An automatic yarn unloading machine

An automatic, one-stop technology, applied in thin material processing, processing textile material carriers, transporting filamentous materials, etc., can solve the problems of low reliability and low degree of automation, and achieve high reliability, high degree of automation, and improved The effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

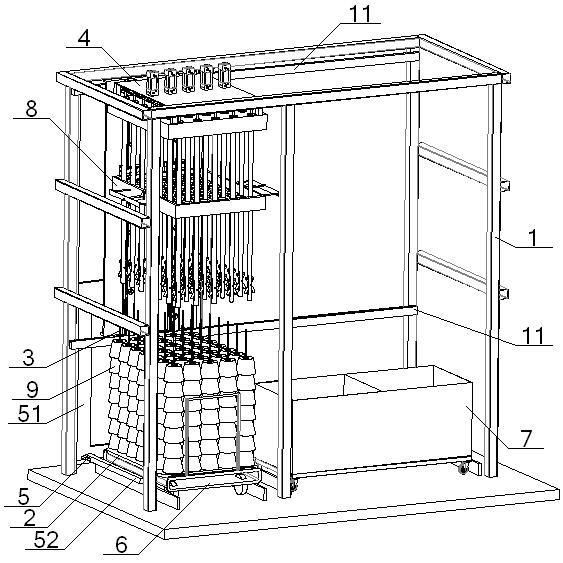

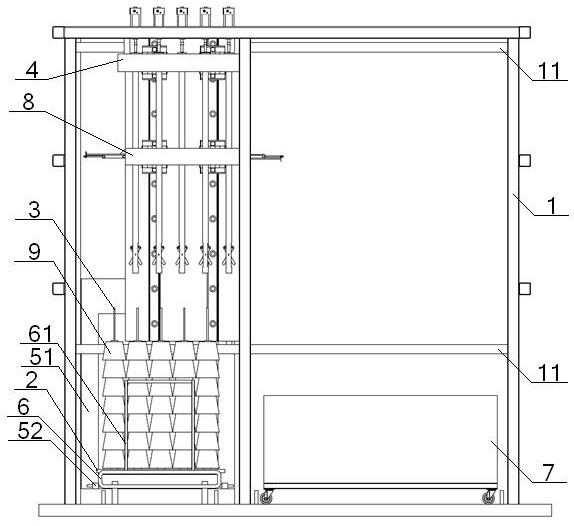

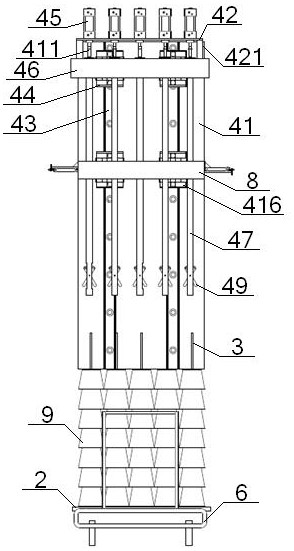

[0054] see Figure 1 to Figure 6, an automatic yarn unloading machine, comprising a frame 1 and a bobbin frame arranged on it, the bobbin frame including a carrier plate 2 and a plurality of bobbins 3 arranged vertically on it, the frame A yarn hanging mechanism 4 is provided at the position above the yarn bobbin stringer 3 on the 1, and the yarn hanging mechanism 4 includes a No. 1 mounting plate 41 and a No. 2 mounting plate 42 perpendicular to each other. There are two No. 1 guide rails 43, a No. 1 slide block 44 is arranged on the No. 1 guide rail 43, a plurality of No. 1 cylinders 45 are arranged on the No. 2 mounting plate 42, and a plurality of No. 1 cylinders 45 are arranged on the No. 2 mounting plate 42. The moving plate 46 is connected to the No. 2 mounting plate 42 through the pillar 421, and the moving plate 46 is connected to the No. 1 slide block 44. There are many sleeve rods 47 vertically set on the moving plate 46, and the sleeve rods 47 and Yarn bobbin stri...

Embodiment 2

[0056] Basic content is the same as embodiment 1, the difference is:

[0057] see Figure 5 , Figure 7 , the end of the sleeve rod 47 close to the yarn bobbin rod 3 is fitted with a bell mouth 410, the small diameter end of the bell mouth 410 is located in the sleeve rod 47, and the outer wall of the large diameter end of the bell mouth 410 is threaded with the inner wall of the sleeve rod 47 end. connect.

Embodiment 3

[0059] Basic content is the same as embodiment 1, the difference is:

[0060] see image 3 , Figure 4 , Figure 5 , Figure 8 , between the No. 2 mounting plate 42 and the moving plate 46, a cylinder connector 411 is provided, and the cylinder connector 411 includes a No. 3 mounting plate 412. The middle part of the upper end of the No. 3 mounting plate 412 is vertically connected with a No. 1 connecting rod 413, the No. 1 connecting rod 413 is connected with the No. 1 cylinder 45, and the lower end of the No. 3 mounting plate 412 is evenly and vertically connected with a plurality of No. 2 connecting rods 414, and the No. 2 connecting rod 414 is threadedly connected with the push rod 48; Sleeve rod 47 comprises rod body 471 and No. 4 mounting plate 472, and one end of described rod body 471 is vertically connected with No. After passing through the moving plate 46, align the yarn bobbin rod 3, and the middle part of the No. 4 mounting plate 472 is provided with a through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com