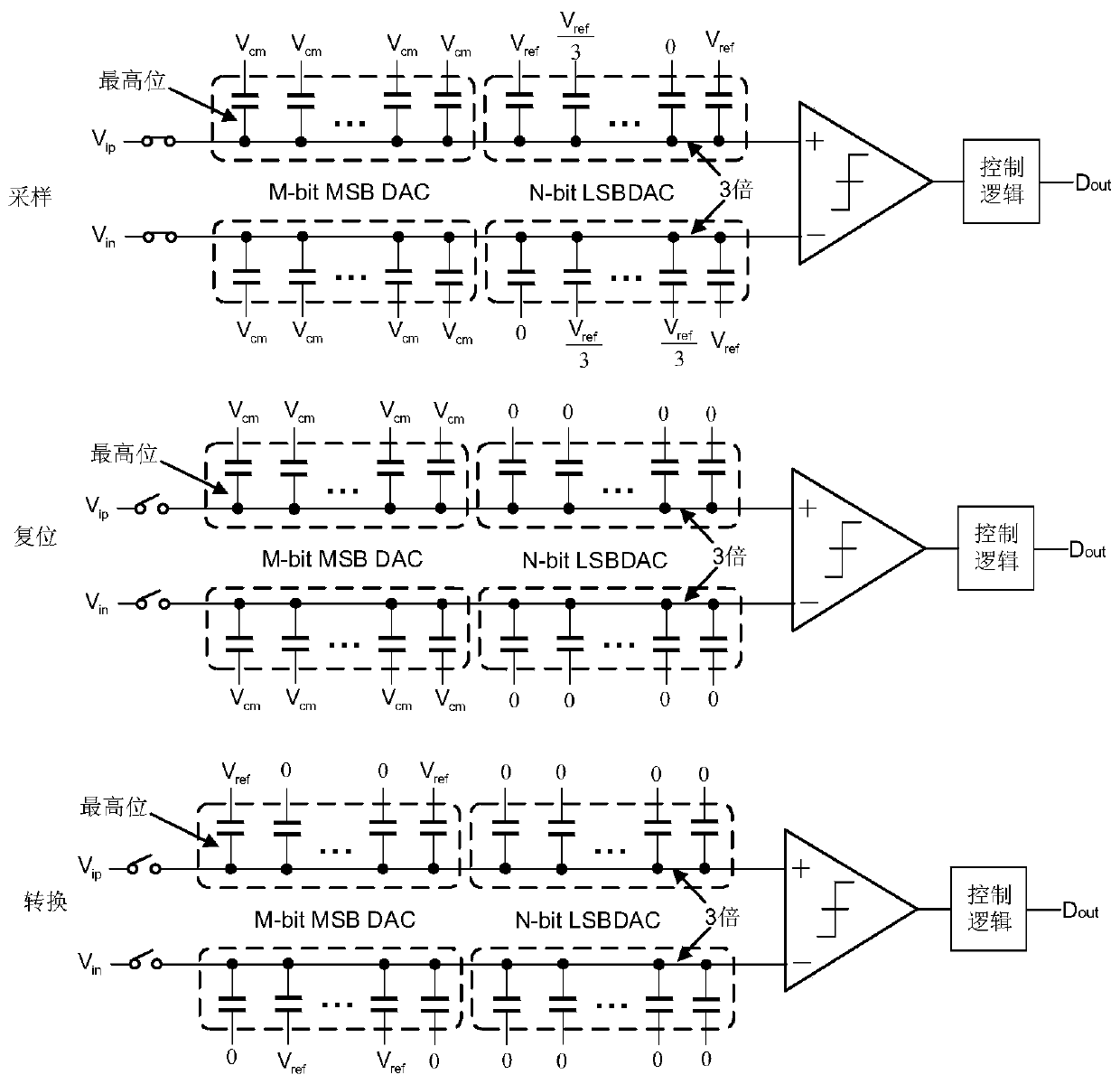

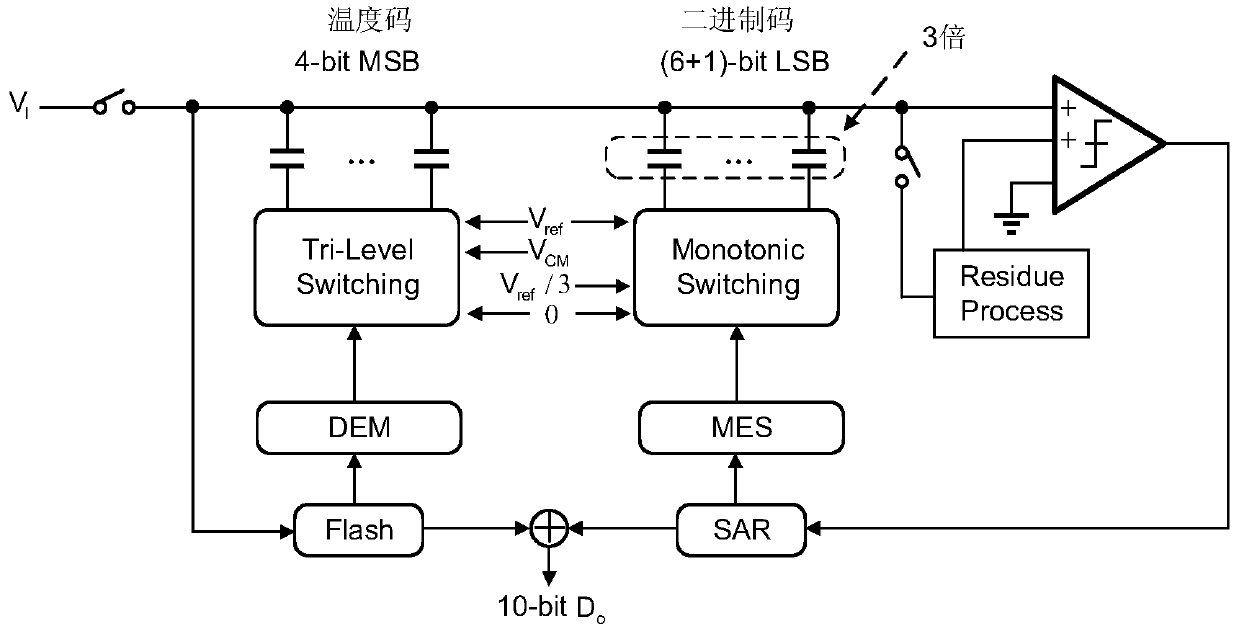

Capacitor mismatch error shaping switching circuit and method suitable for oversampling SAR ADC

ActiveCN110739968ASimple structureReduce capacitanceElectric signal transmission systemsAnalogue/digital conversion calibration/testingCapacitanceHemt circuits

The invention provides a capacitor mismatch error shaping switching circuit and method suitable for an oversampling SARADC, and belongs to the technical field of analog-digital hybrid integrated circuits. According to the invention, the second-order shaping of the capacitor mismatch error can be realized by feeding back the quantization results of the previous two low-order (LSB) and the capacitormismatch error. Compared with a traditional switching algorithm, a reference voltage needs to be additionally introduced, and the LSB capacitance value is changed into three times of the original capacitance value. The circuit is simple in logic, low in circuit overhead, easy to implement, excellent in capacitor mismatch error shaping effect and suitable for high-precision application occasions.

Owner:SOUTHEAST UNIV

Crane

InactiveCN111302243ASimple structureReduced driving force requirementsCranesMarine engineeringDrive by wire

The invention provides a crane, and relates to the technical field of construction machinery. The crane includes a turntable and two sets of counterweight displacement assemblies; the counterweight displacement assemblies include swing frames and linear drive parts. The two swing frames are directly connected to the side walls on the left and right sides of the turntable, and the side walls extendin the front and back directions of the turntable. The two swing frames are used to connect counterweight. The linear drive parts of each group of the counterweight displacement assemblies simultaneously rotate the swinging frames of the same group connected to the turntable, and the linear drive parts of the two sets of the counterweight displacement assemblies are used for driving the two swingframes in an one-to-one corresponding mode to enable the two swing frames to rotate relative to the turntable correspondingly to change the position of the counterweight. According to the crane withthe counterweight displacement assemblies, the problem of super-long structure in the front-rear direction is solved, improving of the adaptability to different working environments is facilitated, and saving of costs is facilitated.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

