Sewing machine

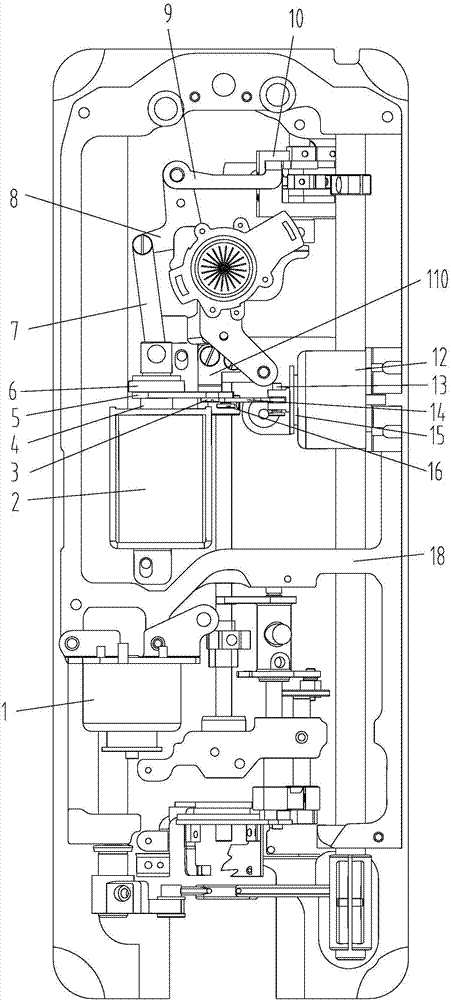

A sewing machine and sewing technology, applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of falling off, affecting the aesthetic feeling, and the stitch distance cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

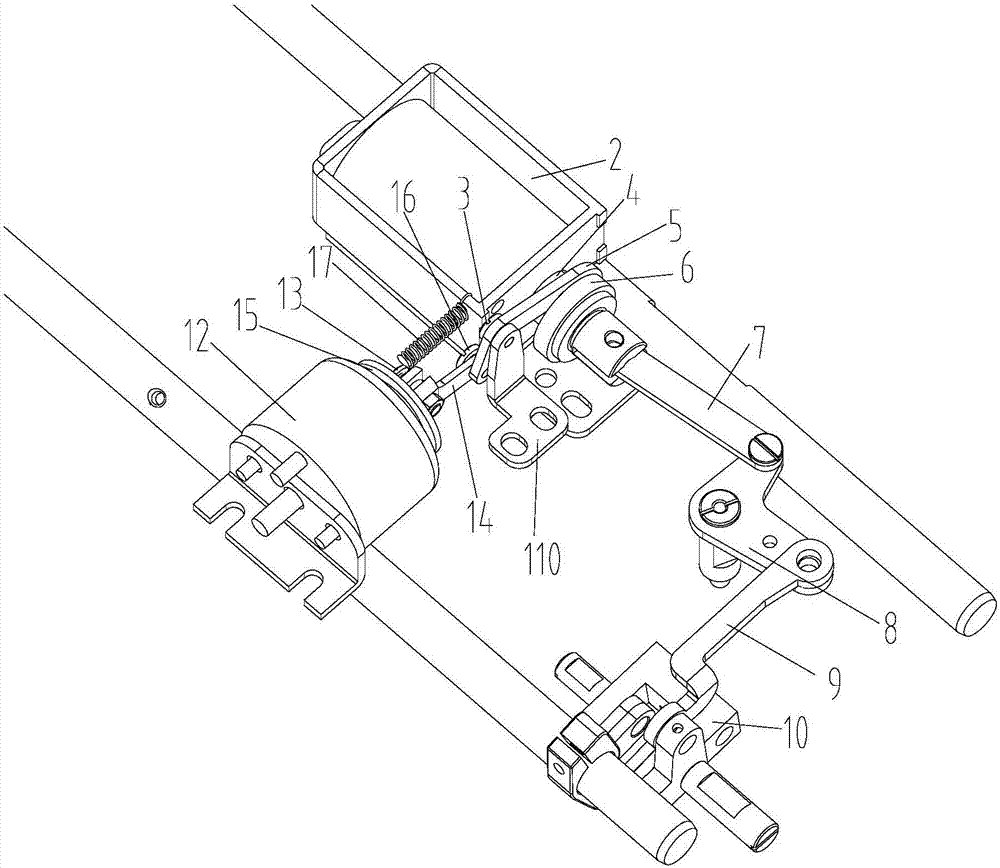

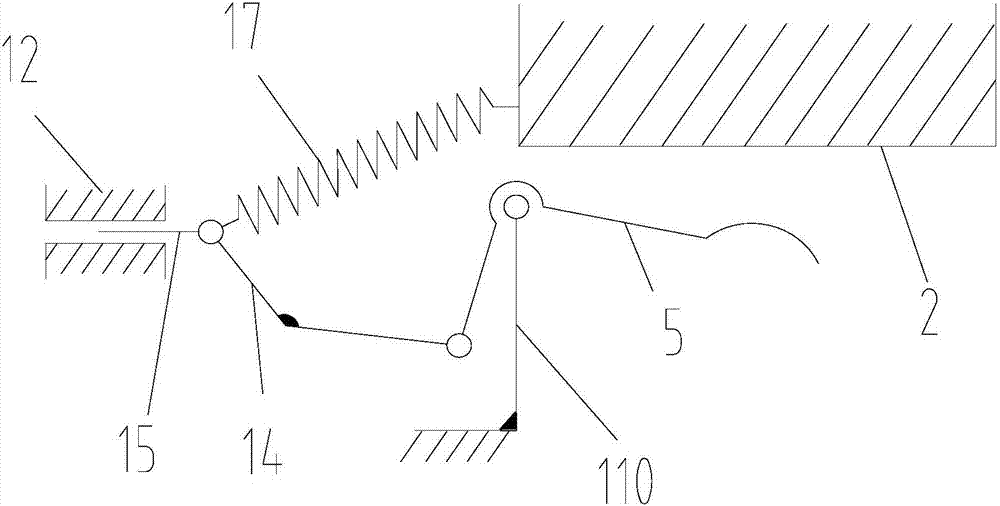

[0050] First, if the instructions are attached figure 2 Attached Figure 7 As shown, the limit rod 5 is similar to a chevron with low ends and a high middle. A tie rod hinge hole 53 is provided at the left end of the limit rod 5, and the tie rod hinge hole 53 and the tight seam tie rod 14 are hinged with the pin at the left end 16. Realize the rotation of the limit rod 5 relative to the tight seam tie rod 14; the middle high point of the limit rod 5 is provided with a fixed-axis hinge hole 52, and the fixed-axis hinge hole 52 is hinged with the fixed shaft 3 in a fixed position through the intermediate pin to realize the limit The rotation of the position rod 5 relative to the fixed axis 3; the right end of the limit rod 5 has an insert end 51, which is in the shape of an upper half arc, and is used to insert and insert between the connecting portion 4 and the buffer portion 6 from above .

[0051] In order to achieve the fixed position of the fixed axis 3, a limit rod bracket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com