A self-balancing elevator traction system

An elevator traction and self-balancing technology, which is applied to elevators in buildings, lifting equipment in mines, elevators, etc., to achieve the effects of reducing driving force requirements, reducing torque requirements, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

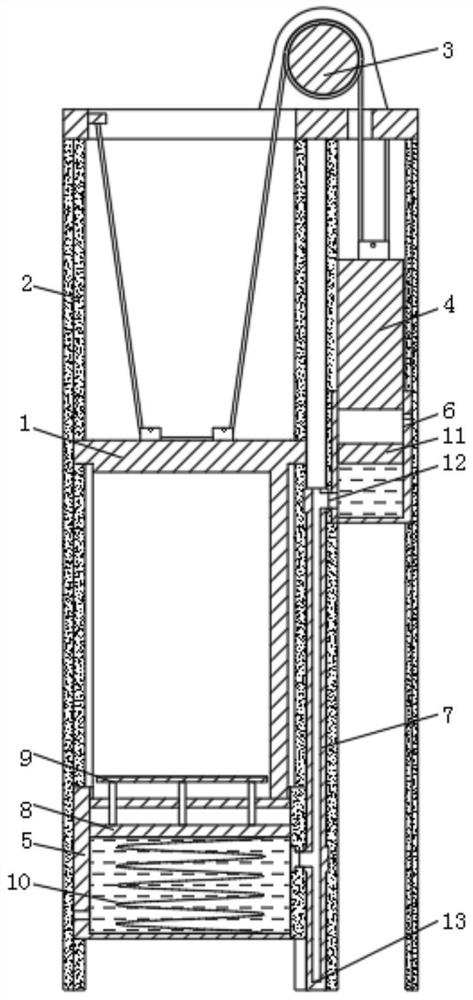

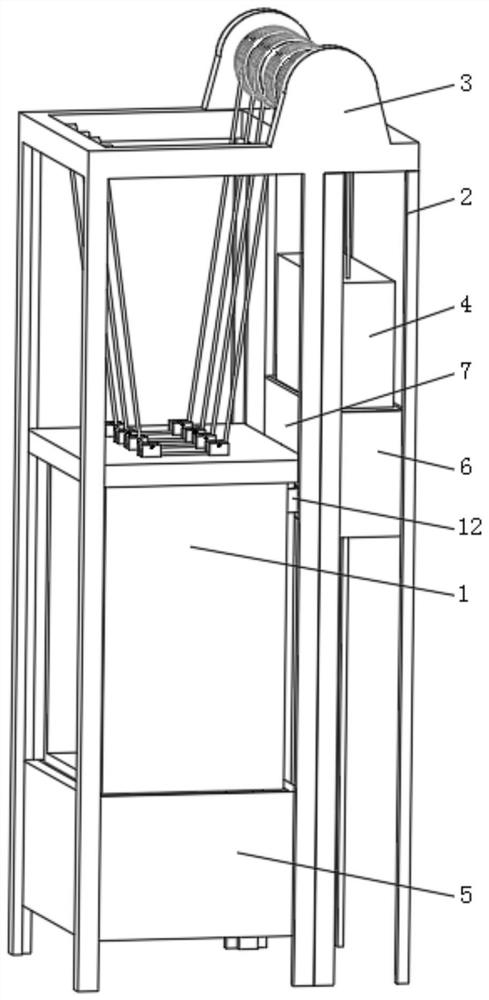

[0024] see Figure 1-2 , is only a simplified diagram of a single-section elevator. A self-balancing elevator traction system includes an elevator car 1, a guide frame 2, a traction roller 3 and a counterweight 4. Both the elevator car 1 and the counterweight 4 are connected with and The guide frame 2 is slidingly connected, the elevator car 1 and the counterweight 4 are respectively located on both sides of the traction roller 3, and the friction force of the rotation of the traction roller 3 controls the elevator car 1 and the counterweight 4 to move up and down. There is a weight-reducing water tank 5, and the lower end of the counterweight 4 is provided with a weight-increasing water tank 6, and the weight-increasing water tank 6 communicates with the weight-reducing water tank 5 through a connecting pipe 7. Flow into the weight-reducing water tank 5 or the weight-increasing water tank 6, change the weight difference on both sides of the traction roller 3, make the weight ...

Embodiment 2

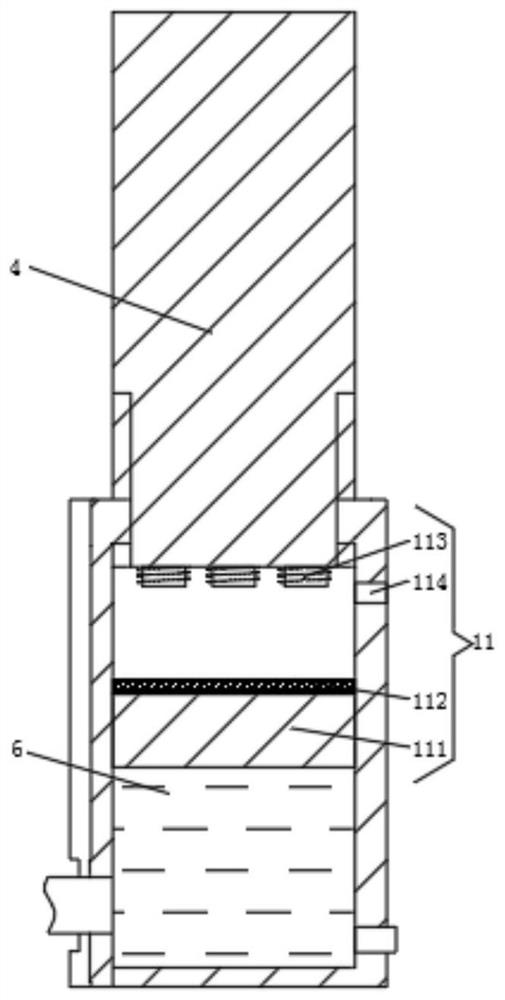

[0030] see Figure 5 , the difference from Embodiment 1 is that the communication pipe 7 is a steel pipe fixedly installed on the guide frame 2, and the connector 12 includes a fixed connection seat 121 installed on the weight-reducing water tank 5 or the weight-increasing water tank 6 and a fixed connection seat 121 installed on the communication pipe. The dynamic connecting seat 122 on the 7, each section is all correspondingly provided with the fixed connecting seat 121 corresponding to the weight-reducing water tank 5 and the weight-increasing water tank 6 respectively, and the moving connecting seat 122 is flexibly connected to the sealing sleeve 126 through the telescopic tube 123, and the sealing Sleeve 126 and fixed connecting seat 121 are provided with shut-off valve 124 with ejector rod 125 inside the connecting pipe, and the outer circumference of the connecting pipe of fixed connecting seat 121 is provided with second permanent magnet 127, and the end of sealing sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com