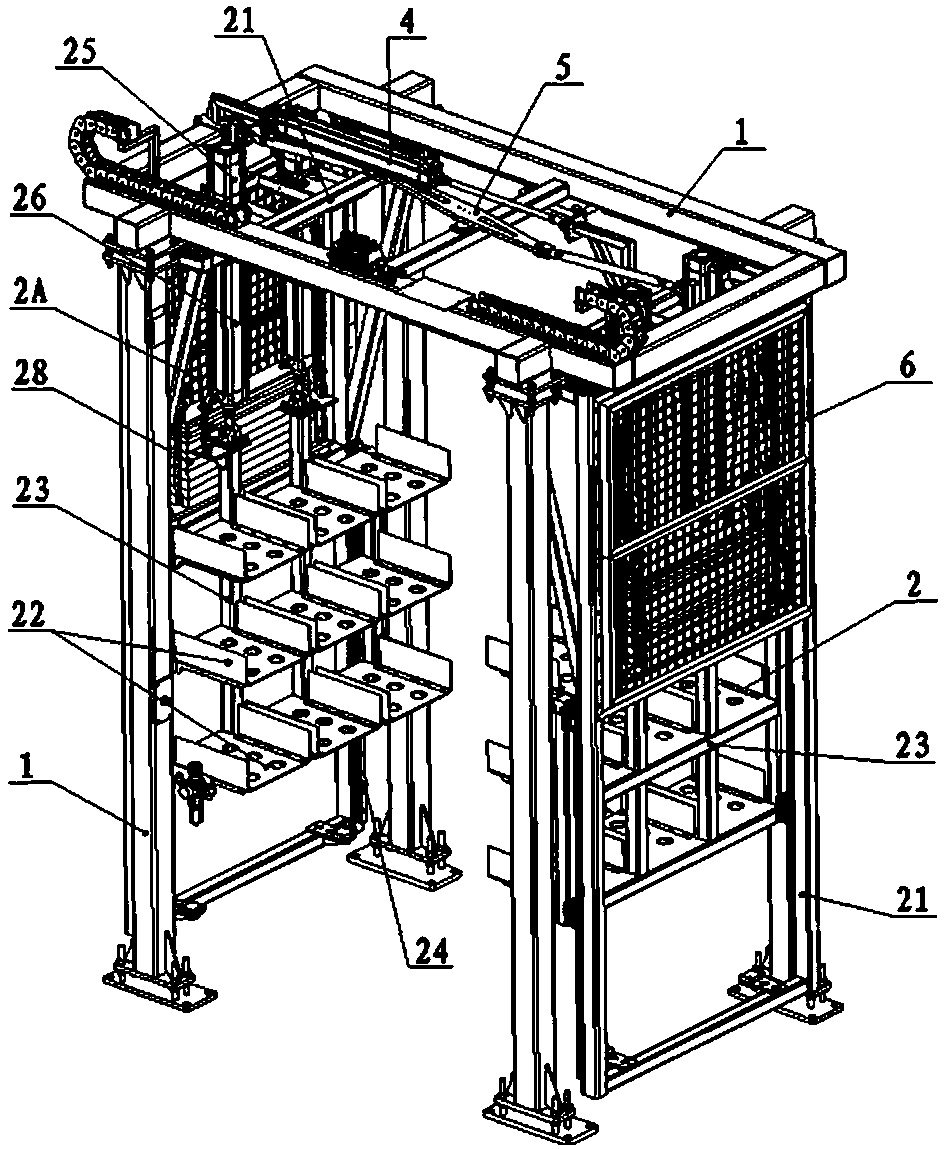

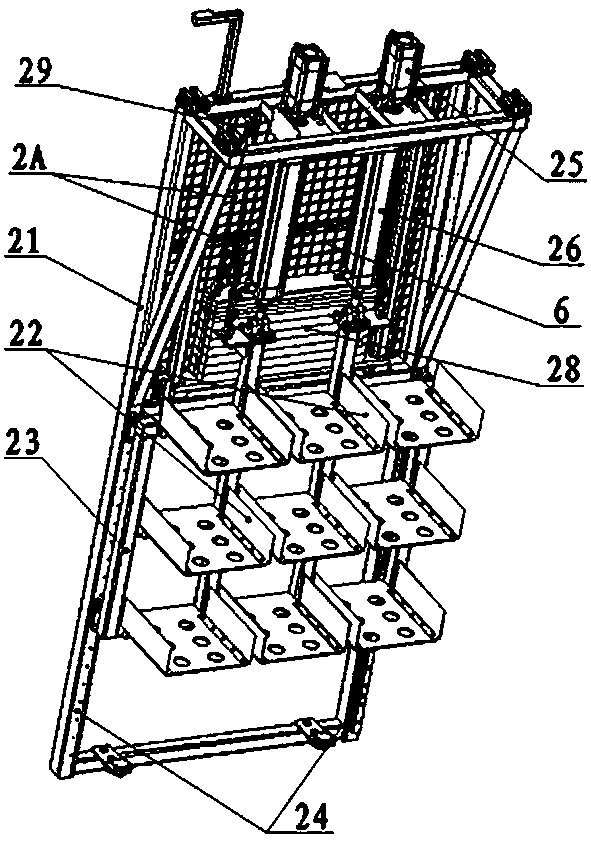

Efficient and reliable automatic yarn discharging machine

ActiveCN108190647AIncrease yarn unloading efficiencyReduce labor intensityFilament handlingTextile disintegration and recoveryYarnEngineering

The invention discloses an efficient and reliable automatic yarn discharging machine including a gantry support, a yarn discharging mechanism, a horizontal guide rail and a horizontal linear drive device, the top portion of the gantry support is fixedly provided with the horizontal guide rail, and the yarn discharging mechanism is vertically arranged at one side of the gantry support; the horizontal linear drive device and the gantry support are connected in a fixed or hinged mode, the yarn discharging mechanism includes a yarn discharging frame, yarn discharging brackets, a yarn discharging seat, vertical guide rails and a first vertical linear drive device, the yarn discharging frame is vertically arranged, and the top portion of the yarn discharging frame is slidably connected with thehorizontal guide rail and connected with an active end of the horizontal linear drive device in a fixed or hinged mode; two sides of one surface of the yarn discharging frame are fixedly provided withthe vertical guide rails, two sides of the yarn discharging seat are separately and slidably connected with the vertical guide rails, and one surface, facing the interior of the gantry support, of the yarn discharging seat is fixedly provided with a plurality of yarn discharging brackets which are perpendicular to the yarn discharging seat; and the first vertical linear drive device is verticallyand fixedly connected with the top portion of the yarn discharging frame and a moving end is connected with the yarn discharging seat in a fixed or hinged mode. The efficient and reliable automatic yarn discharging machine has the characteristics of compact and reliable structure, high efficiency of yarn discharging, difficult-to-deform yarn roll and high adaptability.

