Efficient and reliable automatic yarn discharging machine

A reliable and automatic technology, applied in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of outstanding personnel safety hazards, high labor intensity, and reduced yarn unloading efficiency, and achieves improved yarn unloading efficiency. The effect of reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

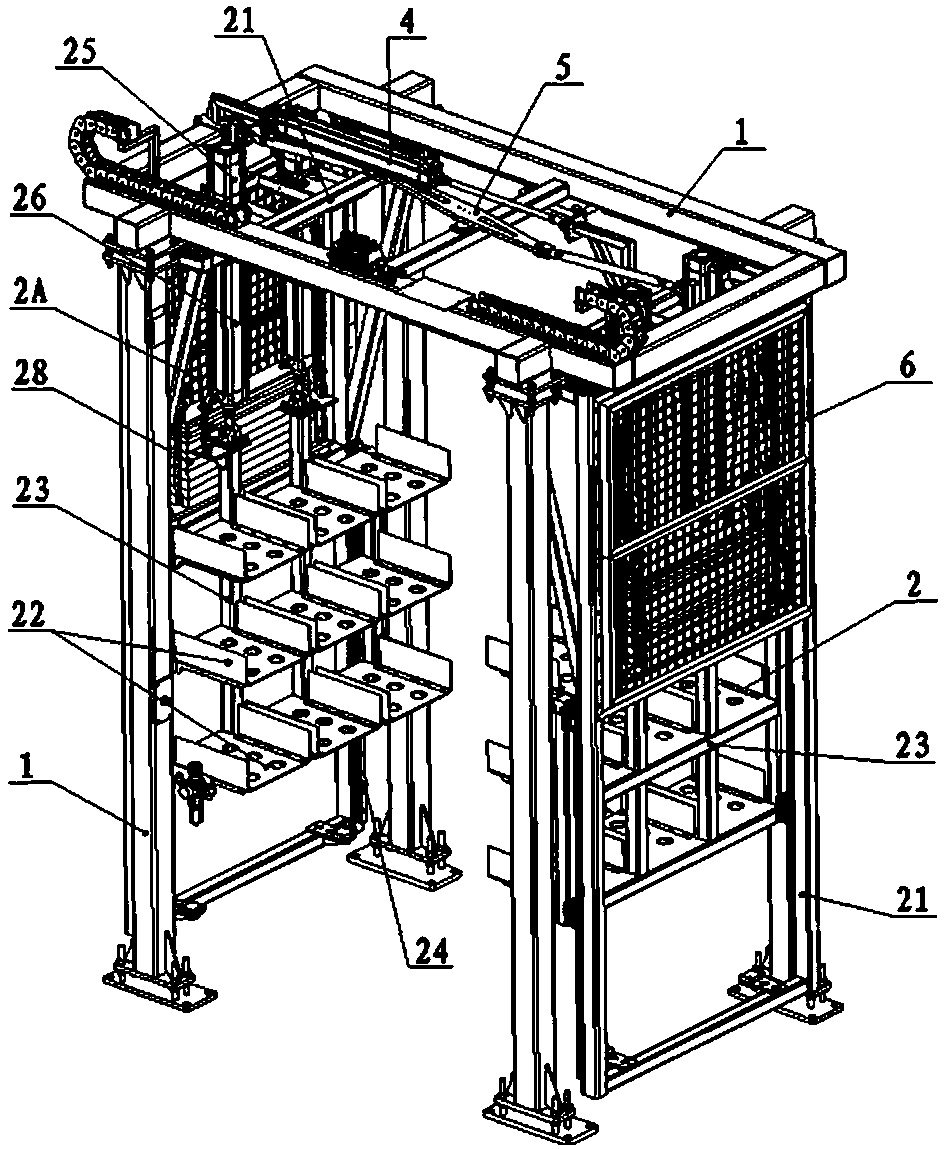

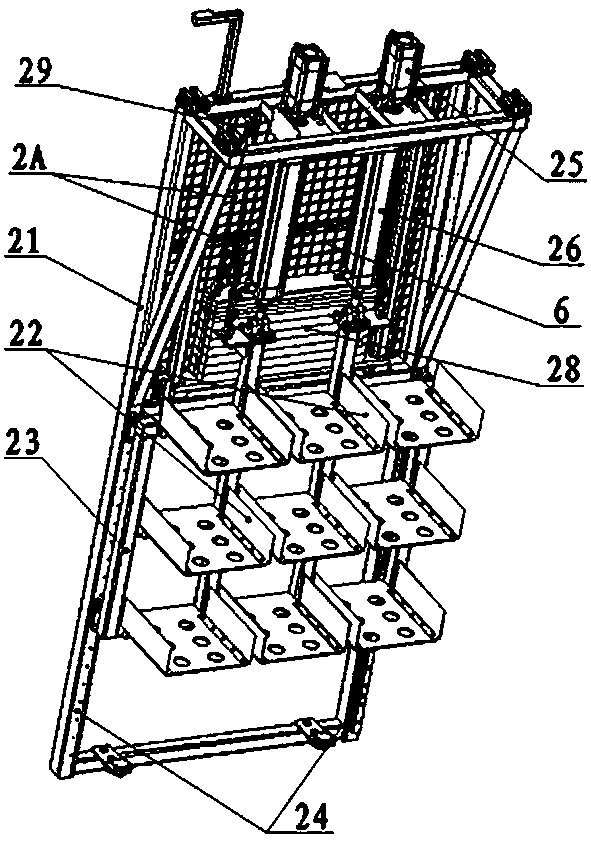

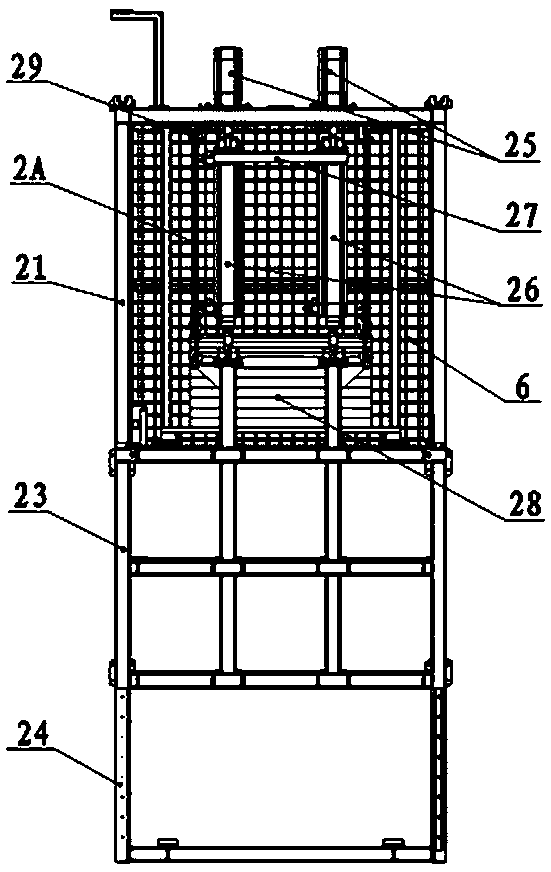

[0023] like Figures 1 to 7 As shown, the present invention includes a gantry support 1, a yarn unloading mechanism 2, a horizontal guide rail 3, and a horizontal linear drive device 4. The top of the gantry support 1 is fixedly provided with horizontal guide rails 3 parallel to each other, and the yarn unloading mechanism 2 is vertically arranged On one side of the gantry support 1, the horizontal linear drive device 4 is fixedly connected or hinged to the gantry support 1, and the yarn unloading mechanism 2 includes a yarn unloading frame 21, a yarn unloading bracket 22, a yarn unloading seat 23, and a vertical guide rail 24 , the first vertical linear drive device 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com