Flexible cooperative mechanical arm and control method thereof

A manipulator and manipulator technology, applied in the field of flexible collaborative manipulators and their control, can solve problems such as lack of low cost, and achieve the effect of improving collaboration and safety with people, avoiding damage, and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

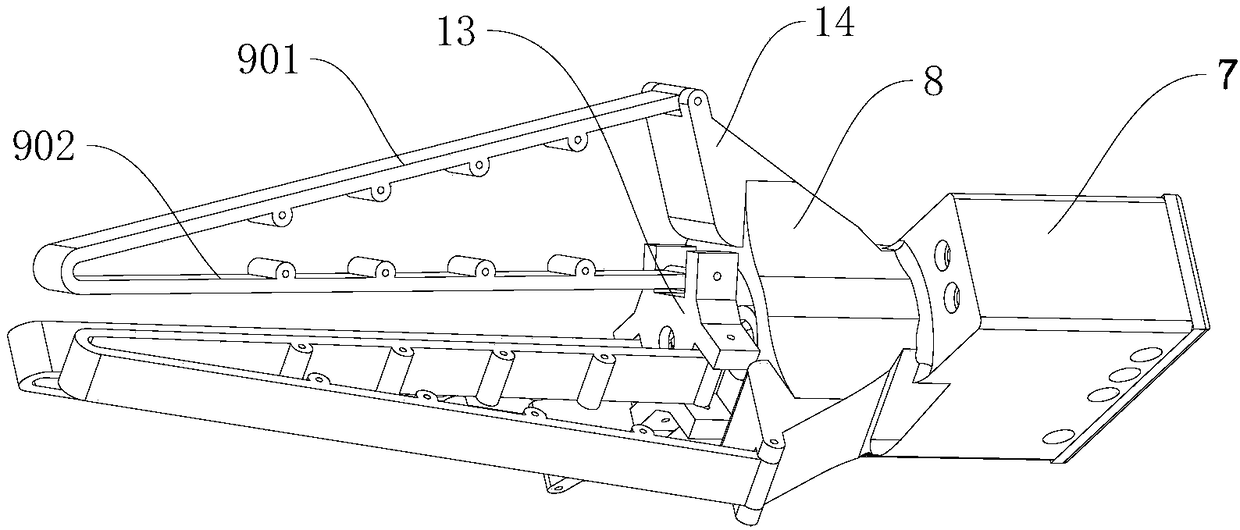

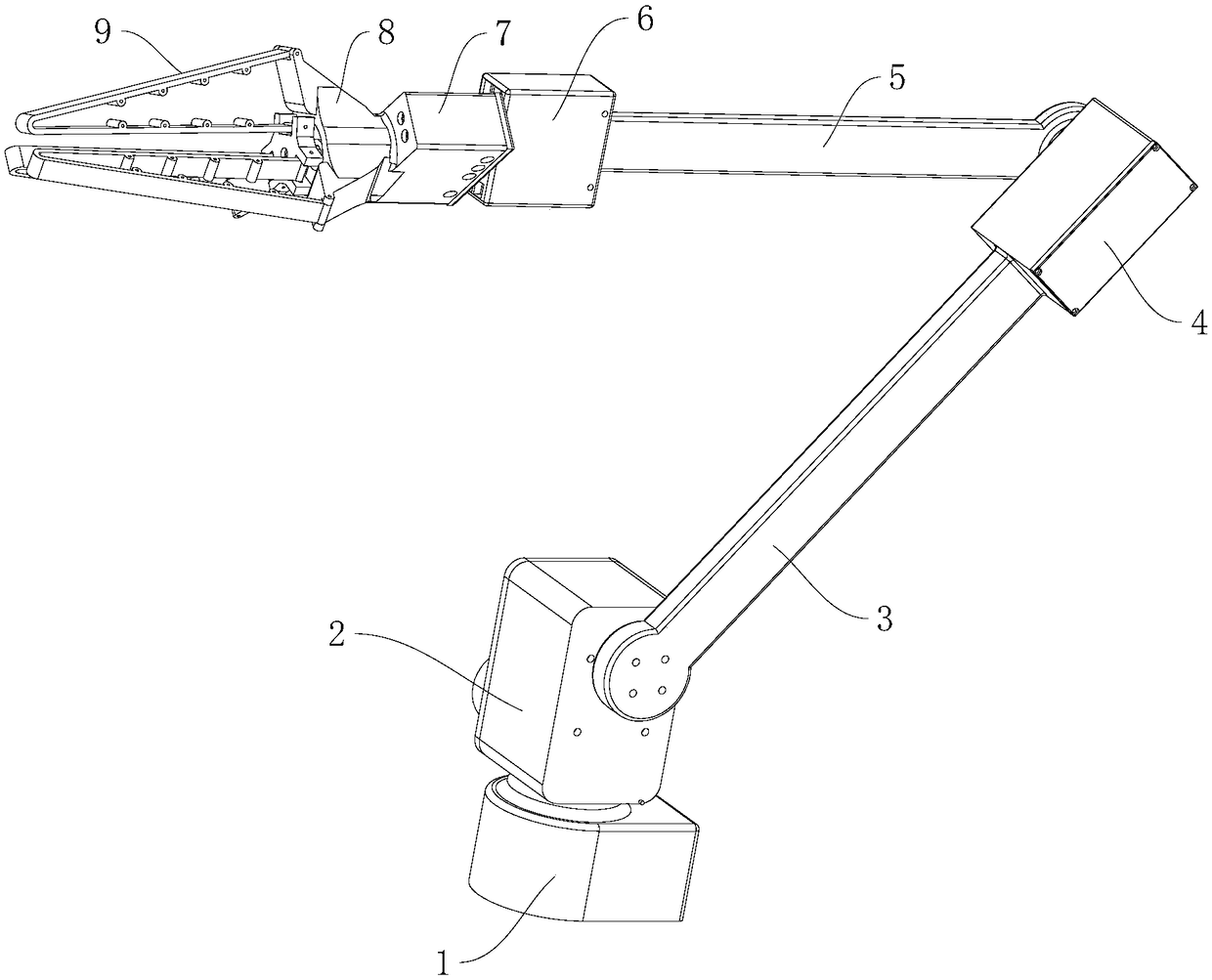

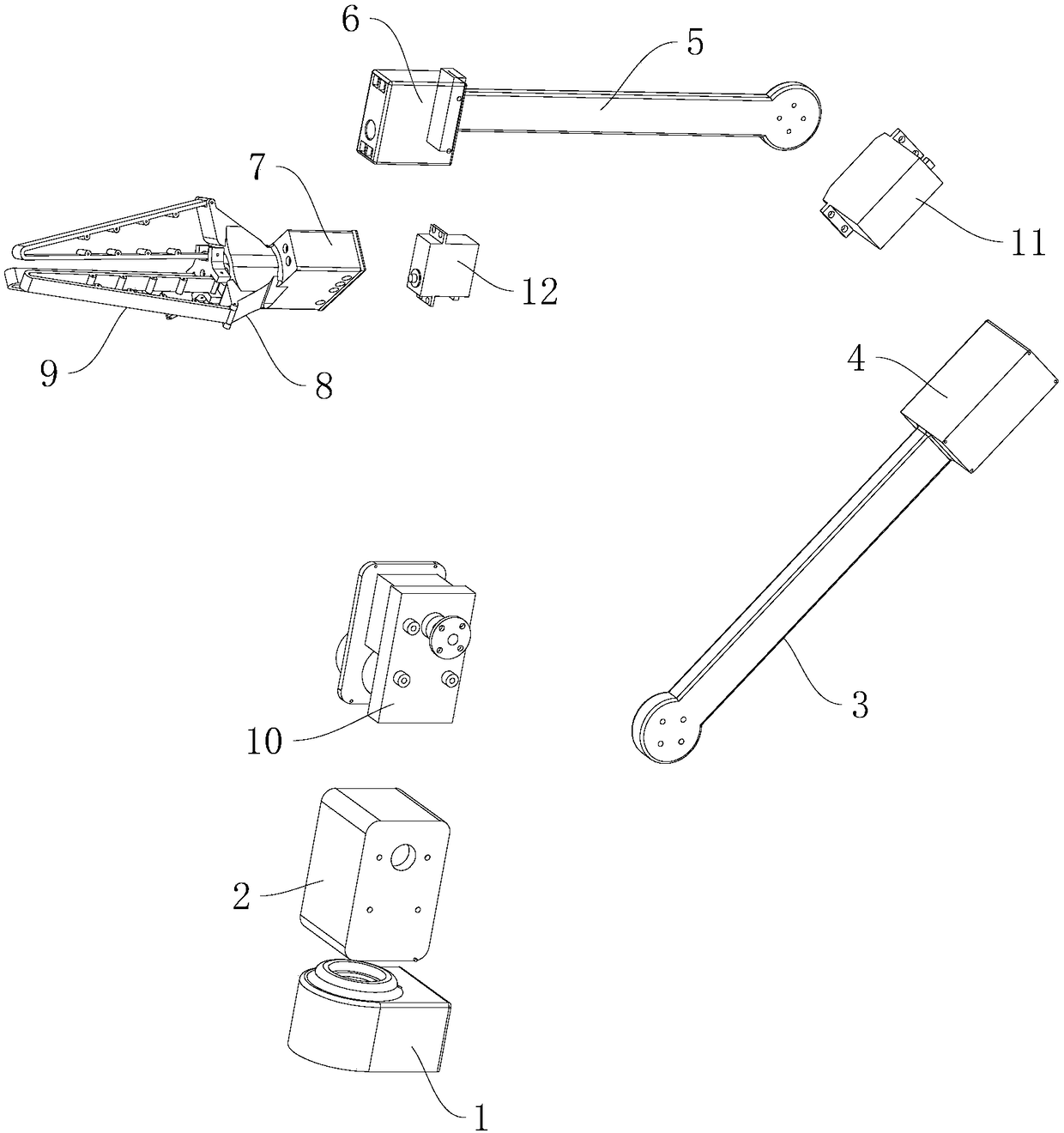

[0053] Such as figure 1 , figure 2 , image 3 As shown, this embodiment discloses a flexible cooperative robot arm, which includes a base 1, a main body of the robot arm, and an execution fixture. Specifically, the base is provided with a control panel and a bottom steering gear, and the bottom steering gear is used to drive the mechanical arm to rotate horizontally; the main body of the mechanical arm includes a first machine arm 3 and a second machine arm 5 that are rotationally connected The first machine arm and the second machine arm are relatively rotated in the vertical direction after being driven by the machine arm steering gear; the described execution fixture includes a plurality of flexible fingers 9, and the execution fixture is driven and clamped by the execution steering gear 7; The bottom steering gear, the arm steering gear and the executive steering gear are all electrically connected to the control board, and a current sensor is connected between each ste...

Embodiment 2

[0067] Such as Figure 4 , Figure 5 As shown, Embodiment 1 discloses the structural composition of the collaborative robot arm. This embodiment provides a control method for a flexible collaborative robot arm, which aims to judge whether the robot arm collides through current induction, and to detect whether the robot arm has collided. Make timely adjustments to reduce the damage caused; at the same time, judge the dynamic deformation of the manipulator according to the detection value of the strain gauge, and perform static filtering on the deformation of the manipulator, so as to eliminate the vibration of the manipulator, so that the cooperative manipulator is more stable in the working process reliable.

[0068] The control method of the collaborative robotic arm disclosed in this embodiment specifically includes the following steps:

[0069] A collision detection method for a flexible robotic arm, used to control a flexible robotic arm described in Embodiment 1, compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com