Owner:云南昆船电子设备有限公司 +1

Fan Stator Inserter

InactiveCN104158360BReduce wearQuality assuranceApplying solid insulationEngineeringMechanical engineering

The invention belongs to the field of motor production equipment, specially relates to a paper inserting machine for a fan stator, and particularly relates to a paper inserting machine for a fan stator of which stator slots are arranged on the outer circumference of the stator. According to the paper inserting machine, a stator bearing mechanism is arranged on a frame on the right side of an indexing mechanism. According to the stator bearing mechanism, a guide rail is arranged on the frame, a sliding seat is arranged on the guide rail, the sliding seat is connected with a stator bearing seat, the upper part of the stator bearing seat is provided with an circular arc bearing concave cavity, and bearing rollers are evenly distributed in the bearing concave cavity along the axial direction. According to the invention, a fan stator paper inserting machine applicable to fan stator paper inserting is designed. The fan stator paper inserting machine has a stator bearing mechanism which can bear a fan stator without the need for hoisting or manual lifting operation, which, on one hand, offers protection to stator slots on the surface of the fan stator, and on the other hand, reduces the labor intensity of workers.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

Lightweight electromagnetic fan clutch

InactiveCN108468725AReduce energy consumptionLight weightCoolant flow controlMagnetically actuated clutchesThrust bearingEngineering

The invention discloses a lightweight electromagnetic fan clutch. The lightweight electromagnetic fan clutch comprises a flange plate, a rotary sleeve, a fan blade fixing disc, an electromagnet and ahollow barrel. The fan blade fixing disc is arranged on the rotary sleeve, a rolling bearing is arranged in an inner hole of the fan blade fixing disc, a thrust bearing is arranged at the front end ofthe fan blade fixing disc, the electromagnet is arranged in front of the rotary sleeve, a first clutch piece is arranged at the rear end of the fan blade fixing disc, a second clutch piece located behind the first clutch piece is arranged on the rotary sleeve, sliding grooves are symmetrically formed in the outer circle of the rotary sleeve, the hollow barrel is concentrically arranged in the rotary sleeve, a supporting rod connected with the hollow barrel through the sliding grooves is arranged in an inner hole of the second clutch piece, and the front end of the hollow barrel stretches outof the rotary sleeve and is provided with an iron piece opposite to the electromagnet. According to the lightweight electromagnetic fan clutch, when the temperature of a water tank is high, engagementand disengagement actions are rapid, the dead weight is low, the requirement on driving force is low, and the energy consumption of an engine can be reduced.

