Gyrostabilized platform locking mechanism

A gyro-stabilized platform and locking technology, which is applied to aircraft parts, transportation and packaging, etc., can solve the problems of platform damage and impact on flight safety, and achieve the effect of improving impact resistance, reducing requirements, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

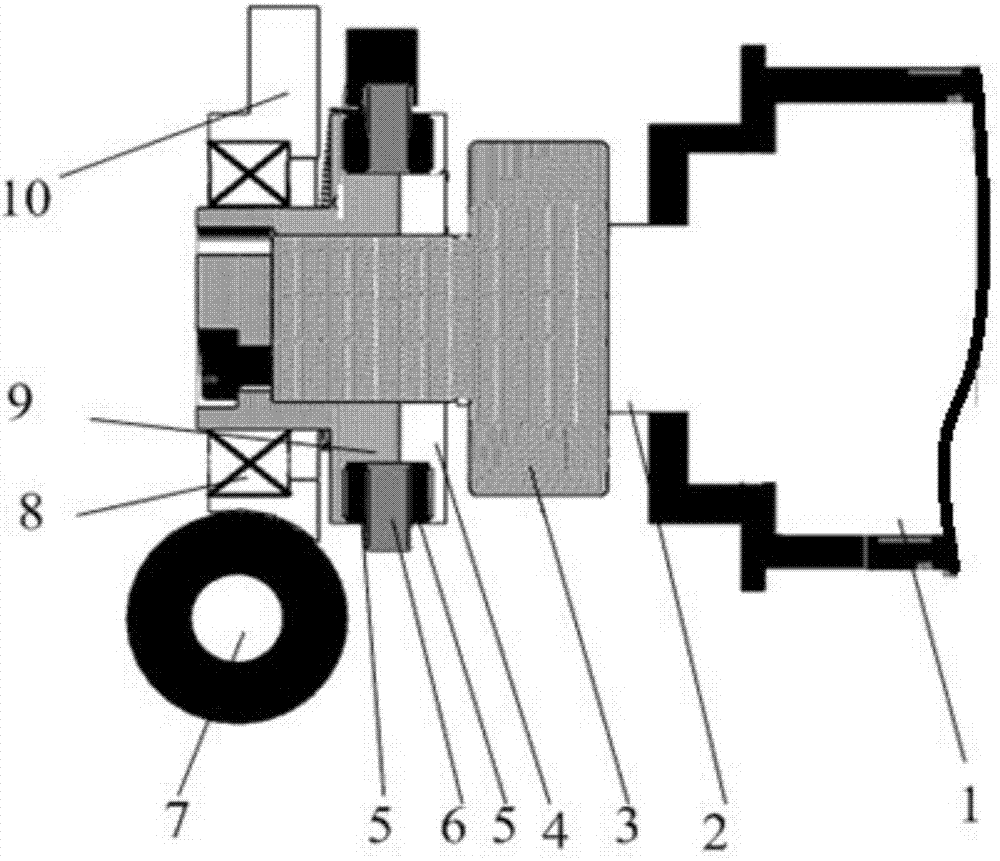

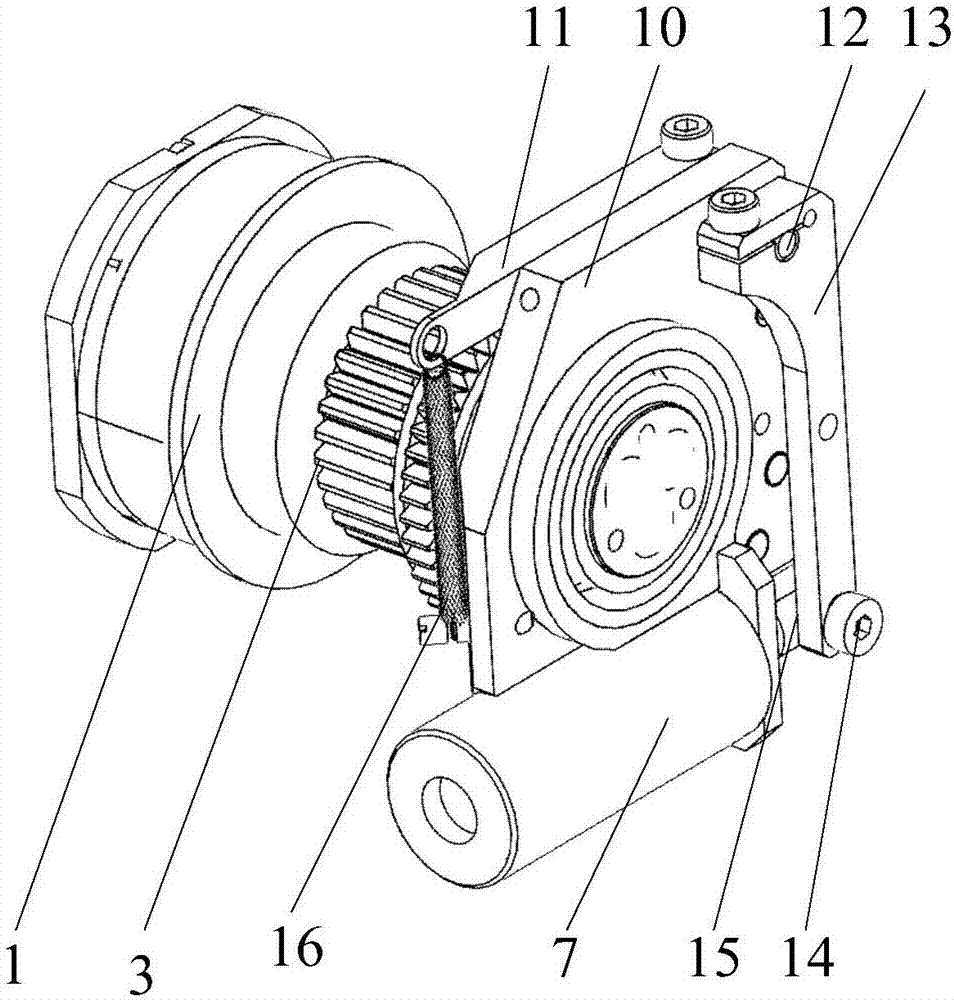

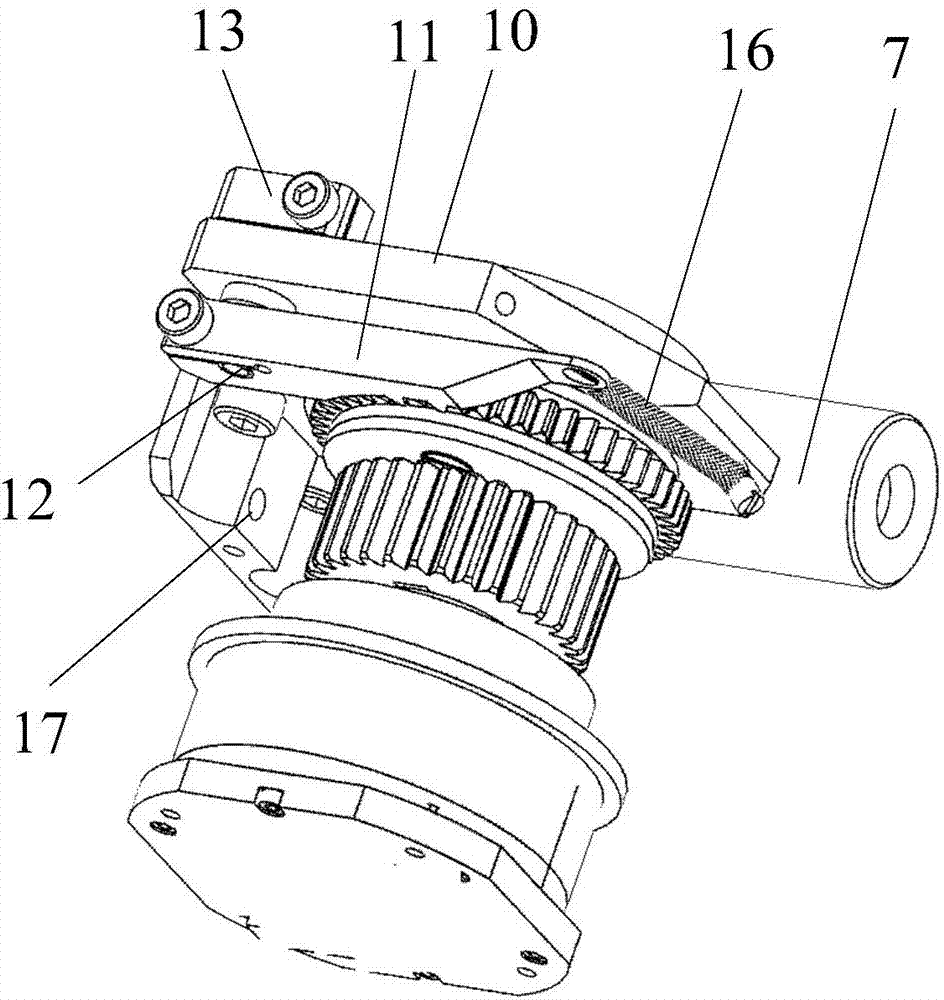

[0020] like figure 1 , 2 , shown in 3, the gyro-stabilized platform locking mechanism of the present invention comprises base 10, electromagnet 7, connecting rod 13, locking rack 11, back-moving spring 16, locking gear 6, buffer rubber 5, 1 fixing ring 9 and II retaining ring 4. see figure 1 , the drive gear 3 is installed on the drive unit output shaft 2, the I fixed ring 9 is connected with the base 10 through the output shaft bearing 8, and the left end face of the I fixed ring 9 is fixedly connected with the gear shaft of the drive gear 3 by a screw 18; I is fixed Ring 9 and II fixed ring 4 are sleeved on the gear shaft of drive gear 3, II fixed ring 4 is located on the right side of I fixed ring 9 and I fixed ring 9 and II fixed ring 4 are fixed together by bolt connection; lock the gear 6. Adhesive buffer rubber 5 on both sides; locking gear 6 and two pieces of buffer rubber 5 are clamped together between I fixing ring 9 and II fixing ring 4, and two pieces of buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com