Owner:苏州奥沃汽车配件有限公司

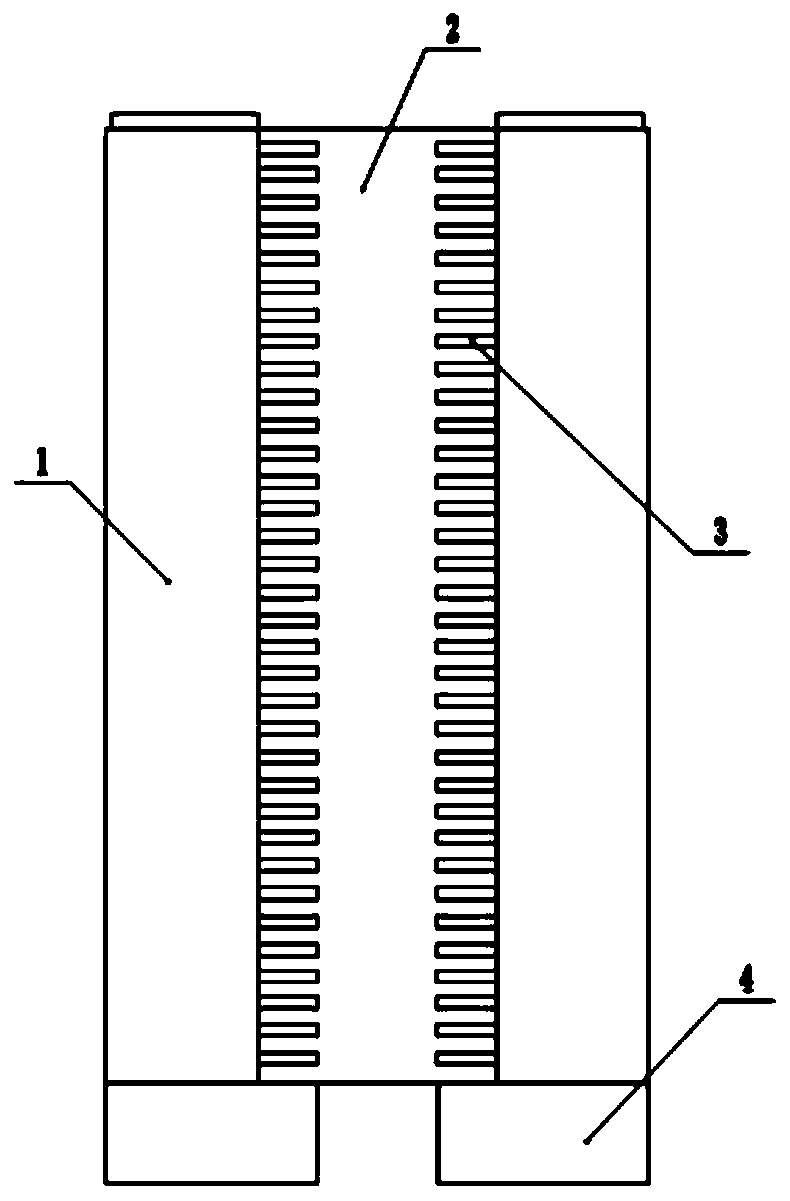

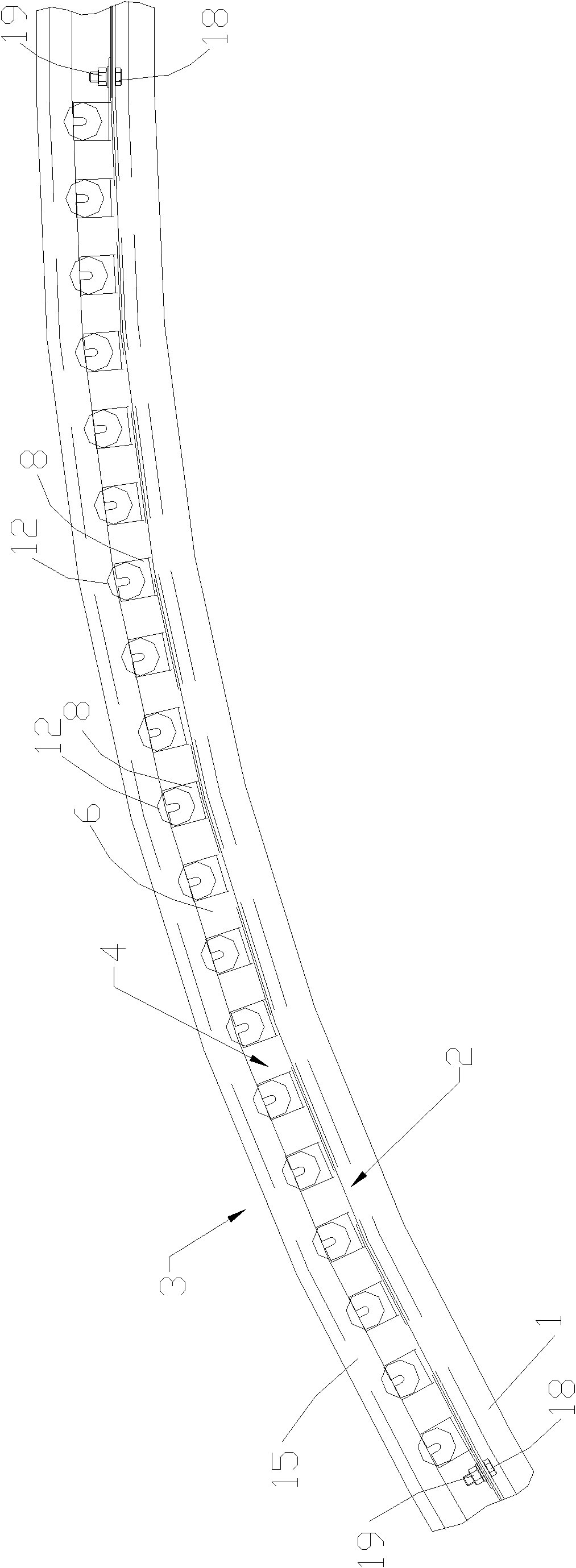

Upper arc-section structure of escalator handrail belt

InactiveCN102134038AReduced driving force requirementsExtended service lifeEscalatorsRolling resistanceEngineering

The invention discloses an upper arc-section structure of an escalator handrail belt, wherein an arc-shaped chain plate which is arranged in an arc-shaped guide rail and is distributed along the arc length direction of a guide rail comprises an arc-shaped bottom plate and a plurality of pairs of side plates extending upwards from the left side and the right side of the arc-shaped bottom plate; the plurality of pairs of side plates are arranged at intervals along the arc length direction of the arc-shaped bottom plate; rolling pieces are arranged between the paired side plates; a base part of the handrail belt is exposed on the inner surface in an opening of a containing space to be contacted with the rolling pieces in a rolling manner; the resistance generated by rolling friction is less;and in fact, the plurality of rolling pieces support the handrail belt, at the moment, gaps exist between the top surfaces of convex lugs on the arc-shaped guide rail and the inner surface of the handrail belt, so that the handrail belt and the top surfaces of the convex lugs are not contacted basically or the contacting area is reduced. Therefore, when the handrail belt runs, the friction resistance generated between the handrail belt and the rolling pieces or the convex lugs is less, and due to reduction of the friction resistance of the upper arc section, the requirement on the driving force of the handrail belt is reduced, the service life of the handrail belt is prolonged and the running comfort of the handrail belt is improved.

Owner:SJEC CORP

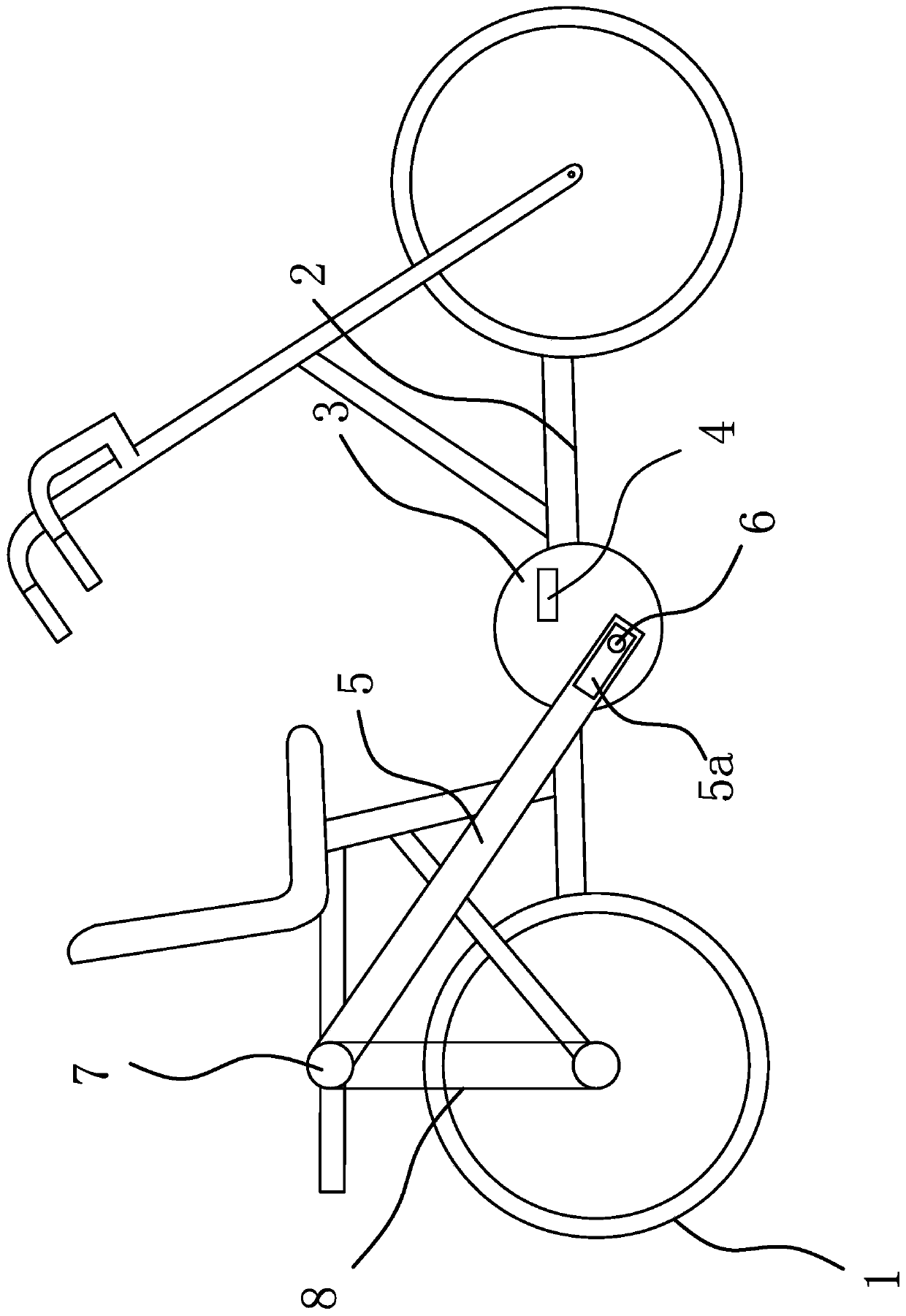

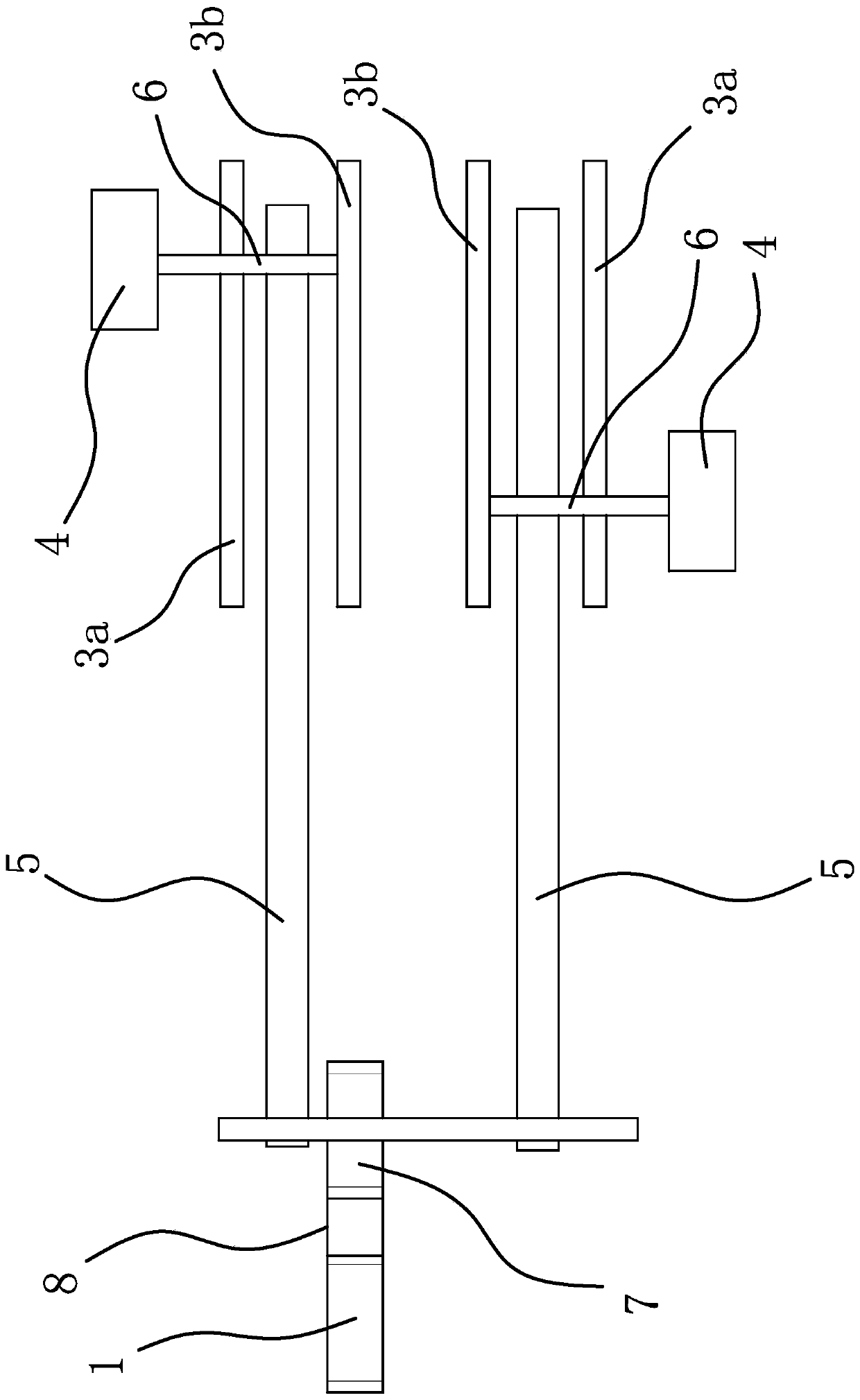

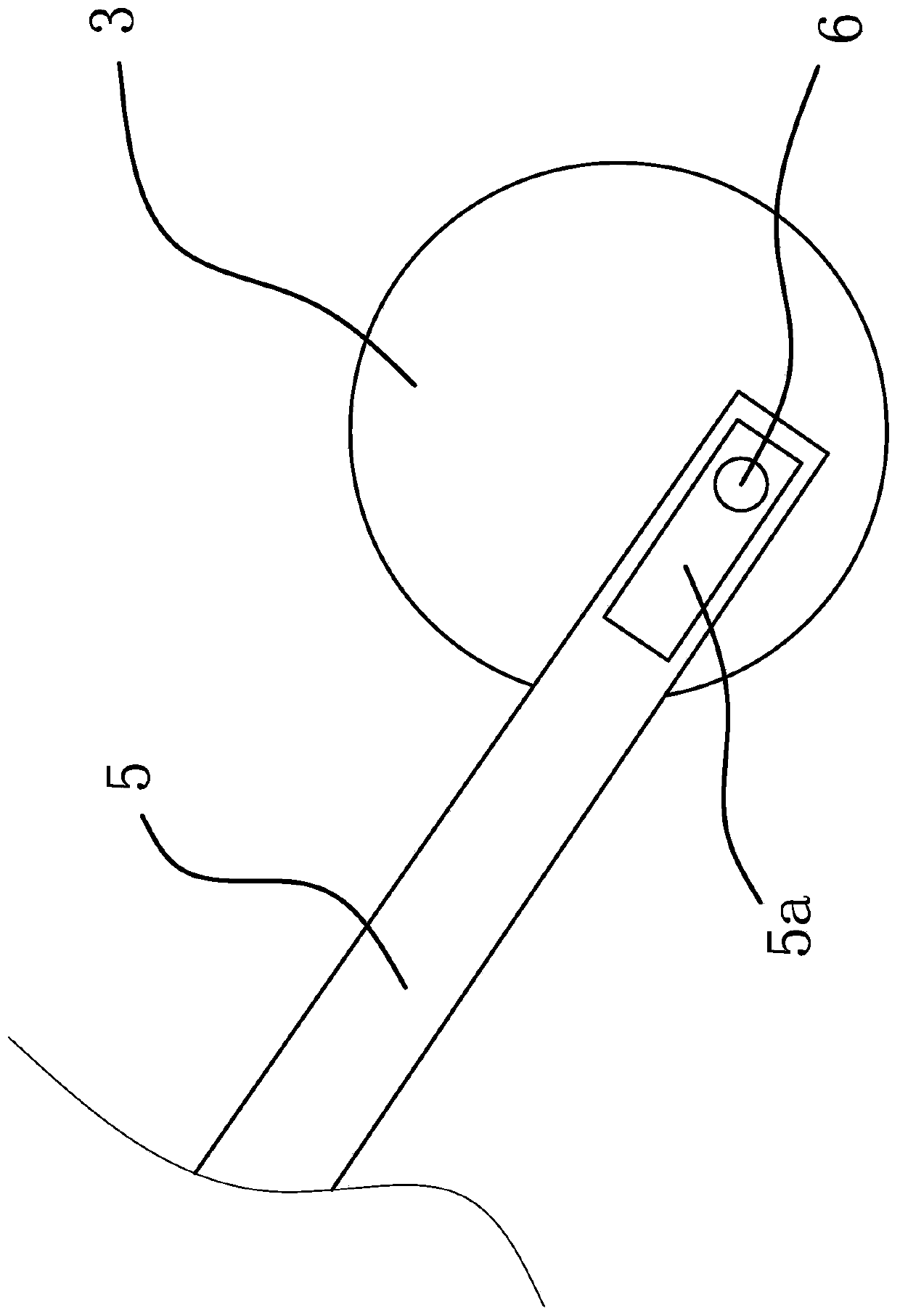

Labor-saving bicycle

PendingCN110282064ALower requirementEffort-saving ridingRider propulsionVehicle frameStructural stability

The invention provides a labor-saving bicycle, and belongs to the technical field of bicycles. The labor-saving bicycle solves the problem that the existing bicycle has poor structural stability. The labor-saving bicycle comprises a frame and a driving wheel, wherein crank discs are connected to two sides of the frame respectively; pedals are connected to the side parts of the crank discs; the labor-saving bicycle further comprises a driving wheel rotationally fixed on the frame and two transmission rods which are arranged on two sides of the frame respectively and are in a long rod shape; one ends of the two transmission rods are connected with the driving wheel; the other ends of the two transmission rods are movably connected to the eccentric positions of two crank discs respectively; the two transmission rods can alternately swing back and forth around the driving wheel when the crank discs rotate in the circumferential direction; a one-way transmission structure is arranged between the driving wheel and the two transmission rods; and the rotation of the driving wheel can be driven by a chain or a belt to rotate the driving wheel. The labor-saving bicycle has the advantage of good stability of the transmission structure.

Owner:张新金

Gyrostabilized platform locking mechanism

The invention relates to a gyrostabilized platform locking mechanism. A fixing ring I of the gyrostabilized platform locking mechanism is connected with a base through an output shaft bearing; the fixing ring I and a fixing ring II are installed in a sleeving mode and are fixed on a gear shaft of a drive gear, the fixing ring II is located at the right side of the fixing ring I and the fixing ring I, and the fixing ring II are fixed together; a locking gear is firmly clamped and fixed between the fixing ring I and the fixing ring II; the base is fixedly connected with an outer frame; a locking rack is meshed with the locking gear, one end of the locking rack is fixedly connected with a rotation shaft, and the other end of the locking rack is connected with a reset spring. The other end of the reset spring is connected with the base; the rotation shaft is mounted at the upper portion of the base and can rotate round the base; a connecting rod is located at the other side, opposite to the locking rack, of the base, and the upper end of the connecting rod is fixedly connected with the rotation shaft; a sliding groove is formed in the lower end of the connecting rod, and a circular shaft is fixed on an electromagnet motion iron score and located in the sliding groove and can slide along the sliding groove. According to the gyrostabilized platform locking mechanism, through the locking gear shaft, the effect of locking a platform axial system is achieved. The gyrostabilized platform locking mechanism has the advantages of being light in weight and small in required space.

Owner:长春长光睿视光电技术有限责任公司

A 3D printer extrusion system that can automatically switch print heads

The invention discloses a three-dimensional printer extrusion system capable of automatically switching a printing head. The three-dimensional printer extrusion system capable of automatically switching the printing head comprises a fixed base, a fixed printing head assembly arranged on the fixed base, a movable base arranged on the fixed base in a lifting and displacement way, a movable printinghead assembly arranged on the movable base, and a switching assembly for moving and positioning the movable base. The switching assembly comprises a micro guide rail assembly for guiding the movable base, a switching motor for driving the movable base, and a sensor for positioning the movable base. According to the three-dimensional printer extrusion system capable of automatically switching the printing head provided by the invention, through designing the movable printing head assembly and the fixed printing head assembly, the switching of the height difference between the two printing headassemblies can be realized through switching the height of the movable printing head assembly, and the movable printing head assembly and the fixed printing head assembly are independent so as to be free of being interacted in any case during printing, so that the printing accuracy is ensured.

Owner:GUANGZHOU ELECTRONICS TECH

A self-balancing elevator traction system

ActiveCN112027857BReduce energy consumptionReduced driving force requirementsElevatorsBuilding liftsTraction systemClassical mechanics

The invention relates to the technical field of elevator equipment, and discloses a self-balancing elevator traction system, which includes an elevator car, a guide frame, a traction roller and a counterweight, and the elevator car and the counterweight both slide with the guide frame The elevator car and the counterweight are respectively located on both sides of the traction roller. The self-balancing elevator traction system distributes the water in the weight-reducing water tank and the weight-increasing water tank through the connecting pipe, and balances the load change in the elevator car, so that the gravity difference on both sides of the traction roller is in a small range. Reduce the driving force requirements for the rotation of the traction roller, and also reduce the torque requirements of the motor inside the traction roller, reducing equipment costs. Secondly, because the weight difference between the two sides of the traction roller is always in a small range when the elevator is running, When the elevator is out of control, the force is small, and the acceleration obtained is small, which finally reduces the falling speed of the elevator car, and when the elevator falls, the movement of the load plate can play a buffering role.

Owner:重庆市华创电梯部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com